Preparation method of anticorrosive paint for coastal electrical equipment

A technology for power equipment and anti-corrosion coatings, applied in anti-corrosion coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems affecting human health, economic losses, heavy metal pollution, etc., to improve corrosion resistance and UV aging resistance Performance, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

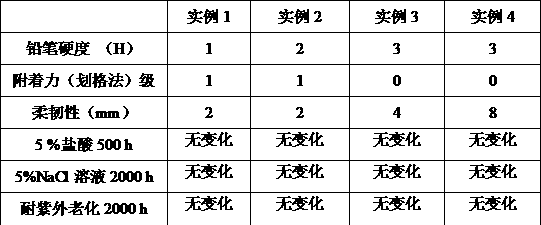

Embodiment 1

[0015] Add hydroxyacrylate to ethyl acetate solvent to prepare a solution with a concentration of 15 wt%, heat and stir evenly; add fluororesin after cooling (mass ratio, hydroxyacrylic resin: fluororesin=1:4), continue to stir evenly, and then add Silica (1 wt%, relative to the total mass of the resin) and titanium nitride (1 wt%, relative to the total mass of the resin) were stirred vigorously for 10 min. After mixing evenly, add hexamethylene diisocyanate (molar ratio, -NCO:-OH=1.5:1), leveling agent (BYK 333, 0.5 wt%) and defoamer (polyether modified silicone, 0.5 wt%) Wait, stir vigorously for 30 minutes, then add butyltin dilaurate (0.5 wt%) catalyst, and stir for another 10 minutes to obtain a special anti-corrosion coating for electric equipment. The amount of butyltin dilaurate catalyst, leveling agent, and defoamer added is calculated according to the total mass of hydroxyacrylate, fluorine-containing resin, and isocyanate.

Embodiment 2

[0017] Add hydroxyacrylate to ethyl acetate solvent to prepare a solution with a concentration of 15 wt%, heat and stir evenly; add fluororesin after cooling (mass ratio, hydroxyacrylic resin: fluororesin=2:3), continue to stir evenly, and then add Silica (1 wt%, relative to the total mass of the resin) and titanium nitride (1 wt%, relative to the total mass of the resin) were stirred vigorously for 10 min. After mixing evenly, add hexamethylene diisocyanate (molar ratio, -NCO:-OH=1.5:1), leveling agent (BYK 333, 0.5 wt%) and defoamer (polyether modified silicone, 0.5 wt%) Wait, stir vigorously for 30 minutes, then add butyltin dilaurate (0.5%) catalyst, and stir for another 10 minutes to obtain a special anti-corrosion coating for electric equipment. The amount of hydroxyacrylate, butyltin dilaurate catalyst, leveling agent and defoamer added is calculated according to the total mass of hydroxyacrylate, fluorine-containing resin and isocyanate.

Embodiment 3

[0019] Add hydroxyacrylate to ethyl acetate solvent to prepare a solution with a concentration of 15 wt%, heat and stir evenly; add fluororesin after cooling (mass ratio, hydroxyacrylic resin: fluororesin=3:2), continue to stir evenly, and then add Silica (1 wt%, relative to the total mass of the resin) and titanium nitride (1 wt%, relative to the total mass of the resin) were stirred vigorously for 10 min. After mixing evenly, add hexamethylene diisocyanate (molar ratio, -NCO:-OH=1.5:1), leveling agent (BYK 333, 0.5 wt%) and defoamer (polyether modified silicone, 0.5 wt%) Wait, stir vigorously for 30 minutes, then add butyltin dilaurate (0.5 wt%) catalyst, and stir for another 10 minutes to obtain a special anti-corrosion coating for electric equipment. The amount of butyltin dilaurate catalyst, leveling agent, and defoamer added is calculated according to the total mass of hydroxyacrylate, fluorine-containing resin, and isocyanate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com