Flame retardant and antistatic polyethylene for mine gas drainage pipeline and preparation method thereof

A flame-retardant, anti-static and polyethylene technology is applied in the field of flame-retardant and anti-static polyethylene and its preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

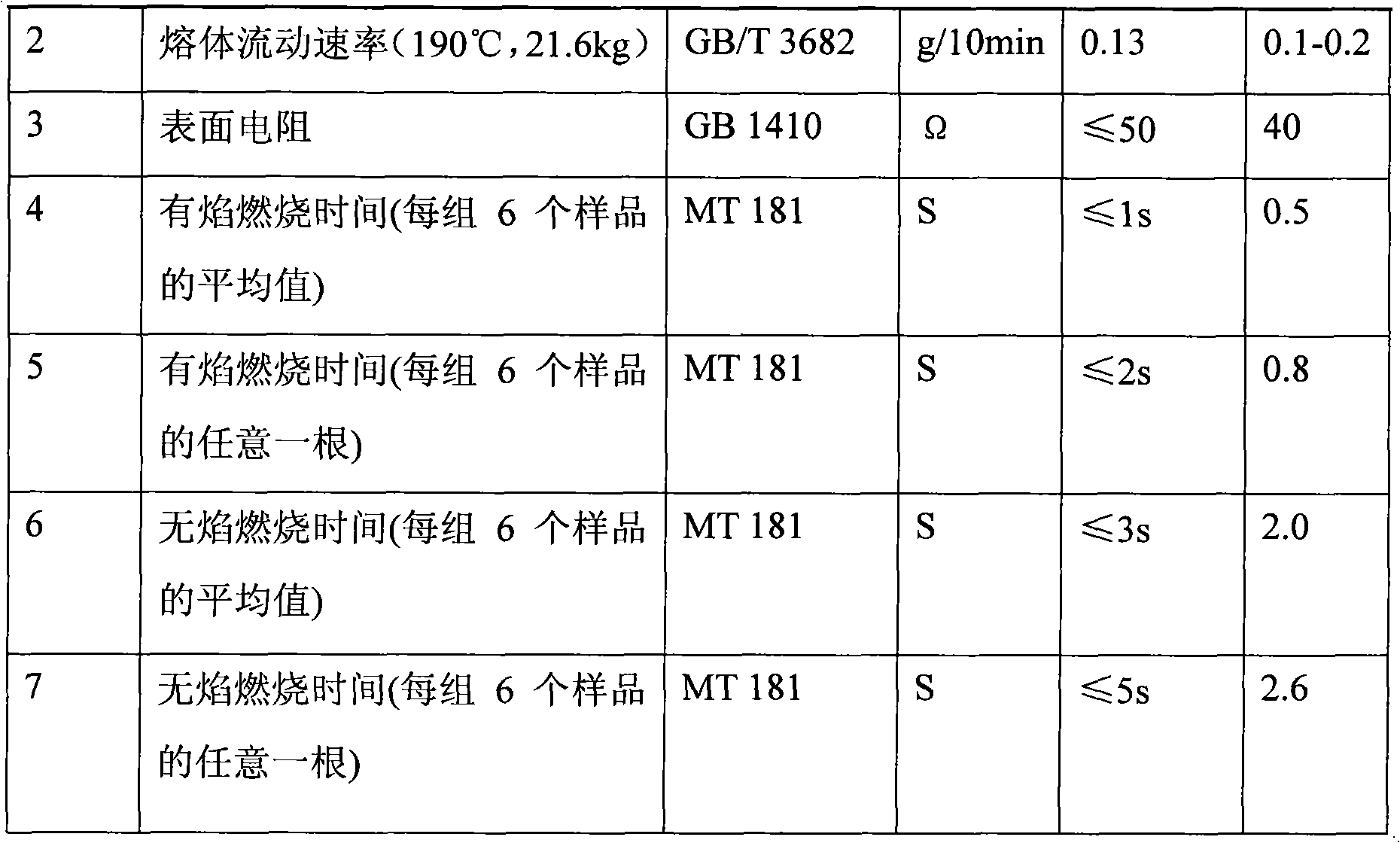

Examples

Embodiment 1

[0027] Mix 95kg of polyethylene, 10kg of copper powder, 15kg of aluminum hydroxide, 5kg of antioxidant 1010 and 10kg of carbon black powder and put them into a high-speed mixer, heat and mix at 50°C first, heat and mix to 80°C, stop heating and continue mixing, After the shear heat temperature rises to 100°C, the mixture is sent to a twin-screw extruder to extrude and pelletize at 140-200°C, and then dried to obtain a flame-retardant and antistatic polyethylene material.

Embodiment 2

[0029] 90kg of polyethylene, 15kg of aluminum powder, 20kg of antimony trioxide, 8kg of antioxidant DLTP, 6kg of carbon black powder and 4kg of carbon fiber are mixed and placed in a high-speed mixer, heated and mixed at 80°C, and the mixed material is fed into a twin-screw The extruder extrudes and pelletizes at 160-200°C, and then the flame-retardant and antistatic polyethylene material can be obtained after drying.

Embodiment 3

[0031] Mix 100kg polyethylene, 15kg copper powder, 15kg aluminum hydroxide, 5kg antioxidant 1010 and 10kg carbon fiber into a high-speed mixer, mix at a high speed at 90°C, and send the mixed mixture into a twin-screw extruder Extrude and granulate at 140-190°C, and dry to obtain flame-retardant and antistatic polyethylene materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com