Low-temperature high-activity nano-composite catalyst for methanation of synthesis gas and preparation method thereof

A nanocomposite and catalyst technology, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems of large environmental impact and impact on catalyst performance, achieve high dispersion, improve conversion rate and selectivity, and improve activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

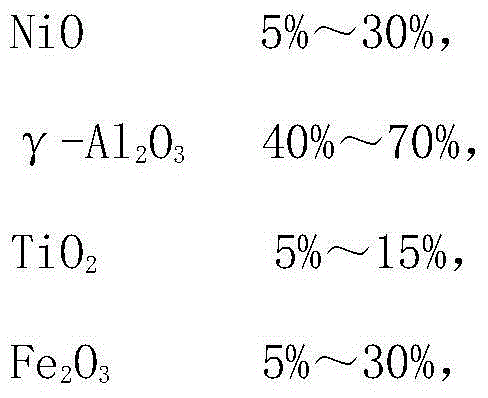

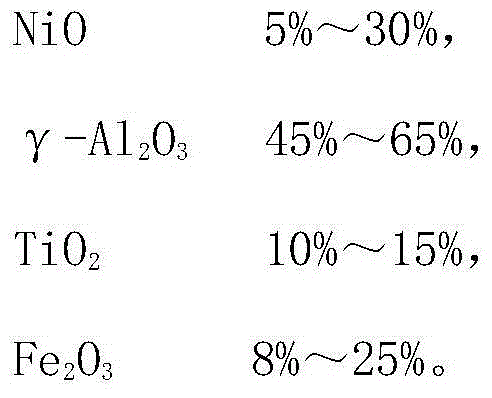

Embodiment 1

[0036] The preparation method of the present embodiment comprises the following steps:

[0037] Step 1. Weigh 42.8ml of tetrabutyl titanate and mix with 128.4ml of absolute ethanol, and stir evenly to obtain tetrabutyl titanate ethanol mixed solution;

[0038] Step 2: Mix 85.6ml of deionized water with 85.6ml of absolute ethanol, add glacial acetic acid to control the pH between 3 and 4, and obtain a mixed aqueous solution of ethanol and acetic acid;

[0039] Step 3. At room temperature, use a peristaltic pump to slowly drop the ethanol-acetic acid mixed aqueous solution into the tetrabutyl titanate ethanol mixed solution, stir vigorously to hydrolyze the tetrabutyl titanate, and continue stirring for 3 hours to obtain a sol;

[0040] Step 4. Slowly add 0.9g γ-Al to the obtained sol at 80°C 2 o 3 The carrier, the sol gradually loses its fluidity and forms a gel, which is dried at a constant temperature of 100°C for 24 hours to remove moisture, organic groups and organic solv...

Embodiment 2

[0045] The preparation method of the present embodiment comprises the following steps:

[0046] Step 1. Weigh 42.8ml of tetrabutyl titanate and mix with 128.4ml of absolute ethanol, and stir evenly to obtain tetrabutyl titanate ethanol mixed solution;

[0047] Step 2: Mix 85.6ml of deionized water with 85.6ml of absolute ethanol, add glacial acetic acid to control the pH between 3 and 4, and obtain a mixed aqueous solution of ethanol and acetic acid;

[0048] Step 3. At room temperature, use a peristaltic pump to slowly drop the ethanol-acetic acid mixed aqueous solution into the tetrabutyl titanate ethanol mixed solution, stir vigorously to hydrolyze the tetrabutyl titanate, and continue stirring for 3 hours to obtain a sol;

[0049] Step 4. Slowly add 0.9g γ-Al to the obtained sol at 80°C 2 o 3 The carrier, the sol gradually loses its fluidity and forms a gel, which is dried at a constant temperature of 100°C for 24 hours to remove moisture, organic groups and organic solv...

Embodiment 3

[0054] The preparation method of the present embodiment comprises the following steps:

[0055] Step 1. Weigh 42.8ml of tetrabutyl titanate and mix with 128.4ml of absolute ethanol, and stir evenly to obtain tetrabutyl titanate ethanol mixed solution;

[0056] Step 2: Mix 85.6ml of deionized water with 85.6ml of absolute ethanol, add glacial acetic acid to control the pH between 3 and 4, and obtain a mixed aqueous solution of ethanol and acetic acid;

[0057] Step 3. At room temperature, use a peristaltic pump to slowly drop the ethanol-acetic acid mixed aqueous solution into the tetrabutyl titanate ethanol mixed solution, stir vigorously to hydrolyze the tetrabutyl titanate, and continue stirring for 3 hours to obtain a sol;

[0058] Step 4. Slowly add 0.9g γ-Al to the obtained sol at 80°C 2 o 3 The carrier, the sol gradually loses its fluidity and forms a gel, which is dried at a constant temperature of 100°C for 24 hours to remove moisture, organic groups and organic solv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com