Carbon fiber/cenosphere/polypropylene ternary composited material and preparation method thereof

The technology of hollow microbeads and composite materials is applied in the field of ternary composite materials and their preparation, which can solve the problems of poor damage resistance, low fracture toughness, long product processing cycle, etc., and achieves wide application prospect, simple preparation method and low cost. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

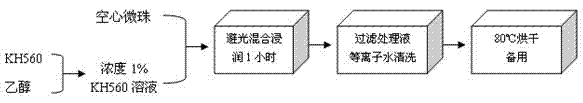

Method used

Image

Examples

specific Embodiment

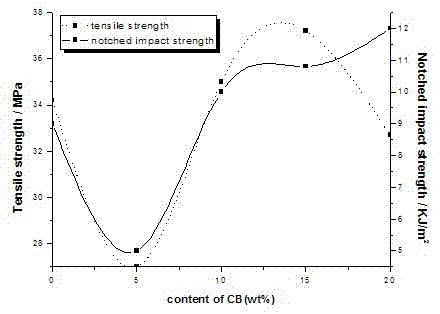

[0035] Specific examples: using 100 parts of polypropylene, 5 parts of carbon fiber, and 0, 5, 10, 15 and 20 parts of hollow microspheres to prepare injection samples CF5, GB5, GB10, GB15, and GB20 respectively.

[0036] Generally speaking, with the increase of filler addition, the fluidity of the composite system will drop sharply. However, the increase in the addition of hollow microspheres makes the fluidity of the composite system improved, mainly due to its spherical structure and larger The hardness. Use RM-200A torque rheometer to measure the maximum torque and balance torque of the CF / GB / PP composite when 0-20 parts of hollow microspheres are added. The temperature is 210℃, the speed is 30r / min, and the feeding amount is 40g. , The test results are shown in the table below.

[0037]

[0038]

[0039] It can be seen from the above table that after adding hollow microspheres, the rheological properties of the system are not as described in most documents. When the amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com