Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

49 results about "Titanium nitrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Titanium nitrate is the inorganic compound with formula Ti(NO₃)₄. It is a colorless, diamagnetic solid that sublimes readily. It is an unusual example of a volatile binary transition metal nitrate. Ill defined species called titanium nitrate are produced upon dissolution of titanium or its oxides in nitric acid.

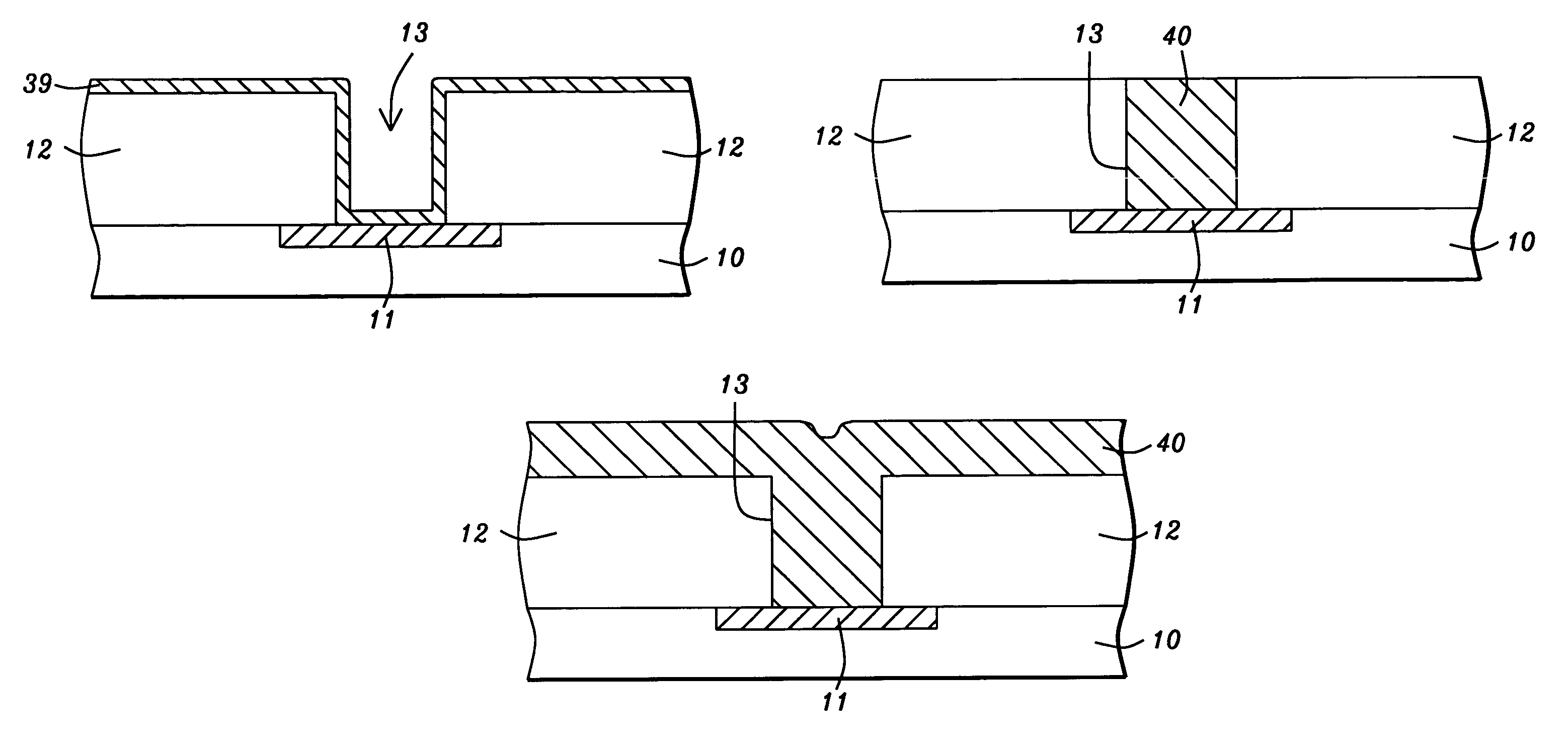

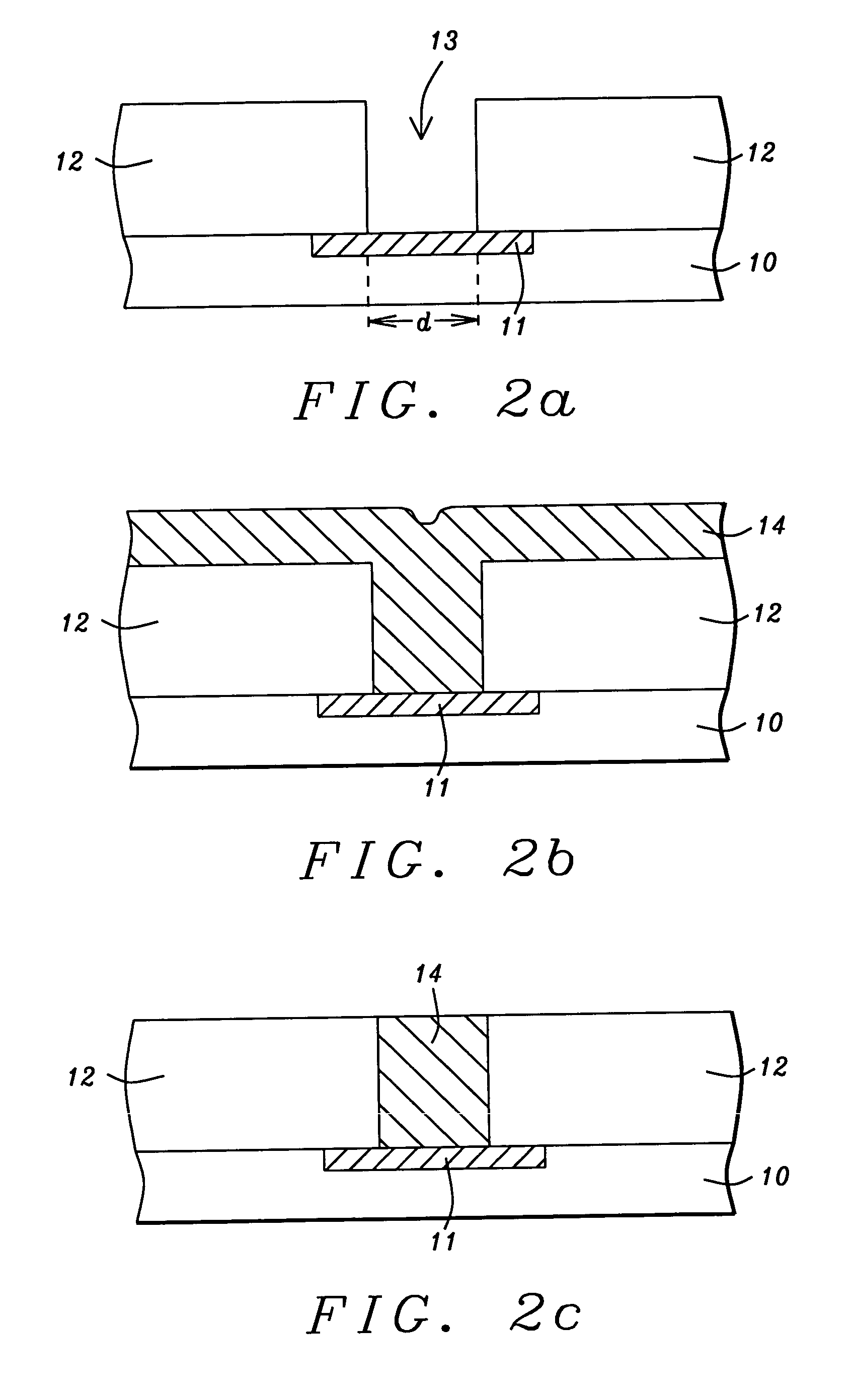

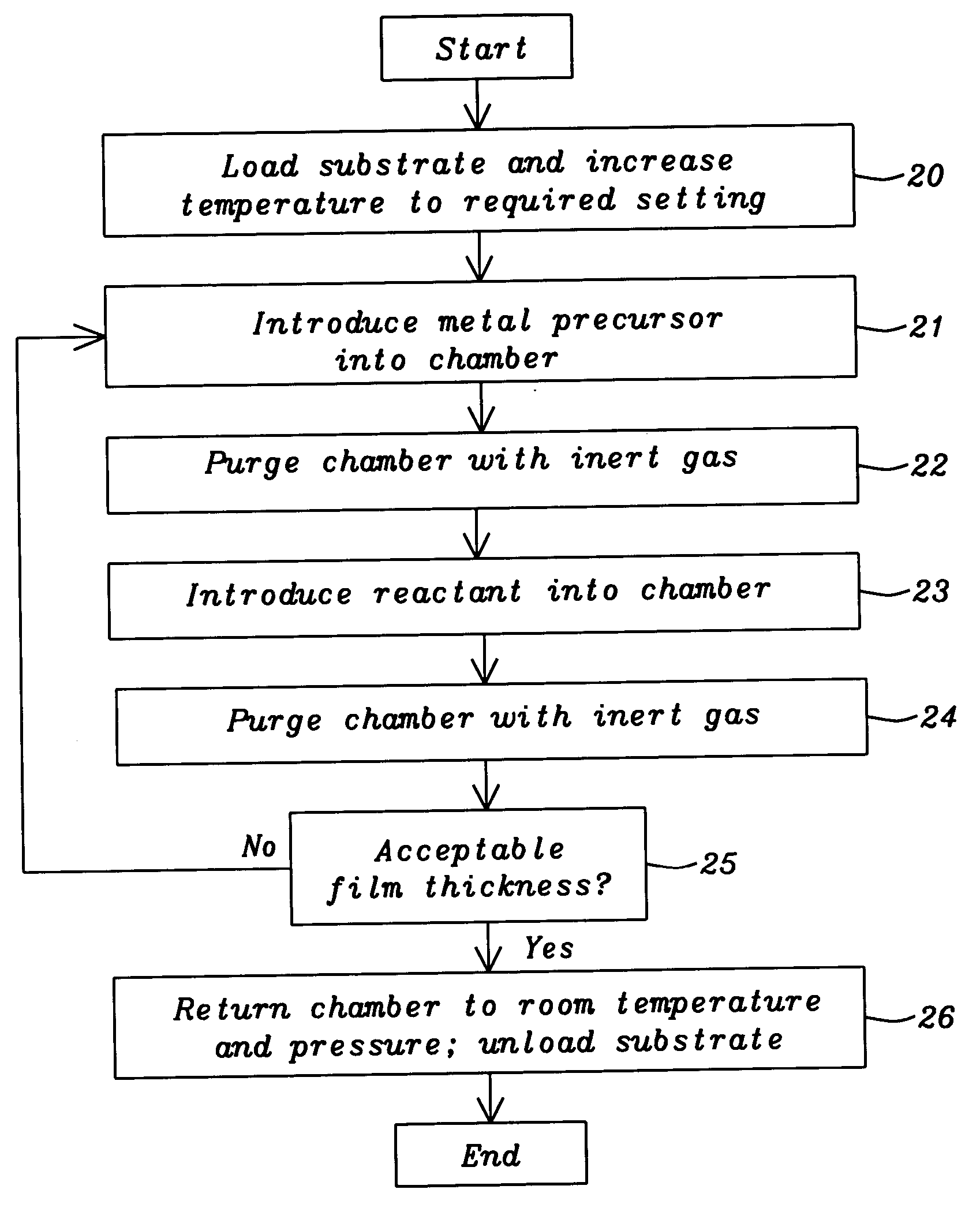

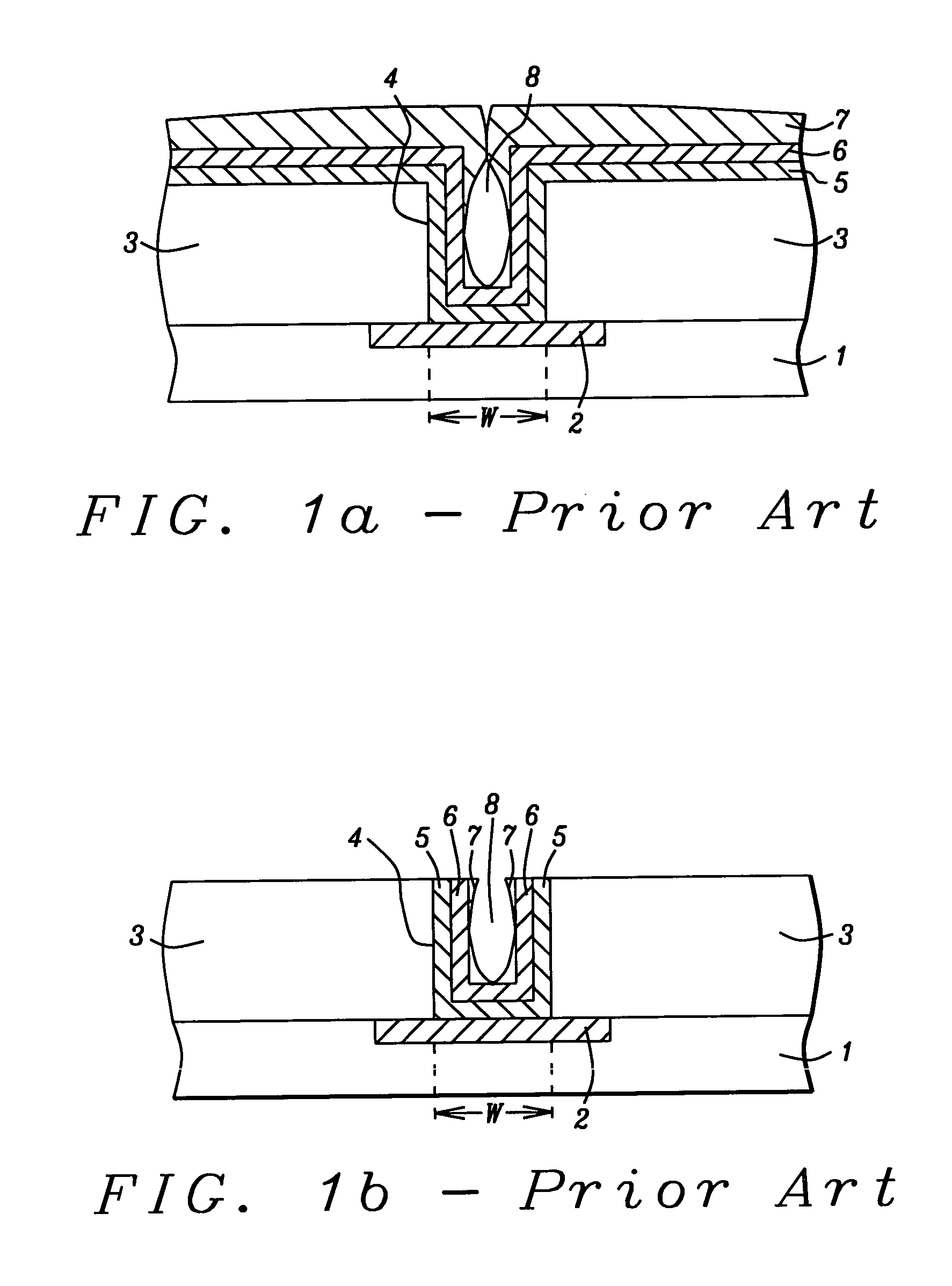

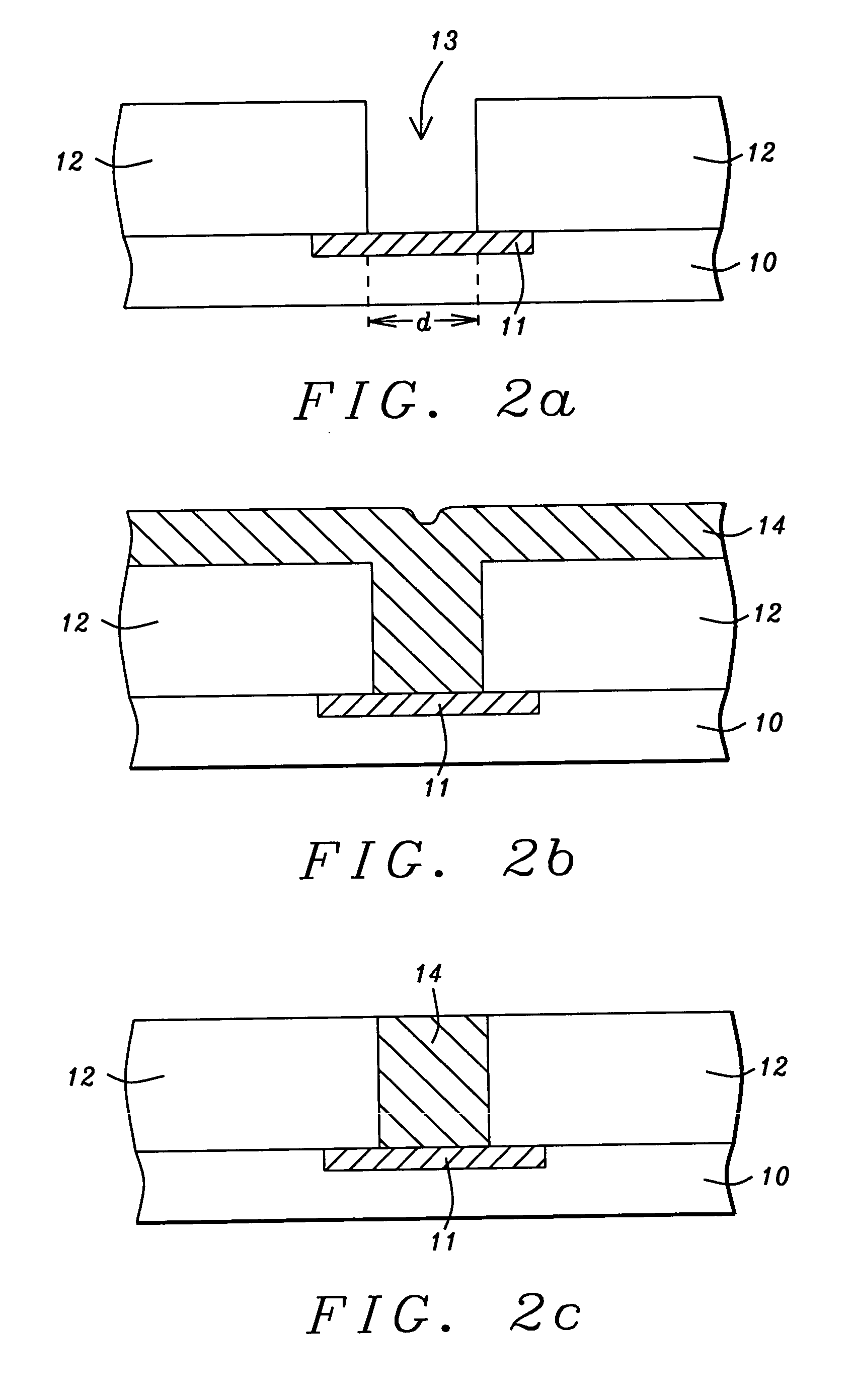

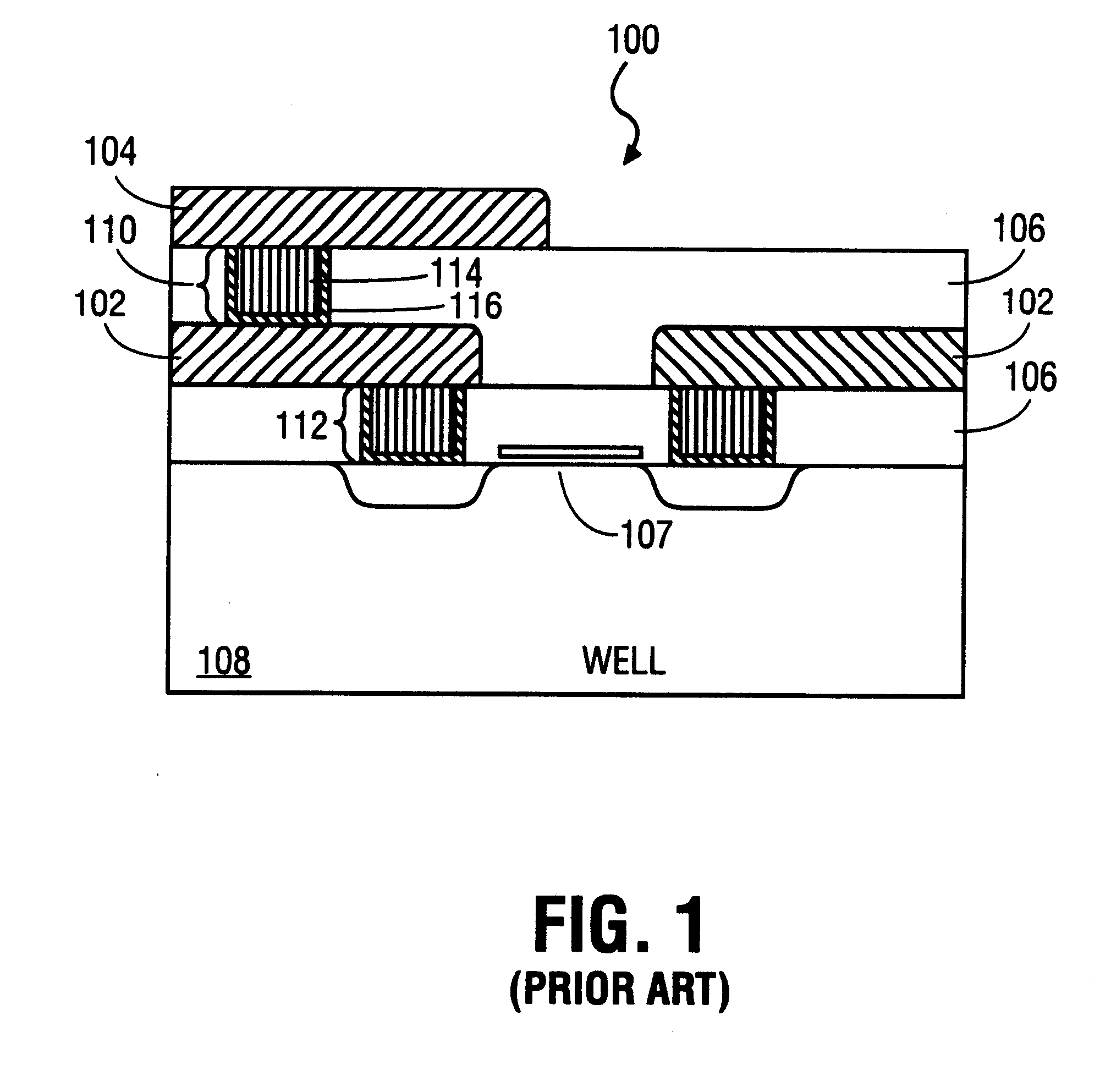

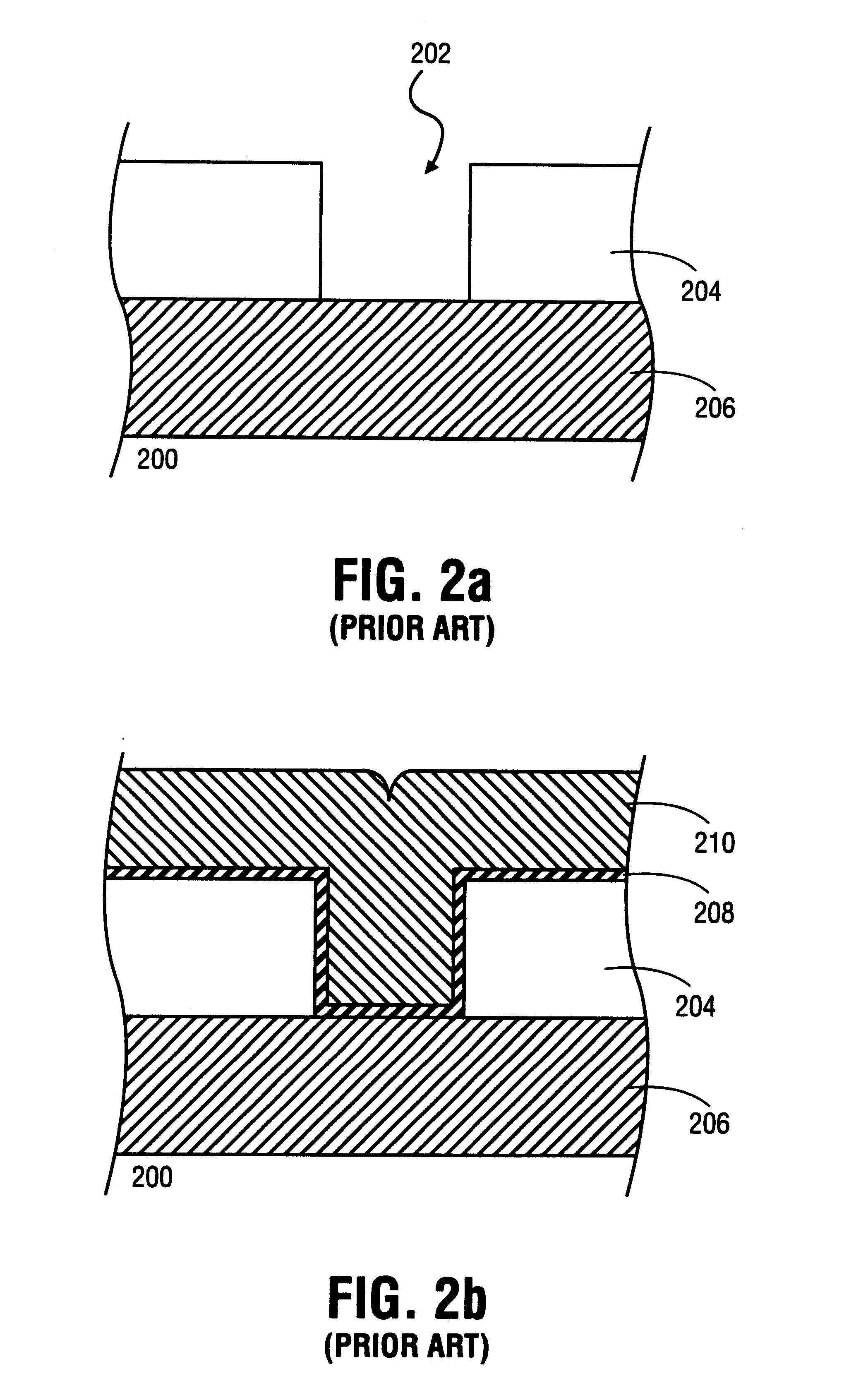

Method of manufacturing a contact interconnection layer containing a metal and nitrogen by atomic layer deposition for deep sub-micron semiconductor technology

ActiveUS7235482B2Good step coverageSafe handlingSemiconductor/solid-state device detailsSolid-state devicesAtomic layer depositionContamination

An atomic layer deposition method is used to deposit a TiN or TiSiN film having a thickness of about 50 nm or less on a substrat. A titanium precursor which is tetrakis(dimethylamido)titanium (TDMAT), tetrakis(diethylamido)titanium (TDEAT), or Ti{OCH(CH3)2}4 avoids halide contamination from a titanium halide precursor and is safer to handle than a titanium nitrate. After a monolayer of the titanium precursor is deposited on a substrate, a nitrogen containing reactant is introduced to form a TiN monolayer which is followed by a second purge. For TiSiN, a silicon source gas is fed into the process chamber after the TiN monolayer formation. The process is repeated several times to produce a composite layer comprised of a plurality of monolayers that fills a contact hole. The ALD method is cost effective and affords an interconnect with lower impurity levels and better step coverage than conventional PECVD or CVD processes.

Owner:TAIWAN SEMICON MFG CO LTD

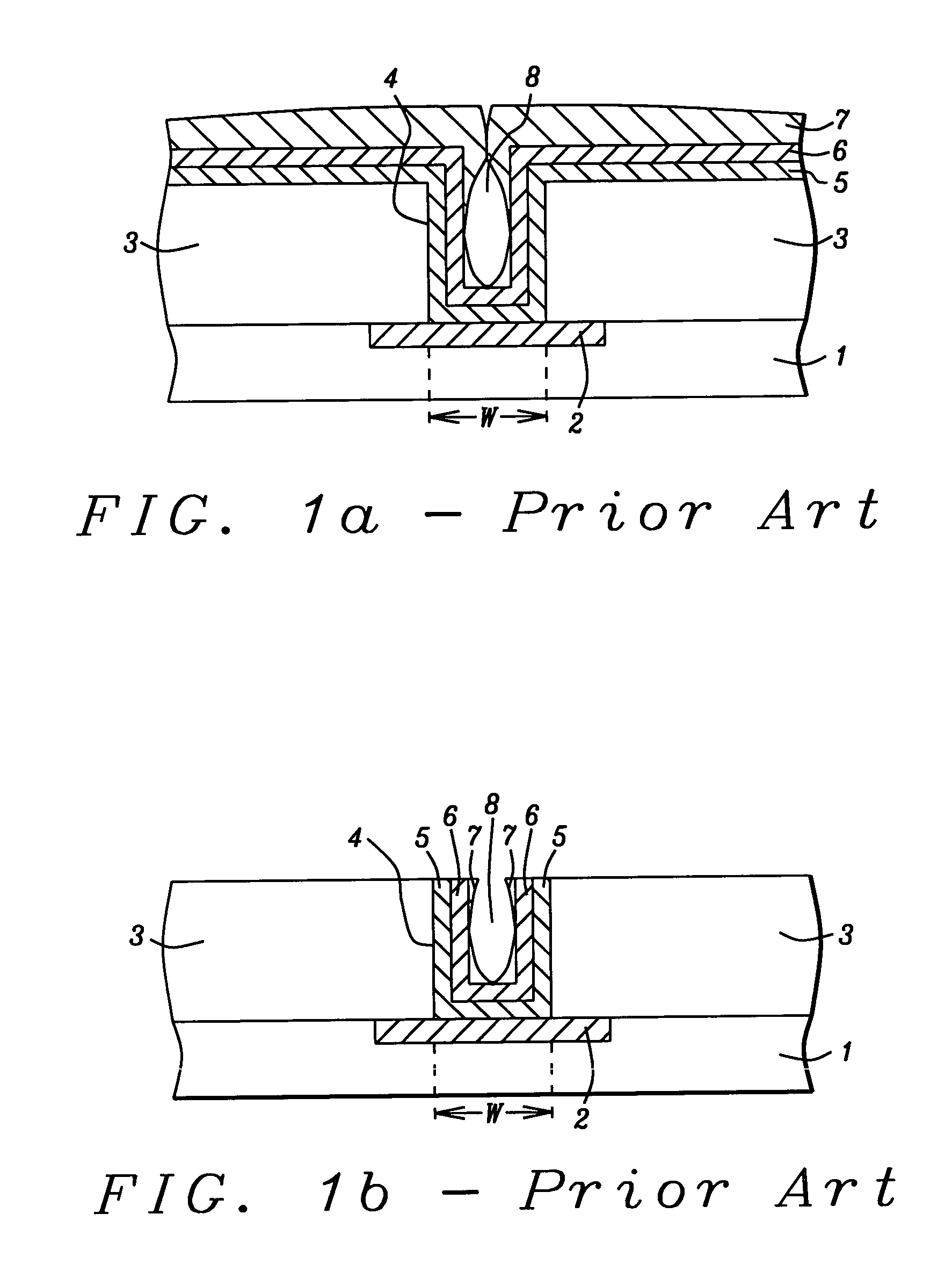

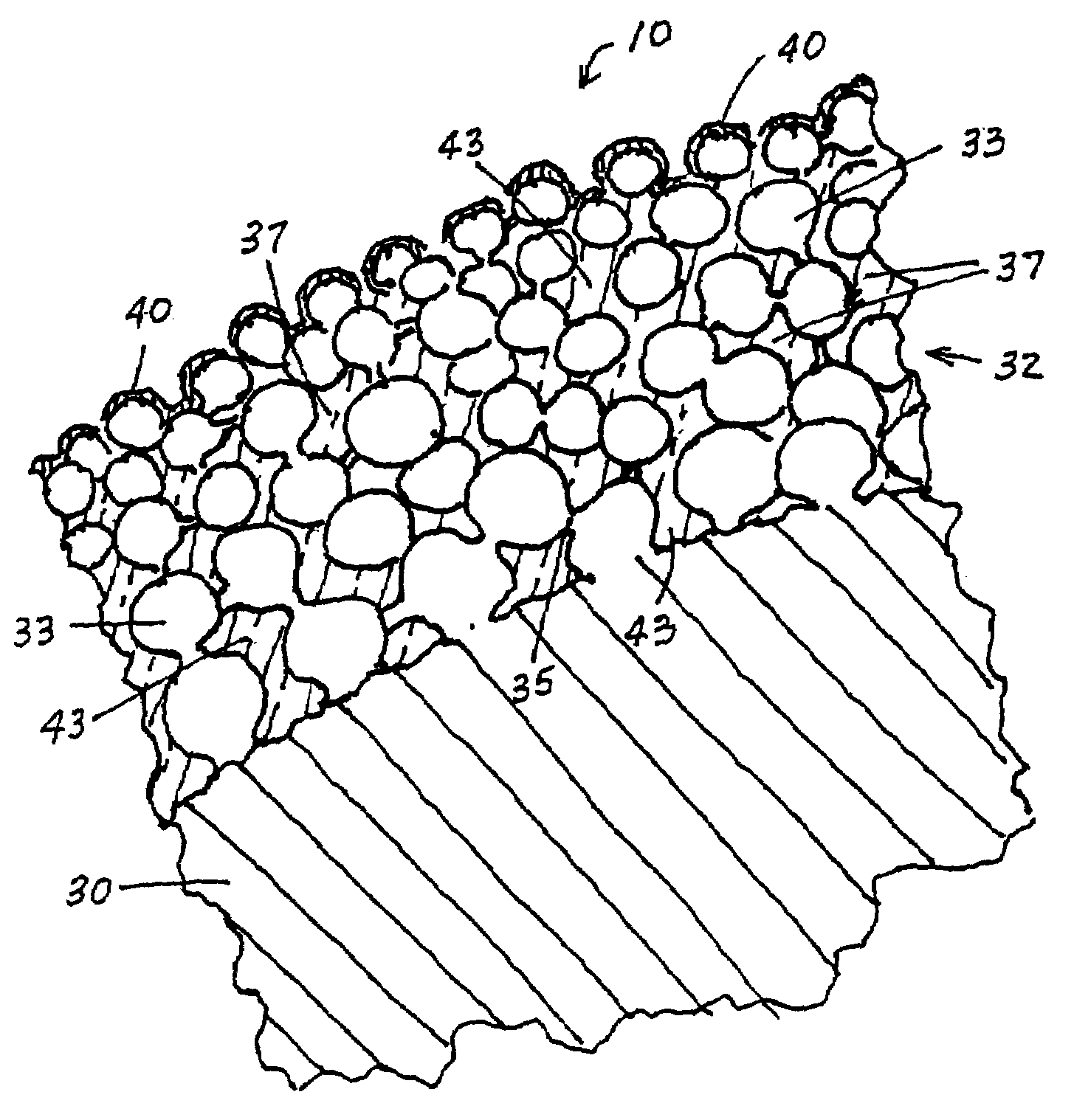

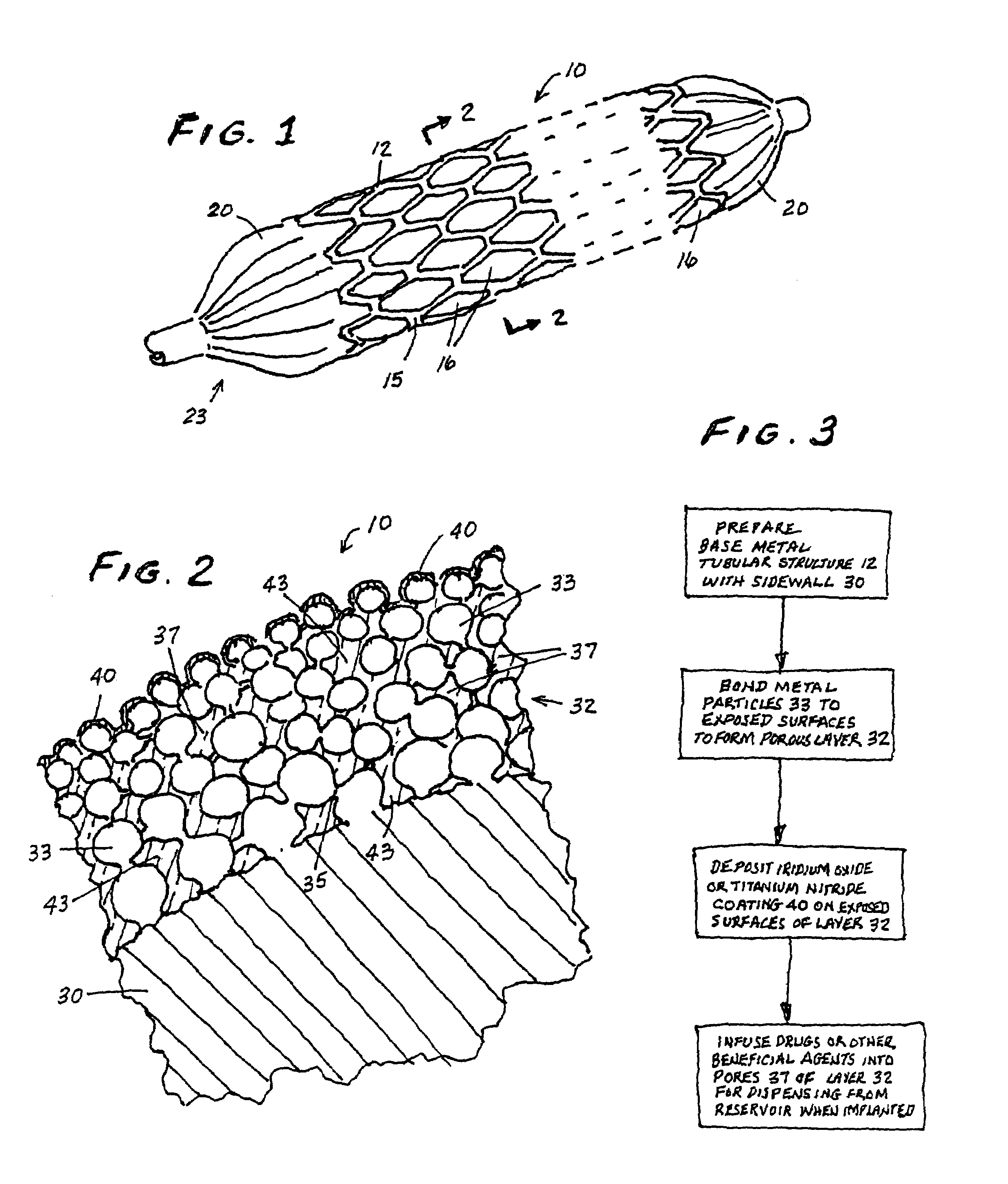

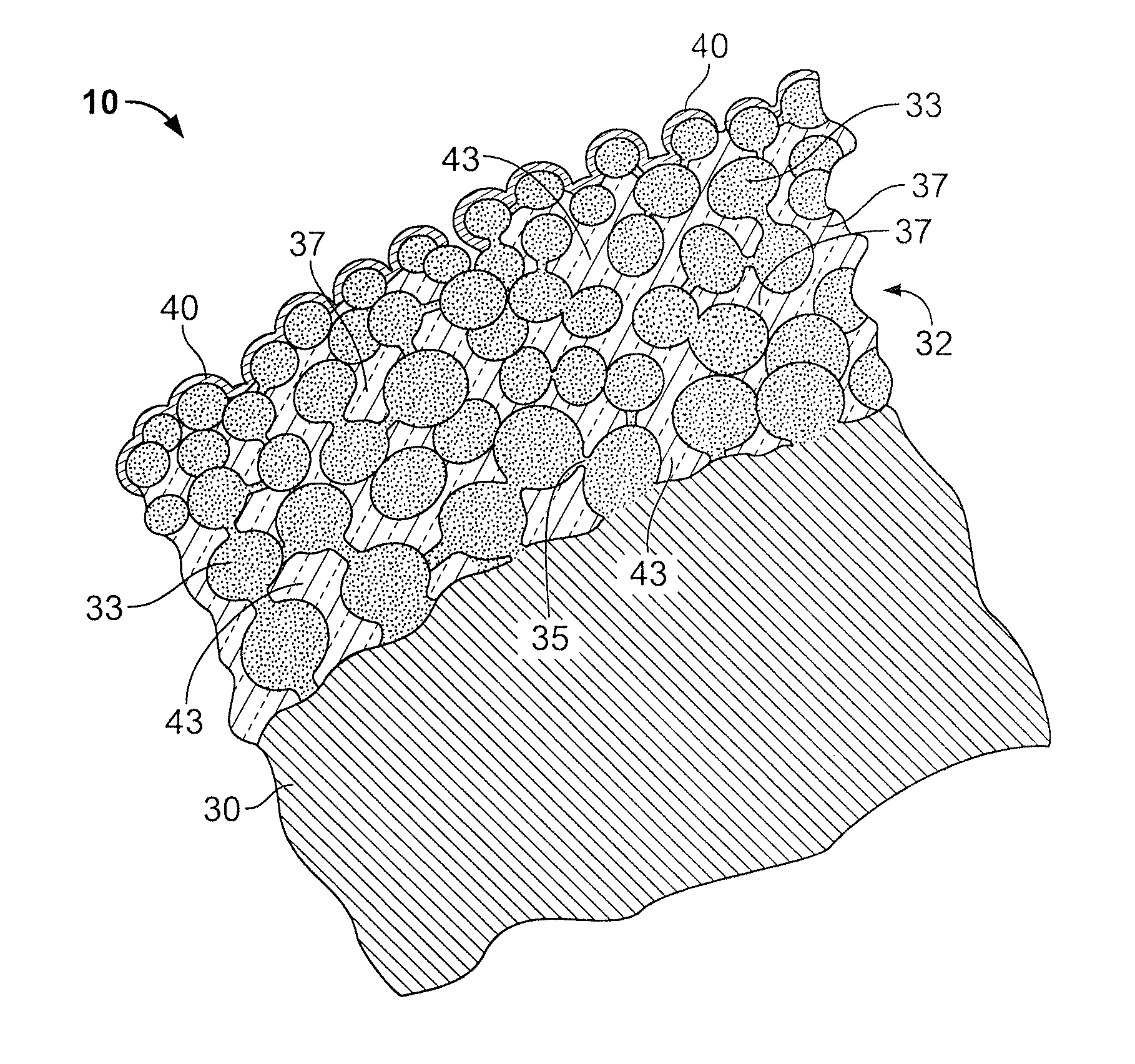

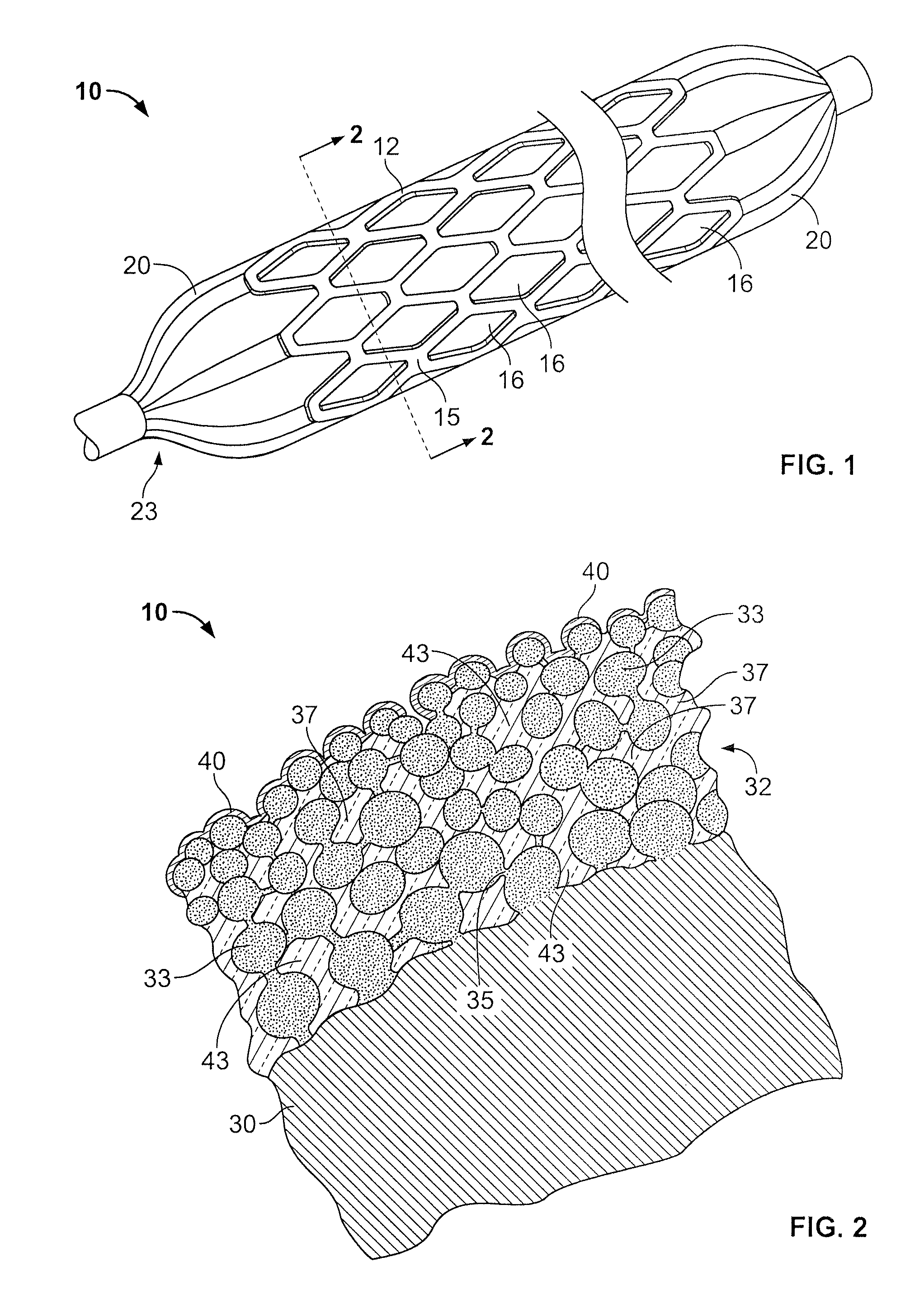

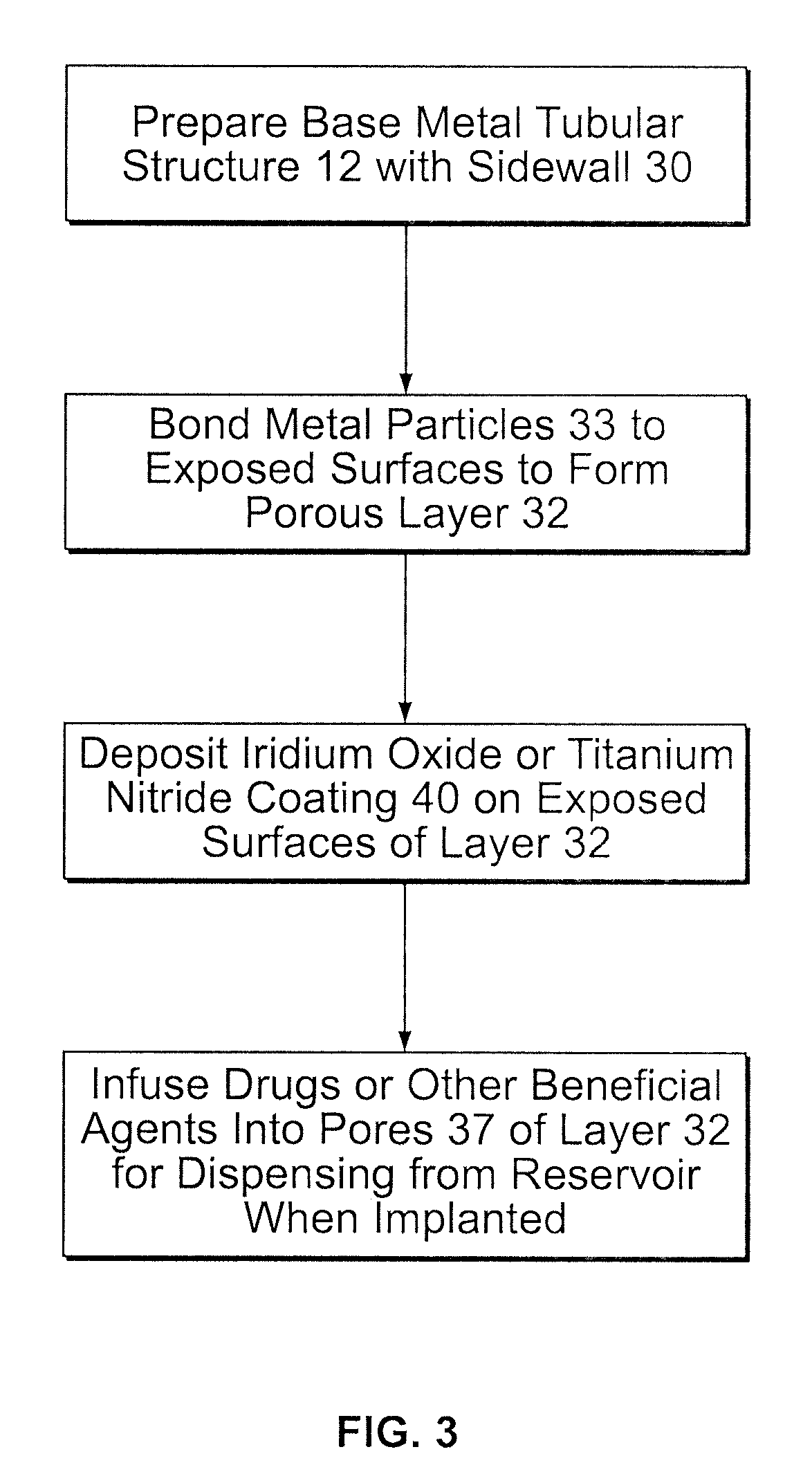

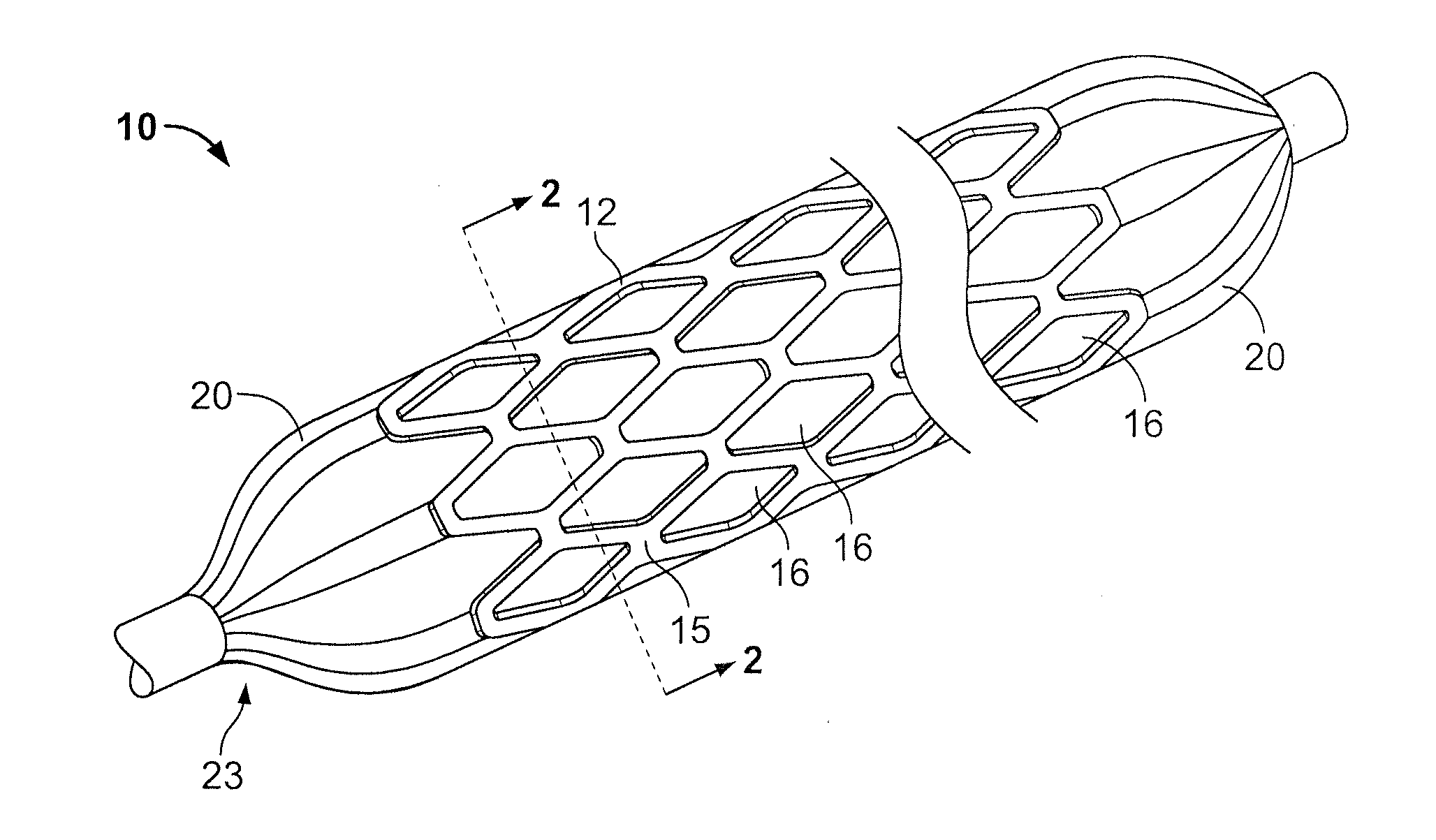

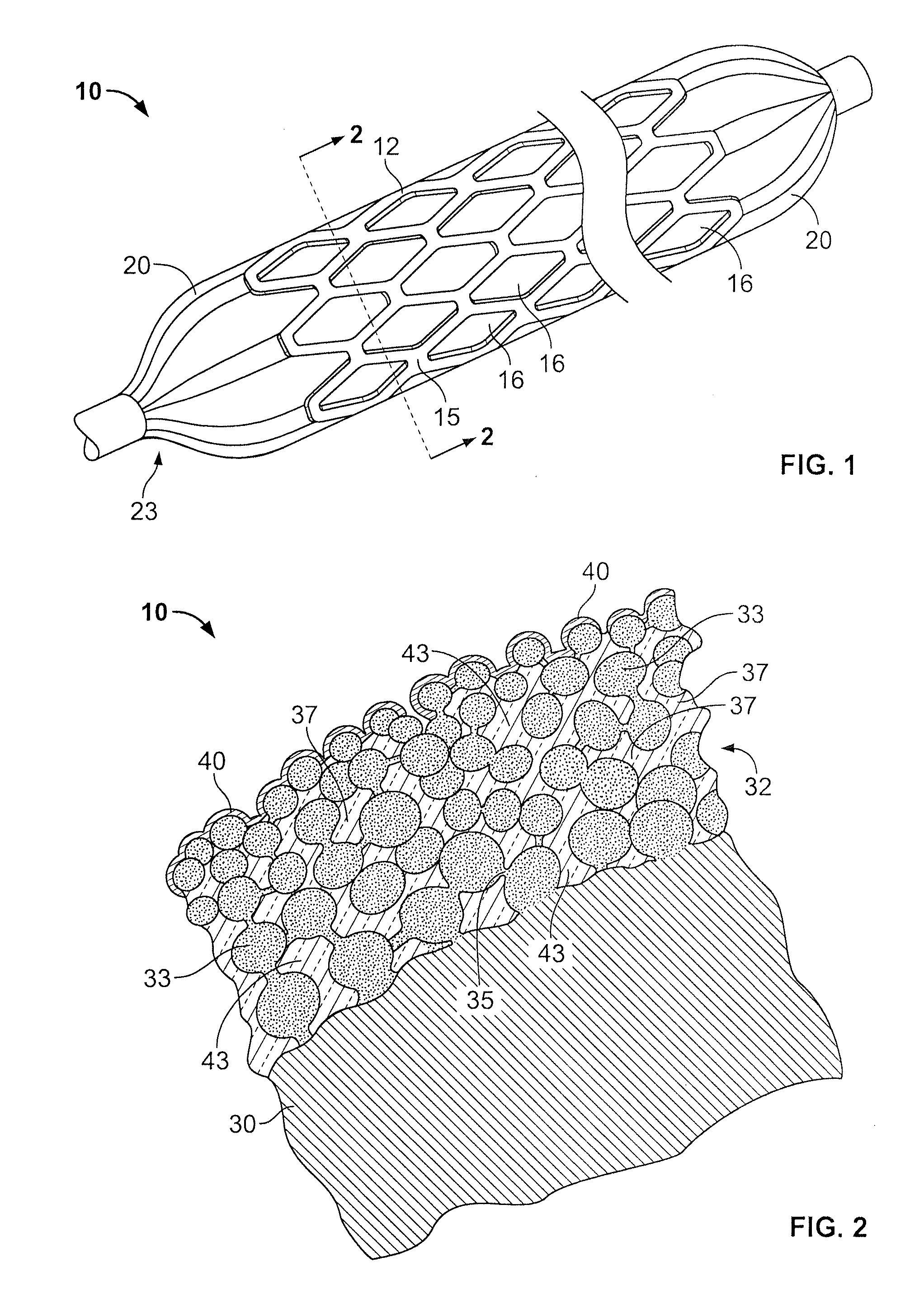

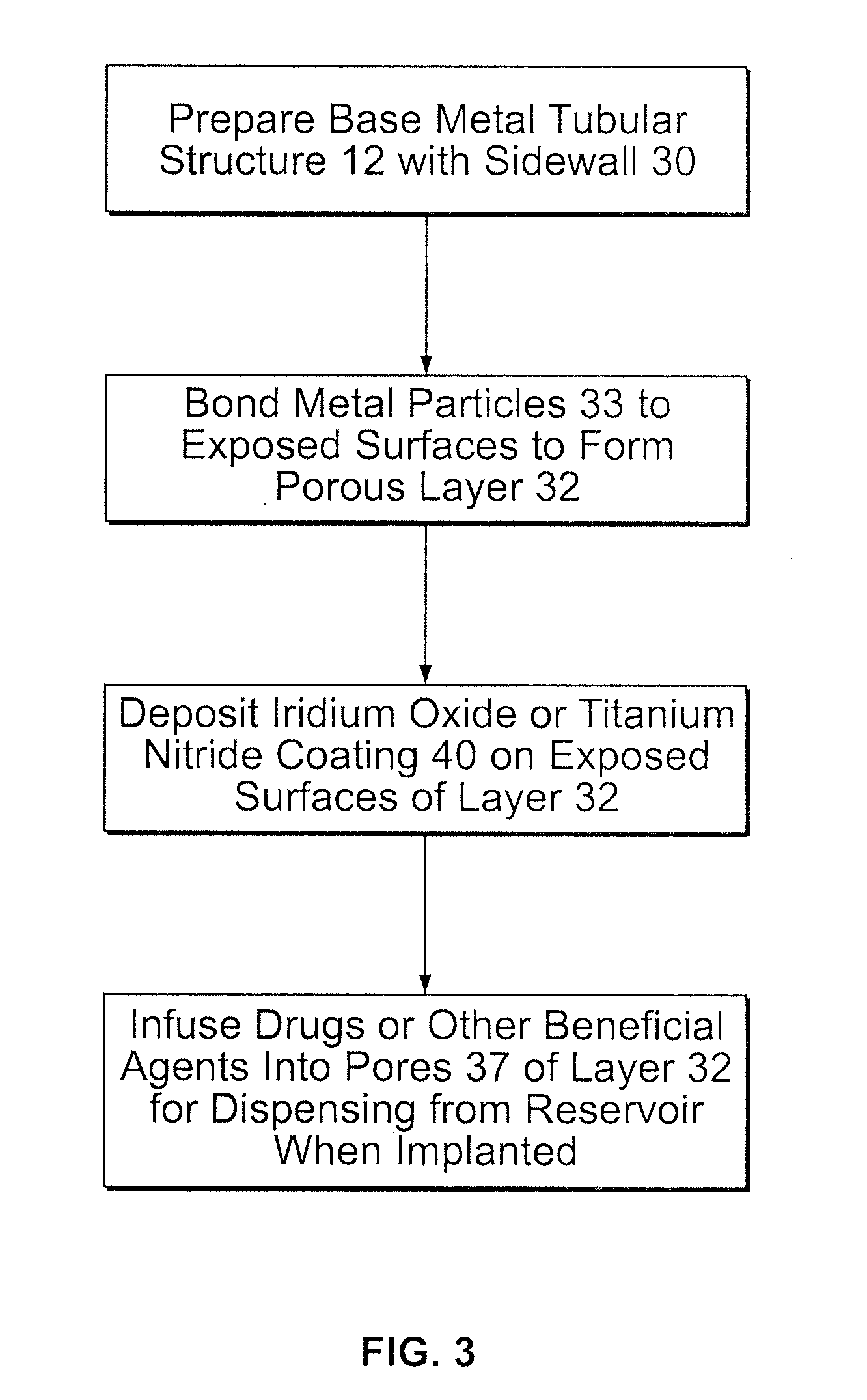

Drug-releasing stent with ceramic-containing layer

InactiveUS7713297B2Prevent proliferationPrevent restenosisStentsSurgeryEndoluminal stentAnti platelet

A vascular or endoluminal stent is adapted to be implanted in a vessel, duct or tract of a human body to maintain an open lumen at the site of the implant. The sidewall of the open-ended tubular structure of the stent is a base layer of a metal biologically compatible with blood and tissue of the human body. An intermediate metal particle layer of substantial greater radiopacity overlies the base layer, with particles bonded to the base layer and to each other to leave interstices therebetween as a repository for retaining and dispensing drugs or other agents for time release therefrom after the stent is implanted, to assist the stent in maintaining the lumen open. The particles are composed primarily of a noble metal—an alloy of platinum-iridium. The sidewall has holes extending therethrough, and the particle layer resides along the outward facing and inward facing surfaces, and the edges of the through holes and open ends of the sidewall. The larger particles are bonded to surfaces of the sidewall and progressively smaller particles are bonded to those and to each other up to the outer portion of the particle layer. Exposed surfaces of the particle layer are coated with ceramic-like iridium oxide or titanium nitrate, as a biocompatible material to inhibit irritation of tissue at the inner lining of the vessel when the stent is implanted. One or more anti-thrombotic, anti-platelet, anti-inflammatory and / or anti-proliferative drugs are retained in the interstices, together with a biodegradable carrier for time release therefrom. In an alternative embodiment, the intermediate layer is solid and the biodegradable carrier and drugs or agents therein are applied to the surface of the ceramic-like coating. Gene transfer is alternatively used to control tissue proliferation.

Owner:BOSTON SCI SCIMED INC

Drug-releasing stent with ceramic-containing layer

InactiveUS8066763B2Maintaining the lumen of the vessel openAvoid cloggingStentsSurgeryEndoluminal stentCatheter

A vascular or endoluminal stent is adapted to be implanted in a vessel, duct or tract of a human body to maintain an open lumen. The stent includes a base layer of a biologically compatible metal. An intermediate metal particle layer of substantial greater radiopacity overlies the base layer, with particles bonded to the base layer and to each other to leave interstices therebetween as a repository for retaining and dispensing drugs or other agents for time release therefrom. The particles are composed primarily of a noble metal. Exposed surfaces of the particle layer are coated with ceramic-like iridium oxide or titanium nitrate, as a biocompatible material to inhibit irritation of tissue at the inner lining of the vessel when the stent is implanted.

Owner:BOSTON SCI SCIMED INC

Method of manufacturing a contact interconnection layer containing a metal and nitrogen by atomic layer deposition for deep sub-micron semiconductor technology

ActiveUS20050054196A1Good step coverageSafe handlingSemiconductor/solid-state device detailsSolid-state devicesAtomic layer depositionImpurity

An atomic layer deposition method is used to deposit a TiN or TiSiN film having a thickness of about 50 nm or less on a substrate. A titanium precursor which is tetrakis(dimethylamido)titanium (TDMAT), tetrakis(diethylamido)titanium (TDEAT), or Ti{OCH(CH3)2}4 avoids halide contamination from a titanium halide precursor and is safer to handle than a titanium nitrate. After a monolayer of the titanium precursor is deposited on a substrate, a nitrogen containing reactant is introduced to form a TiN monolayer which is followed by a second purge. For TiSiN, a silicon source gas is fed into the process chamber after the TiN monolayer formation. The process is repeated several times to produce a composite layer comprised of a plurality of monolayers that fills a contact hole. The ALD method is cost effective and affords an interconnect with lower impurity levels and better step coverage than conventional PECVD or CVD processes.

Owner:TAIWAN SEMICON MFG CO LTD

Slurries for chemical mechanical polishing

InactiveUS6375552B1Pigmenting treatmentOther chemical processesIntegrated circuit manufacturingPotassium ferricyanide

Novel slurries for the chemical mechanical polishing of thin films used in integrated circuit manufacturing. A tungsten slurry of the present invention comprises an oxidizing agent, such as potassium ferricyanide, an abrasive such as silica, and has a pH between two and four. The tungsten slurry of the present invention can be used in a chemical mechanical planarization process to polish back a blanket deposited tungsten film to form plugs or vias. The tungsten slurry can also be used to polish copper, tungsten silicide, and titanium nitrate. A second slurry, which is a 9:1 dilution of the tungsten slurry is ideal for chemical mechanical polishing of titanium nitride films. A third slurry of the present invention comprises a fluoride salt, an abrasive such as silica an has a pH<=8. The third slurry can be used to polish titanium films.

Owner:INTEL CORP

Esterification catalyst for synthesizing ethylene/propylene glycol ether carboxylate, and preparation method thereof

InactiveCN101722027AShort processLess investmentMolecular sieve catalystsOrganic compound preparationHigh energyCerium

The invention provides an esterification method for synthesizing ethylene / propylene glycol ether carboxylate. A catalyst used in the method consists of an active substance and a carrier, wherein the active substance is tin salt (such as tin tetrachloride), titanium salt (such as titanium sulfate, titanium tetrachloride or titanium nitrate), zirconium salt (such as zirconium sulfate, zirconium tetrachloride or zirconium nitrate) or cerium salt (such as cerous sulfate, cerium tetrachloride or cerous nitrate); the carrier is silica gel, hydrogen-type ZSM-5, activated clay or diatomite; the content of the active substance in percentage by mass is 10 to 30 percent; and the content of the carrier in percentage by mass is 70 to 90 percent. The method has the advantages of inhibiting the occurrence of side reaction during production, improving the selectivity of target products, shortening production cycle, reducing investment in production equipment and avoiding the problems of production equipment corrosion, environmental pollution, high energy consumption and the like.

Owner:SHENYANG POLYTECHNIC UNIV

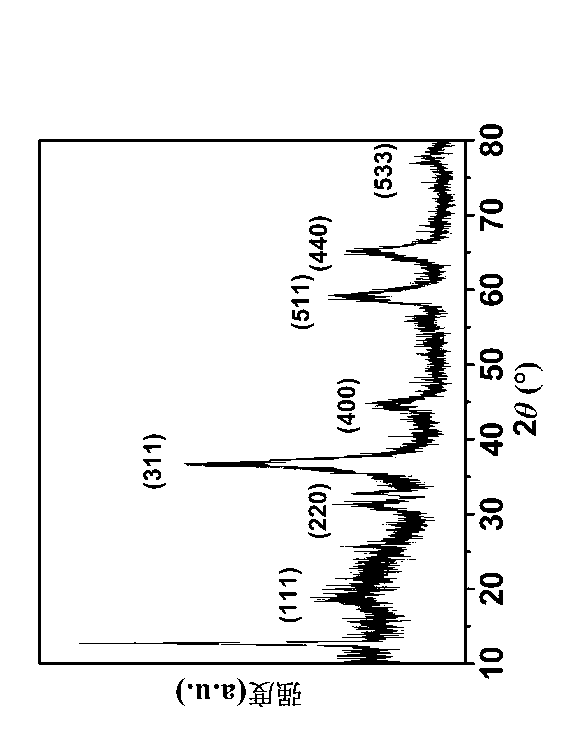

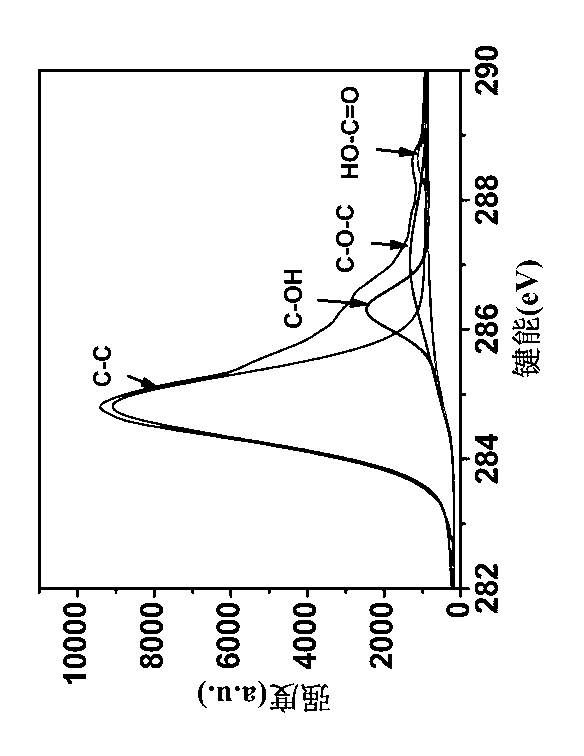

Preparation method for nano metal oxide graphene composite material

InactiveCN103193225AEasy to makeThe preparation process is environmentally friendlyMaterial nanotechnologyOxide/hydroxide preparationCerium nitrateGraphene flake

The invention relates to a preparation method for a nano metal oxide graphene composite material. The preparation method comprises the following steps: preparing graphite oxide aqueous dispersion from graphite oxide and water; throwing the graphite oxide aqueous dispersion into a ball-milling tank of a ball mill; adding nitrate and performing ball milling, wherein the nitrate is selected from one of or a mixture of more of silver nitrate, cobalt nitrate, manganese nitrate, ferric nitrate, nickel nitrate, bismuth nitrate, copper nitrate, cerium nitrate, vanadium nitrate, chromium nitrate, titanium nitrate, beryllium nitrate and vanadium nitrate; and after ball milling, dispersing the mixed liquid obtained by ball milling by using a proper amount of deionized water, standing and layering, filtering out precipitate, washing and drying. The preparation process is simple; the yield is high; the scale is easy to enlarge so as to realize industrialized production; the preparation process is environment-friendly; and in the prepared composite material, the nano metal oxide has the particle size of less than 50 nm, is uniform in size and is dispersed on the surface of graphene uniformly, the thickness of the graphene sheet is between 1 and 10 carbon atoms, and a good crystal structure is obtained.

Owner:LIHAI CHEM IND CO LTD OF JIANGSU JINQIAO SALT & CHEM GRP

Method for impulsive bias arc ion plating multi-player super-hard nano films of titanium/titanium nitrate

InactiveCN1680618AImprove the binding force of membrane baseHigh hardnessVacuum evaporation coatingSputtering coatingTitanium nitrideTitanium oxide

A surface modification technology of nanometer multi-layer hard membrane of Ti / titanium oxide by way of pulsed biasing. Apply to pulsed biasing to improve deposit quality of membrane in the arc process. Interchange Ar and N2 interchange and control the time interval. Then cover is fit on the preface of metal.

Owner:DALIAN UNIV OF TECH

Preparation method of compound catalyst for controlling generation of bromate in process of using ozone

InactiveCN102513088AImprove control efficiencyExtended service lifeMolecular sieve catalystsMetal/metal-oxides/metal-hydroxide catalystsCerium nitratePhysical well being

The invention discloses a preparation method of a compound catalyst for controlling the generation of bromate in the process of using ozone, characterized by using cerium nitrate and titanium nitrate as main raw materials, and carrying out pretreatment and then calcining to prepare the compound catalyst. According to the invention, by controlling the generation of hydroxy free radicals, the generation of bromate in the process of using ozone is controlled, and the bromate problem of influencing people health is solved; the control efficiency of the catalyst is high, the service life is long, the cost is low, no toxicity exists, and no influence on human health exists; simultaneously, in the process of ozone disinfection, the catalyst can effectively adsorb microbes and organic carboxylic acid in water, so as to raise the ozone disinfection effect and the removal rate of oxidized organic matters.

Owner:SOUTHWEST JIAOTONG UNIV

Process for preparing denitrification catalyst

InactiveCN102921430ARich internal voidsActiveDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMass ratioCopper nitrate

The invention relates to a process for preparing a denitrification catalyst. The process is characterized by comprising the following steps of: firstly, selecting and mixing powdered activated carbon or granular activated carbon which has the C content of more than 90 percent and the specific surface area of more than 1000 m<2> / g into an alcohol amine solution to obtain a suspension liquid for later use; secondly, dissolving a mixed solution of ammonium metavanadate, titanium nitrate and aluminium nitrate in the suspension liquid according to the mass ratio of 10-50 percent to form a sizing agent A; thirdly, dissolving a mixed solution of manganese nitrate, ferric nitrate and copper nitrate in the suspension liquid to form a sizing agent B, coating a carrier with the sizing agent A, drying to a constant weight and then heating to 530-570 DEG C under the protective atmosphere, and carrying out heat preservation for 3-5 hours and subsequently cooling to the room temperature at a temperature reduction speed; and finally, the sizing agent B is coated on the surface of the carrier obtained from the last step, the carrier is dried to a constant weight and then heating to 630-670 DEG C under the atmosphere containing 70 percent of N2, 20 percent of CO2 and 10 percent of CO, carrying out heat preservation and then cooling to the room temperature at a temperature reduction speed to achieve the catalyst in which pores and channels are communicated and are in a two-layer structure. The space velocity of the catalyst can be improved by more than 60 percent, and the resistance is reduced by more than 45 percent, so that a small-sized catalyst device is achieved.

Owner:NANJING UNIV

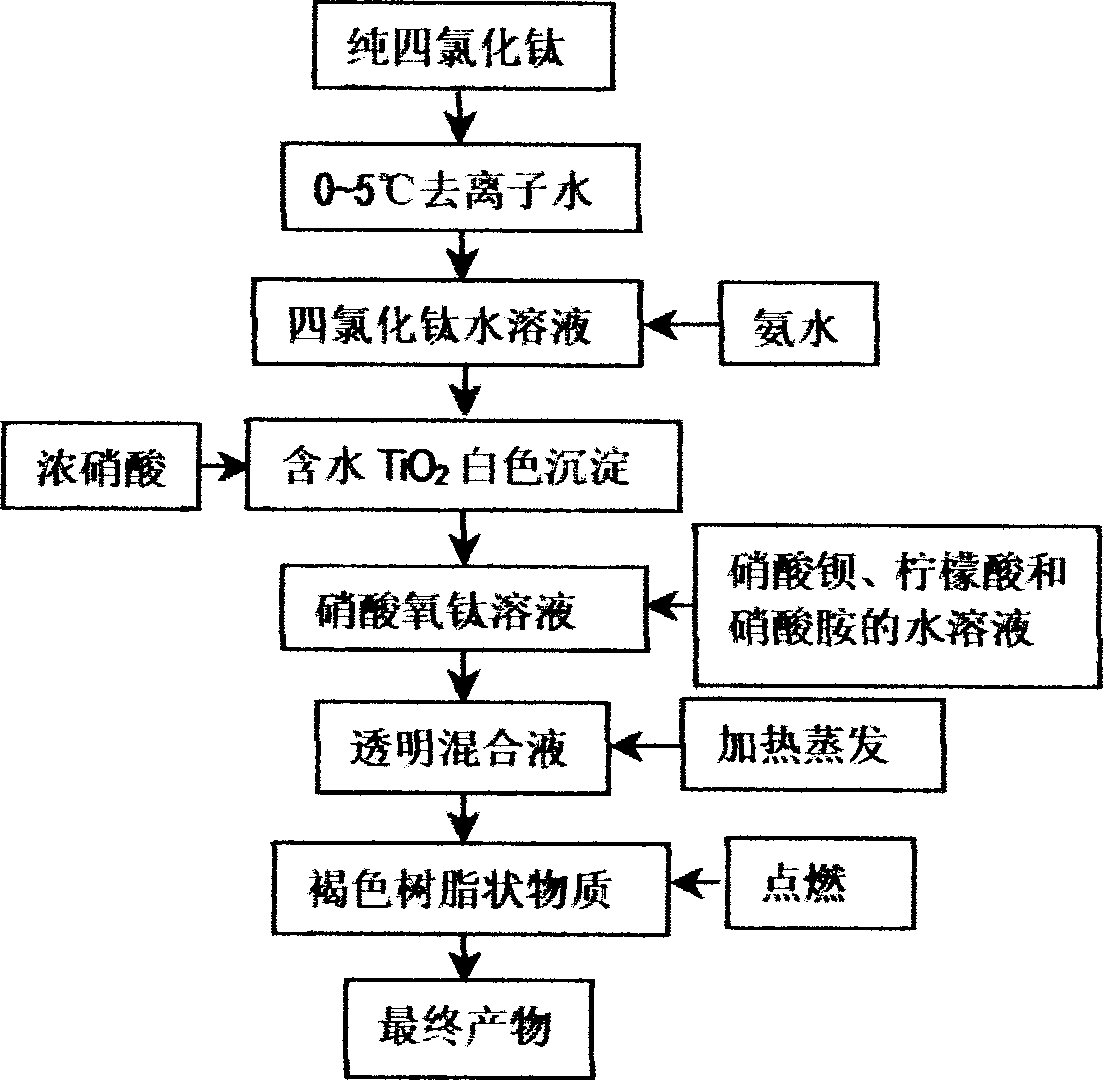

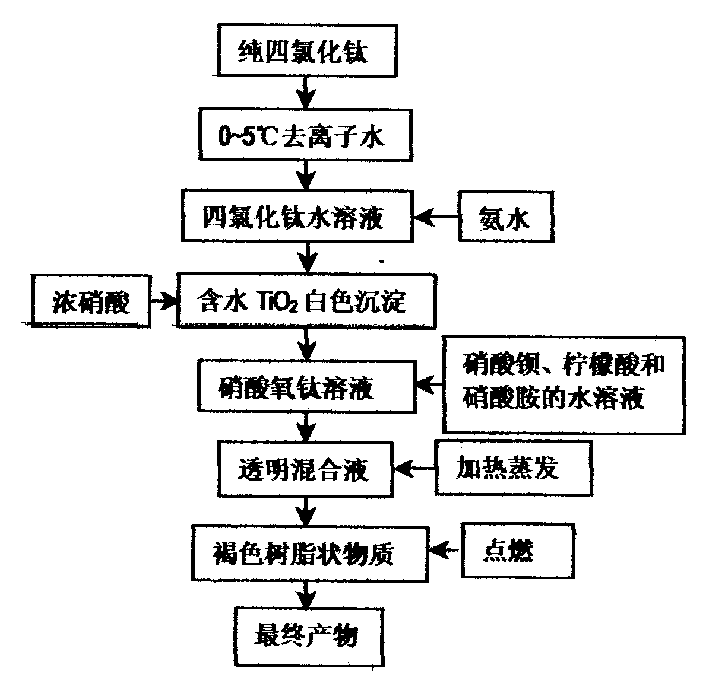

Process for preparing tetragonal nanoparticles of barium titanate

InactiveCN1390806ASimple preparation processProcess parameters are easy to controlTitanium compoundsBarium titanateEvaporation

A process for preparing the tetragonal nanoparticles of barium titanate includes such steps as preparing solution of titanium nitrate oxide, proportionally mixing it with the aqueous solution of barium nitrate, citric acid and ammonium nitrate, heating for becoming colloid by evaporation, and burning. Its advantage are high purity, easily controlled granularity, and low cost.

Owner:TSINGHUA UNIV

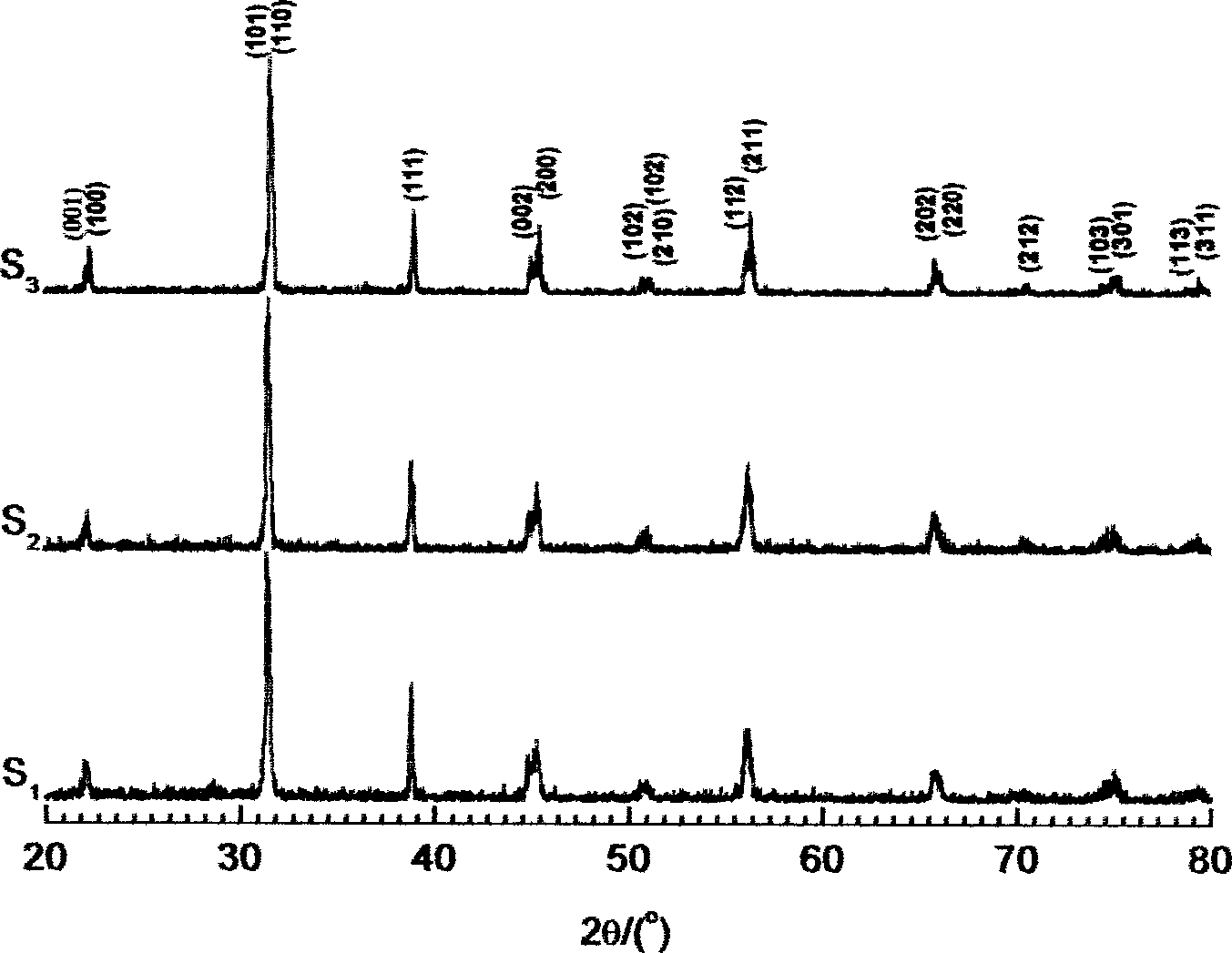

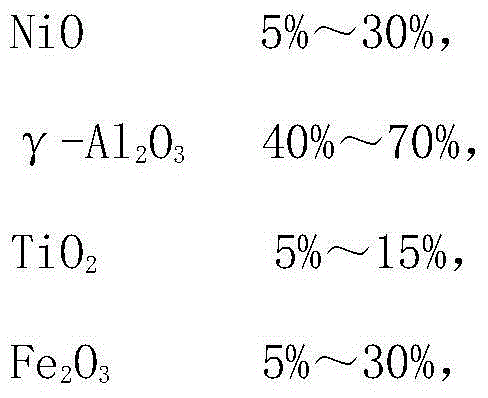

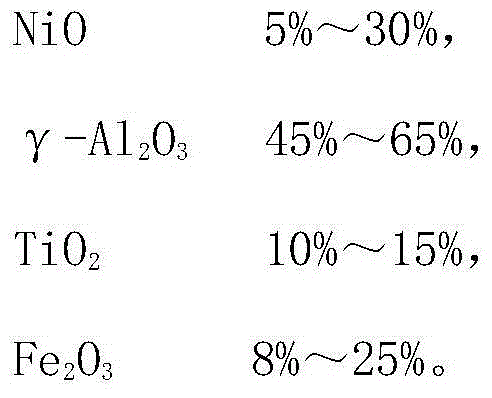

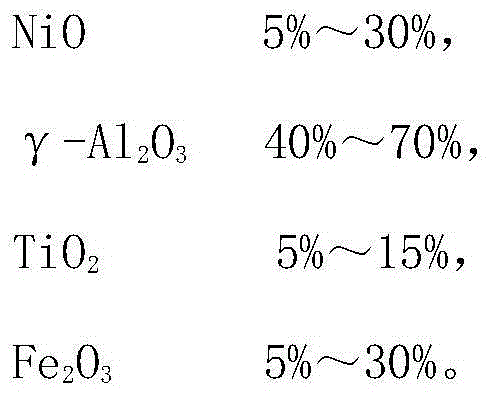

Low-temperature high-activity nano-composite catalyst for methanation of synthesis gas and preparation method thereof

InactiveCN104815662AGood dispersionEnhanced interactionGaseous fuelsMetal/metal-oxides/metal-hydroxide catalystsMethanationHeat stability

The invention discloses a low-temperature high-activity nano-composite catalyst for the methanation of a synthesis gas and a preparation method thereof. The catalyst comprises an active component, a carrier and a coagent, wherein the active component is nickel, the carrier is TiO2(Titanium Oxide) / [lambda]-Al2O3 (Alumina Oxide), and the coagent is metallic iron; the nickel and the metallic iron are in the present of the catalyst in a ferro-nickel way; and the catalyst comprises the following components in parts by weight: 5-30% of NiO (Nickel Oxide), 40-70% of [gamma]-Al2O3, 5-15% of TiO2 and 5-30% of Fe2O3 (Ferric Oxide). When the TiO2 / gamma]-Al2O3 composite carrier is prepared by the method provided by the invention, the nano-scale TiO2 prepared by a sol-gel method has the advantages of high surface uniformity, high dispersion and best heat stability, in comparison with titanium dioxide, which is easy to cluster and agglomerate, obtained by the impregnation and calcinations of titanium nitrate and the like through a traditional impregnation method.

Owner:SOUTHEAST UNIV

Drug-releasing stent with ceramic-containing layer

InactiveUS20100286763A1Maintaining the lumen of the vessel openAvoid cloggingStentsSurgeryEndoluminal stentMetal particle

A vascular or endoluminal stent is adapted to be implanted in a vessel, duct or tract of a human body to maintain an open lumen. The stent includes a base layer of a biologically compatible metal. An intermediate metal particle layer of substantial greater radiopacity overlies the base layer, with particles bonded to the base layer and to each other to leave interstices therebetween as a repository for retaining and dispensing drugs or other agents for time release therefrom. The particles are composed primarily of a noble metal. Exposed surfaces of the particle layer are coated with ceramic-like iridium oxide or titanium nitrate, as a biocompatible material to inhibit irritation of tissue at the inner lining of the vessel when the stent is implanted.

Owner:BOSTON SCI SCIMED INC

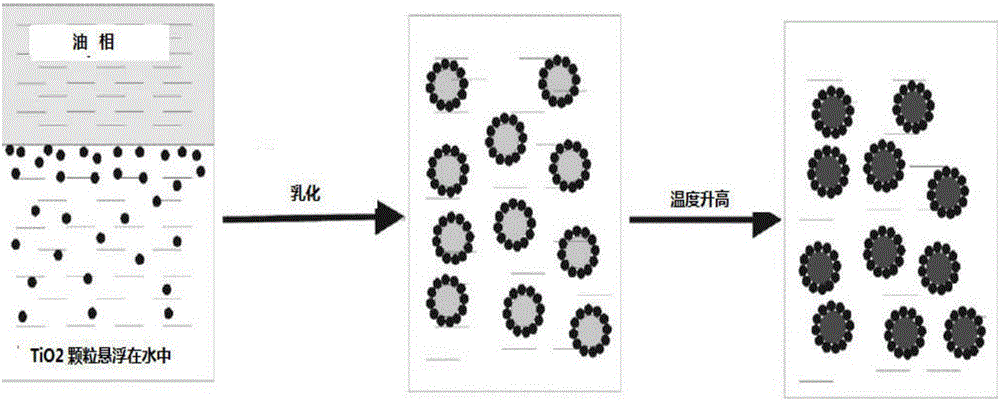

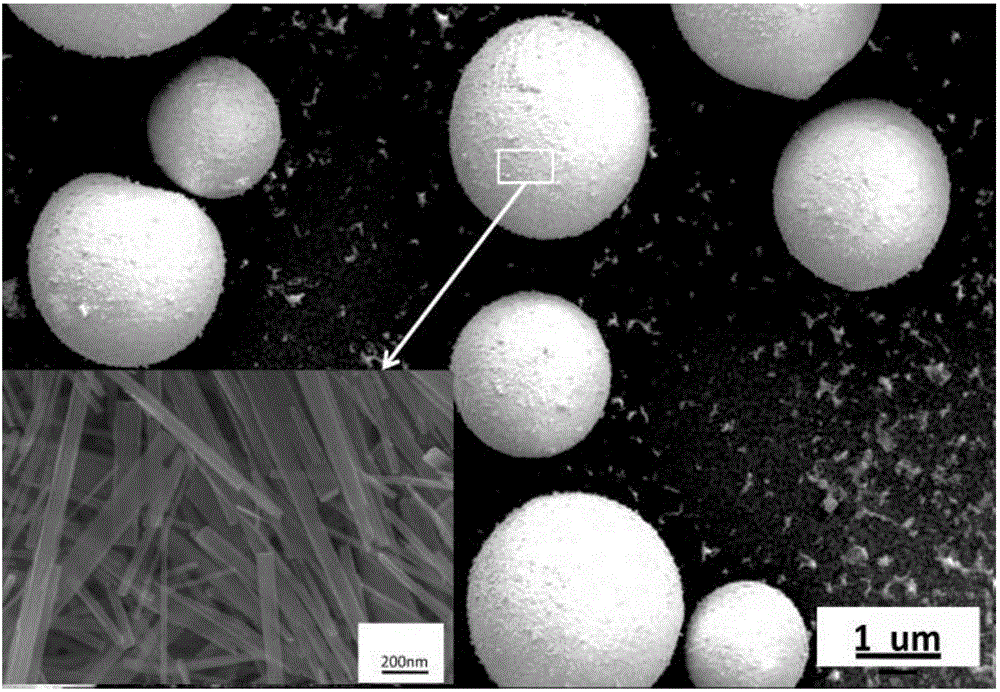

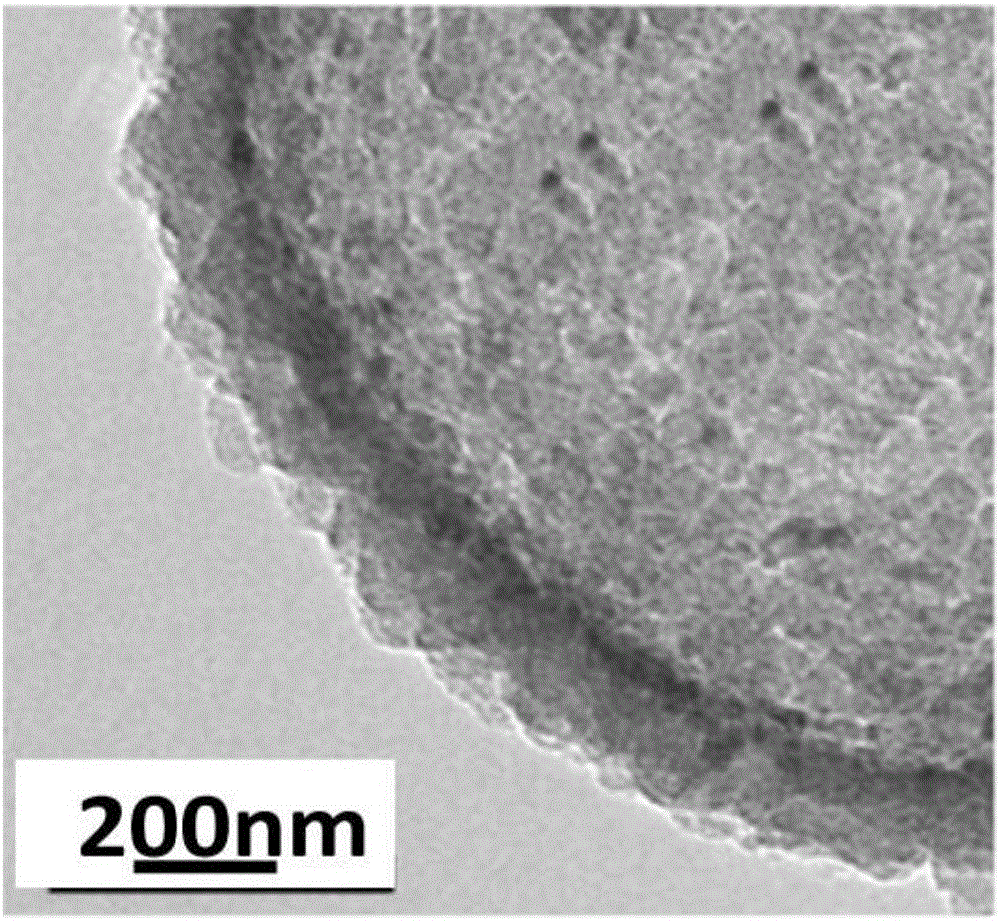

Spherical core-shell type TiO2/TiO2 material and preparation method thereof

InactiveCN106582592ASimple processLow costPhysical/chemical process catalystsWater/sewage treatment by irradiationNanowireMicrosphere

The invention discloses a spherical core-shell structure TiO2 / TiO2 material and a preparation method thereof and belongs to the field of nanocomposite. Titanium nitrate is used as a precursor, and by the combination of homogeneous precipitation process and calcination process, a titanium dioxide solid core is prepared. The surface of the solid core is coated with nano titanium dioxide particles / nanotubes, nanobelts and nanowires through a Pickering emulsion method, a porous shell layer is thus formed, and after high-temperature calcination, a core-shell type TiO2 / TiO2 microsphere is obtained. The core-shell type titanium dioxide material is uniform and spherical, and the particle size of the materials is controllable; the microsphere can be used as a surfactant and has a UV photoresponse property. Compared with TiO2 nanoparticles, the photocatalytic performance of the material is stronger, and the recovery rate is high.

Owner:HUBEI UNIV OF TECH

Production process of multiple aluminum zinc alloy hot-dipped on surface of carbon steel

InactiveCN102560307AImprove corrosion resistanceAvoid isolationHot-dipping/immersion processesPhosphoric acidManganese

The invention relates to a production process of multiple aluminum zinc alloy hot-dipped on the surface of carbon steel, which comprises the following steps of: pickling, assisting in plating, drying, hot-dipping and passivating. Hot-dipping liquid comprises the following components in percentage by weight: 6-8 weight percent of aluminum, 1.2-2.5 weight percent of nickel, 0.5-1.2 weight percent of silicon, 0.5-1.5 weight percent of magnesium, 0.5-0.9 weight percent of manganese, 1.2-1.5 weight percent of titanium and the balance of zinc; and passivating liquid comprises the following components in percentage by weight: 0.3-0.5 weight percent of titanium nitrate, 1.2-2.0 weight percent of hydrogen peroxide, 0.3-0.6 weight percent of phosphoric acid and 0.8-1.2 weight percent of citric acid. With the adoption of the production process, a hot-dipping carbon steel material which is excellent in corrosion resistance and particularly is excellent in corrosion resistance under humid environment can be prepared, and a prepared passivating protective film is uniform, level and compact and can effectively prevent the isolation of corrosion environment from zinc coating and effectively restrain the corrosion.

Owner:周然华

Inorganic nano self-cleaning coating

InactiveCN109535884ANot easy to stainAvoid manpowerAntifouling/underwater paintsPaints with biocidesCalciteTitanium tetrachloride

The invention discloses an inorganic nano self-cleaning coating. The inorganic nano self-cleaning coating is weighed according to the following components in parts by weight: 60-100 parts of a photocatalyst mixed solution, 30-45 parts of a silicone acrylic emulsion, 15-20 parts of a fluorocarbon emulsion, 4-8 parts of a hydrophobic auxiliary agent, 3-13 parts of nano silicon dioxide, 5-10 parts ofpolysiloxane, 5-15 parts of anatase nano titanium dioxide, 1-5 parts of porous konilite, 10-15 parts of titanium tetrachloride, 5-10 parts of titanium nitrate, 2-5 parts of calcite, 1-2 parts of ethylene glycol, 0.5-1 part of a thickener, 1-3 parts of a film forming auxiliary agent, 1-2 parts of a dispersant and 30-40 parts of water. The adopted inorganic nano self-cleaning coating can achieve good self-cleaning effect, is not easily polluted by rainwater and contaminated by stains, avoids repeated cleaning, thereby avoiding consumption of a lot of manpower, material and financial resources and avoiding field high altitude operation, and having obvious social benefits.

Owner:江苏中千碧华新材料有限公司

Porous silver-titanium composite catalyst preparation method

ActiveCN102941086ALarge specific surface areaImprove adsorption capacityMetal/metal-oxides/metal-hydroxide catalystsPtru catalystTriethoxysilane

The present invention discloses a porous silver-titanium composite catalyst preparation method, and belongs to the field of sewage treatment. The preparation method comprises: weighing silver nitrate, titanium tetranitrate and urea, and preparing into a solution, wherein a molar ratio of Ag<+> to Ti<4+> to urea is 2:1:10-4:1:10, and the total concentration of Ag<+> ions and Ti<4+> ions is 4-6 mol / L; carrying out crystallization on the prepared solution for 24-36 h at a temperature of 120-130 DEG C to obtain silver-titanium type hydrotalcite; adding the hydrotalcite to water to prepare a suspension liquid with a solid-liquid ratio of 1:30-1:50, adding an anion surfactant, and stirring for 2-3 h, wherein per g of the hydrotalcite is added with 1-2 mmol of the anion surfactant; and dissolving 30-60 mmol of aminopropyltriethoxysilane in 50 ml of absolute ethanol, adding the obtained solution to the hydrotalcite suspension liquid in a dropwise manner, carrying out solid-liquid separation, drying at a temperature of 90-105 DEG C, and carrying out calcination at a temperature of 450-550 DEG C to prepare the porous silver-titanium composite catalyst with characteristics of large specific surface area, absorption promotion, and good catalysis effect.

Owner:江阴智产汇知识产权运营有限公司

Composite silver-titanium catalyst preparation method

InactiveCN102941087ALarge specific surface areaWith nano effectWater/sewage treatment by irradiationEnergy based wastewater treatmentPtru catalystPhysical chemistry

The present invention discloses a composite silver-titanium catalyst preparation method, and belongs to the field of sewage treatment. The preparation method comprises: weighing a certain mass of silver nitrate, a certain mass of titanium tetranitrate and a certain mass of urea, and preparing into a solution, wherein a molar ratio of Ag<+> to Ti<4+> to urea is 2:1:10-4:1:10, and the total concentration of Ag<+> ions and Ti<4+> ions in the solution is 4-6 mol / L; pouring the solution to a hydrothermal kettle, placing the hydrothermal kettle in an oven to carry out crystallization for 24-36 h at a temperature of 120-130 DEG C; cooling to a room temperature; carrying out suction filtration washing to achieve a neutral state; drying filter cake for 8-12 h at a temperature of 80-90 DEG C to obtain silver-titanium type hydrotalcite; and carrying out calcination on the silver-titanium type hydrotalcite for 3-4 h at a temperature of 450-550 DEG C to prepare the layered composite silver-titanium catalyst with characteristics of nanometer effect and absorption promotion.

Owner:CHANGZHOU UNIV

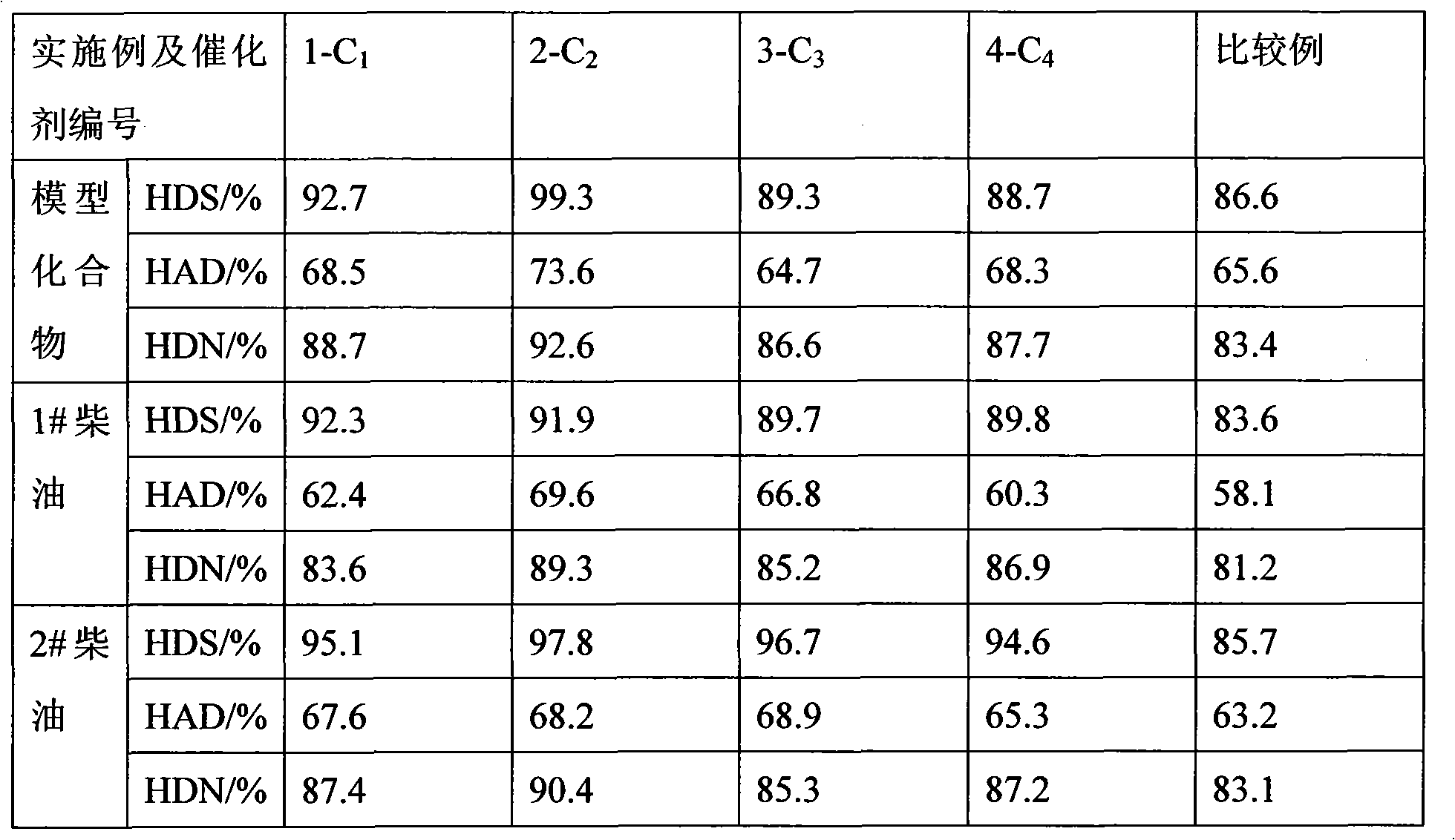

Method for hydrofining light petroleum distillate

InactiveCN102108305ASuitable for catalytic hydrotreatingGood hydrofining performanceCatalyst carriersRefining to eliminate hetero atomsActive componentHydrogenation catalysis

The invention relates to a method for hydrofining light petroleum distillate, which comprises the following steps: treating light petroleum distillate on a fixed bed reactor by using MoP / SiO2-TiO2-ZrO2 as a catalyst; weighing TiCl4 or titanium nitrate or titanium sulfate, silicasol or ethyl orthosilicate, and ZrOCl2.8H2O, wherein in the ternary composite oxides SiO2-TiO2-ZrO2, the mol ratio of Si is 0.163-0.684, the mol ratio of Ti is 0.179-0.809, and the mol ratio of Zr is 0.028-0.589; preparing a mesoporous SiO2-TiO2-ZrO2 nano material by a coprecipitation method, wherein the content of the loaded active component MoP accounts for 20% of the total weight of the catalyst; and regulating the pore structure, acidity and surface properties of the catalyst carrier to obtain the mesoporous substrate material by changing the ratios of Si, Ti and Zr, thereby regulating the properties of the catalyst. The invention is suitable for hydrogenation catalysis of light distillate.

Owner:PETROCHINA CO LTD +1

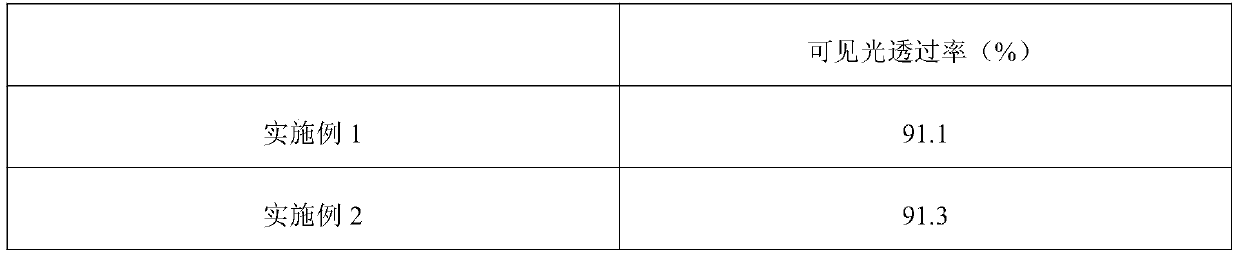

Aerogel heat insulation glass and preparation method thereof

The invention provides aerogel heat insulation glass and a preparation method thereof. The preparation method comprises the following steps: preparing a sol from tetraethyl orthosilicate, vinylmethyldiethoxysilane and trimethyl borate; mixing aluminum nitrate, titanium nitrate and citric acid monohydrate to prepare a premixed solution; mixing the sol and the premixed solution to obtain aerogel; and crushing the aerogel, pouring the crushed aerogel into a silicon dioxide molten liquid, molding in a tin bath, and cutting to obtain the integrated aerogel heat insulation glass. According to the invention, the integrated design fundamentally solves the problem of visible light transmission loss caused by interface difference between glass and aerogel, and ensures the light transmission of the glass product; the aerogel structures evenly distributed in the glass product effectively block heat conduction so as to effective improve the heat insulation performance; and aerogel is dispersed in molten silicon dioxide, and aerogel glass is prepared through float glass and has good mechanical properties.

Owner:长沙而道新能源科技有限公司

Preparation method of high-entropy oxide ceramic fiber material

PendingCN113754432AUniform shapeGood dispersionInorganic material artificial filamentsOxide ceramicMetal nitrate

The invention belongs to the technical field of ceramic fiber materials, and discloses a preparation method of a high-entropy oxide ceramic fiber material. The preparation method comprises the steps: preparing high-entropy oxide ceramic fibers through a template impregnation method, taking viscose as a template, and subjecting the viscose to vacuum impregnation in a metal nitrate mixed solution, wherein metal nitrate in the metal nitrate mixed solution is formed by mixing at least four of cerous nitrate, zirconium nitrate, yttrium nitrate, hafnium nitrate, titanium nitrate and lanthanum nitrate in equal molar mass; and after the impregnation,performing washing, centrifuging, drying and heat treatment to obtain the high-entropy oxide ceramic fiber. According to the preparation method, liquid-phase burdening is adopted, the method can guarantee that multiple metal elements are mixed uniformly, the prepared high-entropy oxide ceramic fiber material is uniform in morphology, the phase structure is of a fluorite type, and the proportion of elements contained in the fiber material is close to equal moles.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

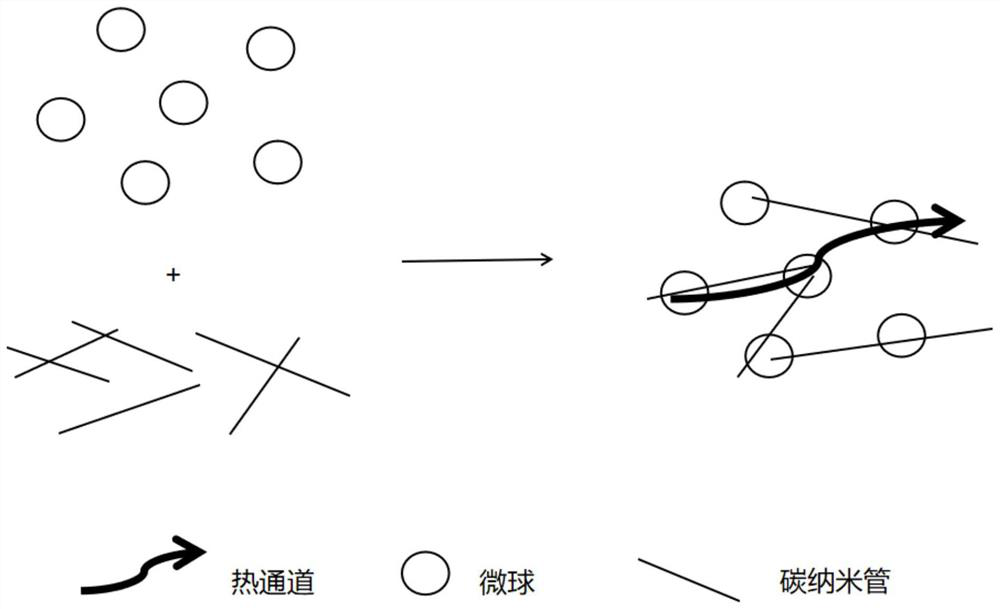

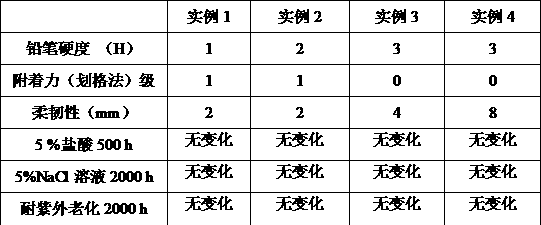

Heat dissipation coating and preparation method thereof

ActiveCN114213922AImprove heat resistanceStrong adhesionFireproof paintsChemical industryAcrylic resinMicrosphere

The invention provides a heat dissipation coating and a preparation method thereof, and belongs to the technical field of coatings. The preparation method comprises the following steps: reacting titanium nitrate, aluminum nitrate and copper nitrate with a complexing agent to form sol, heating to form xerogel, igniting to obtain metal oxide composite nano ceramic powder, reacting with ferrous sulfate and ammonium bicarbonate to obtain iron oxide coated metal oxide nano ceramic powder, and reacting with dopamine hydrochloride under the catalysis of a Tris-HCl solution containing Co ions to obtain the iron oxide coated metal oxide nano ceramic powder. And uniformly mixing the polydopamine-coated ceramic powder microspheres with silane coupling agent modified carbon nanotubes, organic silicon modified acrylic resin, urea resin, a dispersing agent and an auxiliary agent to obtain the heat dissipation coating. The heat dissipation coating prepared by the invention has the advantages of favorable mechanical properties, favorable heat resistance, favorable weather resistance, favorable chemical corrosion resistance, favorable flexibility, favorable elasticity and favorable film-forming property, has the functions of self-heat dissipation and far infrared release, and has wide application prospects.

Owner:东莞市安宿泰电子科技有限公司

Process for preparing denitrification catalyst

InactiveCN102921430BEvenly distributedDifferent purpose of workDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsMass ratioCopper nitrate

A method for preparing a denitration catalyst, which is characterized in that it includes the following steps: first, select powdered activated carbon or granular activated carbon with a C content greater than 90% and a specific surface area greater than 1000m2 / g and mix it into an alcoholamine aqueous solution to obtain a suspension for later use; secondly, , dissolve the mixed solution of ammonium metavanadate, titanium nitrate, and aluminum nitrate into the suspension at a mass ratio of 10% to 50% to form slurry A; thirdly, dissolve the mixed solution of manganese nitrate, iron nitrate, and copper nitrate into the suspension. Slurry B is formed in the suspension; coat the carrier with slurry A, dry to constant weight, and then raise the temperature to 530-570°C under a protective atmosphere. After holding for 3-5 hours, cool down to room temperature at a cooling rate; finally , apply slurry B on the surface of the carrier prepared in the previous step, dry it to constant weight, and then raise the temperature to 630-670°C in an atmosphere of 70% N2, 20% CO2, and 10% CO. After insulation, By cooling to room temperature at a cooling rate, the pores and channels are connected, forming a catalyst with a two-layer structure. The space velocity of the catalyst of the present invention can be increased by more than 60%, and the resistance can be reduced by more than 45%, so the catalyst device can be miniaturized.

Owner:NANJING UNIV

Preparation method of anticorrosive paint for coastal electrical equipment

InactiveCN107629658AAccelerated corrosionAdapt to anti-corrosion requirementsAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinSilicon dioxide

The invention discloses a preparation method of an anticorrosive paint for coastal electrical equipment. The preparation method comprises the following steps: dissolving hydroxy acrylic resin and fluororesin in a butyl acetate solvent, then adding silicon dioxide and titanium nitrate, and stirring; then adding hexamethylene diisocyanate and a dibutyltin dilaurate catalyst, stirring and mixing uniformly, and thus preparing the special anticorrosive paint for the coastal electrical equipment. The preparation method disclosed by the invention has the advantages that since the fluororesin is introduced into a polyurethane coating, the corrosion resistance and ultraviolet ageing resistance of the polyurethane coating are improved, and the polyurethane coating can adapt to the anticorrosive needof the coastal electrical equipment completely and has wide application prospect.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD NANTONG POWER SUPPLY BRANCH +2

Preparation method of Ti-CA-EG water solution

The invention discloses a preparation method of a Ti-CA-EG water solution. The preparation method comprises the steps of adding TiO2 powder into HF (hydrogen fluoride), and heating in a water bath until TiO2 is completely dissolved; adding ammonium water into a solution, performing neutralization reaction to generate metatitanic acid deposits, performing suction filtration, washing the deposits, adding the deposits into nitric acid, and magnetically stirring until the deposits are completely dissolved to obtain a titanium nitrate solution; adding citric acid into the nitric acid solution to completely dissolve the nitric acid solution; adding an ethylene glycol solution into the solution, heating and mixing to be uniform; standing for 24 hours to obtain a Ti-CA-EG water solution, magnetically stirring at 60 DEG C, and heating until nitric acid is completely volatilized to obtain a stable Ti-CA-EG water solution. According to the method, Ti<4+> and citric acid easily form complexation to obtain the stable Ti-CA-EG water solution by introducing an intermediate phase, namely titanium nitrate, and the production cost is reduced. The method is a novel method for preparing a Ti-containing solution.

Owner:TIANJIN UNIV

Golden hard alloy

The present invention relates to one kind of golden hard alloy, and features that the golden hard alloy consists of titanium nitrate 50-80 wt%, tantalum carbide 6-12 wt%, niobium carbide 4-10 wt%, Ni 7-20 wt%, Mo 2-5 wt% and C 1-3 wt%. The golden hard alloy has no need of electroplating to colorize causing environmental pollution, and no discoloring.

Owner:SHANGHAI YIXIANG GARMENTS

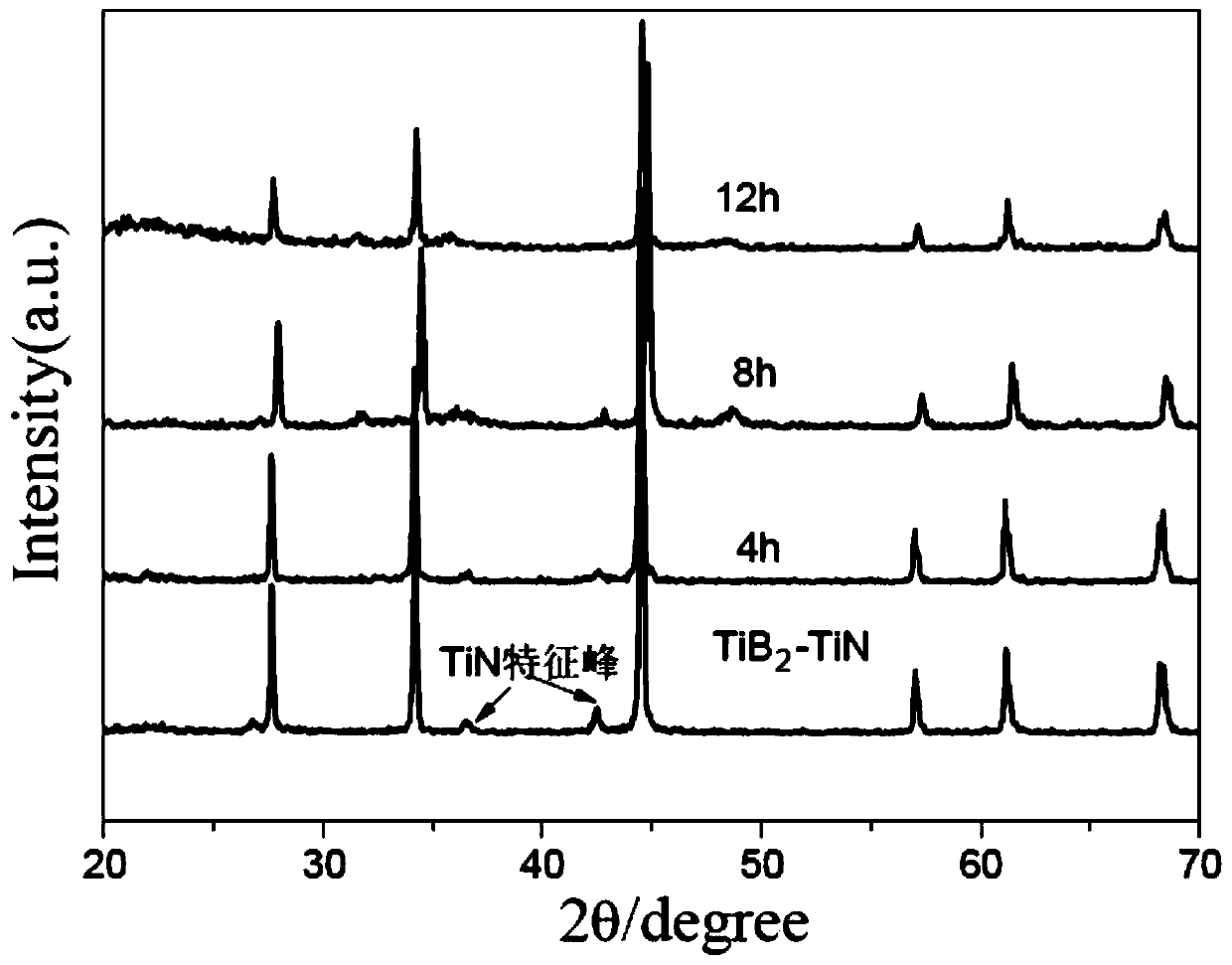

Preparation method of nano titanium diboride powder

ActiveCN110817896AHigh purityUniform particle size distributionMaterial nanotechnologyMetal boridesBorideTitanium nitride

The invention discloses a preparation method of nano titanium diboride powder, and relates to the technical field of preparation of high-melting-point boride powder. Titanium nitrate, magnesium powderand boron tribromide are taken and placed in a sealed high-pressure reaction kettle and undergo a reaction, a reaction product is washed, filtered and dried, titanium diboride coarse powder is obtained, and the coarse powder contains part of titanium nitride impurities; a ball-milling tank filled with the titanium diboride coarse powder and a grinding aid is put into a plasma ball mill, the rotating speed and the ball-milling time are set, and then ball-milling treatment is carried out; and after the ball milling is finished, a reaction product is taken out and is subjected to grading treatment to obtain the nano titanium diboride powder with different particle size distributions. No harmful substance is generated in the ball milling process, and environmental protection is facilitated. Meanwhile, plasmas with certain strength are introduced in the ball milling process, so that the surface activity of powder particles is enhanced, further reaction of impurity phases in the raw materials is induced, the structural defects of the powder are further controlled, the product is purified, and meanwhile, the ball milling process is accelerated.

Owner:安徽中航纳米技术发展有限公司

Adsorbent for removing antimony in printing and dyeing wastewater and preparation method and application thereof

ActiveCN112121776AImprove adsorption capacityAchieve recyclabilityOther chemical processesWater contaminantsCerium nitrateDyeing wastewater

The invention provides an adsorbent for removing antimony in printing and dyeing wastewater and a preparation method and application thereof. The preparation method comprises the following steps: preparing a metal oxide by taking titanium nitrate and cerium nitrate as raw materials; then preparing amidoximation polyacrylonitrile by taking polyacrylonitrile fiber as a raw material; finally, takingacrylamide and N (4aminophenyl) acrylamide as raw materials for a polymerization reaction, adding metal oxide and amidoximation polyacrylonitrile fiber in the polymerization process, obtaining hydrogel, obtaining dry gel through aftertreatment, carrying out modification treatment, and obtaining the adsorbent, wherein the maximum adsorption capacity of the adsorbent on antimony in the printing anddyeing wastewater is high, and excellent cyclic utilization performance of the adsorbent is achieved.

Owner:HANGZHOU FUYANG WEIWEN ENVIRONMENTAL PROTECTION TECH CO LTD

Preparation method of low-temperature selective catalytic reduction (SCR) catalyst by removing NOx from flue gas

ActiveCN102008956BLower operating temperatureHigh NO removal rateNitrous oxide captureDispersed particle separationFlue gasSulfur

The invention provides a preparation method of a selective catalytic reduction (SCR) catalyst Mn-Ce-M / TiO2 by removing NOx from flue gas, wherein M represents one or more of composite oxides, namely Fe, Co, Cu, Cr, Zr and Al, the molar ratio of the elements is Ti: Mn: Ce: M =1:(0.005-1):(0.005-1):(0-1). In the invention, an improved coprecipitation method is adopted, and an intermediate compound,namely titanium nitrate Ti(NO3)4 is taken as a precursor of TiO2, thus the influence of the other impurities in the precipitation process is overcome; by changing the dispersing homogeneous degree ofMnOx and CeO2 on the surface of a carrier TiO2, the activity of the catalyst is improved and the temperature of the SCR reaction is reduced; by adjusting the preparation condition of the TiO2 precursor, the sulfur resistance and water resistance of the catalyst are improved completely; and by adding the elements, such as Fe, Co, Cu, Cr, Zr and Al and the like, the activity and resistance of the catalyst are further modified.

Owner:GUODIAN SCI & TECH RES INST +1

A kind of preparation method of porous silver-titanium composite catalyst

ActiveCN102941086BLarge specific surface areaImprove adsorption capacityMetal/metal-oxides/metal-hydroxide catalystsPtru catalystTriethoxysilane

The present invention discloses a porous silver-titanium composite catalyst preparation method, and belongs to the field of sewage treatment. The preparation method comprises: weighing silver nitrate, titanium tetranitrate and urea, and preparing into a solution, wherein a molar ratio of Ag<+> to Ti<4+> to urea is 2:1:10-4:1:10, and the total concentration of Ag<+> ions and Ti<4+> ions is 4-6 mol / L; carrying out crystallization on the prepared solution for 24-36 h at a temperature of 120-130 DEG C to obtain silver-titanium type hydrotalcite; adding the hydrotalcite to water to prepare a suspension liquid with a solid-liquid ratio of 1:30-1:50, adding an anion surfactant, and stirring for 2-3 h, wherein per g of the hydrotalcite is added with 1-2 mmol of the anion surfactant; and dissolving 30-60 mmol of aminopropyltriethoxysilane in 50 ml of absolute ethanol, adding the obtained solution to the hydrotalcite suspension liquid in a dropwise manner, carrying out solid-liquid separation, drying at a temperature of 90-105 DEG C, and carrying out calcination at a temperature of 450-550 DEG C to prepare the porous silver-titanium composite catalyst with characteristics of large specific surface area, absorption promotion, and good catalysis effect.

Owner:江阴智产汇知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com