Nano inorganic oxide/silicic acid/cellulose multilayered structure composite enhanced biodegradable material and preparation method thereof

A technology of biodegradable materials and nano-oxides, which is applied in the field of composite reinforced biodegradable materials and its preparation, can solve the problems of polylactic acid’s poor impact resistance and thermal stability, and achieve excellent mechanical properties, performance improvement, and interface compatibility The effect of improving the situation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

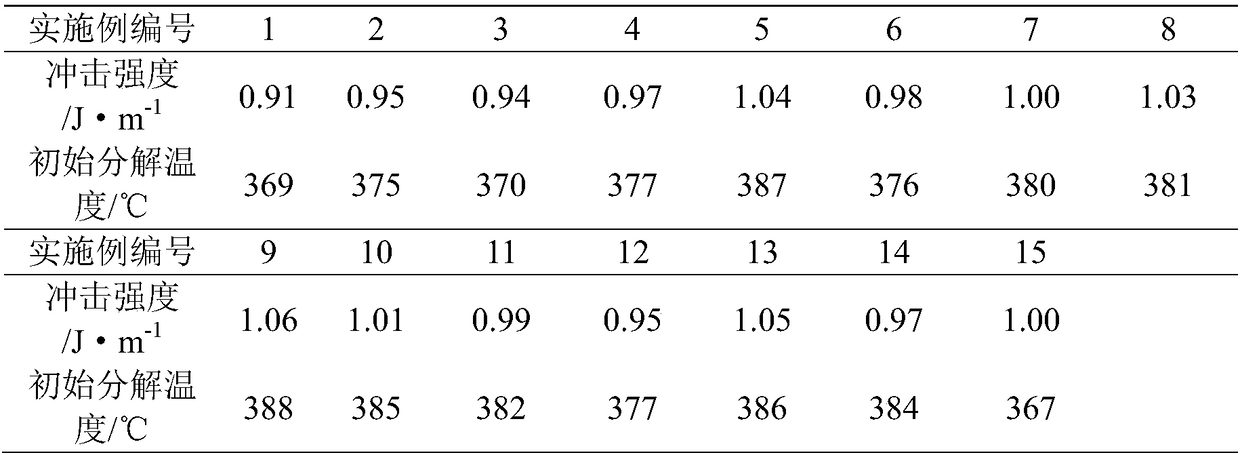

Examples

specific Embodiment approach 1

[0031] Specific Embodiment 1: In this embodiment, the nano-inorganic oxide / silicic acid / cellulose multilayer composite reinforced biodegradable material is obtained by modifying polylactic acid together with toughening materials and coated particles. The toughening material is polybutylene succinate, polyhydroxybutyrate, polycarbonate, polypropylene carbonate or polycaprolactone. The coated particles are particles coated with cellulose as the core, the middle layer is silicic acid, and the outer layer is nanometer oxide.

specific Embodiment approach 2

[0032] Specific embodiment two: the preparation method of the nano-inorganic oxide / silicic acid / cellulose multilayer structure composite reinforced biodegradable material in this embodiment includes the following steps:

[0033] 1. Preparation of cellulose / silicic acid / nano-oxide coated particles:

[0034] Disperse cellulose in sodium silicate aqueous solution to obtain cellulose dispersion, disperse nano-oxides in organic acid to obtain oxide organic acid dispersion, drop cellulose dispersion in alcohol and divide into supernatant A and lower layer Liquid B, collect the lower layer liquid B, and drop the lower layer liquid B into the oxide organic acid dispersion liquid at room temperature while stirring. After the particles are solidified, the core is cellulose, the middle layer is silicic acid, and the outer layer is nano oxide Coated particles coated with material; wherein the mass ratio of cellulose and sodium silicate aqueous solution is (1-10): (3-50), and the mass rati...

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the cellulose in step 1 is nanocellulose or microcrystalline cellulose. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com