Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Achieve toughening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nano composite polyformaldehyde material and its prepn

The present invention discloses one kind of nano composite polyformaldehyde material, and the composite contains polyformaldehyde 55-90 wt% and elastomer 2.5-30 wt% as well as characterized inorganicnano stuffing 0.1-10 wt% and compatibilizing agent 0.1-10 wt%. During the preparation, inorganic nano stuffing, compatibilizing agent and elastomer in certain proportion are smelted and mixed to obtain agglomerate; and the agglomerate is then diluted and dispersed in polyformaldehyde or polyformaldehyde / elastomer to obtain the product through further smelting and mixing. The present invention canstrengthen and toughen polyformaldehyde while reducing cost.

Owner:SICHUAN UNIV

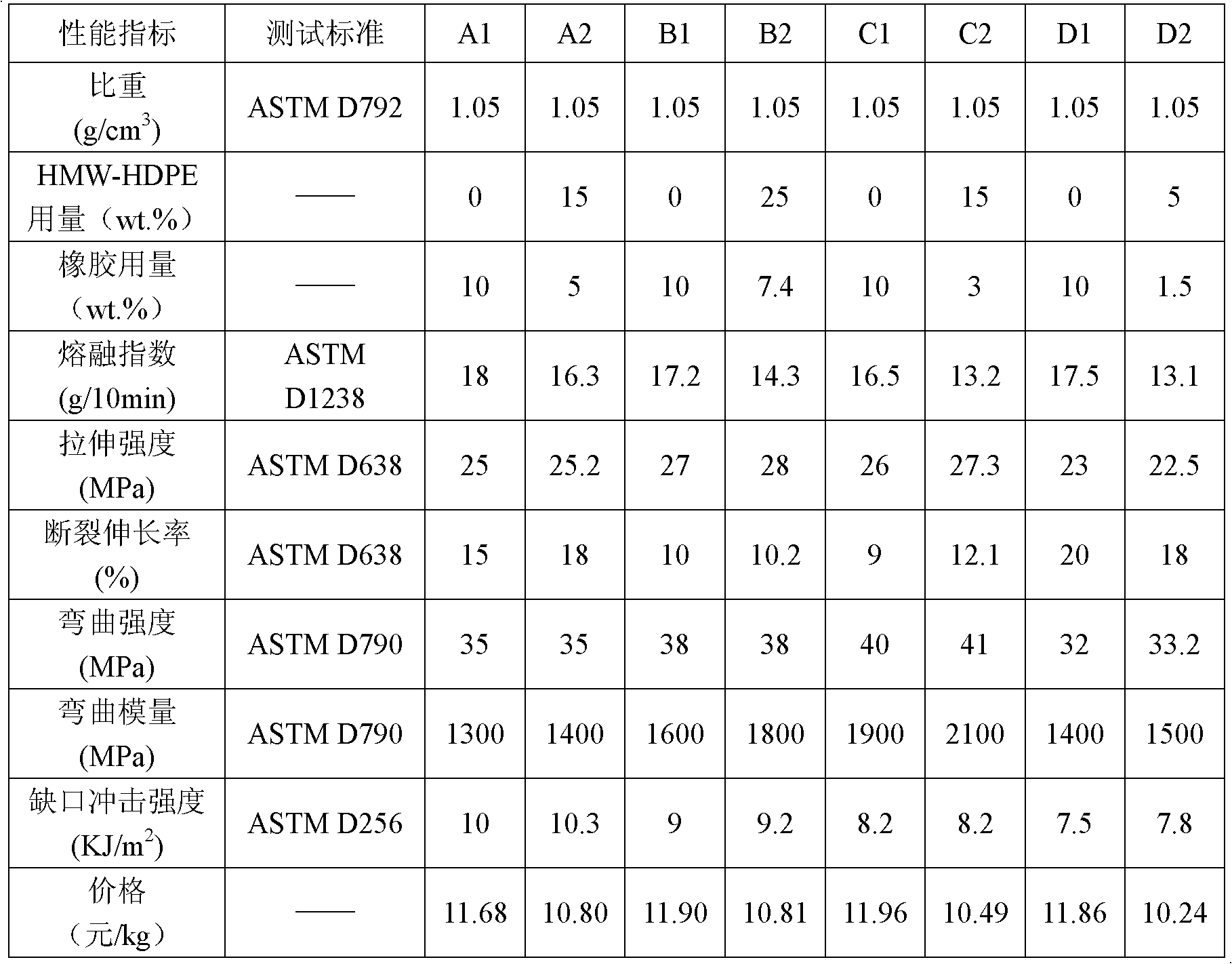

Polypropylene-high molecular weight high density polyethylene-filling material blend and preparation method thereof

The invention discloses a polypropylene-high molecular weight high density polyethylene-filling material blend which comprises, by weight, 30 to 80 parts of polypropylene, 5 to 25 parts of high molecular weight high density polyethylene, 10 to 30 parts of a filling material, 2 to 8 parts of a compatilizer, 2 to 8 parts of a compatilizing agent and 0.01 to 0.03 part of an anti-oxidant. Polypropylene, high molecular weight high density polyethylene, the compatilizer, the compatilizing agent, the filling material and the anti-oxidant are successively added into a mixer and uniformly mixed at a speed of 500 to 1000 r / min, and a mixed material is put in a double-screw extruder for extrusion and granulation with granulation temperature being 160 to 210 DEG C. Compared with a conventional polypropylene-rubber-filling material blend, the polypropylene-high molecular weight high density polyethylene-filling material blend provided by the invention has excellent balanced rigidity and toughness, compatibility and better cost performance under the condition of a small usage amount of rubber.

Owner:昆山博富新材料科技有限公司

Preparation method of cardanol-containing polyphenol modified amine epoxy resin curing agent

The invention relates to a preparation method of an epoxy resin adhesive curing agent, in particular to a preparation method of a cardanol-containing polyphenol modified amine epoxy resin curing agent and aims to improve the toughness of phenolic amine curing agents in consideration with the heat resistance of the curing agents. The preparation method comprises the steps as follows: 1, cardanol and phenols are added to a reaction device and heated to 40-50 DEG C, an acid catalyst is added, the mixture is heated to 95-100 DEG C and reacts at the constant temperature for 1-3 h, and an intermediate product is obtained; 2, the intermediate product is cooled to 20-50 DEG C, polyamine is dropwise added, aldehydes are added after addition, the mixture is heated to 90-100 DEG C and reacts at the constant temperature for 2-5 h and then cooled to 75-85 DEG C after the reaction ends, reduced pressure dehydration is performed until no water exists, and the cardanol-containing polyphenol modified amine epoxy resin curing agent is obtained. The prepared cardanol-containing polyphenol modified amine curing agent has good heat resistance of phenol phenolic amine epoxy curing products and has 90-degree stripping up to 2-5 KN / m.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Preparation method for in-situ generated Ti3SiC2-phase toughening silicon carbide ceramic matrix composite material

The invention belongs to the technical field of the ceramic matrix composite material preparation, and particularly relates to a preparation method for an in-situ generated Ti3SiC2-phase toughening silicon carbide ceramic matrix composite material. The method comprises the following steps: enabling TiC powder, connection resin and an organic solvent to be prepared as slurry, and preparing prepregwith fibers, to obtain a fiber / C-TiC porous body through hot-pressing and carbonizing, covering the surface of the porous body by using Si powder, and generating Ti3SiC2 in situ in a process of generating a silicon carbide matrix by using a high-temperature melting silicon permeation technology. The method is capable of not only eliminating the residual silicon content in the matrix, but also weakening the adverse effect of silicon to mechanical properties of the composite material; in addition, because of an own stratified structure of a MAX-phase material, while the ceramic matrix compositematerial bears load, a crack is expanded to the layer interface and is hindered so that deflection or passivation is produced, the stress concentration of the point of the crack is weakened, and the toughening to the ceramic matrix composite material is finally realized.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

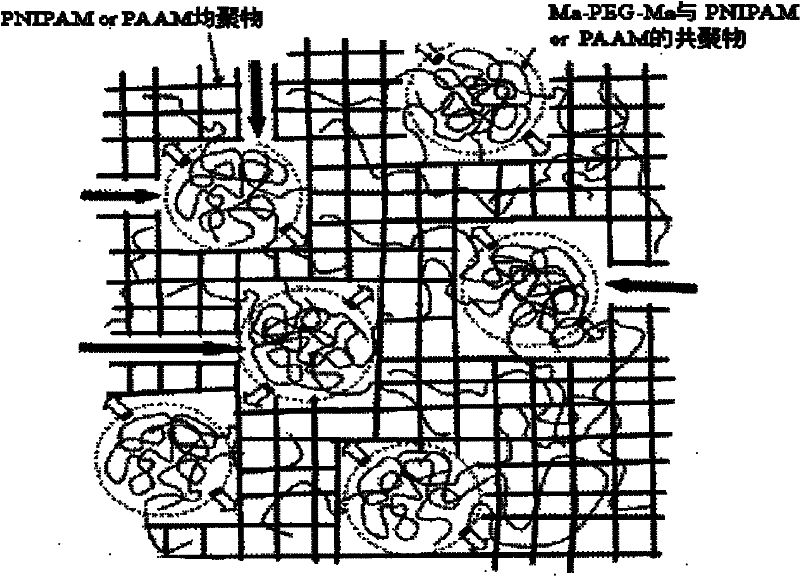

Double network polymer hydrogel and preparation method thereof

ActiveCN102226007ABroad application prospectsTo disperse external forceMaleic anhydrideFunctional monomer

A double network polymer hydrogel and a preparation method thereof provided in the invention, relate to a biomedical material. The polymer hydrogel comprises the following ingredients: 60-90wt% of polyethylene glycol maleic anhydride diester and N-isopropyl acrylamide or acrylamide copolymer, and 10-40wt% of N-isopropyl acrylamide or acrylamide homopolymer. The preparation method comprises the following two steps: first, utilizing an esterification reaction between polyethylene glycol PEG and maleic anhydride to obtain polyethylene glycol maleic anhydride diester with carboxyl as end group, then carrying out in situ polymerization, chemical crosslinking or UV photo-initiation crosslinking between polyethylene glycol maleic anhydride diester and a functional monomer such as N-isopropyl acrylamide or acrylamide and the like to form a soft network micro-area by the copolymer and form a hard network framework by the homopolymer of the functional monomer, so as to obtain the double network polymer hydrogel consisting of the soft network micro-area and the hard network framework. According to the invention, the hydrophilcity and biocompatibility of the hydrogel are improved, and the hydrophilcity has high mechanical strength, and sensitivities of rapid PH, temperature and electric field. The preparation method is simple and easy for industrialization.

Owner:XIAMEN UNIV

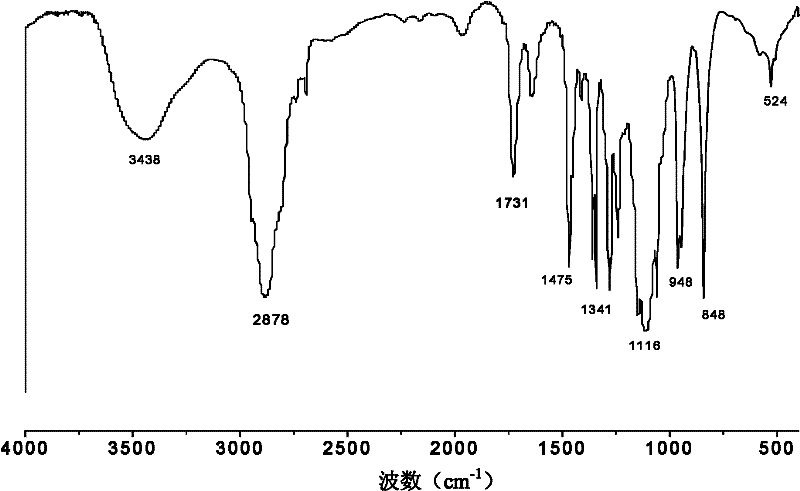

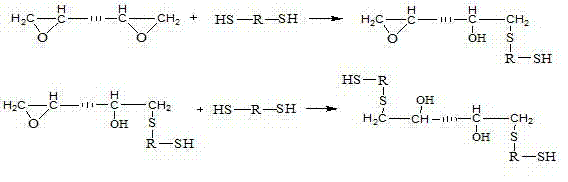

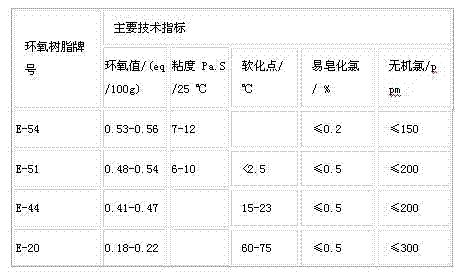

High-temperature-resistant flexible adhesive cured at normal temperature and preparation method thereof

InactiveCN102732209AImprove high temperature resistanceImprove toughnessNon-macromolecular adhesive additivesPolymer sciencePolysulfide rubber

The invention discloses a high-temperature-resistant flexible adhesive cured at normal temperature and a preparation method thereof. The high-temperature-resistant flexible adhesive is prepared by adopting bisphenol-A epoxy resin, high-polymerization-degree epoxy resin, polysulfide rubber and organic silicon resin as bonding components, adopting polyamide as a main curing component, and adding inorganic auxiliary materials with different proportions. The high-temperature-resistant flexible adhesive disclosed by the invention has the advantages that a Si-O chain section in organic silicon and a flexible chained structure in the polysulfide rubber are formed by changing grafting positions of the organic silicon and the epoxy resin, so that not only are the high-temperature resistance and the toughness of a cured product improved, but also the consumption of epoxy groups in a process of modification is reduced. The epoxy resin adhesive prepared by the method solves the problems that the cost is high, the purchasing of raw materials is difficult and the modification of the bonding components consumes a great quantity of epoxy groups to cause insufficient curing reaction and further cause reduction of the strength of the adhesive in the epoxy resin adhesive in the prior art. The high-temperature-resistant flexible adhesive has the characteristics that the operation can be carried out under the room-temperature condition, and simultaneously the high temperature can be resisted.

Owner:ZHENGZHOU UNIV

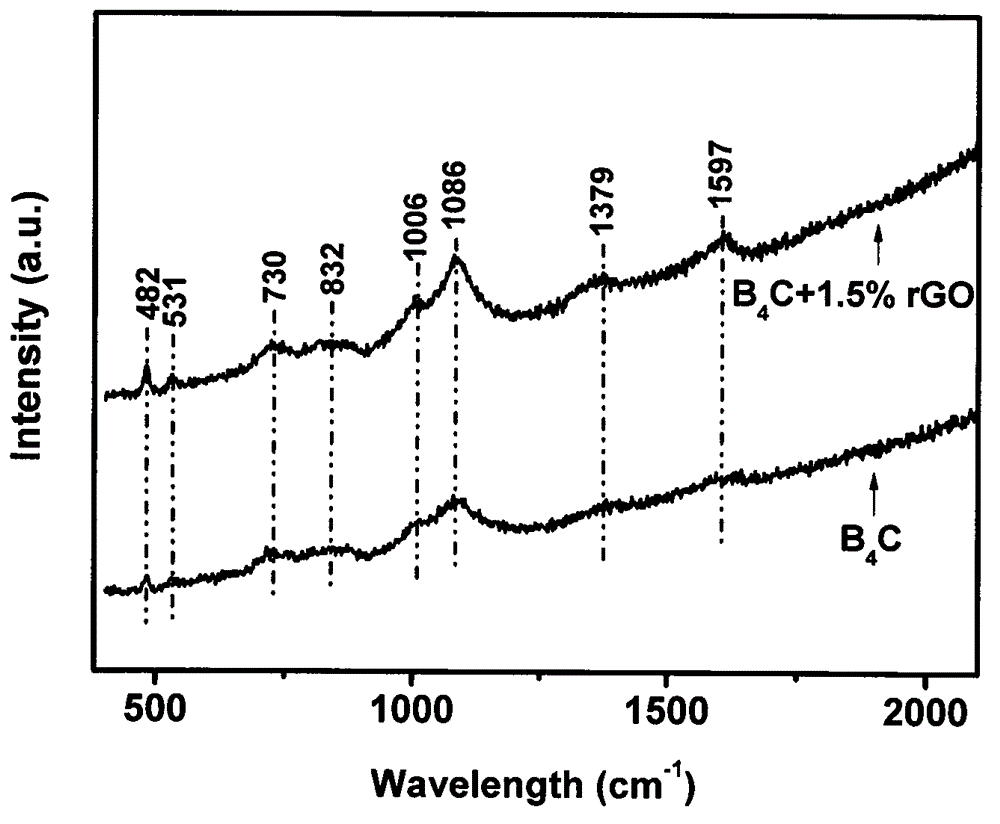

Graphene composite B4C superhard material preparation method

A graphene composite B4C superhard material preparation method is characterized by comprising the following steps: graphene oxide with the sheet diameter greater than 1mum and the layer number not more than five is mixed with B4C powder with the particle size not more than 3mum, the graphene oxide volume fraction is 0.3% -5%, water with the mass of 20-40 times of the mass of the B4C are added for ultrasonic treatment for 10-30min to obtain a graphene oxide / B4C mixture liquid, the graphene oxide / B4C mixture liquid is stirred for 2h more for more uniform mixing, and finally the graphene oxide / B4C mixture liquid is stirred and dried at a drying temperature below 100 DEG C at atmospheric pressure to obtain mixed powder; the mixed powder is pre-pressed into an initial blank in a molding apparatus; the initial blank is put into a high temperature and high pressure apparatus for high pressure sintering to obtain a graphene composite B4C superhard material, wherein the sintering temperature 1300-1600 DEG C, the sintering pressure is greater than 3GPa, and the sintering time is greater than 10min. The superhard material is harder than 19GPa, the fracture toughness reaches 8.76MPa. m1 / 2, and the fracture toughness of the graphene composite B4C superhard material is improved by more than 1 times compared with that of a pure B4C material.

Owner:INST OF FLUID PHYSICS CHINA ACAD OF ENG PHYSICS

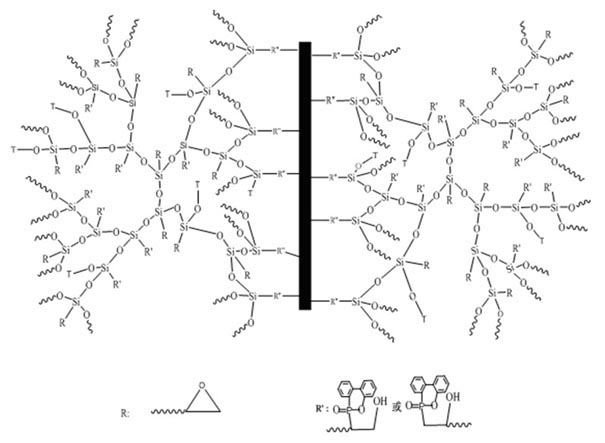

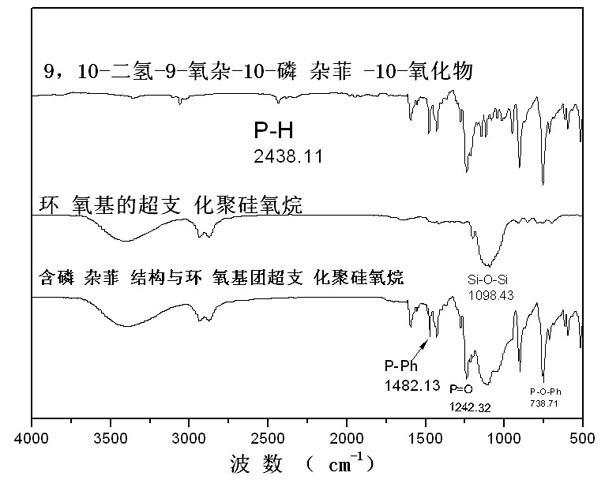

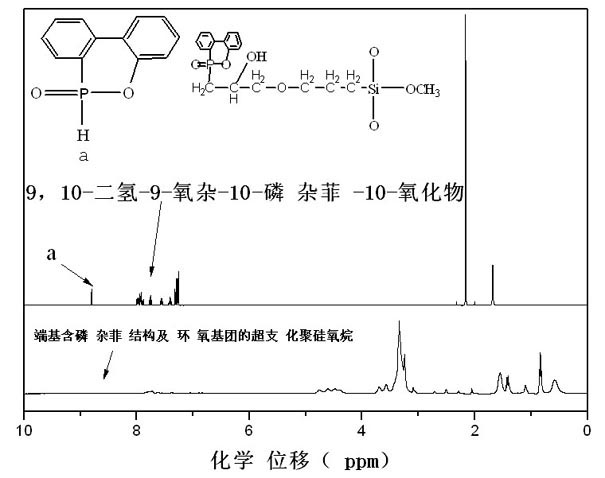

Surface modified carbon nanotube and preparation method thereof

InactiveCN102442660AImprove stabilityTo achieve the "amplification" effectMaterial nanotechnologyCarbon compoundsPolymer sciencePolymer modified

The invention relates to a surface modified carbon nanotube, the surface of which is grafted with hyperbranched polysiloxane containing a phosphaphenanthrene structure and epoxide groups through chemical bonding. A preparation method for the surface modified carbon nanotube comprises the following steps: mixing prepared hyperbranched polysiloxane containing a phosphaphenanthrene structure and epoxide groups with a functionalized carbon nanotube, adding the catalyst triphenylphosphine, adding an obtained mixture into a solvent, carrying out ultrasonic treatment, and removing the solvent after a reaction is finished so as to obtain the surface modified carbon nanotube. The surface modified carbon nanotube provided in the invention contains active reactive groups, can well disperse in thermosetting resin and endows the thermosetting resin with good flame resistance and toughness on the basis of maintaining heat resistance and rigidity of the thermosetting resin; therefore, the surface modified carbon nanotube has immense application potential in the fields of research and development of novel high-molecular materials, modification, high performance development and multi-functionalization of polymers, etc.

Owner:SUZHOU UNIV +1

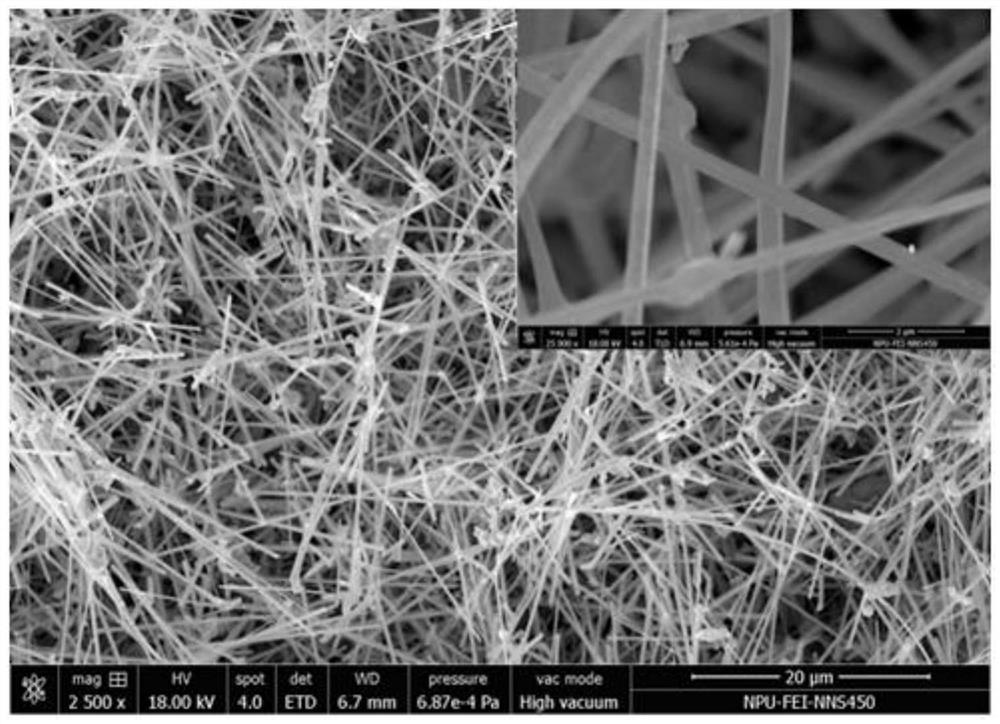

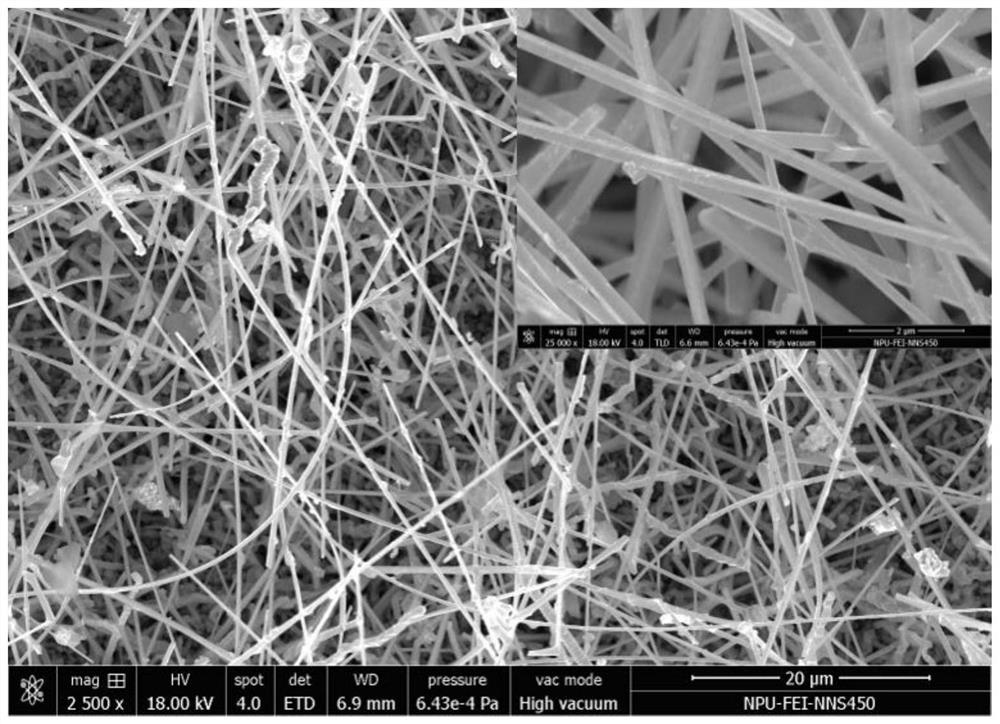

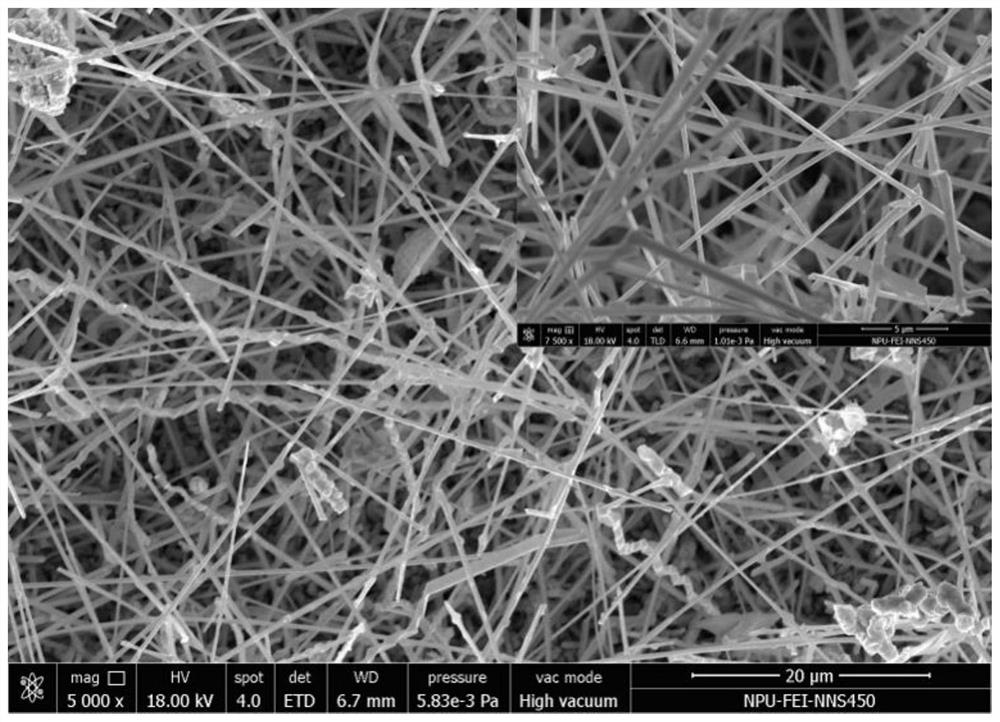

Method for preparing monocrystalline silicon carbide nanofiber/silicon carbide ceramic matrix composite material by reaction sintering

ActiveCN110256082ARelieve heat stressImprove mechanical properties and service lifeCarbon blackMonocrystalline silicon

The invention discloses a method for preparing a monocrystalline silicon carbide nanofiber / silicon carbide ceramic matrix composite material by reaction sintering. The method comprises the following steps: preparing a SiC nanofiber coated with a carbon / BN coating from a monocrystalline silicon carbide nanofiber; impregnating or stirring and dispersing the SiC nanofiber in an ethanol / water suspension containing nanometer carbon black / silicon carbide particles; and preparing a SiCNf preform by vacuum suction filtration or rolling: placing the above interfacial layer deposited nanofiber preform in a molding die, further carrying out press molding, carrying out high-temperature dumping to obtain a high-density SiCNf preform, and then performing reaction infiltration. Compared with in-situ grown SiC nanowire / fiber (SiCnf) reinforced SiC ceramic matrix composite materials, the composite material of the invention has the advantages of easiness in preparation of the interfacial coating of the SiCNf and the matrix, high volume content of the SiCNf, and high density.

Owner:ZHEJIANG SCI-TECH UNIV

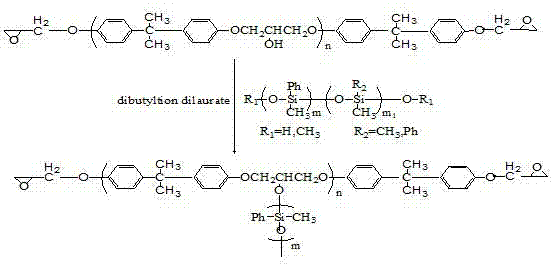

Polysiloxane modified epoxy resin and preparation method thereof

The invention discloses polysiloxane modified epoxy resin and a preparation method thereof. The preparation method comprises the following steps: firstly mixing and dissolving epoxy resin and polysiloxane in an organic solvent, dropwise adding a catalyst at a temperature of 60-100 DEG C in a nitrogen environment, then carrying out stirring for reacting to obtain polysiloxane modified epoxy resin,removing unreacted polysiloxane after the reaction is finished, and carrying out reduced-pressure distillation to remove the organic solvent to obtain the pure modified resin. The polysiloxane modified epoxy resin prepared by the invention can be cured into a film at room temperature, the obtained coating has good flexibility and impact resistance, the ultraviolet aging resistance is remarkably improved, and the service life is greatly prolonged. In addition, the process is simple, and energy consumption is low.

Owner:FUZHOU UNIV

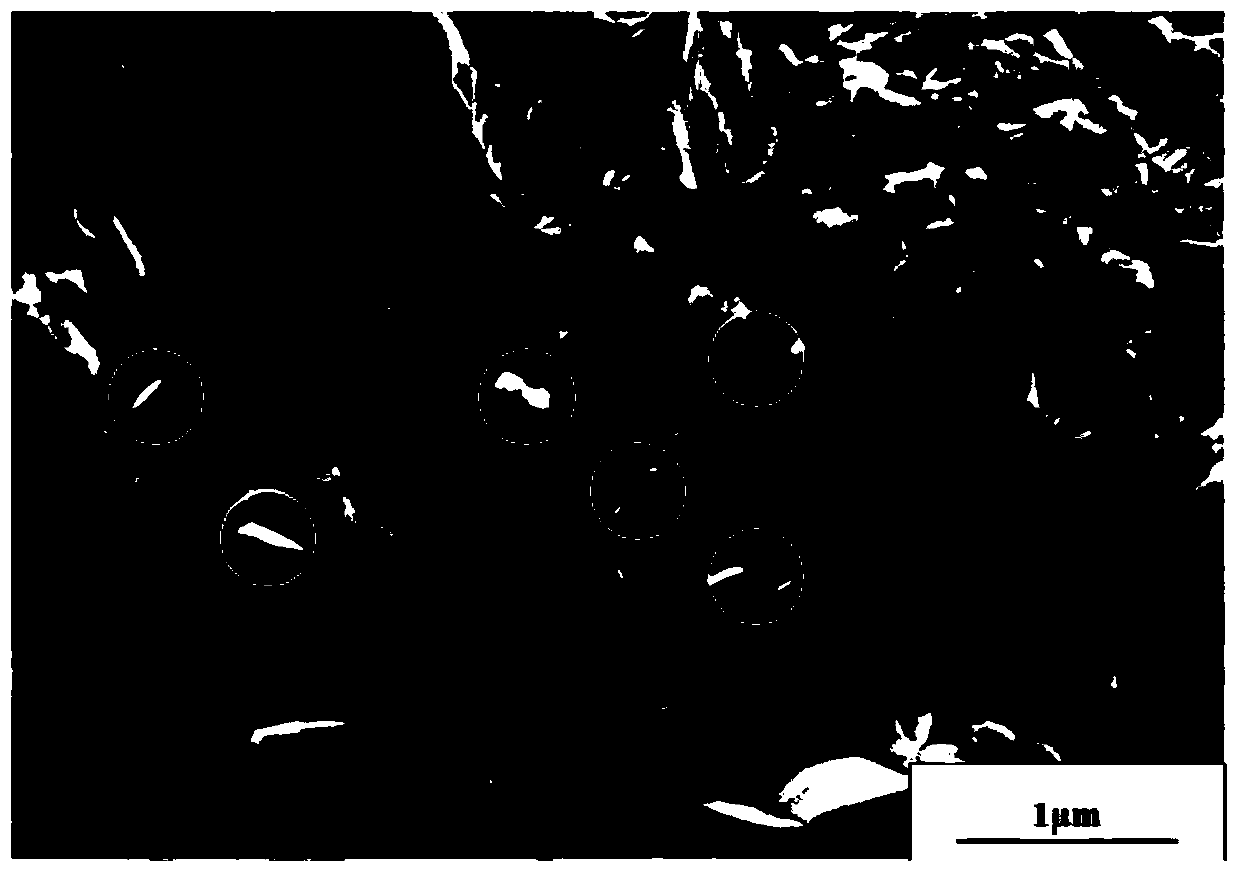

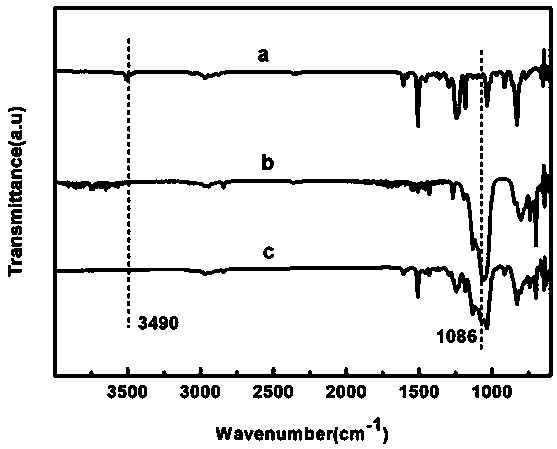

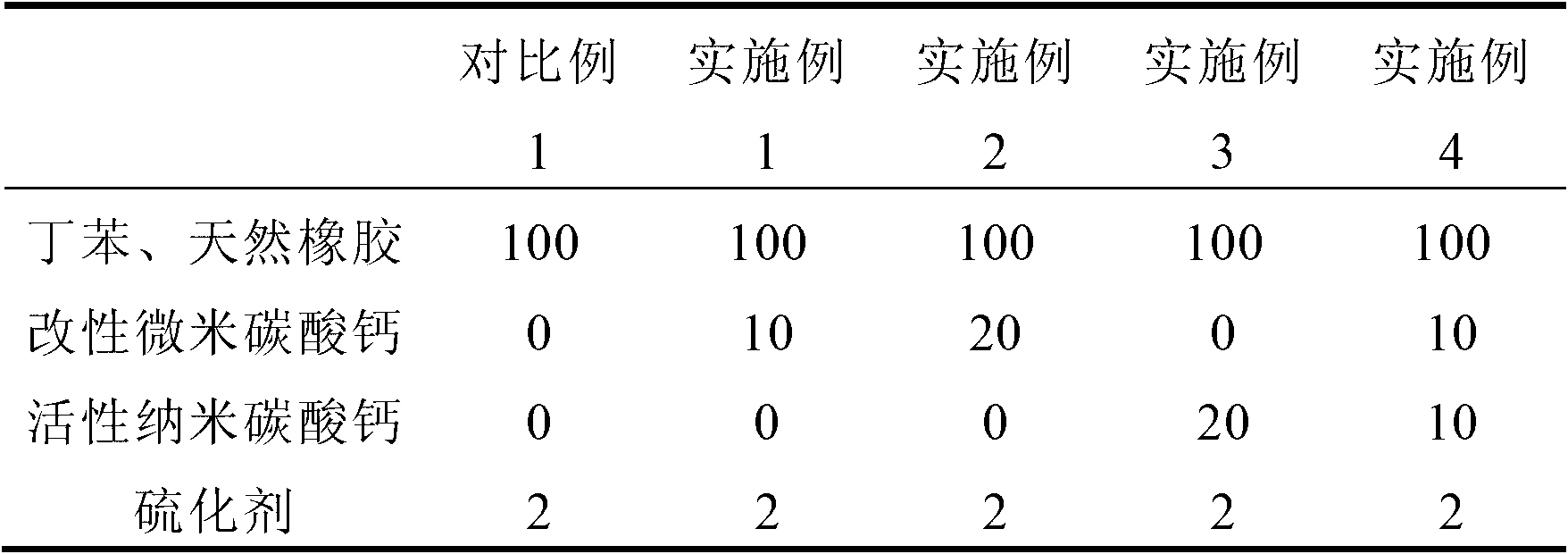

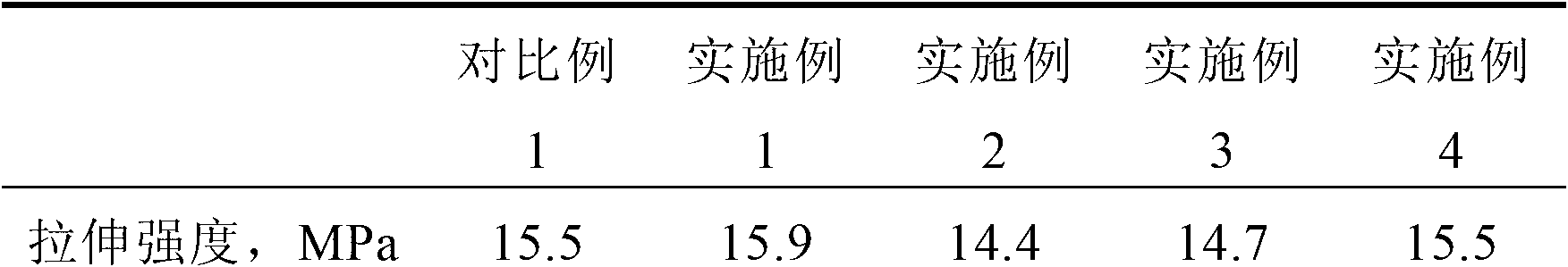

Preparation method of calcium carbonate modified butylbenzene/natural rubber composite material

InactiveCN102796294AAchieve incremental cost reductionRealize reinforcementUltimate tensile strengthToughness

The invention discloses a preparation method of a calcium carbonate modified butylbenzene / natural rubber composite material, which is characterized by comprising a micrometer calcium carbonate surface treatment through using a surface conditioning agent which contains unsaturated bond and a function group capable of reacting with a calcium carbonate surface group, and comprising a mixed modification technology for butylbenzene / natural rubber composite material through using modified calcium carbonate and active nanometer calcium carbonate. The increased amount and reduced cost of the butylbenzene / natural rubber by calcium carbonate can be ensured, and the good strength and toughness of butylbenzene / natural rubber can be kept. The method has the characteristic of simple production technology, and can be directly used in the industrial production.

Owner:ZHEJIANG UNIV OF TECH +2

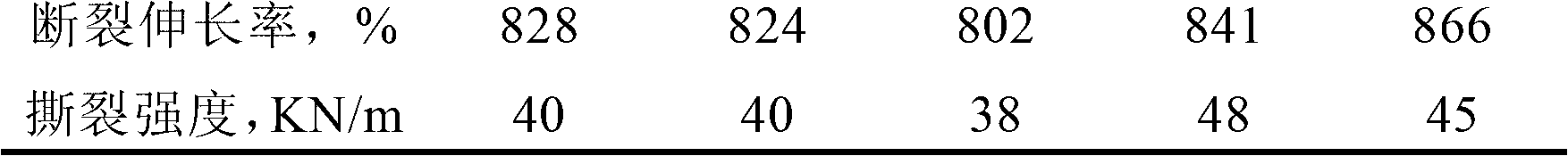

Nano inorganic oxide/silicic acid/cellulose multilayered structure composite enhanced biodegradable material and preparation method thereof

The invention discloses a nano inorganic oxide / silicic acid / cellulose multilayered structure composite enhanced biodegradable material and a preparation method thereof, and relates to the composite enhanced biodegradable material and the preparation method thereof. The invention aims to solve the problem that current polylactic acid has poor impact resistance and thermal stability. The biodegradable material is obtained by co-modification of polylactic acid by a toughening material and coating particles. The method comprises the following steps: 1, preparation of the cellulose / silicic acid / nano oxide coating particles; 2, surface modification of the cellulose / silicic acid / nano oxide coating particles; and 3, preparation of the nano inorganic oxide / silicic acid / cellulose multilayered structure composite enhanced biodegradable material. The material disclosed by the invention has excellent mechanical properties and thermal stability, the impact strength is 1-1.06 J*m<-1>, and the initialdecomposition temperature is 380-388 DEG C; and the material is used in the field of biodegradable materials.

Owner:NORTHEAST FORESTRY UNIVERSITY

Zirconium oxide refractory with homogeneous micro-crystallized structure and preparation method thereof

The invention discloses a zirconium oxide refractory with a homogeneous micro-crystallized structure. The raw materials of the zirconium oxide refractory comprise the following components by weight percent: 92-96wt% of fused monoclinic zirconium oxide, 4-8wt% of compound stabilizer and sintering aid and 0-1wt% of yellow dextrin. Simultaneously, the invention also discloses a preparation method ofthe zirconium oxide refractory. The preparation method comprises the following steps of: firstly, mixing the raw material dry powder for 1-2 minutes by adopting a high-speed mixing and pelleting machine; after additionally adding 8-12wt% of combining agent, carrying out high-speed pug milling for 5-8 minutes, and then cutting for 1-3 minutes at a high speed; after boiling drying and screening, pelleting, and pressing and forming at the pressure of 150-200MPa; drying a formed green body for 12-24 hours at the temperature of 110 DEG C; and calcining for 2-3 hours at the temperature of 1600-1650DEG C. The zirconium oxide refractory of the invention has the advantages of high temperature and high strength, low apparent porosity, small pore aperture, good scouring resistance and stripping resistance and strong thermal shock resistance. The zirconium oxide refractory of the invention not only can adapt to longevity requirements of a steel ladle, an intermediate ladle sliding plate and a continuous casting sizing water gap but also can be used as longevous kiln furniture.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

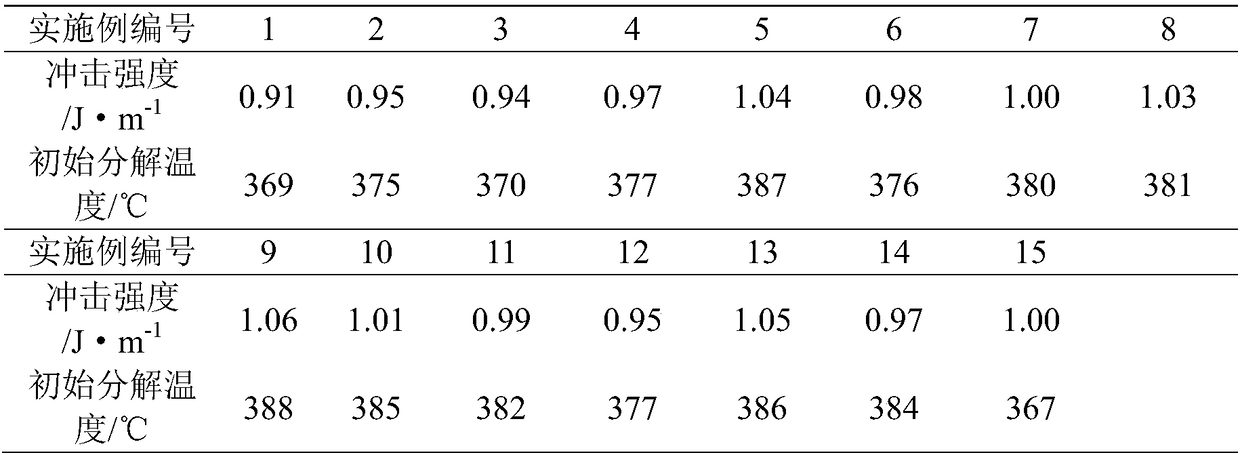

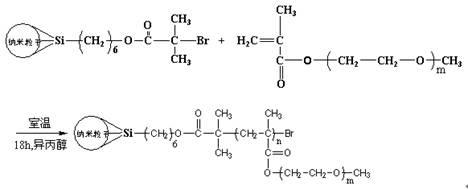

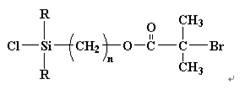

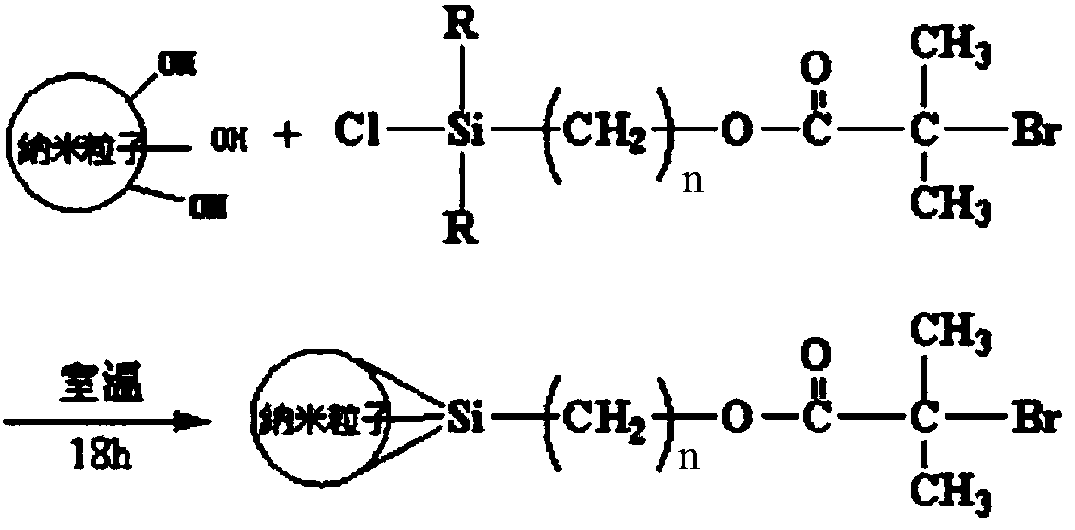

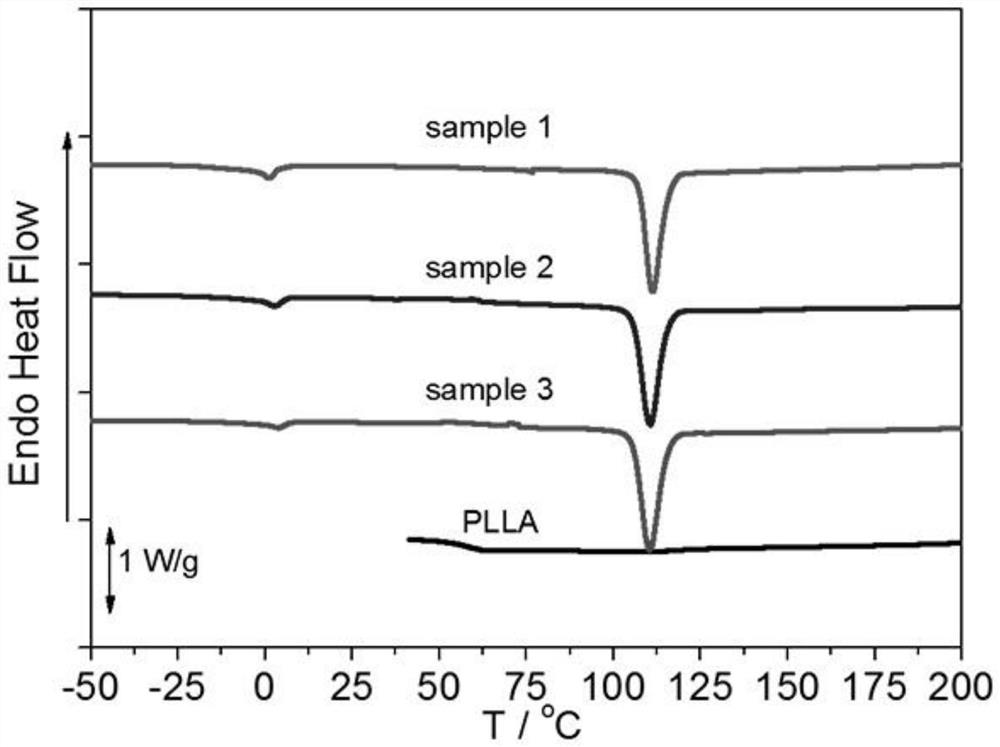

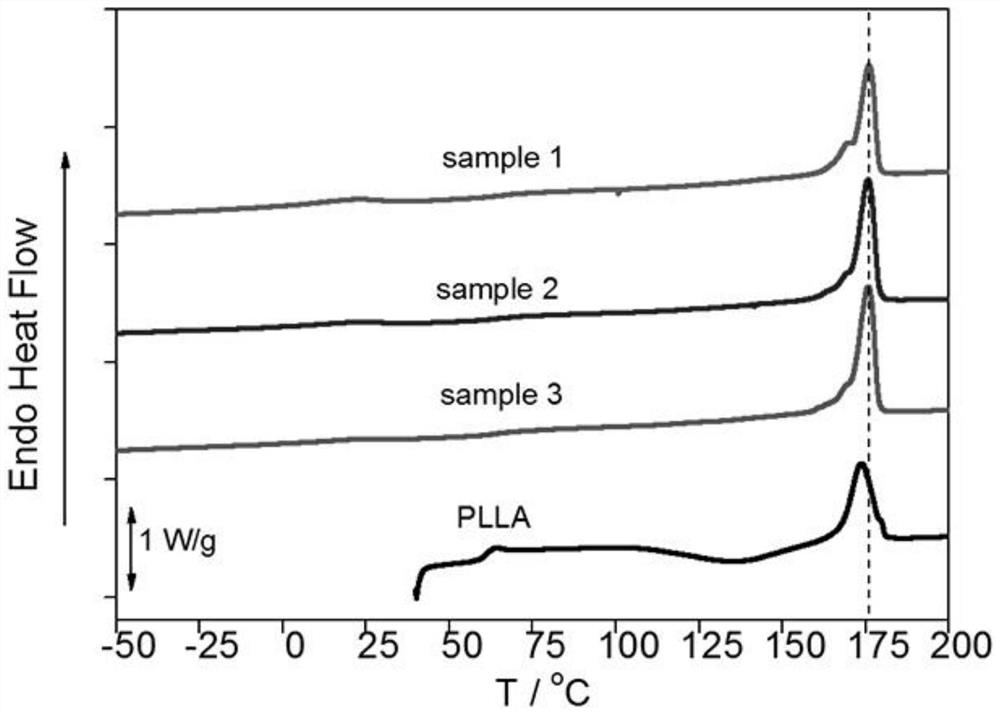

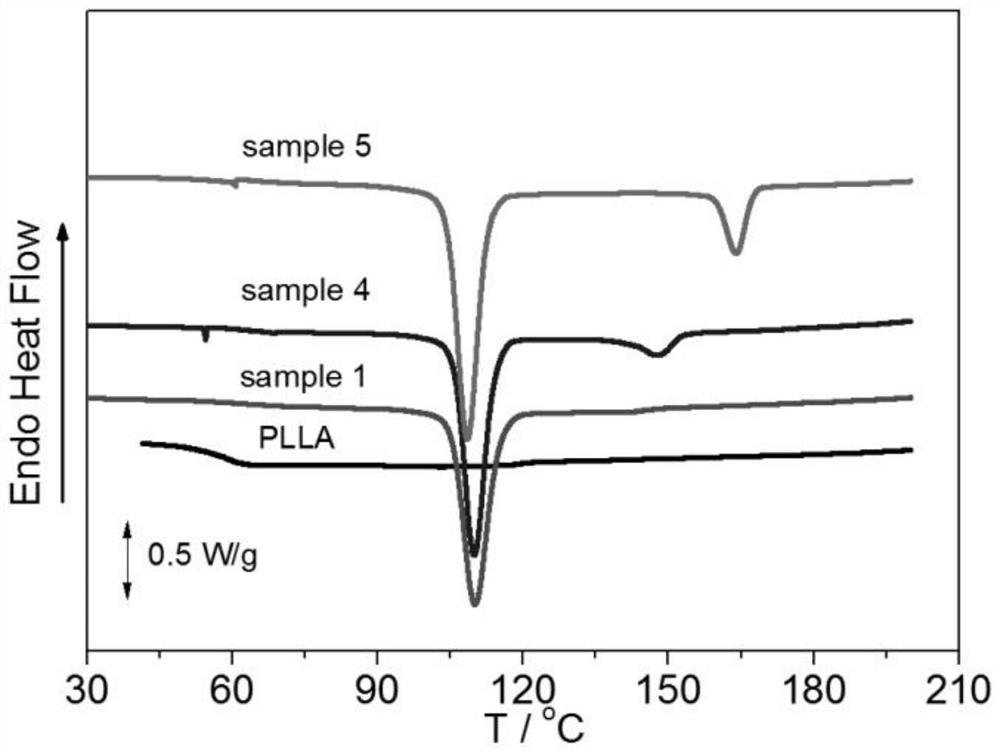

Preparation method of surface modified nano particles and application of product thereof

InactiveCN102181175AUniform chain length distributionImprove dispersibility and stabilityCoatingsPigment treatment with macromolecular organic compoundsChemistryChain length

The invention discloses a preparation method of surface modified nano particles and application of a product thereof. The method comprises the following steps of: reacting the surfaces of nano particles, atom transfer radical polymerization (ATRP) surface initiator and 2-bromoisobutyryl with silicon chlorine bond to anchor the ATRP surface initiator on the surfaces of the nano particles, and then performing ATRP with methacrylate monomer, catalyst, coordination agent and the like to prepare acrylate polymer modified inorganic nano particles. Therefore, the ATRP method for modifying the nano particles has controllability on the nano particle surface grafted acrylate polymer, the advantages of the nano particles are fully exerted, and the effects of enhancing and toughening the nano particles and the like are achieved under the condition of low adding amount; meanwhile, the chain length distribution of the acrylate polymer is uniform, so the dispersibility and the stability of the modified nano particles in an acrylate coating are improved; and the abrasion resistance of the coating is improved, and high transparency of the coating is kept at the same time.

Owner:WUJIANG YOUXIN NEW MATERIAL TECH

Method for toughening gypsum by means of nickel slag and product prepared through method

ActiveCN106278102ARealize comprehensive utilizationPromote sustainable developmentSolid waste managementCeramic shaping apparatusFiberSlag

The invention discloses a method for toughening gypsum by means of nickel slag and a product prepared through the method. The method comprises the steps that the nickel slag, industrial gypsum, calcium-containing waste and aluminum-containing waste are mixed to be uniform, water is added, grinding is conducted for 20 min, the mixed material is poured into a mold, demolding is conducted after molding is achieved, and a sample is obtained, wherein the water-cement ratio ranges from 0.4 to 0.55; after standard curing is conducted on the sample for 3 d to 5 d, hydrothermal curing is conducted for 3 h to 24 h at the curing temperature of 50 DEG C to 135 DEG C, and the nickel slag self-toughening product is obtained. The nickel slag thermal curing product prepared through the method has the good toughness, organic matter harmful to a human body does not need to be added, and fibers do not need to be mixed.

Owner:YANCHENG INST OF TECH

Composite skeleton reinforced ceramic based filter material preparation method

InactiveCN109824377ARealize chemical bond connectionImprove pore structureSustainable biological treatmentFiltration separationFiltrationMechanical property

The invention belongs to the technical field of environment-friendly materials and discloses a composite skeleton reinforced ceramic based filter material preparation method. The method includes: uniformly stirring and dispersing modified graphene oxide, macromolecular organic matter dispersion liquid and an antifoaming agent to obtain graphene oxide dispersion liquid; mixing diatomite with strongacid solution, performing hydrothermal reaction, filtering, washing, drying and calcining to obtain pretreated diatomite; subjecting the pretreated diatomite, the graphene oxide dispersion liquid, calcium carbonate, magnesium carbonate, sodium fluoride and nano iron powder to ball milling and mixing, and then standing for aging to obtain an aged material; rubbing the aged material to make balls,naturally drying, performing heat-preservation sintering at different temperatures under the protection of nitrogen while the temperature rise rate is controlled, cooling, and discharging to obtain acomposite skeleton reinforced ceramic based filter material. The ceramic based filter material prepared according to the technical scheme has excellent filtration performances as well as mechanical properties and has a promising prospect in development of the technical industry of environment-friendly materials.

Owner:吕莉

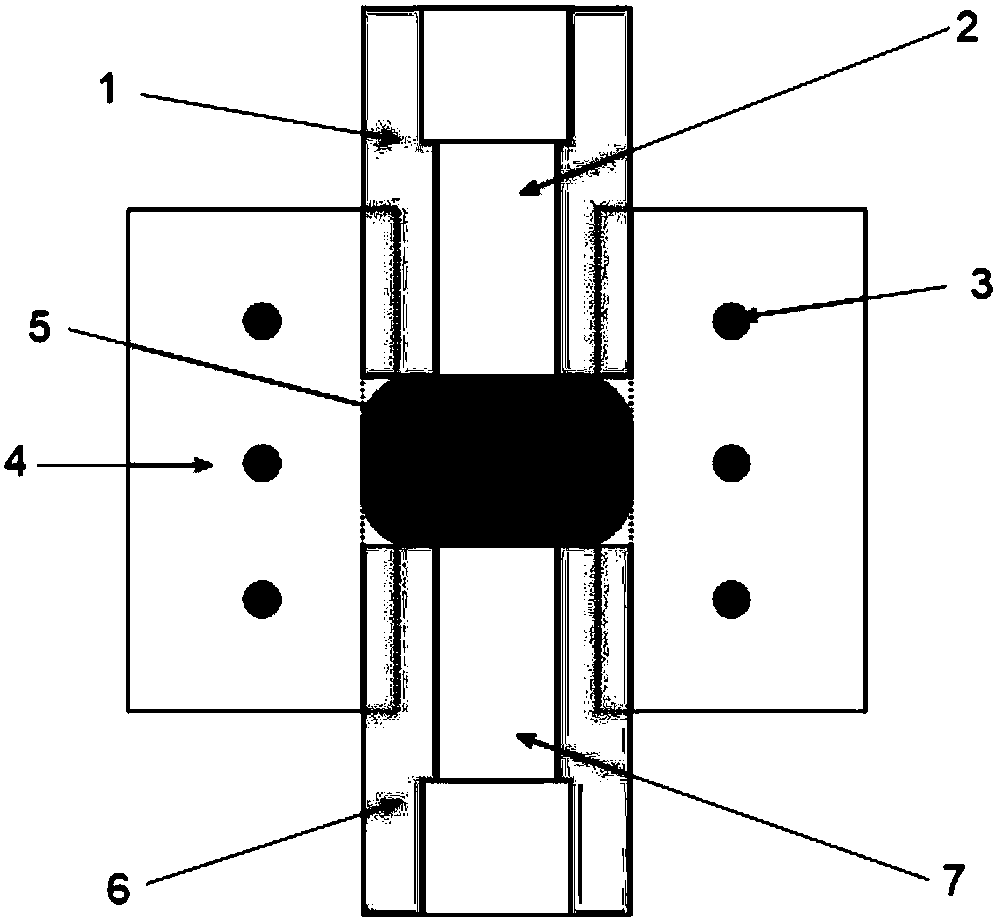

Plastic forming and toughening technology method based on ultrasonic vibration and device thereof

ActiveCN108085632AThe process is simpleShorten forming timeShaping toolsMachining timeUltrasonic vibration

The invention belongs to the field of amorphous alloy thermoplastic forming and discloses a plastic forming and toughening method and a device based on ultrasonic vibration. The method comprises the steps: (a) dividing a part with toughness to be enhanced on an amorphous ally part to be formed to be used for generating a nanocrystalline toughening phase; (b) designing a toughening device for forming, wherein the toughening device comprises an insert block connected with an ultrasonic vibration amplitude change pole and a heating rod, the insert block corresponds to the part with the toughnessto be enhanced and is used for exerting ultrasonic vibration on the part with the toughness to be enhanced, and the heating rod is used for heating raw material blank to be processed to a forming temperature; (c) putting the raw material blank in the device, heating by the heating rod, mould closing the device to form a required amorphous alloy part, starting ultrasonic vibration in a mould closing process and stopping in mould opening. Meanwhile, the invention further discloses the utilized device. By means of the plastic forming and toughening method disclosed by the invention, toughening and plastic forming can be performed at the same time, so that forming and toughening integration is achieved, production work procedures are simplified, processing time is shortened, and dimensional accuracy is improved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

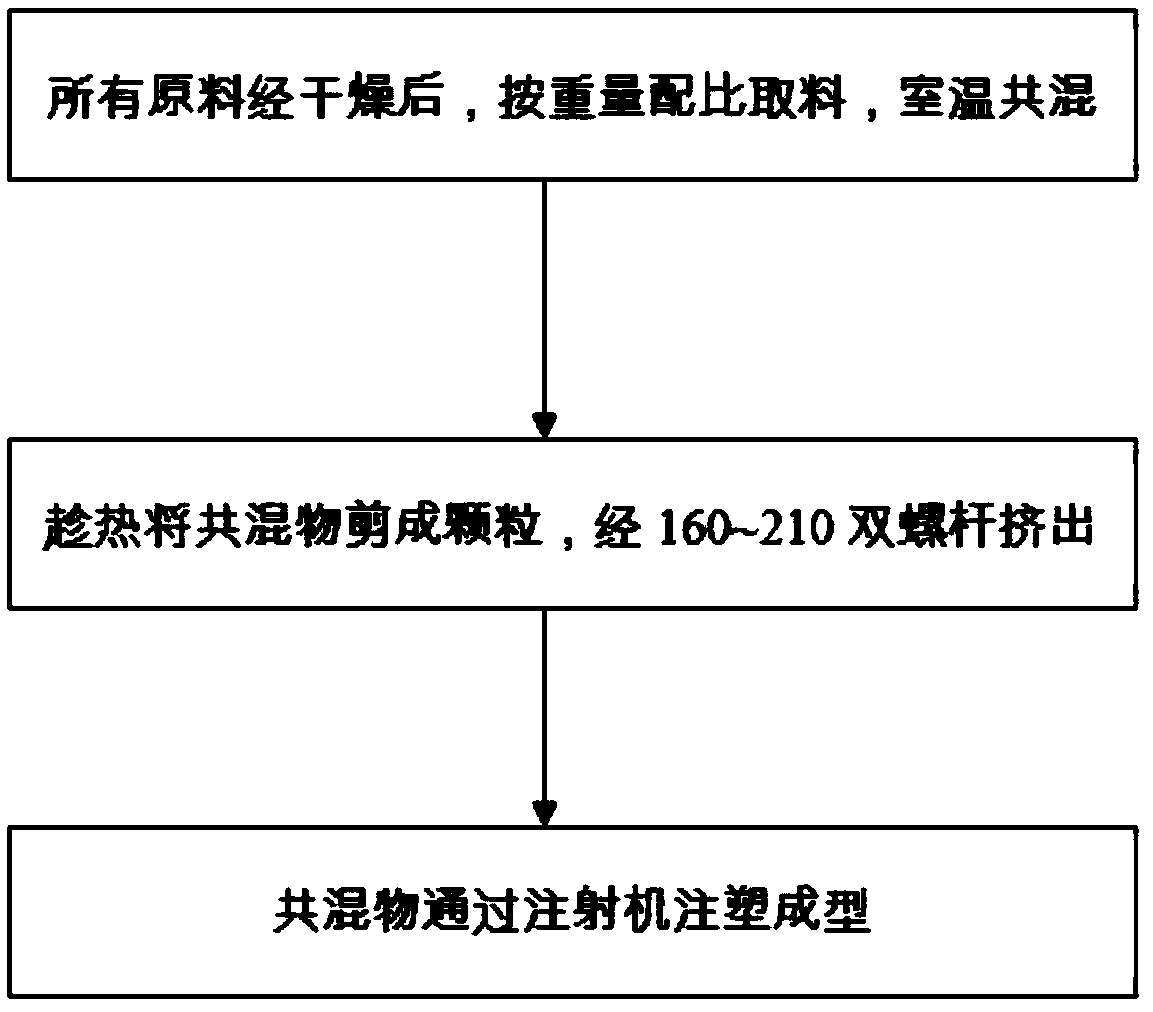

Fully biodegradable component-toughened PLA composite material and preparation method thereof

The invention discloses a fully biodegradable component-toughened PLA composite material and a preparation method thereof. The material is prepared from, by weight, 66-95.9 parts of polylactic acid, 3-15 parts of an alginic acid natural polymer, 1-18 parts of vegetable oil or derivatives thereof and 0.1-1.0 part of an alkaline catalyst. The preparation method comprises the following steps of drying the components, conducting blending and granulating in an internal mixer, then putting granules into an extruder for extrusion, and performing injection molding by an injection molding machine. Thecomposite material has the advantages that the production cost is low, the material is biodegradable, a plasticizer is unlikely to permeate and migrate, no pollution is caused, a good toughening effect is achieved, and the mechanical property is excellent.

Owner:GUIZHOU UNIV

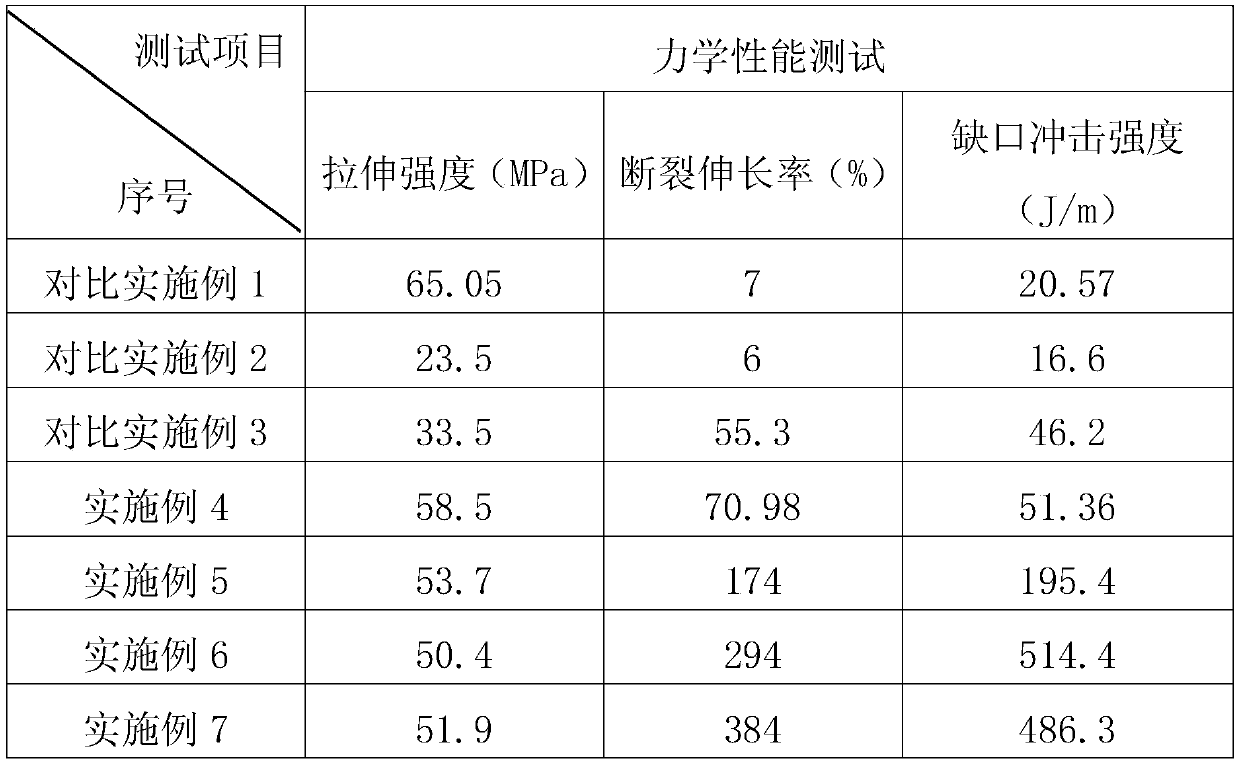

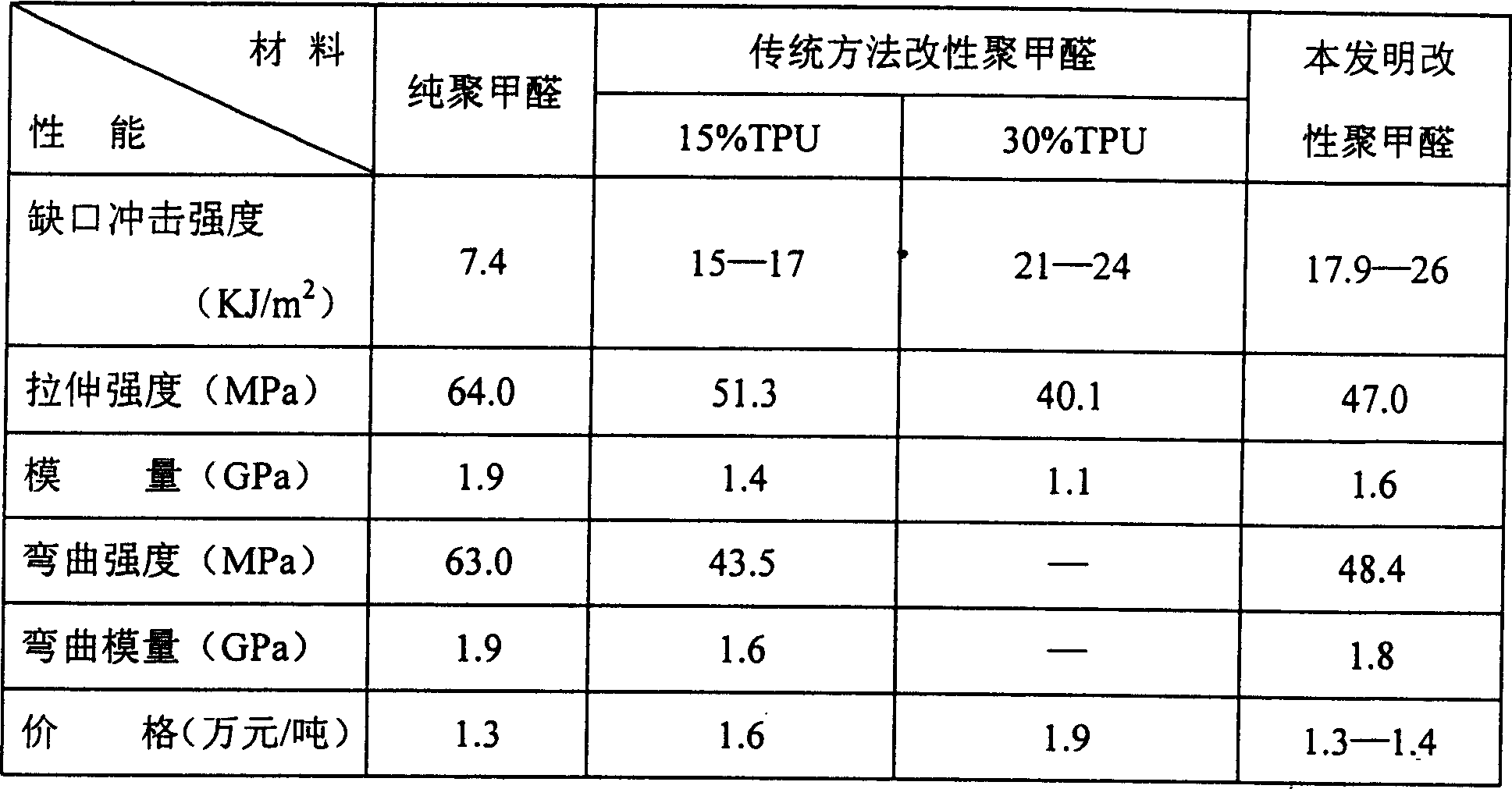

Nano composite polyformaldehyde material and its preparation

The present invention discloses one kind of nano composite polyformaldehyde material, and the composite contains polyformaldehyde 55-90 wt% and elastomer 2.5-30 wt% as well as characterized inorganic nano stuffing 0.1-10 wt% and compatibilizing agent 0.1-10 wt%. During the preparation, inorganic nano stuffing, compatibilizing agent and elastomer in certain proportion are smelted and mixed to obtain agglomerate; and the agglomerate is then diluted and dispersed in polyformaldehyde or polyformaldehyde / elastomer to obtain the product through further smelting and mixing. The present invention can strengthen and toughen polyformaldehyde while reducing cost.

Owner:SICHUAN UNIV

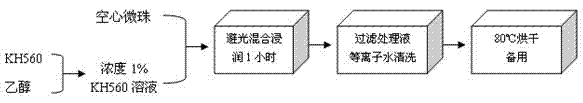

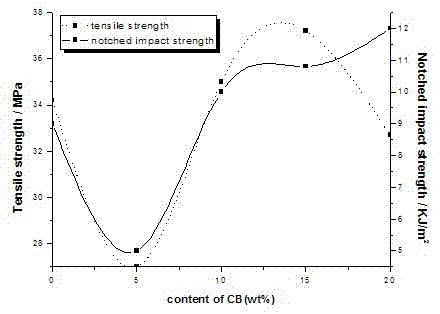

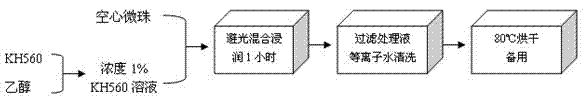

Carbon fiber/cenosphere/polypropylene ternary composited material and preparation method thereof

The invention discloses a carbon fiber / cenosphere / polypropylene ternary composited material and a preparation method thereof. The proportion by weight of carbon fibers, cenospheres and polypropylene includes: 100 parts of polypropylene, 2 to 30 parts of carbon fibers and cenospheres which are larger than 0 part but smaller than 30 parts. Thermoplastic polypropylene resin is used as a base material and is modified by blending with the carbon fiber and the cenospheres, and accordingly, a carbon fiber / cenosphere / polypropylene blending system which is reinforced and toughened is formed on the condition of adding few carbon fibers. Since third-phase cenospheres are introduced into a carbon fiber / polypropylene composite system, the carbon fibers but the cenospheres are used as main carriers so that toughness of the composite system is improved. Besides, affection on mechanical performance of the system is more evident and cost is reduced evidently on the premise of identical additive amount as compared with those of a system added with PP-g-MAH.

Owner:CHONGQING UNIV OF TECH

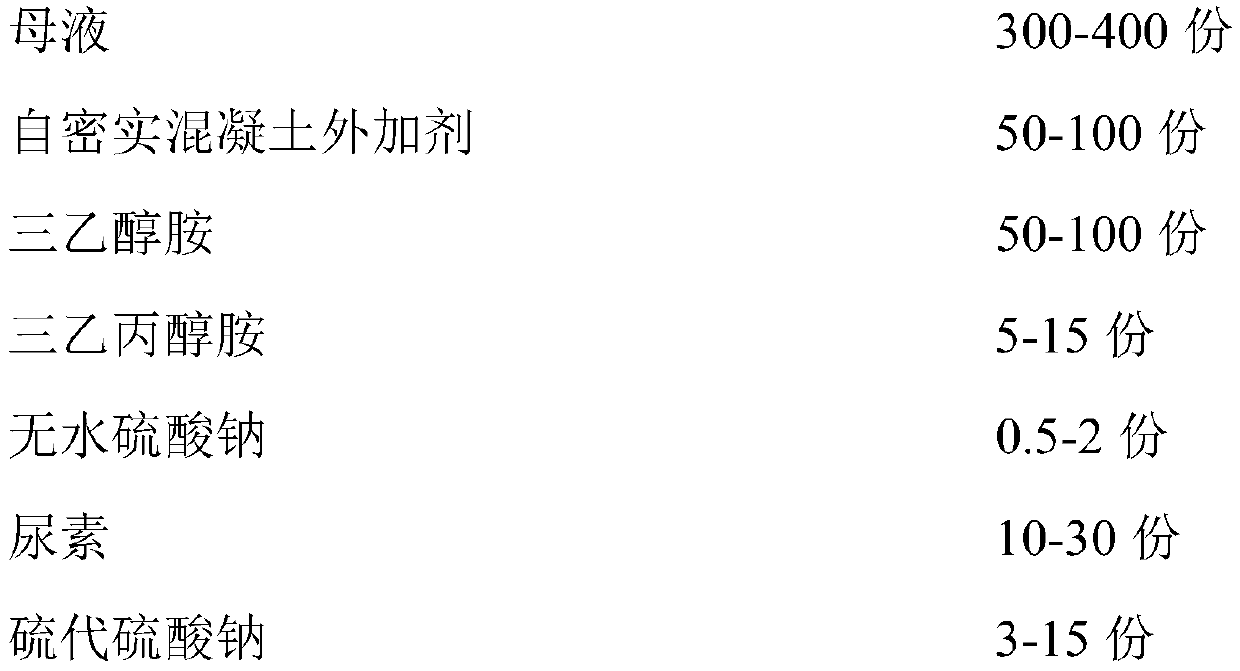

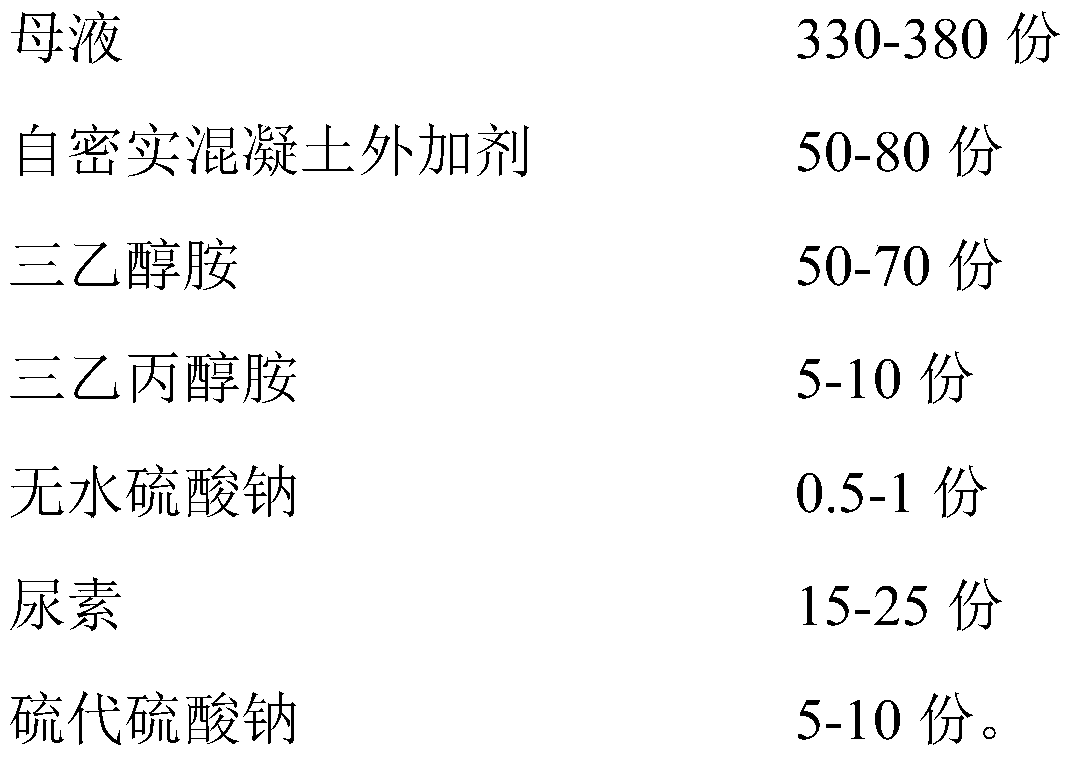

Reactive powder concrete as well as preparation and application thereof

The invention discloses reactive powder concrete as well as a preparation and an application thereof. The reactive powder concrete comprises the following components: cement, silica fume, mineral powder, sand, an additive, steel fibers and water. The preparation method comprises the step of uniformly mixing the cement, the silica fume, the mineral powder, the sand, the additive, the steel fiber and the water to obtain the active powder concrete. The problems that the traditional building outer wall material is poor in texture, short in service life, high in manufacturing cost, thick and heavyare solved. By using the reactive powder concrete material with ultrahigh durability and ultrahigh mechanical property, the fabricated architectural decoration outer wall with the artistic effect is manufactured, and compared with traditional concrete, the reactive powder concrete has the material characteristics of high strength, high compactness, high durability and high toughness.

Owner:上海城建建设实业集团新型建筑材料有限公司

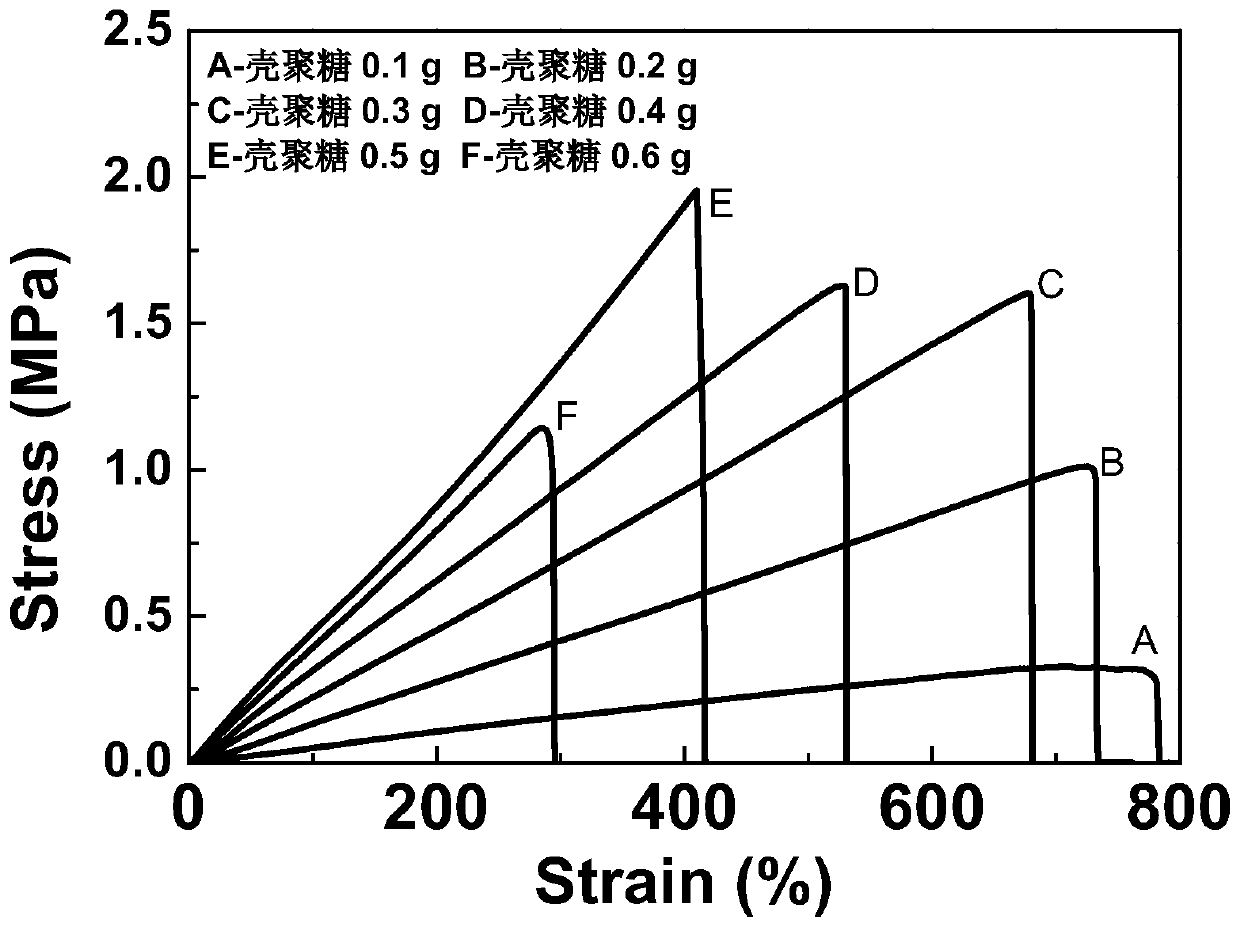

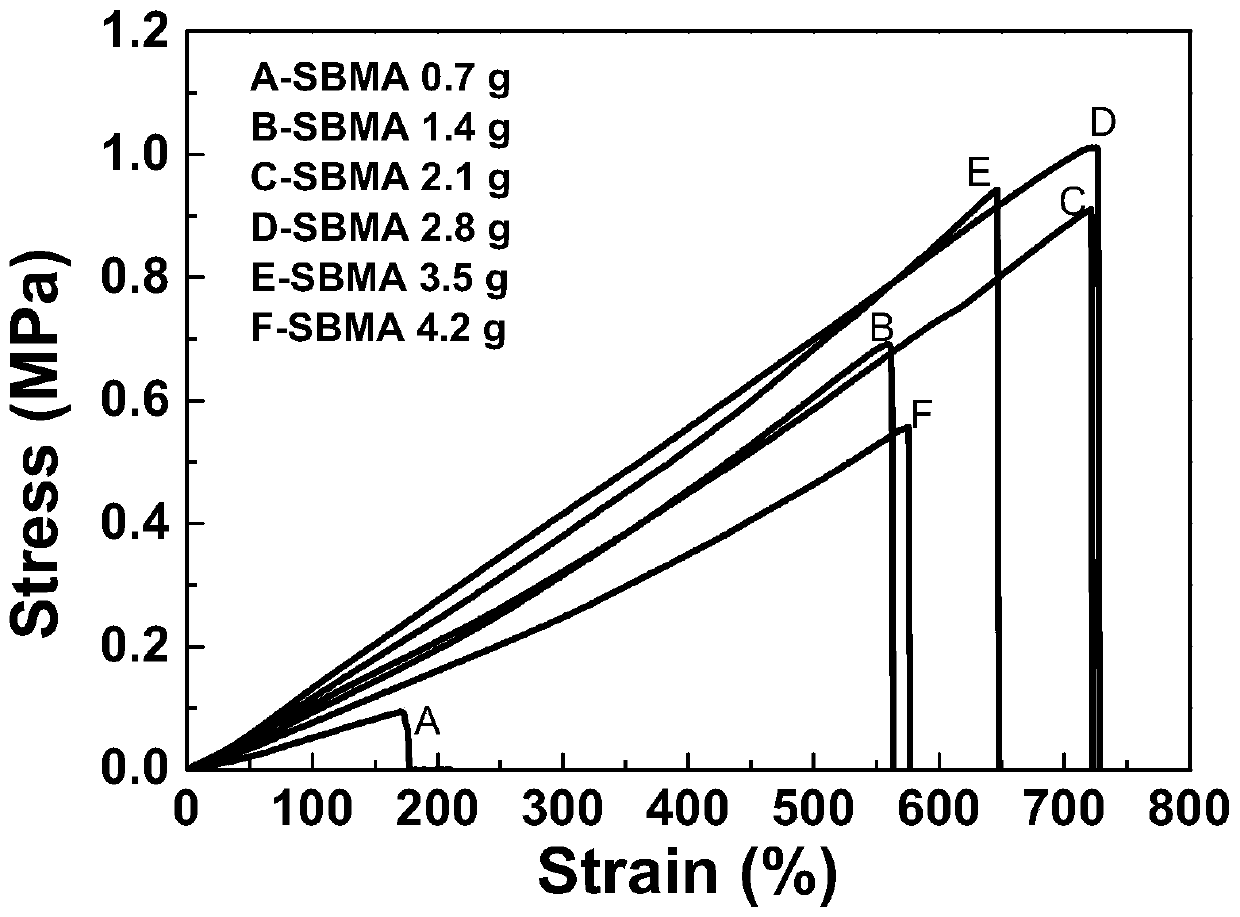

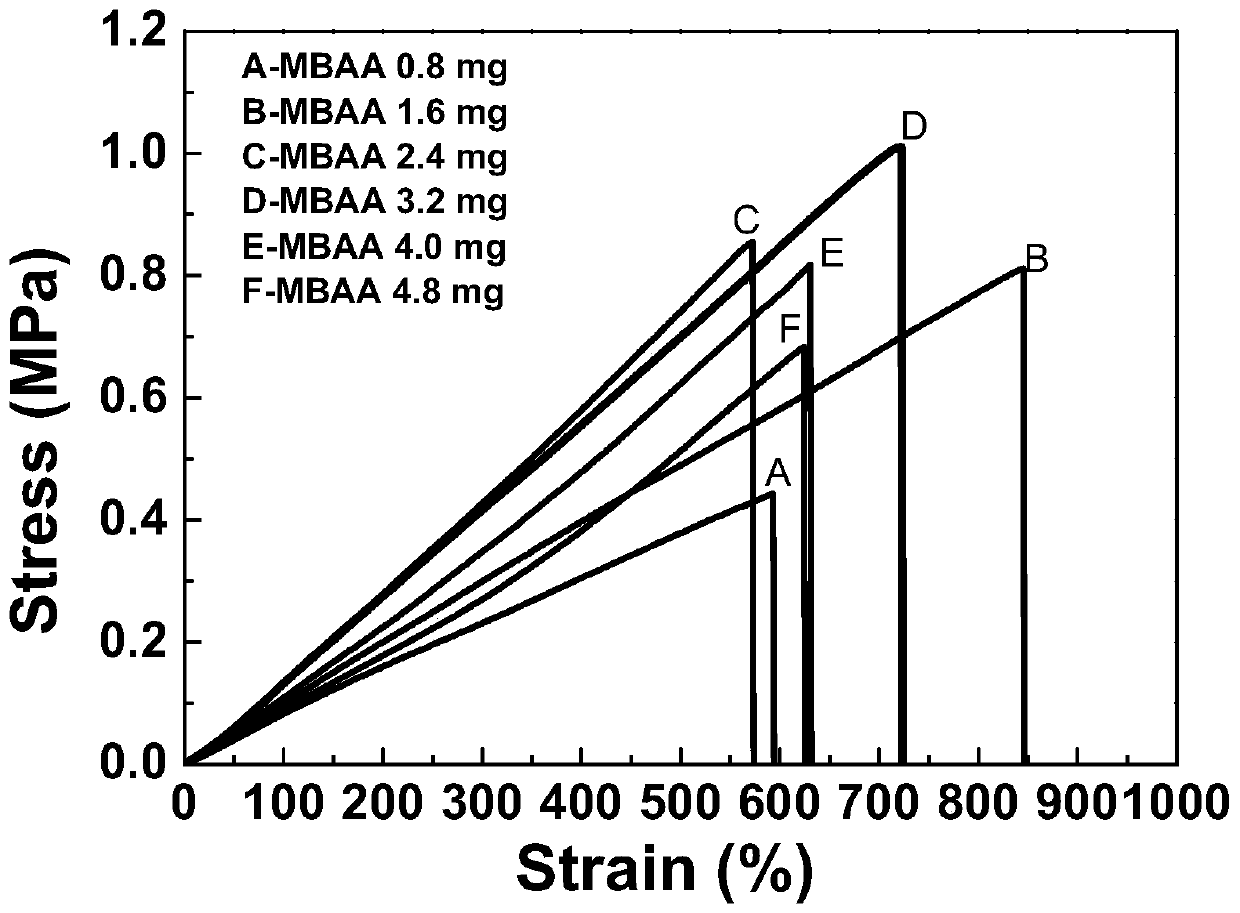

Chitosan/polysulphobetaine ionic and covalent double-network hydrogel and production method thereof

InactiveCN109970999AImprove featuresImprove adhesionOther chemical processesAlkali metal oxides/hydroxidesCell adhesionAdhesion process

The invention relates to the technical field of polymer hydrogel, in particular to chitosan / polysulphobetaine ionic and covalent double-network hydrogel and a production method thereof. The chitosan / polysulphobetaine ionic and covalent double-network hydrogel is of a double-network structure, and is formed through interpenetration of a first network and a second network, wherein the first networkis a physical cross-linking network formed through coordination of chitosan and multivalent anions, the second network is a chemical cross-linking network formed by polysulphobetaine, and the first network interpenetrates the second network. The produced double-network hydrogel has excellent obdurability and elasticity, further has good antibacterial performance, nonspecific protein adsorption resistance performance and cell adhesion resistance performance, and thus has wide application prospects in the field of biomedical application; and a production method is concise, efficient and environmentally friendly.

Owner:ZHEJIANG UNIV OF TECH

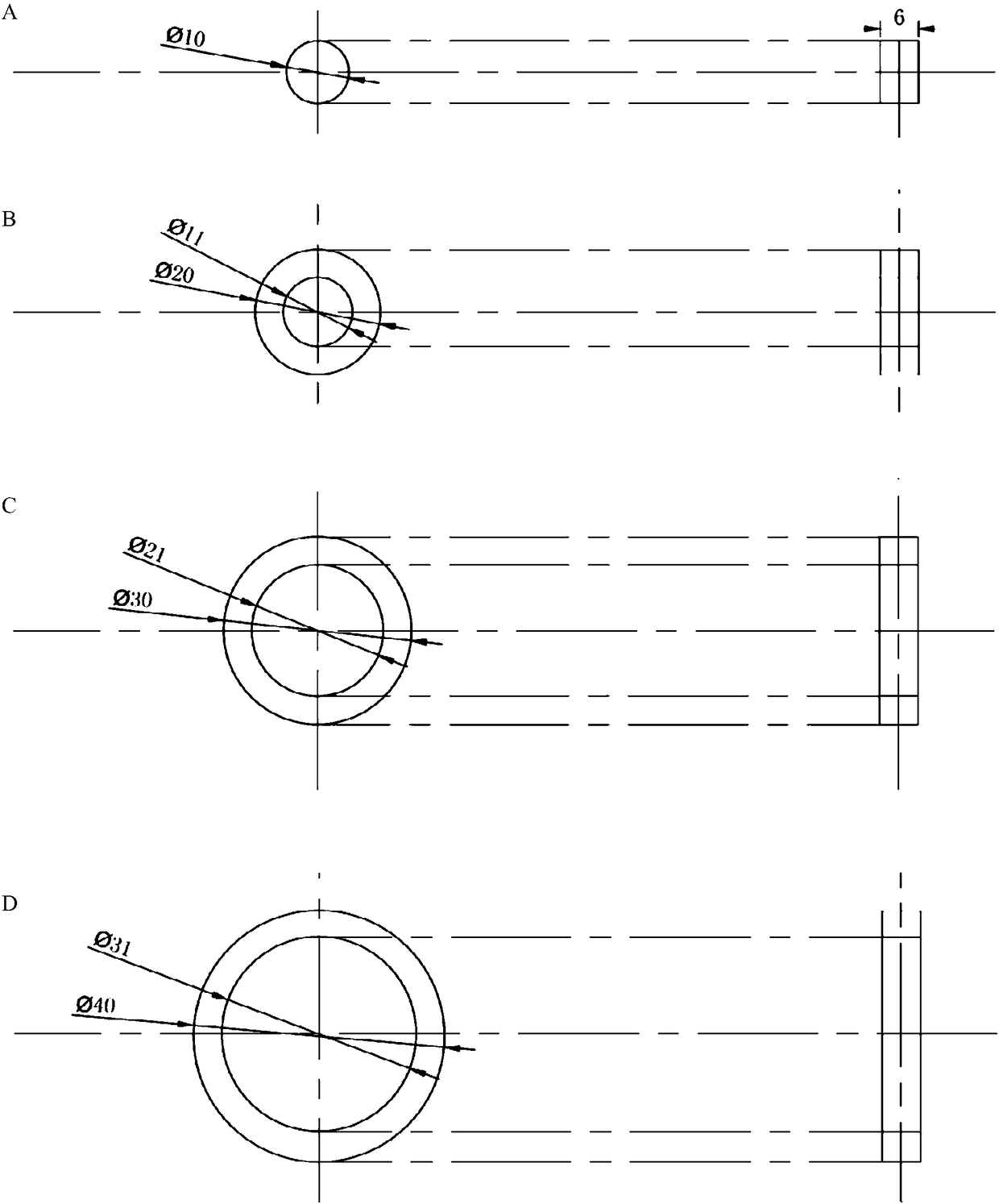

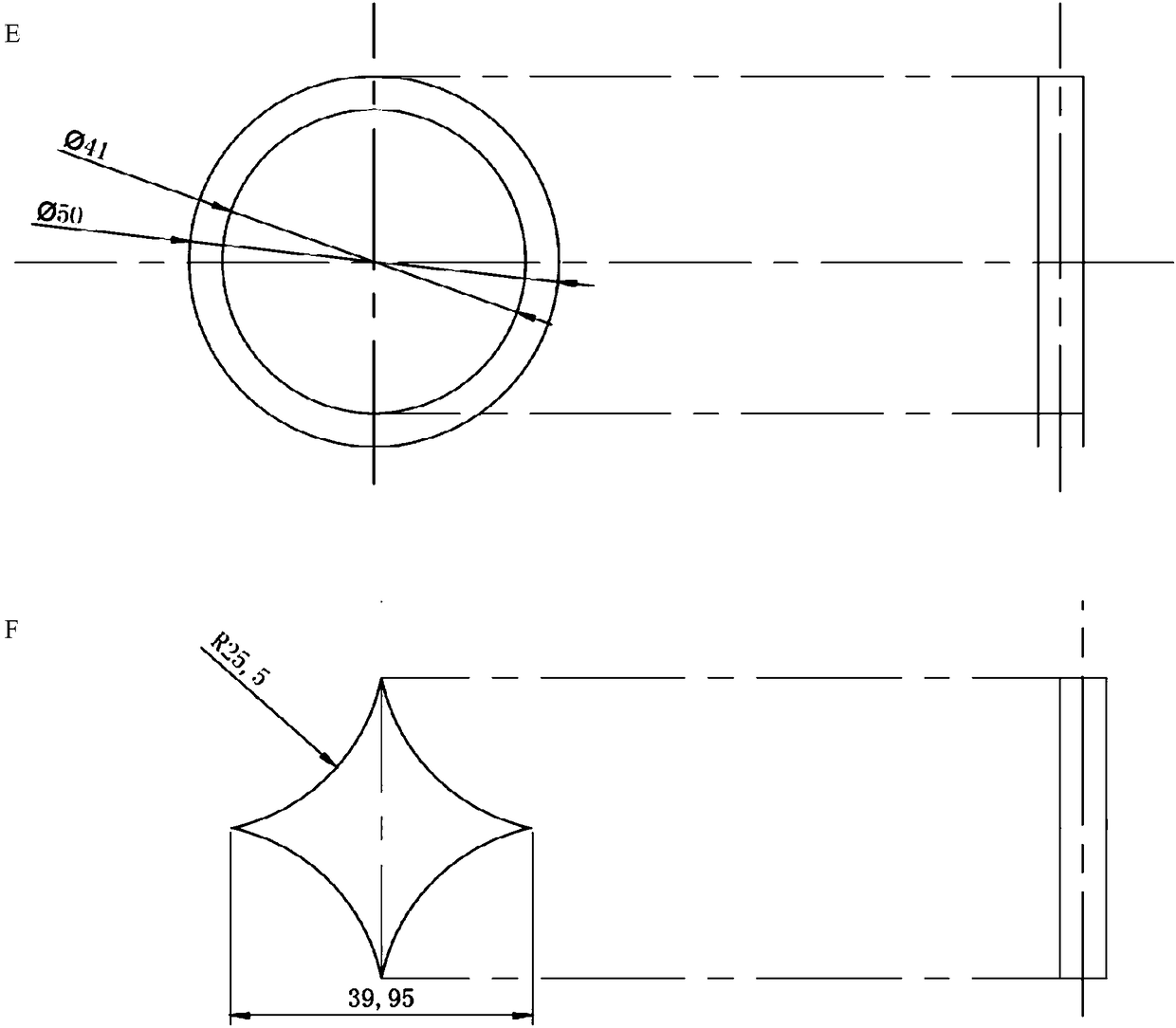

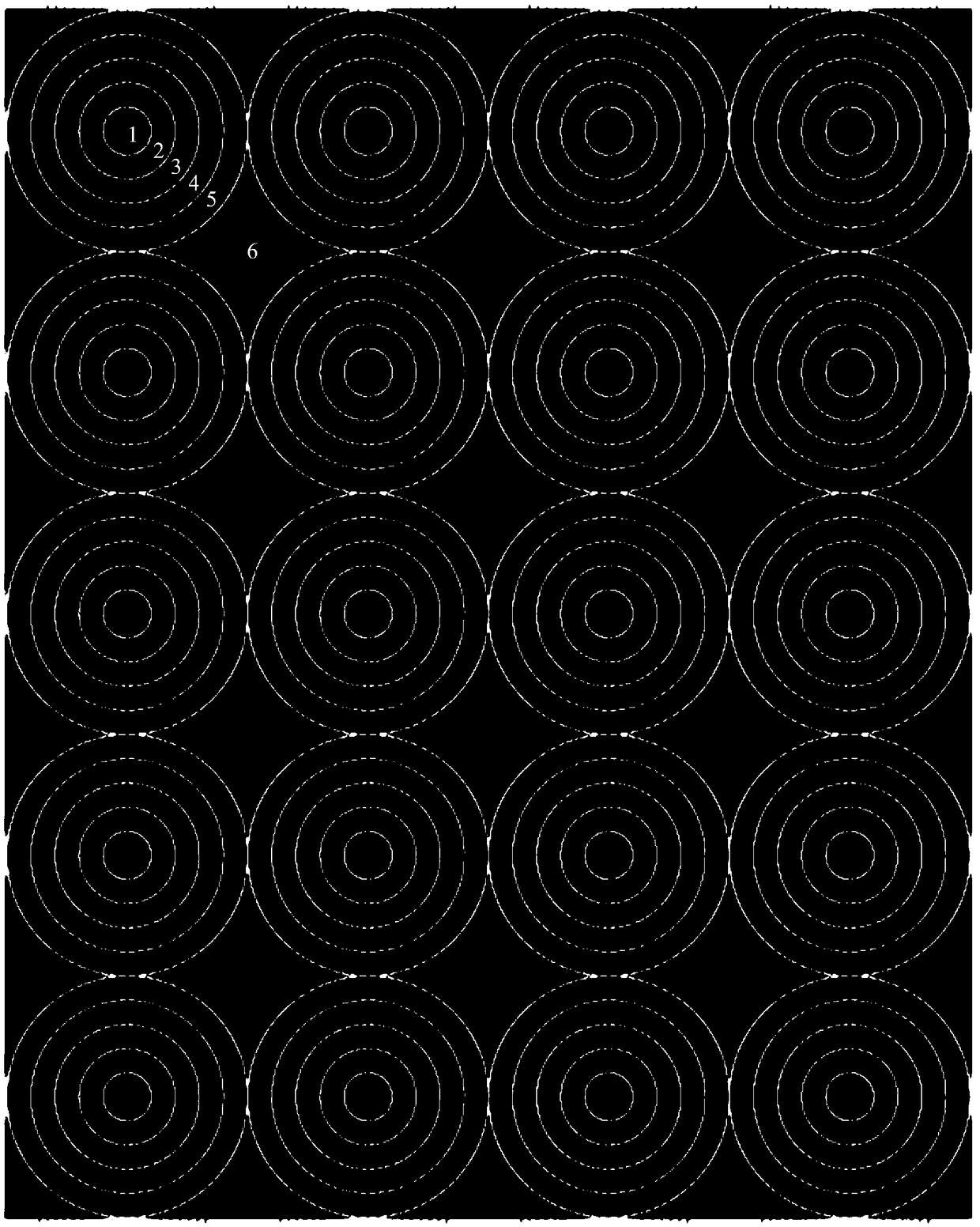

Bulletproof ceramic chip with cyclic structure and bulletproof target plate as well as preparation methods of bulletproof ceramic chip and bulletproof target plate

The invention discloses a bulletproof ceramic chip with a cyclic structure and a bulletproof target plate as well as preparation methods of the bulletproof ceramic chip and the bulletproof target plate. The bulletproof ceramic chip is circular and is formed by nesting a central ceramic circular plate and multiple groups of rings, wherein the inner diameters of the multiple groups of rings are sequentially increased. The bulletproof target plate comprises the bulletproof ceramic chip with the cyclic structure and a PE back plate; the bulletproof ceramic chips are uniformly distributed on the PEback plate. According to the bulletproof ceramic chip disclosed by the invention, a cyclic structural design is introduced, so that the bulletproof performance of the bulletproof ceramic chip can beimproved; a certain amount of TiO2 and MgO powder is introduced into an Al2O3 powder so as to achieve low-temperature sintering; a certain amount of 3Y-ZrO2 is introduced so as to achieve the toughness; due to the existence of filling powder among the rings, the ceramic chip, ceramic rings and special parts can be bonded by sintering and the production efficiency of the bulletproof plate is favorably improved; the preparation methods disclosed by the invention have the characteristics of abundant raw material powder sources, low cost, simple production process and stable product quality.

Owner:HUNAN ZHONGTAI SPECIAL EQUIP

Flame-retardant PP (polypropylene) pipe

InactiveCN107618211AImprove heat resistanceImprove anti-agingSynthetic resin layered productsLaminationMicrocrystalline waxEngineering

The invention discloses a flame-retardant PP (polypropylene) pipe which comprises a body. The body comprises an inner layer, a composite reinforcement layer and a flame-retardant layer sequentially from inside to outside. The inner layer is prepared from 2-4 parts of a calcium-zinc stabilizing agent, 4-5 parts of ACR, 2-3 parts of PE wax, 10-15 parts of nitrile rubber, 6-8 parts of chlorinated polyethylene, 2-3 parts of graphite, 2-3 parts of microcrystalline wax, 8-10 parts of nano calcium carbonate, 4-5 parts of titanium dioxide, 160-180 parts of PP resin and 3-4 parts of calcium stearate. The flame-retardant layer is prepared from 5-10 parts of vinyl acetate, 0.2-0.3 part of stearic acid and 20-25 parts of light calcium carbonate. The flame-retardant PP pipe has advantages that flame resistance is improved by the flame-retardant layer, high heat resistance, ageing resistance and impact resistance of the PP pipe are achieved due to the inner layer and the composite reinforcement layer, toughness improvement of the PP pipe is realized, and the service life of the PP pipe is prolonged.

Owner:江苏由迎管材有限公司

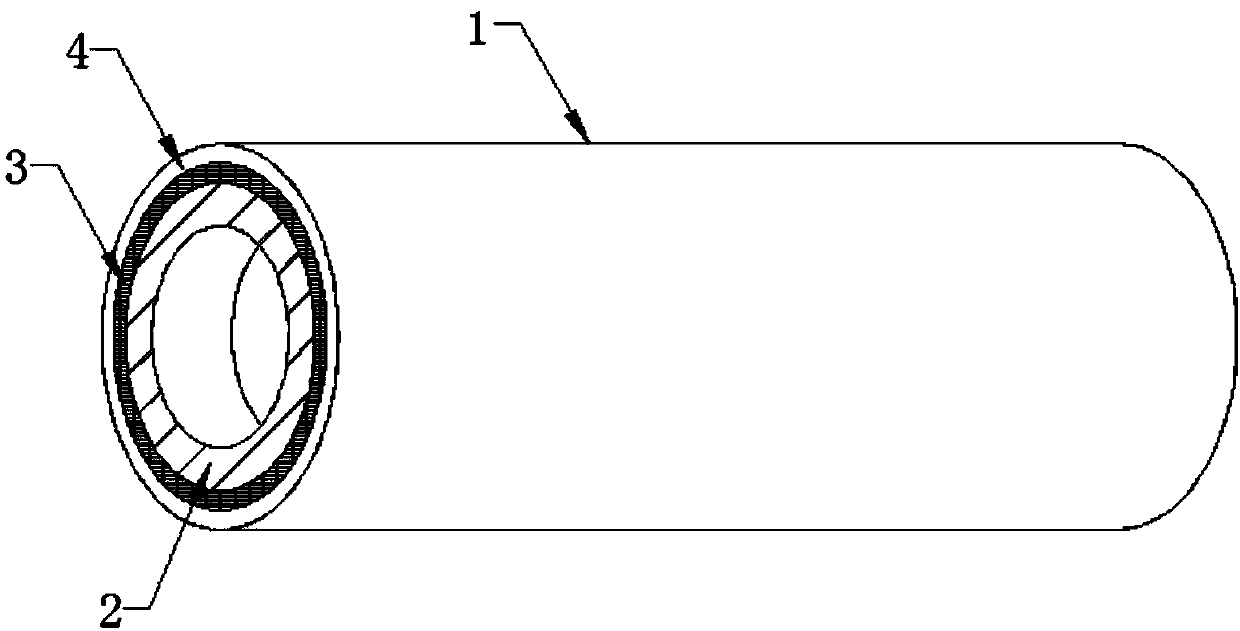

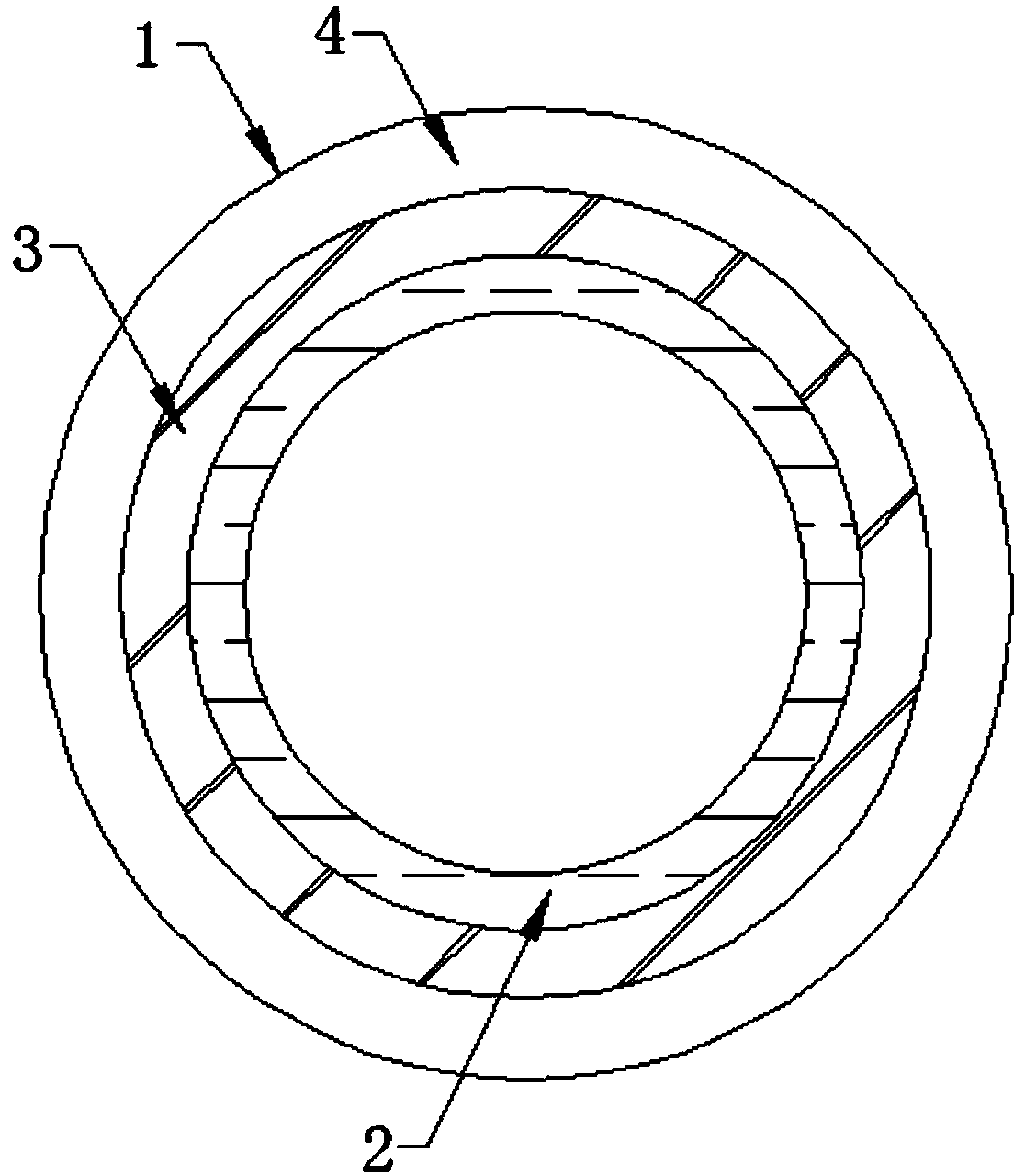

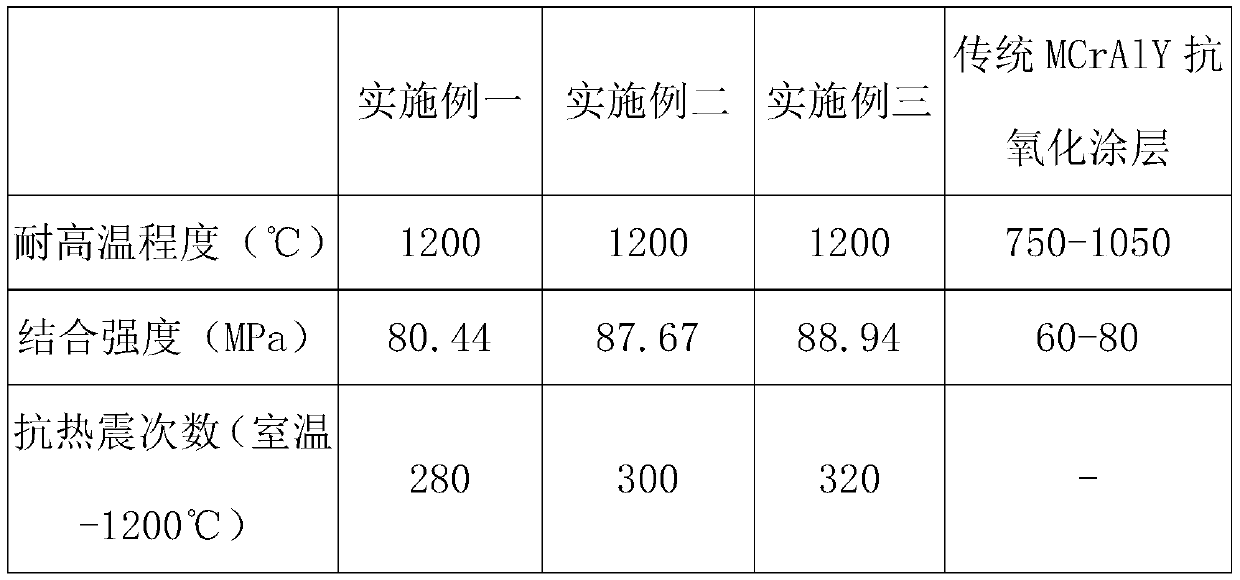

Anti-oxidation coating material resisting to high temperature of 1200 DEG C and preparation method thereof as well as coating preparation method

InactiveCN110438433AImprove high temperature corrosion resistanceHigh temperature resistanceMolten spray coatingElectrophoretic coatingsRare earthOxidation resistant

The invention relates to the technical field of materials, and particularly relates to an anti-oxidation coating material resisting to high temperature of 1200 DEG C and a preparation method thereof as well as a coating preparation method. The anti-oxidation coating is a graphene loaded rare earth oxide modified MCrAlY material. In a current identical system, the limit temperature-resistant temperature of the most advanced hexahydric NiCoCrAlYTa is merely 1050 DEG C, which can have difficulty in meeting using conditions in a working condition. According to the method, graphene is creatively selected to be laded with a rare earth oxide through an electrophoretic deposition technique, and prepared graphene loaded rare earth oxide nano-particles are in mechanical recombination with a MCrAlY material, thus forming a novel uniformly-dispersed coating material; furthermore, a graphene / ReOx-MCrAlY composite coating is prepared through a thermal coating process, so that high-temperature-resistant and corrosion-resistant performance of the coating is improved; and finally, the temperature-resistant temperature of the coating can be increased to 1200 DEG C, and gas-corrosion-resistant performance of the coating can be improved as well.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method of Cf-HfCnw micronano multiscale toughened carbon matrix composite

The invention relates to a preparation method of a Cf-HfCnw micronano multiscale toughened carbon matrix composite. The preparation method comprises the following steps: soaking a low-density C / C composite with the density of 0.7-1.0 g / cm<3> in a nickel nitrate ethanol solution, wherein generation of unnecessary change of state is avoided in the drying process; adding a 0.01-1% peroxide as an initiator to initiate the cross-linked polymerization of a precursor PHC and divinyl benzene; and successively preparing an HfC nanowire on the surface of the low-density C / C composite by adopting a precursor conversion method to realize the toughing of the carbon matrix composite on the micronano scale to obtain the Cf-HfCnw micronano multiscale toughened carbon matrix composite. The large-scale in-situ growth of the HfC nanowire on the surface of the low-density C / C composite is realized, and the effectively control to the appearance and the purity of the HfC nanowire can be realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Preparation method of organic silicon modified epoxy resin

The invention discloses a preparation method of organic silicon modified epoxy resin. The method comprises the following steps: mixing epoxy resin and a first catalyst, stirring in an oil-bath pot at70 to 120 DEG C, dropwise adding an organic silicon monomer A, after the organic silicon monomer is completely added, dropwise adding distilled water, reacting for 4 to 8 hours, and obtaining a firstmodified product B, wherein the organic silicon monomer A is one of dimethyldimethoxysiloxane, methyl vinyl dimethoxysiloxane and methyl phenyl dimethoxysiloxane; and under an oil-bath stirring condition at 50 to 90 DEG C, dropwise adding the organic silicon monomer C into the modified product B, adding a second catalyst, reacting for 30 to 90 minutes, and obtaining organic silicon modified epoxyresin. By adopting the preparation method, the organic silicon modified epoxy resin with good heat resistance and toughness is prepared. The preparation method is simple in process, environment-friendly, capable of adopting an ordinary epoxy resin curing process for the modified epoxy resin and suitable for the industrialized production.

Owner:SOUTH CHINA UNIV OF TECH +1

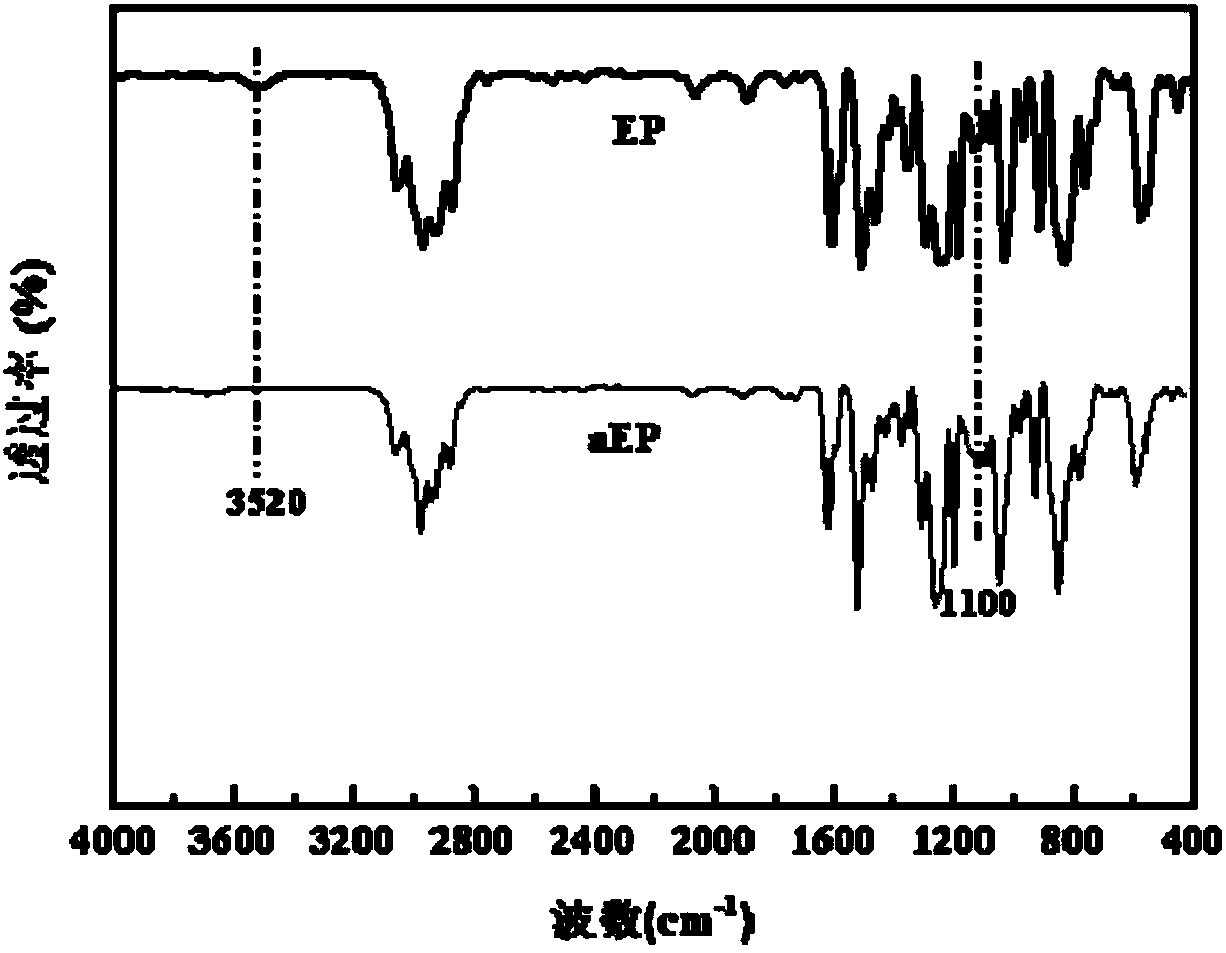

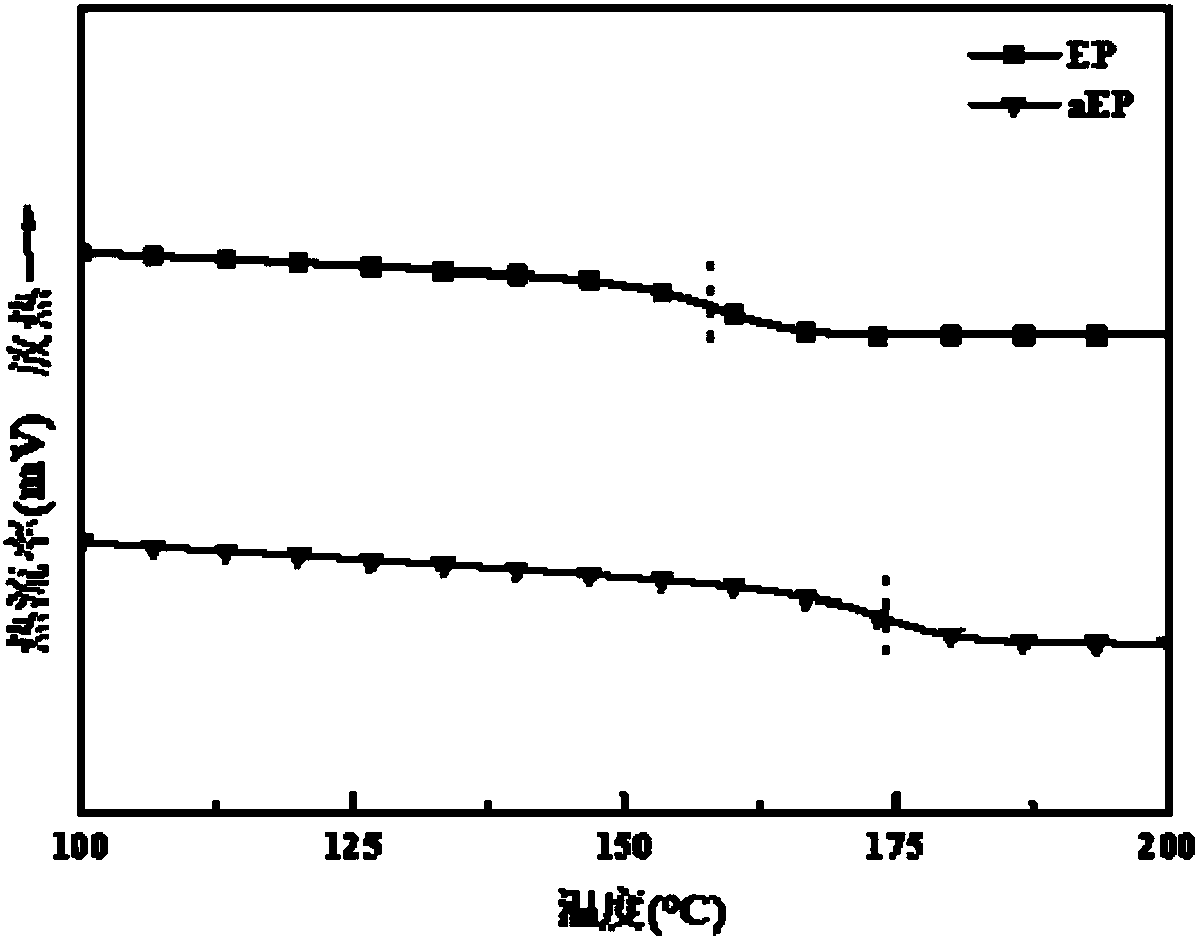

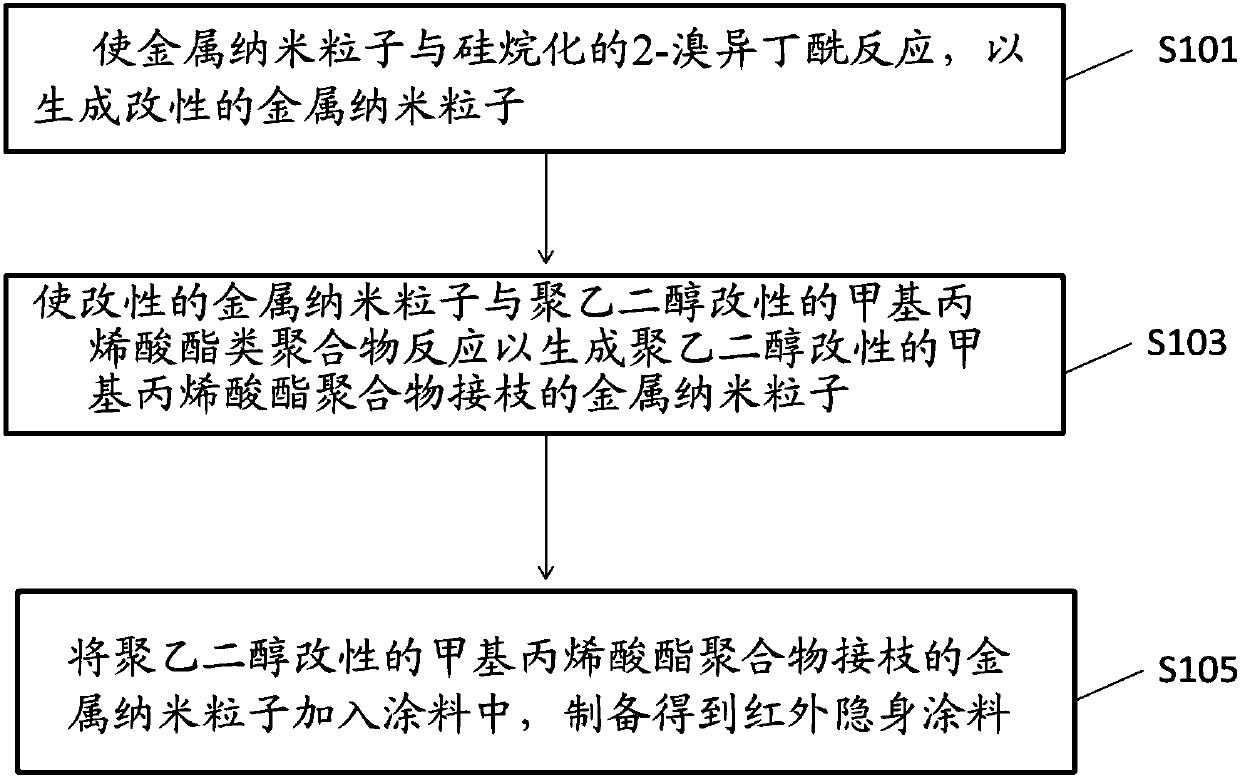

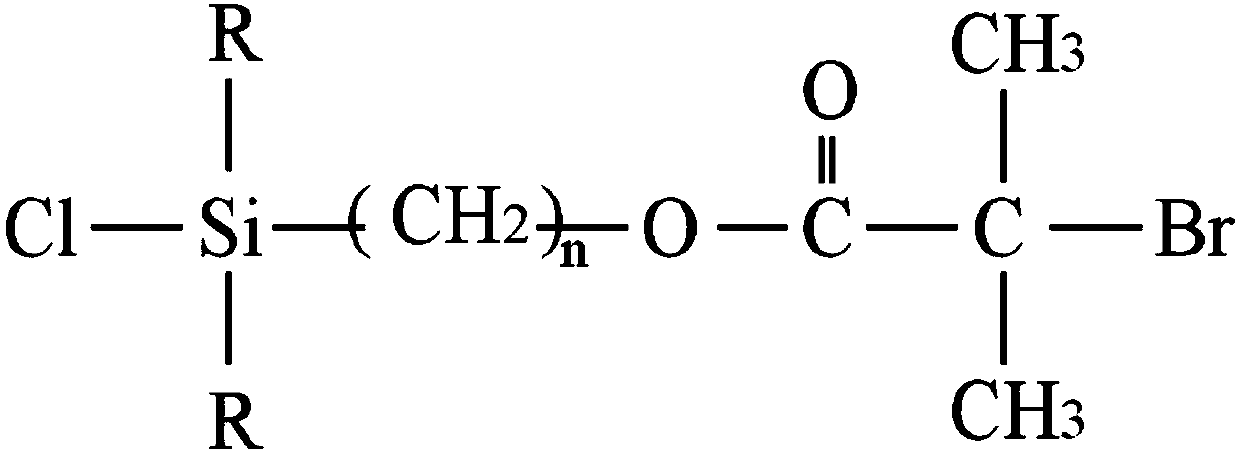

Infrared stealth coating material and preparation method thereof

PendingCN109554088AControllableAchieve tougheningPolyurea/polyurethane coatingsCamouflage paintsMaterials preparationPolyethylene glycol

The invention provides an infrared stealth coating material preparation method, which comprises: carrying out a reaction on metal nanoparticles and silanized 2-bromoisobutyryl to form modified metal nanoparticles; carrying out a reaction on the modified metal nanoparticles and a polyethylene glycol modified methacrylate polymer to form polyethylene glycol modified methacrylate polymer-grafted metal nanoparticles; and adding the polyethylene glycol modified methacrylate polymer-grafted metal nanoparticles into a coating material to prepare the infrared stealth coating material. According to thepresent invention, with the application of the polyethylene glycol modified methacrylate polymer-grafted metal nanoparticles in preparation of the infrared stealth coating material, the grafted modified metal nanoparticles have advantages of high dispersibility, less settling, long-time storage and good stability in the infrared stealth coating material.

Owner:LUOYANG INST OF CUTTING EDGE TECH +1

Toughened polylactic acid plastic and preparation method thereof

The invention discloses a toughened polylactic acid plastic and a preparation method thereof. The toughened polylactic acid plastic comprises polylactic acid resin, a polyamide thermoplastic elastomer and a processing aid. The polyamide thermoplastic elastomer phase is dispersed in the polylactic resin matrix phase in an island shape. The preparation method of the toughened polylactic acid plastic comprises the following steps: selecting the polylactic acid resin, the polyamide thermoplastic elastomer and the processing aid in proportion, uniformly stirring to obtain a mixed material, and extruding and granulating the mixed material to obtain the toughened polylactic acid plastic. The crystallization temperature of the used polyamide thermoplastic elastomer is higher than that of the polylactic acid, so that a good nucleation induction effect is achieved, and the aims of toughening the polylactic acid and improving the crystallinity of the polylactic acid are fulfilled.

Owner:INST OF CHEM CHINESE ACAD OF SCI

HfxZr1-xC ceramic solid solution nanowire and preparation method thereof

InactiveCN111943678AMicrostructure controlAchieve tougheningMaterial nanotechnologyCarbon compositesNanowire

The invention relates to an HfxZr1-xC ceramic solid solution nanowire and a preparation method. The method comprises: respectively weighing precursors with different masses, and configuring accordingto different molar ratios; and preparing the HfxZr1-xC solid solution nanowire on the surface of a carbon / carbon composite material by adopting a low-pressure chemical vapor deposition (LPCVD) technology. The atomic molar ratio in the solid solution nanowire can be regulated and controlled by regulating and controlling the content of each component in the mixed precursor powder, and the microstructure of the solid solution nanowire can be effectively controlled by regulating and controlling LPCVD process parameters. The preparation process is simple and easy to operate, the morphology of the nanowire can be effectively controlled, and the application of the nanowire in the fields of various materials is expanded.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com