Dirt-proof and antibacterial textile fabric and preparation method thereof

A textile fabric and anti-fouling technology, applied in the direction of cellulose/protein conjugated artificial filament, conjugated synthetic polymer artificial filament, etc., can solve the problem of difficult removal of stains, achieve cheap raw materials, good application prospects, suitable The effect of large-scale industrial application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

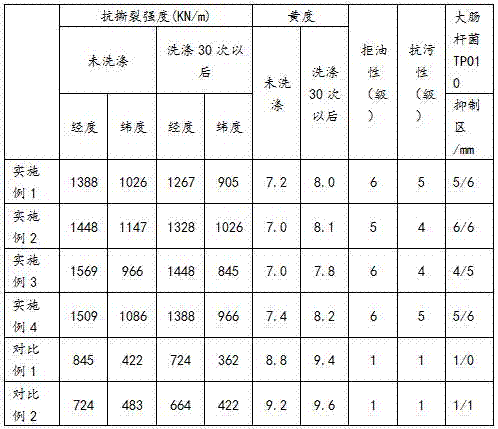

Examples

Embodiment 1

[0025] (1) Weigh 5 parts of polyester yarn, 10 parts of mugwort fiber, 10 parts of soybean fiber, 5 parts of polylactic acid fiber, 15 parts of water-absorbing fiber, 8 parts of polyacrylonitrile fiber, and 10 parts of polyethylene terephthalate by weight. 1 part of hexamethylcyclotrisiloxane, 2 parts of polyvinylpyrrolidone, 1 part of alkaline pectinase, 2 parts of tung oil anhydride, 1 part of tea saponin, 2 parts of benzoyl peroxide butyl acetate, acetyl 1 part of tri-n-hexyl citrate, 3 parts of potassium chloride, 1 part of 3-acrylic acid propyltrimethoxysilane, 2 parts of oleic acid acyl, 2 parts of zinc palmitate;

[0026] (2) Soak polyester yarn, mugwort fiber, soybean fiber, alkaline pectinase, tung oil anhydride, and tea saponin in 3% hydrogen peroxide for disinfection and activation, soak for 2 hours, dry at 60°C, and ultrasonically pulverize for 30 minutes , the ultrasonic power is 200KW;

[0027] (3) Add polylactic acid fiber, water-absorbing fiber, polyacrylonitr...

Embodiment 2

[0034] (1) Weigh 7 parts of polyester yarn, 13 parts of mugwort fiber, 12 parts of soybean fiber, 6 parts of polylactic acid fiber, 16 parts of water-absorbing fiber, 10 parts of polyacrylonitrile fiber, and 12 parts of polyethylene terephthalate by weight. Parts, 2 parts of hexamethylcyclotrisiloxane, 3 parts of polyvinylpyrrolidone, 1 part of alkaline pectinase, 3 parts of tung oil anhydride, 2 parts of tea saponin, 2 parts of butyl peroxide benzoyl acetate, acetyl 1 part of tri-n-hexyl citrate, 4 parts of potassium chloride, 2 parts of N-2 (aminoethyl) 3-aminopropylmethyldimethoxysilane, 3 parts of glyceryl tristearate, lauric acid Calcium 2 parts;

[0035] (2) Soak polyester yarn, mugwort fiber, soybean fiber, alkaline pectinase, tung oil anhydride, and tea saponin in 3% hydrogen peroxide for disinfection and activation, soak for 2.4 hours, dry at 62°C, and ultrasonically pulverize for 30 minutes , the ultrasonic power is 220KW;

[0036] (3) Polylactic acid fiber, absorb...

Embodiment 3

[0043](1) Weigh 9 parts of polyester yarn, 17 parts of mugwort fiber, 16 parts of soybean fiber, 13 parts of polylactic acid fiber, 19 parts of water-absorbing fiber, 13 parts of polyacrylonitrile fiber, and 14 parts of polyethylene terephthalate by weight. 3 parts, 3 parts of hexamethylcyclotrisiloxane, 4 parts of polyvinylpyrrolidone, 2 parts of alkaline pectinase, 4 parts of tung oil anhydride, 3 parts of tea saponin, 3 parts of benzoyl peroxide butyl acetate, acetyl 2 parts of tri-n-hexyl citrate, 5 parts of potassium chloride, 3 parts of N-2 (aminoethyl) 3-aminopropylmethyltrimethoxysilane, 4 parts of hexenylbisstearamide, naphthenic acid Barium 3 parts;

[0044] (2) Soak polyester yarn, mugwort fiber, soybean fiber, alkaline pectinase, tung oil anhydride, and tea saponin in 3% hydrogen peroxide for disinfection and activation, soak for 2.7 hours, dry at 64°C, and ultrasonically pulverize for 30 minutes , the ultrasonic power is 240KW;

[0045] (3) Polylactic acid fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com