Preparation method of nano titanium diboride powder

A nano-titanium diboride, titanium diboride technology, applied in nanotechnology, nanotechnology, boron/boride, etc., can solve the problems of poor powder dispersion, uneven particle size distribution, and many structural defects , to achieve the effects of accelerating the ball milling process, enhancing surface activity, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention proposes a preparation method of nano titanium diboride powder, the steps are as follows:

[0020] Step 1, preparing titanium diboride coarse powder

[0021] According to the weight ratio of 1:3~5:2~3, take titanium nitrate, magnesium powder, and boron tribromide and place them in a sealed high-pressure reactor, and react at 200~300°C for 1~5 hours, and the reaction product is washed with acid Remove impurities, filter, and dry to obtain titanium diboride coarse powder, which contains some titanium nitride impurities (titanium nitride cannot be removed by pickling).

[0022] Step 2, ball milling to prepare nano-titanium diboride powder

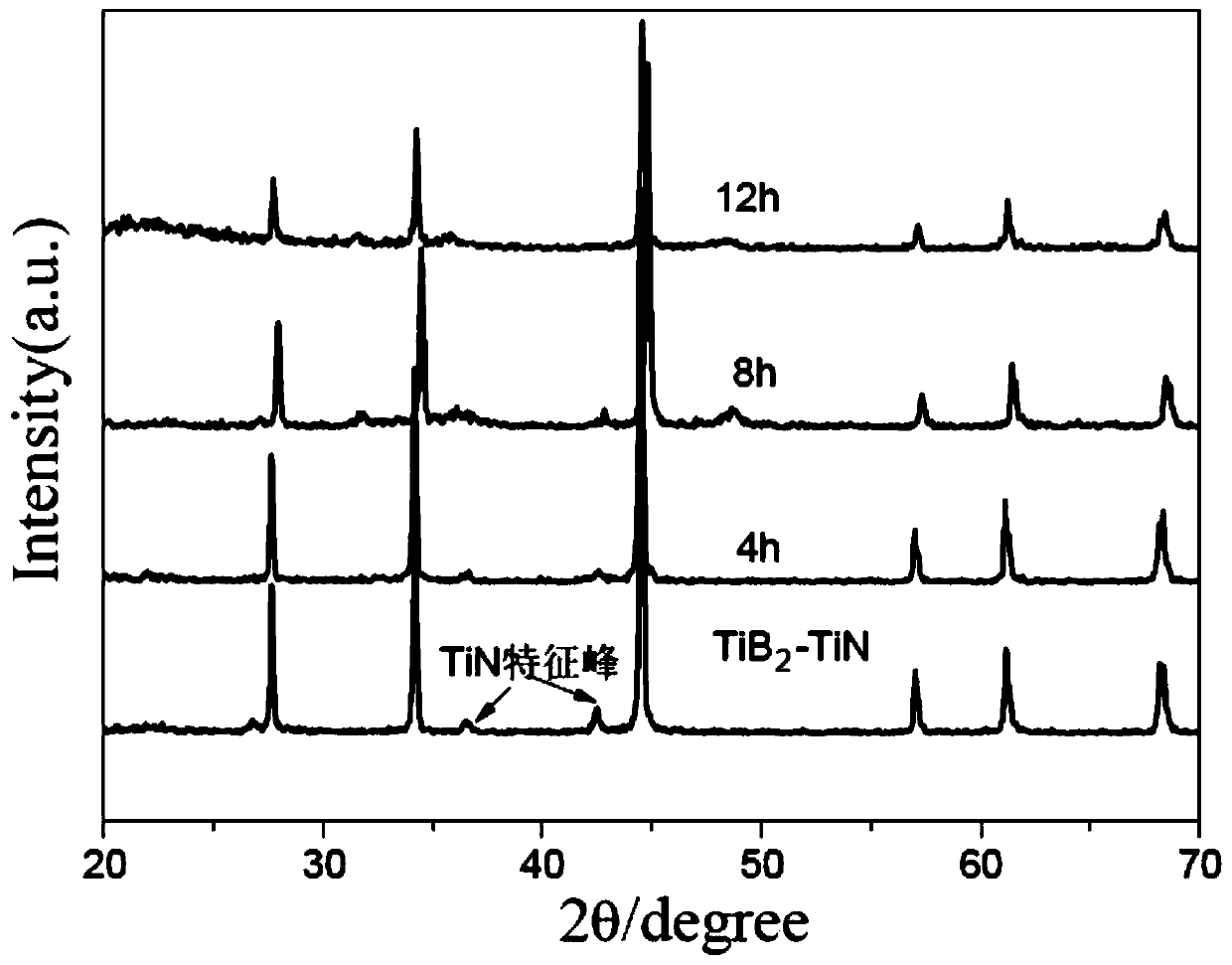

[0023] Put the ball mill tank containing titanium diboride coarse powder and grinding aid ethylene glycol (the weight ratio of the two is 1:1) into the plasma ball mill, set the rotation speed of 300-600 rpm and the milling time ( 4, 8, 12 hours) after ball milling.

[0024] After the ball milling is finished, t...

Embodiment 1

[0032] The preparation of nano titanium diboride powder, the steps are as follows:

[0033] Step 1, preparing titanium diboride coarse powder

[0034] According to the weight ratio of 1:3:2, take titanium nitrate, magnesium powder, and boron tribromide in a sealed high-pressure reactor, and react at 260°C for 3 hours. The reaction product is washed with acid to remove impurities, filtered, and dried to obtain two Coarse titanium boride powder contains some titanium nitride impurities.

[0035] Step 2, ball milling to prepare nano-titanium diboride powder

[0036] Put the ball mill tank containing titanium diboride coarse powder and grinding aid ethylene glycol (the weight ratio of the two is 1:1) into the plasma ball mill, set the speed at 400 rpm and the ball milling time for 4 hours Perform ball milling.

[0037] After the ball milling is finished, the reaction product is taken out and classified to obtain titanium diboride nanopowders with different particle size distrib...

Embodiment 2

[0039] The preparation of nano titanium diboride powder, the steps are as follows:

[0040] Step 1, preparing titanium diboride coarse powder

[0041] According to the weight ratio of 1:5:3, take titanium nitrate, magnesium powder, and boron tribromide in a sealed high-pressure reactor, and react at 220°C for 4 hours. The reaction product is washed with acid to remove impurities, filtered, and dried to obtain two Coarse titanium boride powder contains some titanium nitride impurities.

[0042] Step 2, ball milling to prepare nano-titanium diboride powder

[0043] Put the ball mill tank containing titanium diboride coarse powder and grinding aid ethylene glycol (the weight ratio of the two is 1:1) into the plasma ball mill, set the speed at 600 rpm and the ball milling time for 8 hours Perform ball milling.

[0044] After the ball milling is finished, the reaction product is taken out and classified to obtain titanium diboride nanopowders with different particle size distrib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com