Chitosan/polysulphobetaine ionic and covalent double-network hydrogel and production method thereof

A sulfobetaine, polysulfonic acid group technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve problems such as poor stability and loose chitosan network, and achieve balanced water absorption performance, The effect of balanced water retention performance and stable network structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A kind of preparation method of chitosan / polysulfobetaine ion supply double network hydrogel, described preparation method comprises the following preparation steps:

[0048] 1) Dissolve 2.8g sulfobetaine, 15mg initiator and 3mg cross-linking agent in 5mL water, stir for 10min, add 0.5g chitosan and ultrasonically shake for 30min to dissolve, prepare chitosan, sulfobetaine, initiator Mixed solution of agent and crosslinking agent;

[0049] 2) The mixed solution is placed in a mold, and the mold is composed of two pieces of glass sheets indirectly provided with a silicon rubber sheet with a thickness of 2mm. The mixed solution is placed in the mold and then sealed. The reaction was irradiated with ultraviolet light for 6 hours, and a pregel was obtained after the reaction;

[0050] 3) The pregel was immersed in a saturated trisodium citrate solution for 30 minutes to obtain the chitosan / polysulfobetaine ion-donating double network hydrogel.

[0051] Among them, sulfobe...

Embodiment 2

[0054] The difference between this example and Example 1 is that the chitosan added in step 1) is respectively 0.1 g, 0.2 g, 0.3 g, 0.4 g and 0.6 g; the remaining parts are exactly the same as in Example 1.

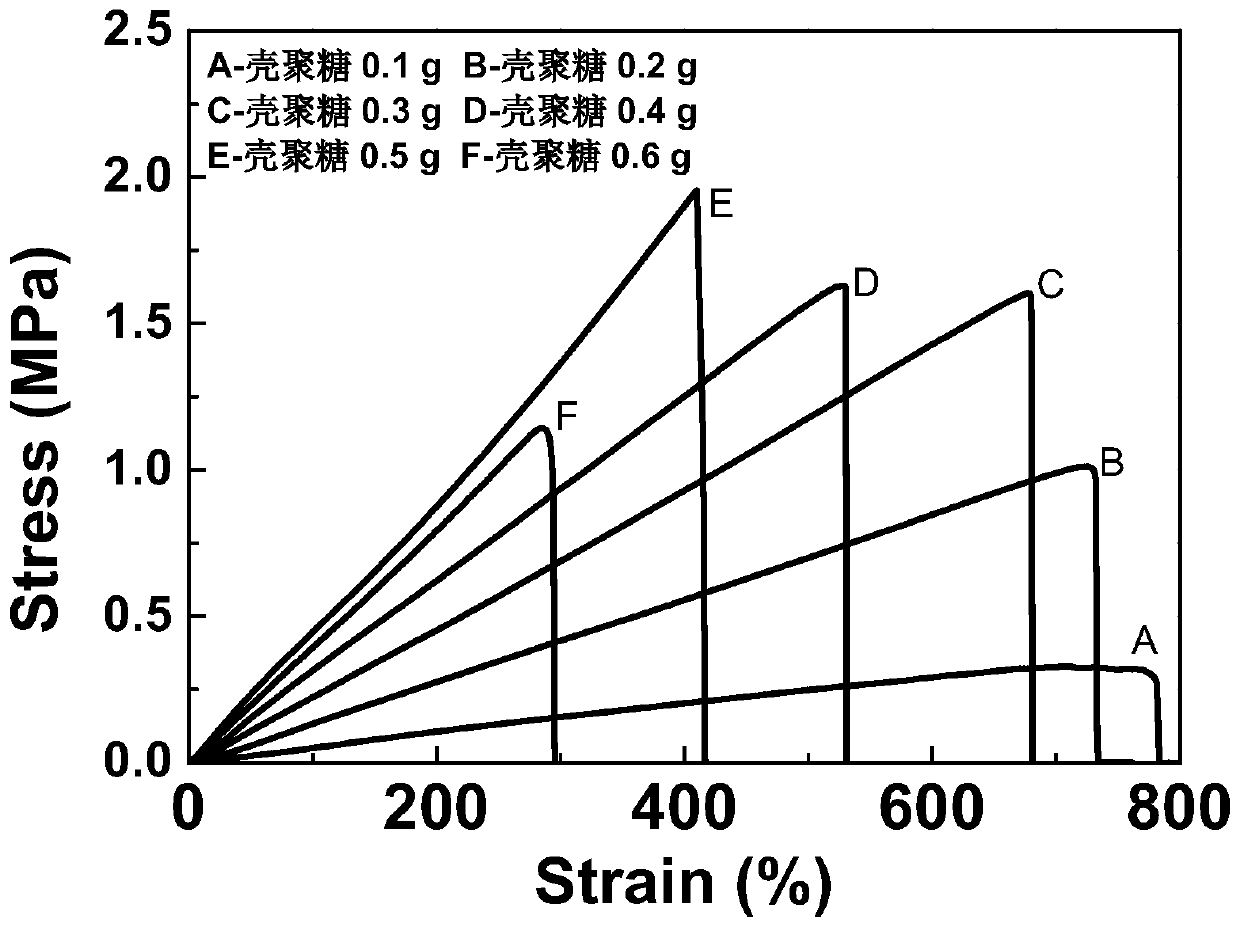

[0055] The tensile stress-strain curve of the chitosan / polysulfonic acid betaine ion-supplied double-network hydrogel prepared by the present embodiment is as follows: figure 1 As shown in the A curve, B curve, C curve, D curve and F curve, the tensile strength is 0.34MPa, 1.01MPa, 1.61MPa, 1.63MPa and 1.14MPa, and the elongation at break is 782%, 727%, 681%, 531%, and 292%.

Embodiment 3

[0057] A kind of preparation method of chitosan / polysulfobetaine ion supply double network hydrogel, described preparation method comprises the following preparation steps:

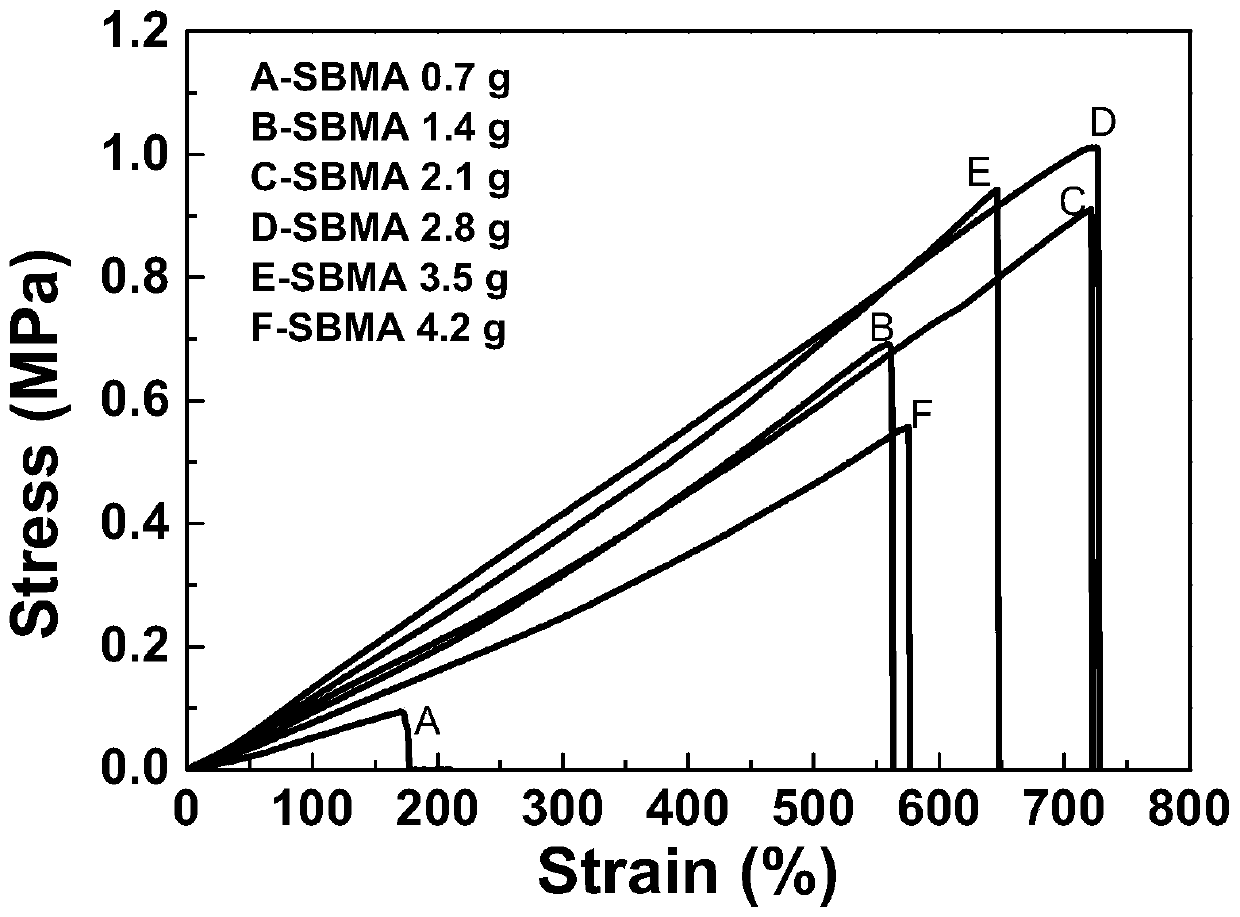

[0058] 1) Dissolve 0.7g sulfobetaine, 3.8mg initiator and 0.8mg cross-linking agent in 5mL water, stir for 10min, add 0.2g chitosan and ultrasonically shake for 30min to dissolve, and prepare chitosan and sulfobetaine , a mixed solution of an initiator and a crosslinking agent;

[0059] 2) The mixed solution is placed in a mold, and the mold is composed of two pieces of glass sheets indirectly provided with a silicon rubber sheet with a thickness of 2mm. The mixed solution is placed in the mold and then sealed. The reaction was irradiated with ultraviolet light for 6 hours, and a pregel was obtained after the reaction;

[0060] 3) The pregel was immersed in a saturated trisodium citrate solution for 30 minutes to obtain the chitosan / polysulfobetaine ion-donating double network hydrogel.

[0061] Among the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com