Fully biodegradable component-toughened PLA composite material and preparation method thereof

A composite material and all-biological technology, which is applied in the field of all-biodegradable component toughened PLA composite materials and its preparation, can solve the problems of insufficient toughening effect and poor toughening effect of direct blending, so as to improve toughness, The effect of preventing penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

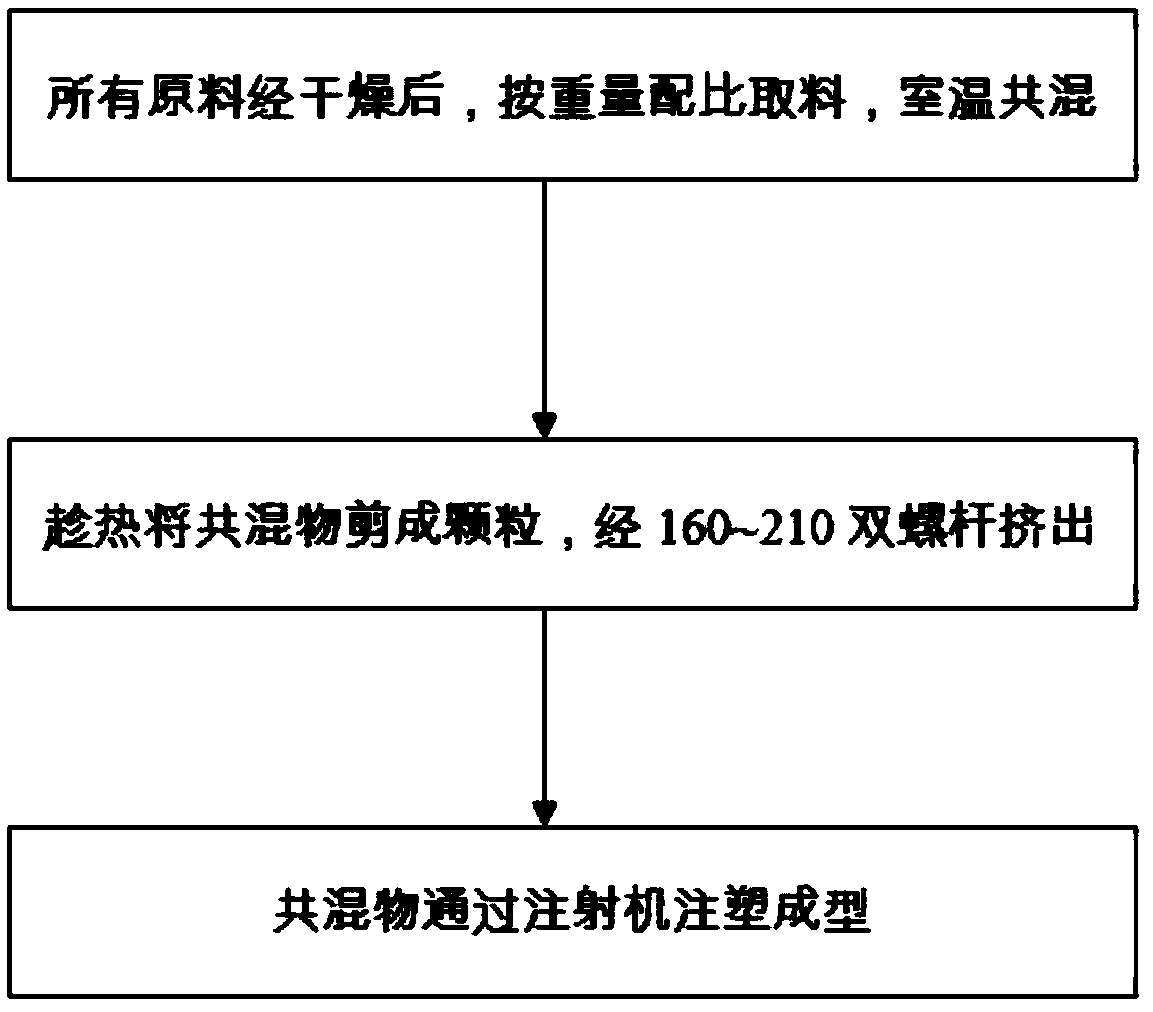

Method used

Image

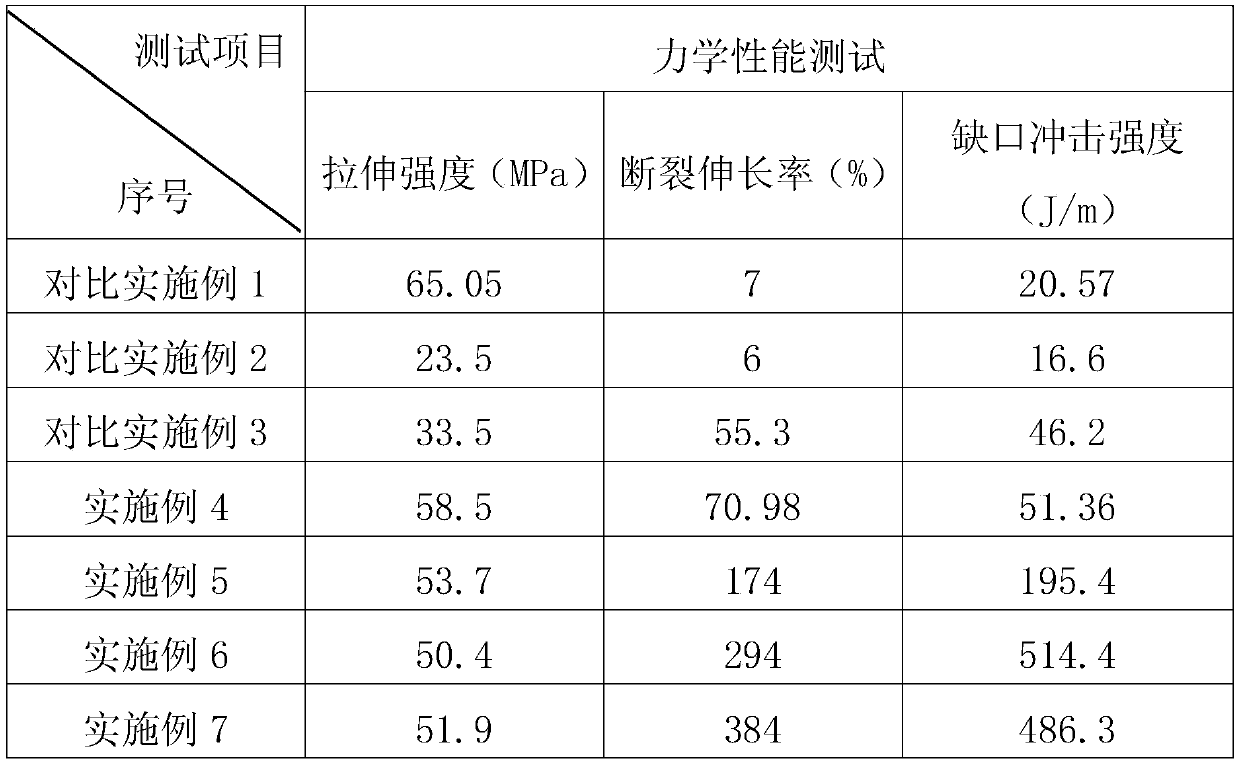

Examples

Embodiment 1

[0026] Embodiment 1: A kind of all-biodegradable component toughened PLA composite material, by weight, by polylactic acid 88 parts, alginate natural polymer 4.5 parts, vegetable oil or its derivative 7 parts and basic catalyst 0.5 parts portion composition.

Embodiment 2

[0027] Embodiment 2: A kind of all-biodegradable component toughened PLA composite material, by weight, by polylactic acid 66 parts, alginic acid natural polymer 15 parts, vegetable oil or its derivative 18 parts and basic catalyst 1 portion composition.

Embodiment 3

[0028] Embodiment 3: A kind of all-biodegradable component toughened PLA composite material, by weight, by polylactic acid 92.8 parts, alginic acid natural polymer 5 parts, vegetable oil or its derivative 2 parts and basic catalyst 0.2 portion composition.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com