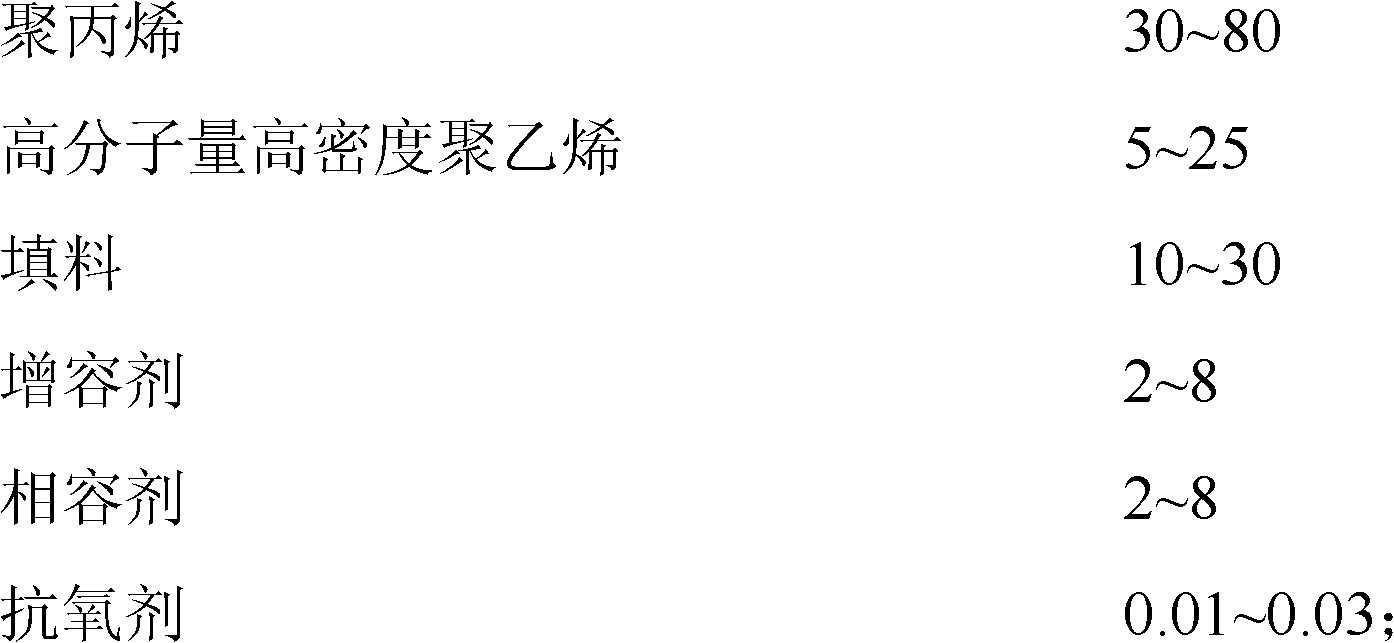

Polypropylene-high molecular weight high density polyethylene-filling material blend and preparation method thereof

A high-density polyethylene and high-molecular-weight technology, which is applied in the field of polypropylene-polyethylene-filler blends and their preparation, can solve the problems of high crystallization speed of high-molecular-weight high-density polyethylene, poor toughening effect of polypropylene, and difficulty in injection molding. Large-scale products and other problems, to achieve the effect of easy rigidity and toughness balance, improved compatibility, and good cost performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

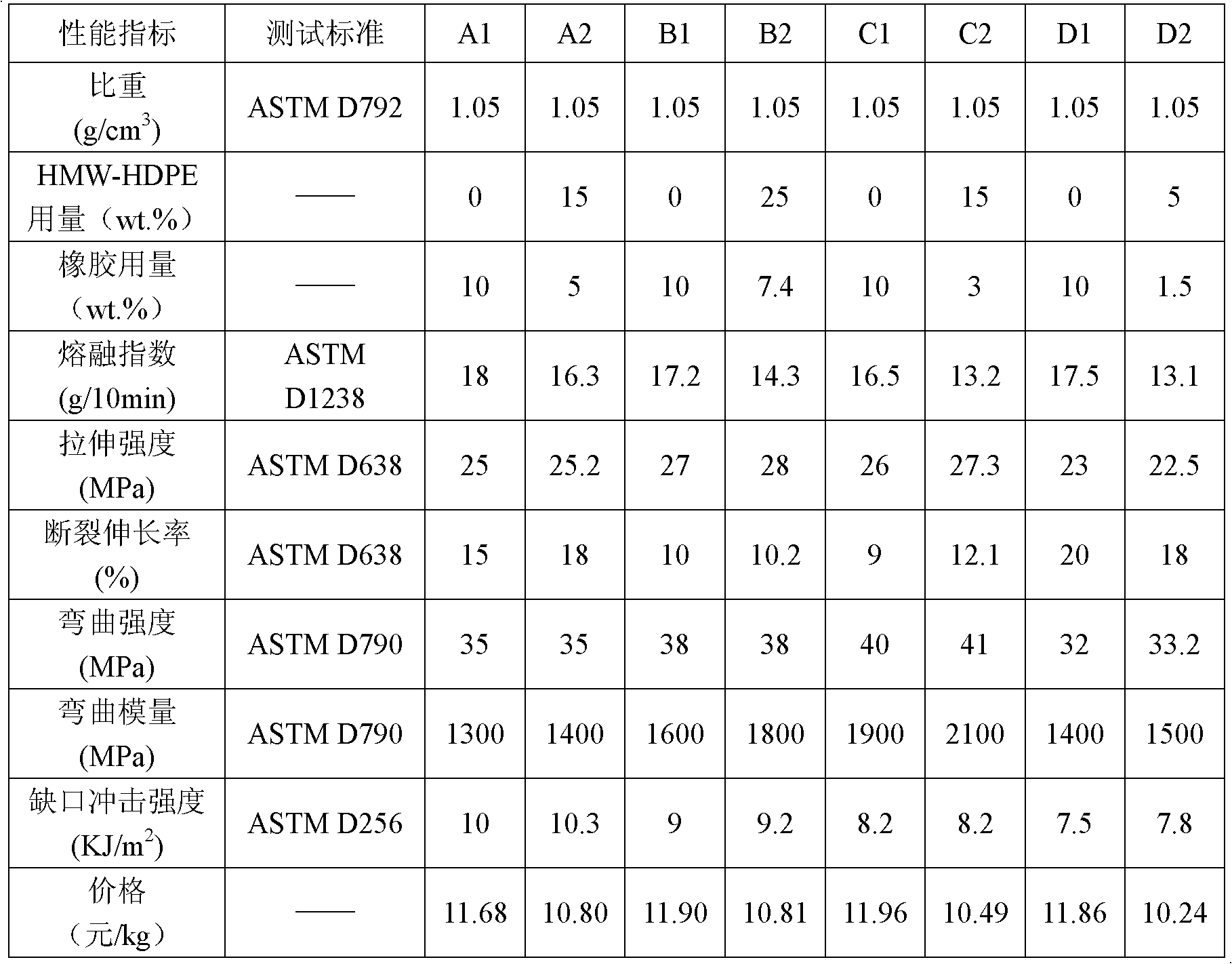

Embodiment 1

[0023] Get the homopolymeric PP 1650g that melt index is 30g / min, HWM-HDPE (density is 0.945g / cm 3 , molecular weight is 250000, melt index is 12g / min) 450g, calcium carbonate 600g, EPDM 150g, PP-g-MAH 150g, titanate coupling agent 15g, antioxidant (antioxidant 1010: antioxidant 168= 0.5:1) 0.6g; first mix titanate coupling agent and calcium carbonate at high speed, then add homopolymer PP, HWM-HDPE, EPDM, PP-g-MAH and antioxidant into the mixer in sequence , mixed uniformly at a speed of 1000 rpm, and then the mixed material was extruded and granulated in a twin-screw extruder, and the granulation temperature was 160°C. After drying, it is injected into a standard sample and tested for performance. The performance index test results of the obtained blend A2 are shown in Table 1.

Embodiment 2

[0027] Get the homopolymeric PP 900g that melt index is 40g / min, HMW-HDPE (density is 0.945g / 10cm 3 , molecular weight 300000, melt index 10g / min) 750g, talc powder 900g, EPDM 132g, POE 88g, PP-g-MAH 135g, PE-g-MAH (polyethylene grafted maleic anhydride) 67.5g, aluminum acid Ester coupling agent 22.5g, antioxidant (antioxidant 1010: antioxidant 168=1: 1) 0.9g; Aluminate coupling agent and talcum powder are mixed at high speed first, then homopolymerized PP, Add HMW-HDPE, EPDM, POE, PP-g-MAH, PE-g-MAH and antioxidants into the mixer in turn, mix evenly at a speed of 800 rpm, and then mix the mixed materials in the twin-screw Extrude and granulate in an extruder, and the granulation temperature is 180°C. After drying, it is injected into a standard sample and tested for performance. The performance index test results of the obtained blend B2 are shown in Table 1.

Embodiment 3

[0031]Get the copolymerization type PP 1650g that melt index is 30g / min, HMW-HDPE (density is 0.945g / 10cm 3 , molecular weight 400000, melt index 8g / min) 450g, mica powder 600g, propylene-based elastomer 90g, LLDPE (linear low density polyethylene) 60g, PP-g-MAH 135g, silane coupling agent 15g, antioxidant agent (antioxidant 1010:antioxidant 168=1.5:1) 0.6g; first mix the silane ester coupling agent and mica powder at high speed, and then mix the copolymerized PP, HMW-HDPE, propylene-based elastomer, LLDPE, PP-g-MAH and antioxidants are added to the mixer in turn, mixed evenly at a speed of 600 rpm, and then the mixed material is extruded into granules in a twin-screw extruder, and the granulation temperature is 200 ℃. After drying, it is injected into a standard sample and tested for performance. The performance index test results of the obtained blend C2 are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com