Method for preparing monocrystalline silicon carbide nanofiber/silicon carbide ceramic matrix composite material by reaction sintering

A technology of silicon carbide ceramic base and single crystal silicon carbide, which is applied in the field of preparation of silicon carbide composite materials, can solve the problems that the interface between SiCnf and matrix is difficult to control, it is difficult to fully reflect the mechanical properties of SiC, and the volume content of SiCnf is small. Performance and service life, high density, high volume content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

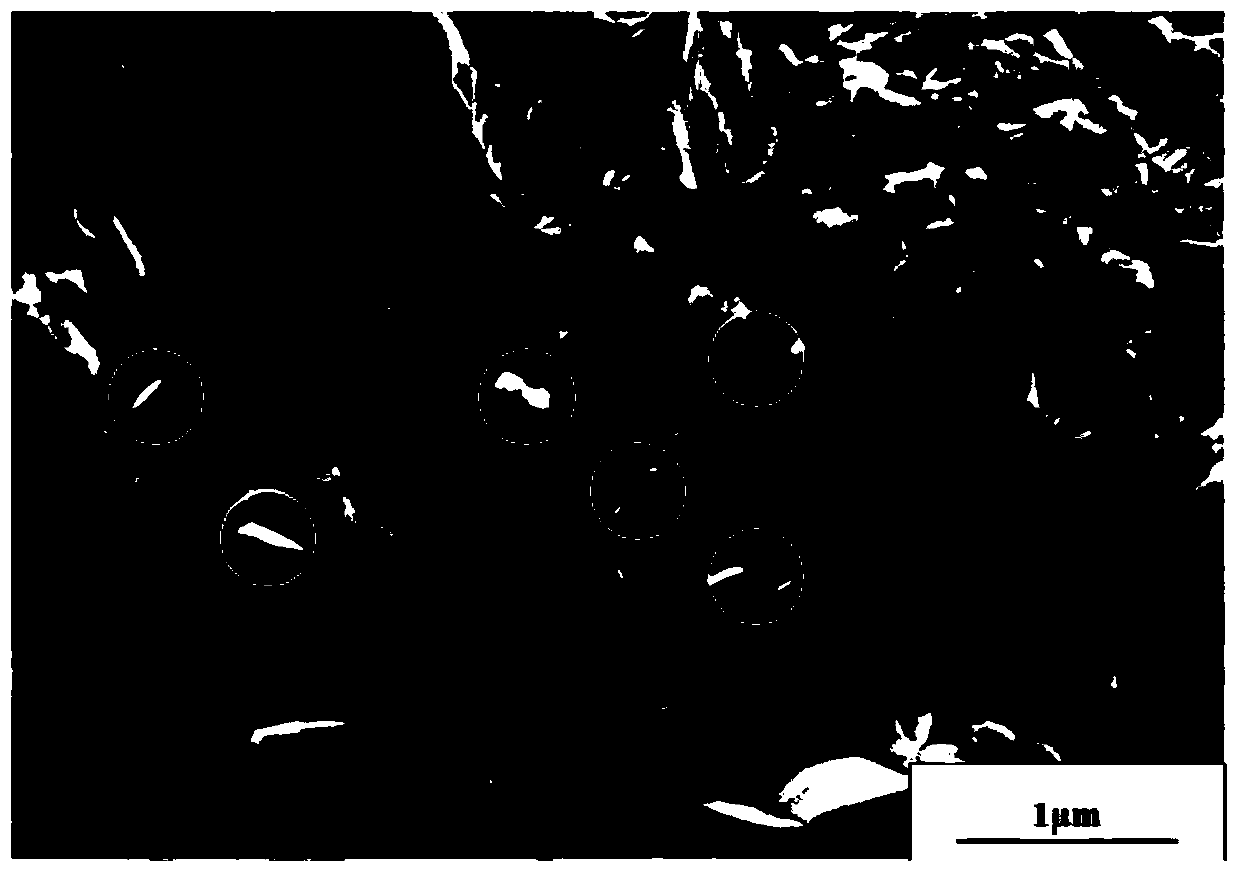

[0054] First, BN coated SiC nanofibers: Dissolve boric acid and urea in a mixture of ethanol and deionized water, wherein the mass ratio of boric acid and urea is 1:3, and the volume ratio of ethanol and deionized water is 2:1, and the heating configuration Boric acid and urea mixed saturated solution. 30g of SiC nanofibers were dipped into a beaker filled with a mixed solution of boric acid and urea, dipped and dried to obtain nanofibers with a coating layer. The coated SiC nanofibers were put into a tube furnace, and a nitriding reaction was carried out in a nitrogen atmosphere at a temperature of 1000° C., and kept for 1.5 hours to obtain BN-coated SiC nanofibers.

[0055] Then carbon coating: take 30g of BN-coated SiC nanofibers and place them in an alcohol solution filled with phenolic resin, wherein the mass ratio of phenolic resin to alcohol solution is 1:4; and dry. The carbon / BN-coated SiC nanofibers were placed in a tube furnace, sintered at a maximum temperature of...

Embodiment 2

[0061] First, BN coated SiC nanofibers, boric acid and urea were dissolved in a mixture of ethanol and deionized water, wherein the mass ratio of boric acid and urea was 2:3, and the volume ratio of ethanol and deionized water was 3:1, and the heating configuration Boric acid and urea mixed saturated solution. 30g of SiC nanofibers were dipped into a beaker filled with a mixed solution of boric acid and urea, dipped and dried to obtain nanofibers with a coating layer. The coated SiC nanofibers were put into a tube furnace, and a nitriding reaction was carried out in a nitrogen atmosphere at a temperature of 900° C., and kept for 1 hour to obtain BN-coated SiC nanofibers.

[0062] Then carbon coating: take 25g of BN-coated SiC nanofibers and place them in an alcohol solution filled with phenolic resin, wherein the mass ratio of phenolic resin to alcohol solution is 1:5; and dry. The carbon / BN-coated SiC nanofibers were placed in a tube furnace, sintered at a maximum temperatur...

Embodiment 3

[0068] First, BN coated SiC nanofibers, boric acid and urea were dissolved in a mixture of ethanol and deionized water, wherein the mass ratio of boric acid and urea was 2:3, and the volume ratio of ethanol and deionized water was 3:1, and the heating configuration Boric acid and urea mixed saturated solution. 35g of SiC nanofibers were dipped into a beaker filled with a mixed solution of boric acid and urea, dipped and dried to obtain nanofibers with a coating layer. The coated SiC nanofibers were put into a tube furnace, and a nitriding reaction was carried out in a nitrogen atmosphere at a temperature of 1200° C., and kept for 2 hours to obtain BN-coated SiC nanofibers.

[0069] Then carbon coating: take 35g of BN-coated SiC nanofibers and place them in an alcohol solution filled with phenolic resin, wherein the mass ratio of phenolic resin to alcohol solution is 1:4; and dry. The carbon / BN-coated SiC nanofibers were placed in a tube furnace, sintered at a maximum temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com