Spherical core-shell type TiO2/TiO2 material and preparation method thereof

A core-shell type, spherical technology, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical/physical processes, etc., can solve the problem of inability to recycle and reuse, obtain dispersible particles, and affect photocatalytic efficiency and other issues, to achieve the effect of photocatalytic activity recovery, reusability, low cost, and reduced risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

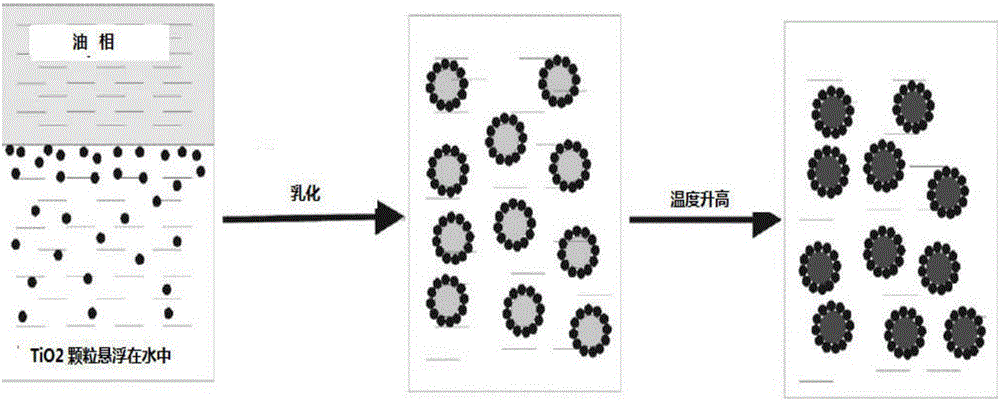

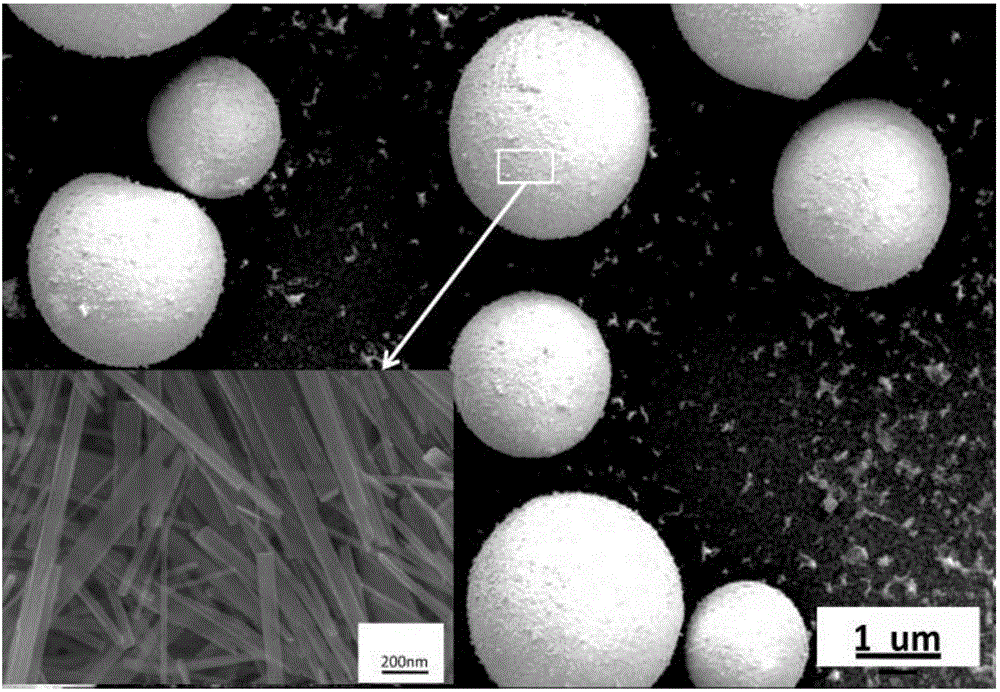

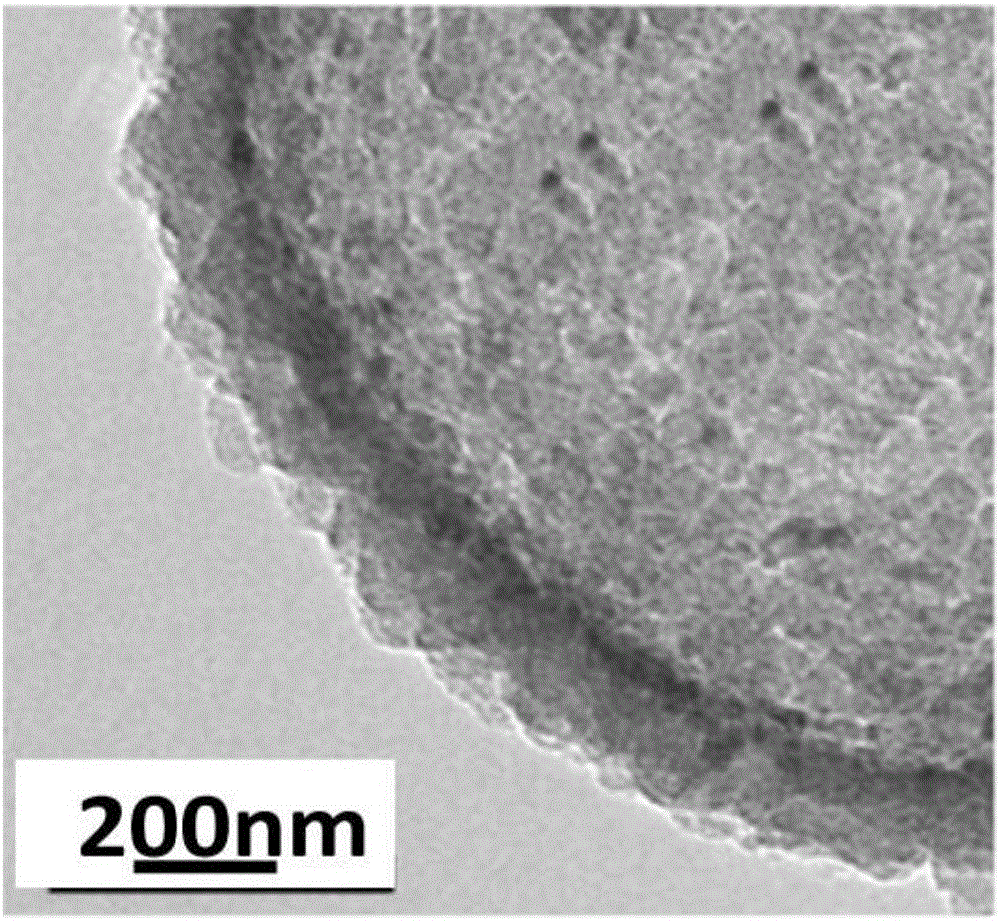

[0034] A kind of spherical core-shell type TiO provided by the invention 2 / TiO 2 Material and preparation method thereof (preparation schematic diagram sees figure 1 ), comprising the following steps: first take commercially available TiO 2 (P25) The powder is placed in a reaction kettle filled with NaOH solution and reacted at 120-300°C for 6-48 hours. The reaction product washed with deionized water is immersed in HCl solution for ion exchange reaction to replace Na + , washed again with deionized water until neutral, and then dried in a blast drying oven at 80°C for 2h. The obtained product is mixed with a solution dissolved in titanium nitrate and urea to form a suspension; the suspension is stirred, mixed and emulsified with liquid paraffin dissolved in Triton X-100 to form a Pickering emulsion; then the above-mentioned emulsion is placed at 60- React in an oil bath at 150°C for 3 to 10 hours to obtain a precipitate, which is distilled, dried, and calcined to obtain s...

Embodiment 1

[0042] (1) Commercially purchased TiO 2 (P25) 2g of powder was placed in a reaction kettle filled with 70ml of 5.3mol / l NaOH solution and reacted at 140°C for 24h, and the reaction product was washed with deionized water to obtain a white titanium dioxide nanotube precursor.

[0043] (2) Submerge the product obtained in (1) in a 0.1 mol / l HCl solution for 1 hour of ultrasonication, then let it stand for 24 hours, and then wash it with deionized water until neutral.

[0044] (3) Dry the product obtained in (2) at 80° C. for 2 h in a forced air drying oven.

[0045] (4) Dissolve urea and titanium nitrate in 30ml deionized water, press Ti 4+ The concentration is 0.5mol / L, and the concentration of urea is 3mol / L to make a solution;

[0046] (5) Mix 0.5 g of the product obtained in (3) with the solution described in (4), and magnetically stir for 0.5 h (500 rpm) to form a suspension;

[0047] (6) Dissolve 0.1g Triton X-100 in 20ml liquid paraffin, stir magnetically for 0.5h (500...

Embodiment 2

[0052] (1) Commercially purchased TiO 2 (P25) 2g of powder was placed in a reaction kettle filled with 70ml of 10mol / l KOH solution and reacted at 220°C for 36h, and the reaction product was washed with deionized water to obtain a white titanium dioxide nanowire precursor.

[0053] (2) Submerge the product obtained in (1) in a 0.1 mol / l HCl solution for 1 hour of ultrasonication, then let it stand for 24 hours, and then wash it with deionized water until neutral.

[0054] (3) Dry the product obtained in (2) at 80° C. for 2 h in a forced air drying oven.

[0055] (4) Dissolve urea and titanium nitrate in 30ml deionized water, press Ti 4+ The concentration is 1.0mol / L, and the concentration of urea is 6mol / L to prepare a solution;

[0056] (5) Mix 0.5 g of the product obtained in (3) with the solution described in (4), and magnetically stir for 0.5 h (500 rpm) to form a suspension;

[0057] (6) Dissolve 0.1g Triton X-100 in 20ml liquid paraffin, stir magnetically for 0.5h (50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com