Heat dissipation coating and preparation method thereof

A technology for heat-dissipating coatings and metals, applied in anti-corrosion coatings, fire-retardant coatings, coatings, etc., to achieve the effects of good heat resistance, enhanced adhesion, and good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

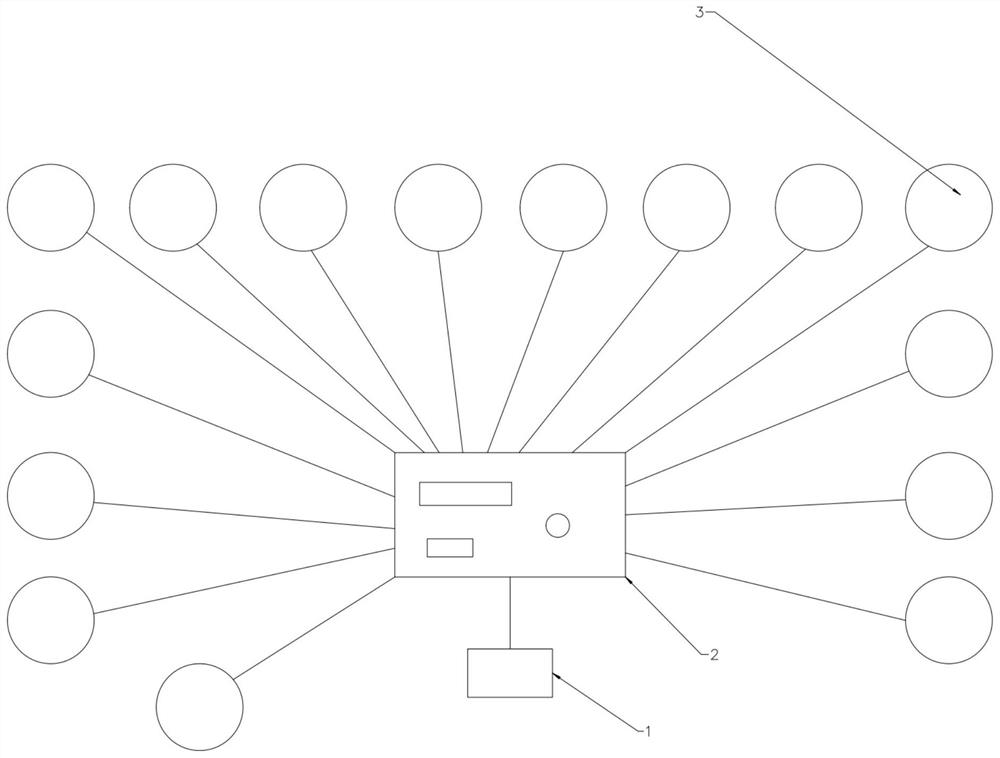

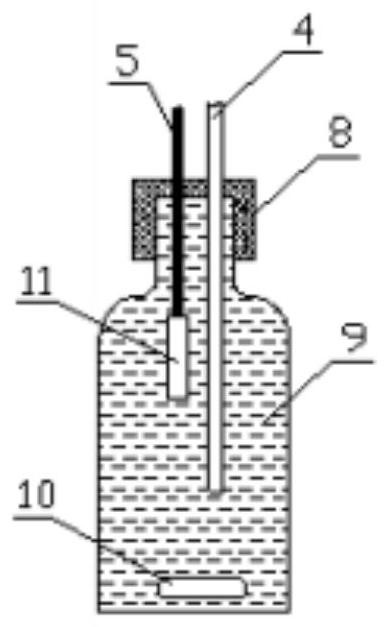

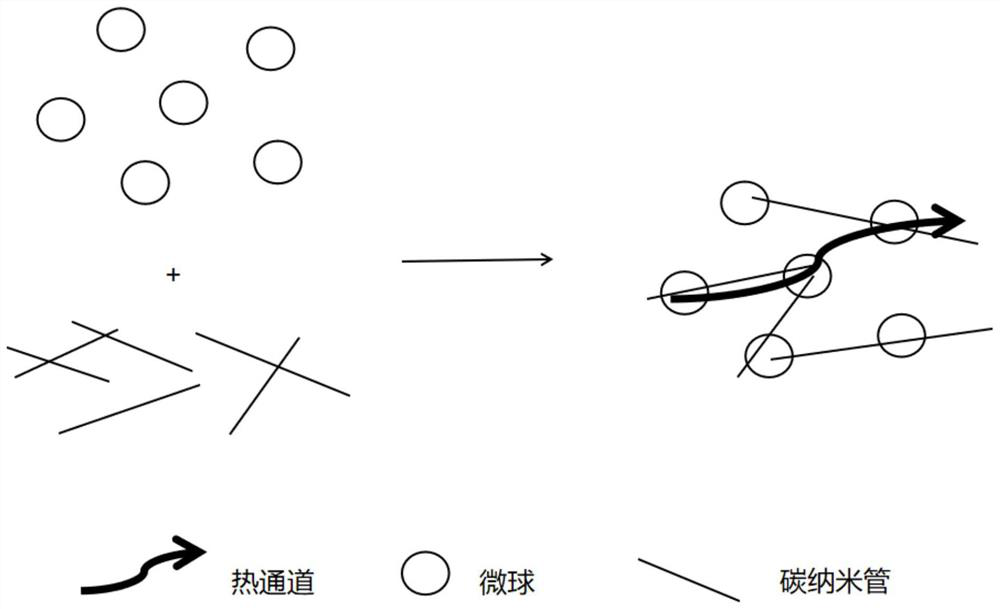

Image

Examples

Embodiment 1

[0057] The present embodiment provides a heat-dissipating paint, specifically comprising the following steps:

[0058] S1. Preparation of metal oxide composite nano-ceramic powder: Dissolve 1g titanium nitrate, 1g aluminum nitrate, and 2g copper nitrate in 100g water, add 15g citric acid, heat to 60°C, evaporate the solvent for 2 hours to obtain a sol; then increase to 150 ℃, reduce the pressure to 0.01MPa to form xerogel, take it out, ignite the xerogel, and grind it finely to obtain metal oxide composite nano-ceramic powder;

[0059]S2. Preparation of ferrite-coated metal oxide nano-ceramic powder: uniformly disperse 10 g of the metal oxide composite nano-ceramic powder prepared in step S1 in 50 g of an aqueous solution containing polyvinyl alcohol, the content of which is 2 wt%. Obtain suspension, be heated to 40 ℃, configure the solution of ferrous sulfate solution and ammonium bicarbonate, the content of ferrous sulfate in ferrous sulfate solution is 15wt%, and the conten...

Embodiment 2

[0064] The present embodiment provides a heat-dissipating paint, specifically comprising the following steps:

[0065] S1. Preparation of metal oxide composite nano-ceramic powder: dissolve 1g titanium nitrate, 3g aluminum nitrate, 4g copper nitrate in 100g water, add 25g sodium citrate, heat to 80°C, evaporate the solvent for 4h to obtain a sol; then increase to 170°C, reduce the pressure to 0.1MPa to form a xerogel, take it out, ignite the xerogel, and grind it finely to obtain metal oxide composite nano-ceramic powder;

[0066] S2. Preparation of ferrite-coated metal oxide nano-ceramic powder: uniformly disperse 10 g of the metal oxide composite nano-ceramic powder prepared in step S1 in 50 g of an aqueous solution containing polyvinyl alcohol, the content of which is 7 wt%. Obtain suspension, be heated to 50 ℃, configure the solution of ferrous sulfate solution and ammonium bicarbonate, the content of ferrous sulfate in the ferrous sulfate solution is 20wt%, the content of...

Embodiment 3

[0071] The present embodiment provides a heat-dissipating paint, specifically comprising the following steps:

[0072] S1. Preparation of metal oxide composite nano-ceramic powder: Dissolve 1g titanium nitrate, 2g aluminum nitrate, and 3g copper nitrate in 100g water, add 20g citric acid, heat to 70°C, evaporate the solvent for 3h to obtain a sol; then increase to 160 ℃, reduce the pressure to 0.05MPa to form xerogel, take it out, ignite the xerogel, and grind it finely to obtain metal oxide composite nano-ceramic powder;

[0073] S2. Preparation of ferrite-coated metal oxide nano-ceramic powder: uniformly disperse 10 g of the metal oxide composite nano-ceramic powder prepared in step S1 in 50 g of an aqueous solution containing polyvinyl alcohol, the content of which is 5 wt%. Obtain suspension, be heated to 45 ℃, configure the solution of ferrous sulfate solution and ammonium bicarbonate, the content of ferrous sulfate in ferrous sulfate solution is 17wt%, and the content of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com