Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

68 results about "Solvent effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

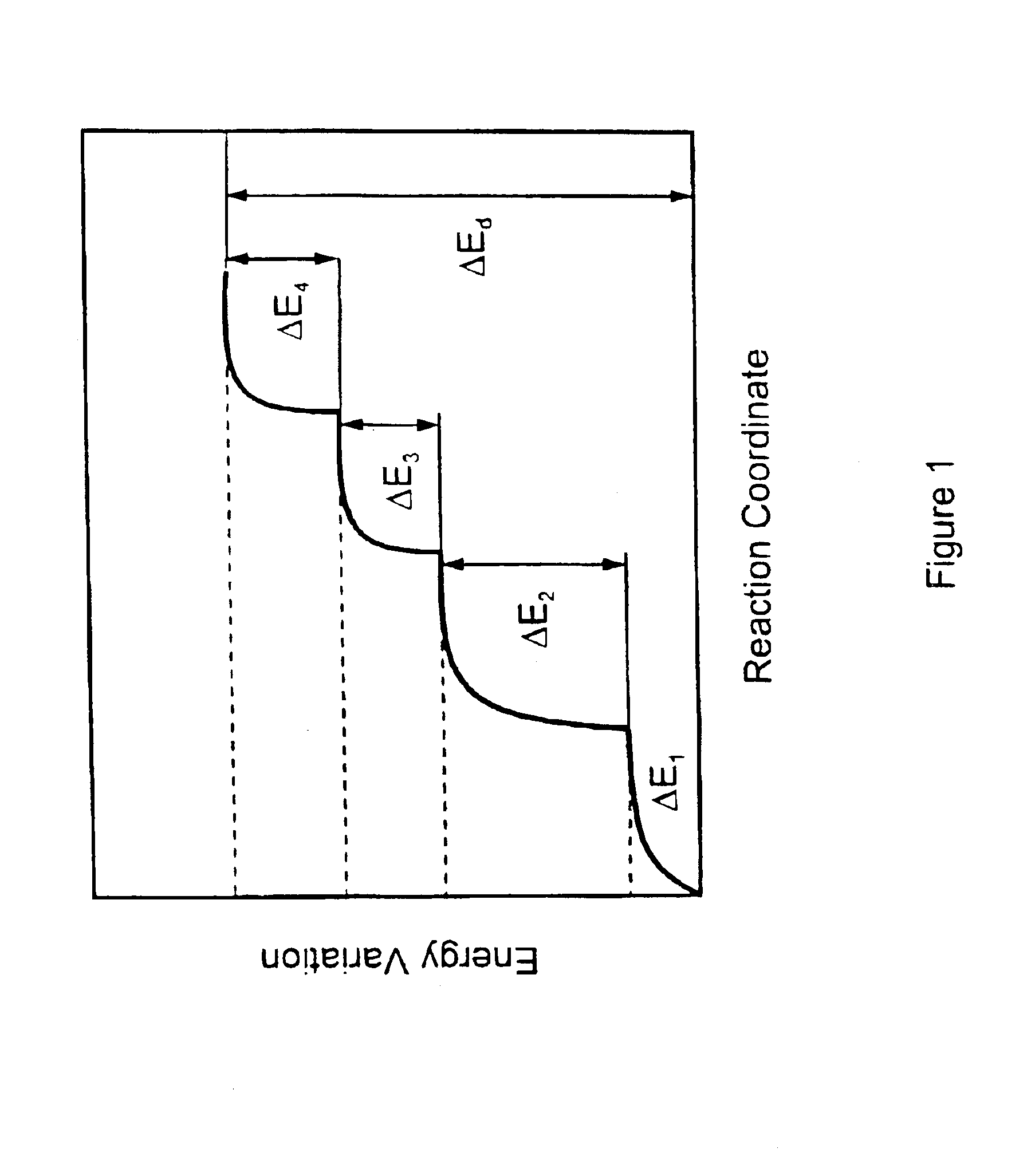

In chemistry, solvent effects are the influence of a solvent on chemical reactivity or molecular associations. Solvents can have an effect on solubility, stability and reaction rates and choosing the appropriate solvent allows for thermodynamic and kinetic control over a chemical reaction.

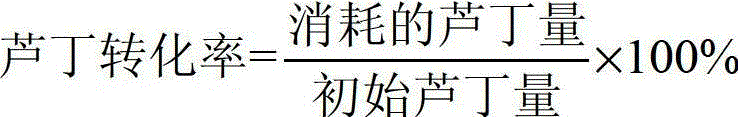

Method of ionic liquid cosolvent effect reinforced enzymatic synthesis of isoquercitrin

The invention relates to a method of ionic liquid cosolvent effect reinforced enzymatic synthesis of isoquercitrin. The method comprises a reaction system for synthesizing isoquercitrin by hydrolyzing rutin with a hesperidin enzyme or a naringin enzyme. The reaction system comprises a rutin mother liquid prepared by a disodium hydrogen phosphate-citrate buffer solution and a hesperidin enzyme liquid or a naringin enzyme liquid. The reaction system contains an ionic liquid formed by cations and anions. In the ionic liquid cosolvent system, the prepared isoquercitrin by hydrolyzing rutin under enzyme catalysis has increased reaction rate and higher yield than that in a conventional aqueous solution system, so that the ionic liquid cosolvent system provides a novel reaction medium for the production of isoquercitrin. The method is simple in operation and mild in reaction conditions, is environment-friendly, and has good application prospects.

Owner:JIANGSU UNIV OF SCI & TECH

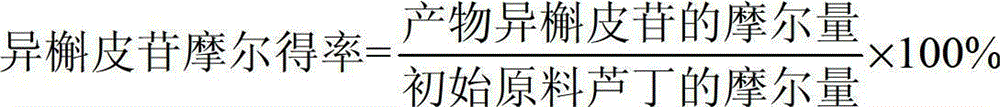

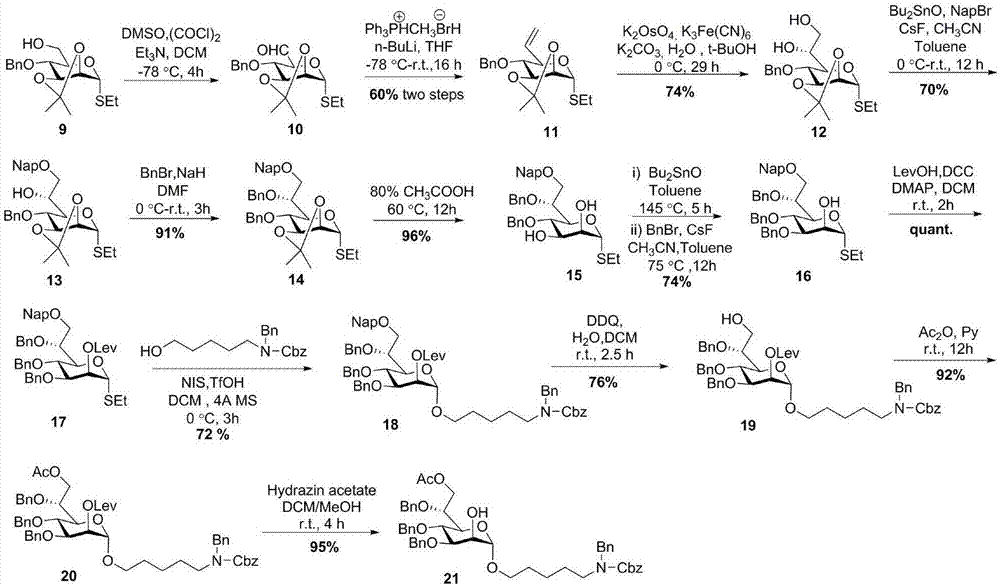

Preparation method of helicobacter pylori lipopolysaccharide outer-core octasaccharide

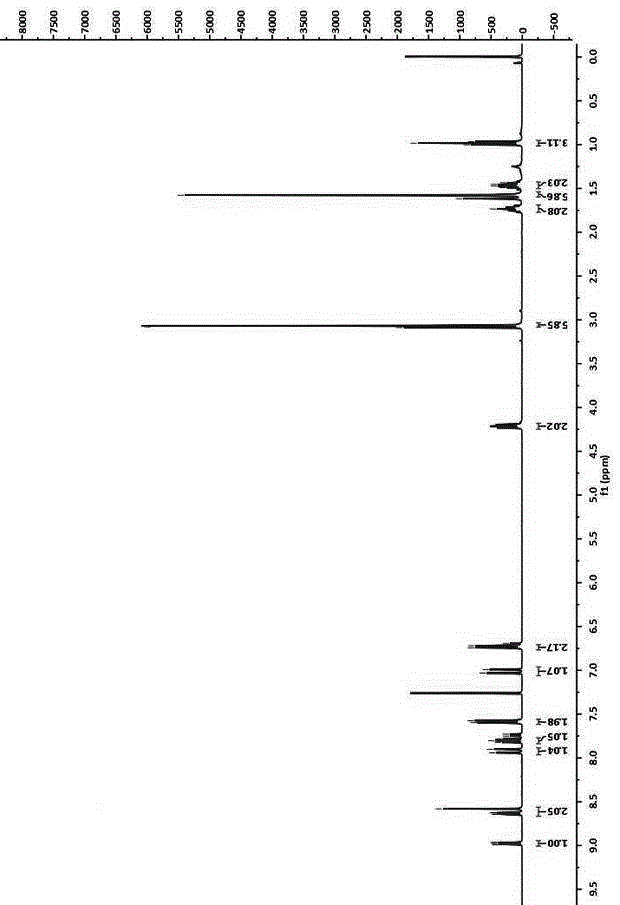

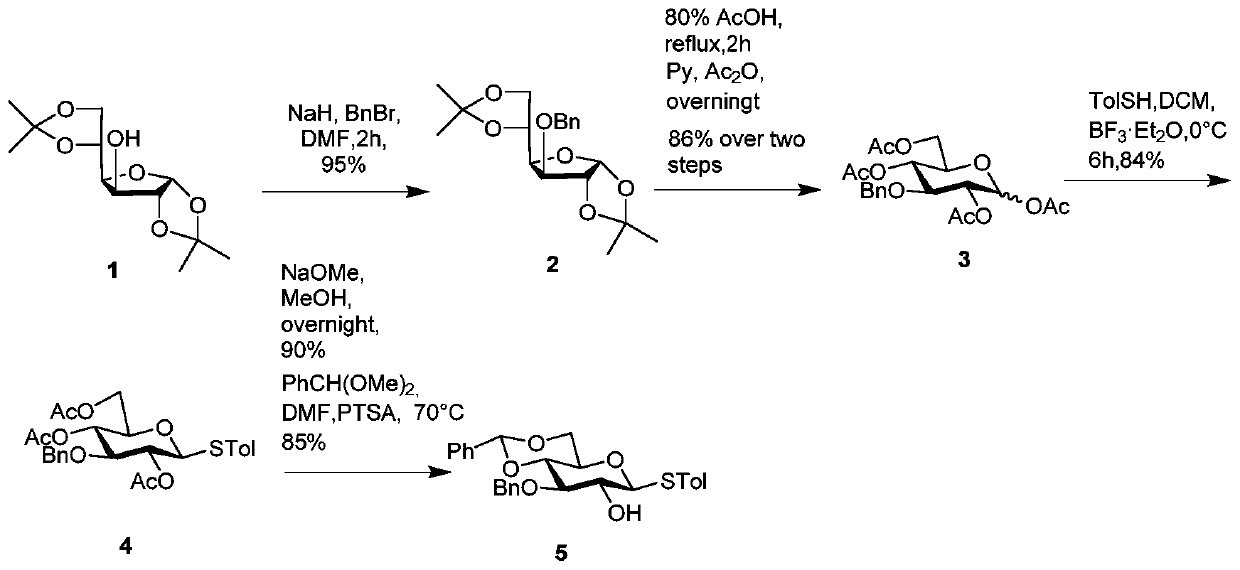

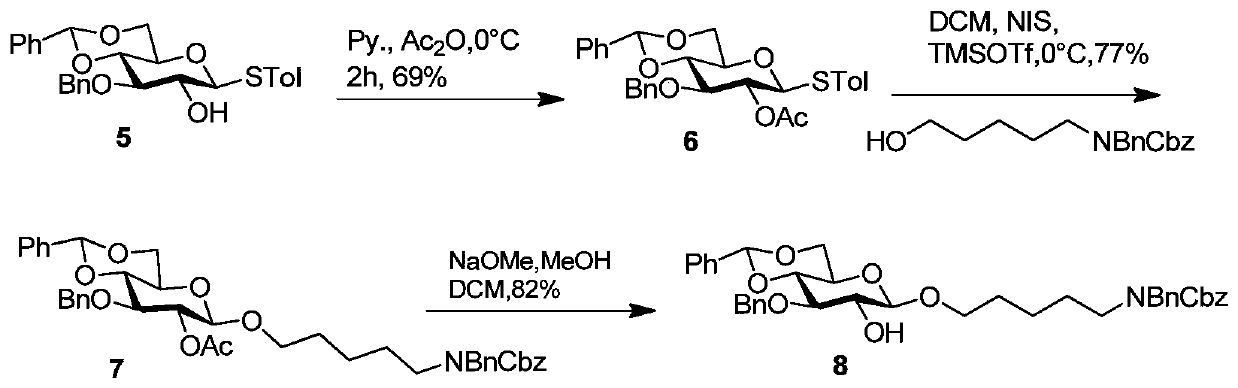

The invention discloses a preparation method of helicobacter pylori lipopolysaccharide outer-core octasaccharide and belongs to the field of chemistry. Structure of the helicobacter pylori lipopolysaccharide outer-core octasaccharide is (alpha-D-Glc-(1-3)-alpha-D-Glc-(1-4)-beta-D-Gal-(1-7)-D-alpha-D-Hep[alpha-D-Glc-(1-6)-alpha-D-Glc-(1-6)-alpha-D-Glc-(1-2)-D-alpha-D-Hep]-Linker. The structure is composed of three kinds of monosaccharide including glucose, galactose and heptasaccharide, wherein the structure contains 5 glucose alpha glucosidic bonds, a galactose beta glucosidic bond and two heptasaccharide alpha glucosidic bonds. The octasaccharide is prepared by utilizing remote neighboring participation effect, solvent effect, temperature effect and synergism of additive and leaving group. A reducing end of the octasaccharide can be connected with a connection arm used for being connected with protein in the future to form glycoconjugate for immunology research.

Owner:JIANGNAN UNIV

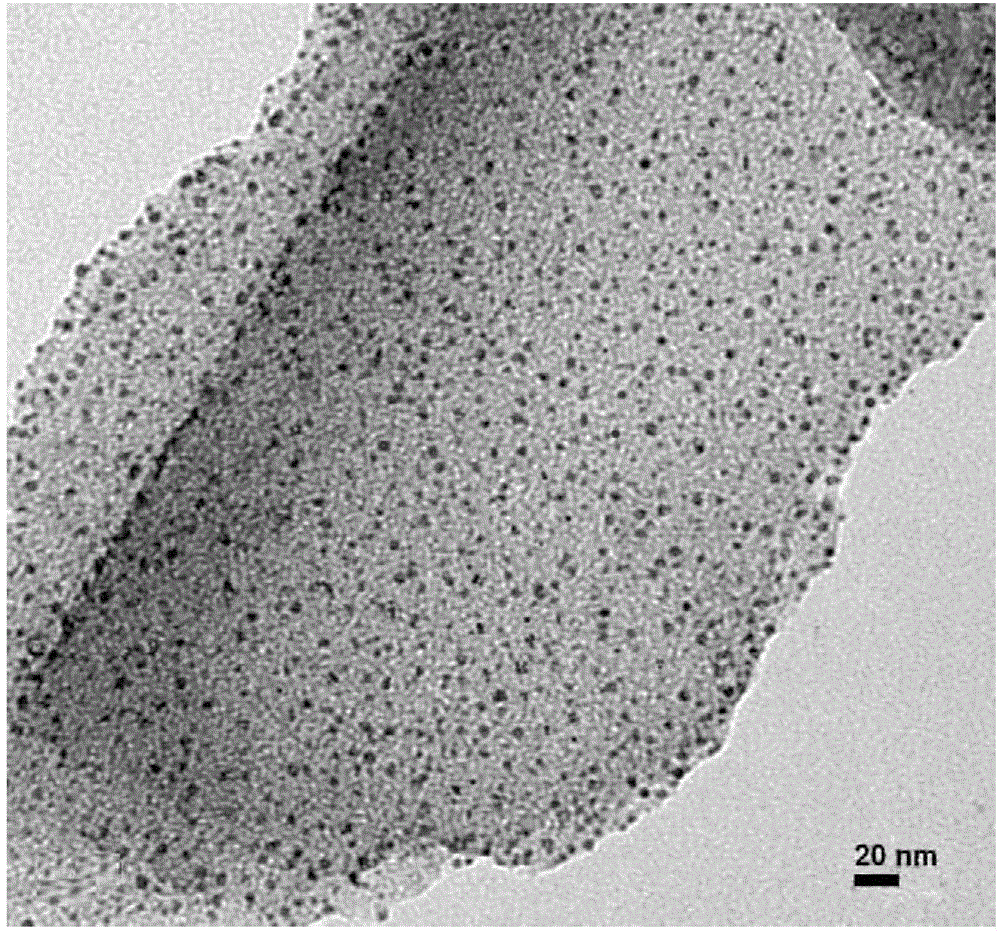

Supported Co-MoS2/LDHS hydro-refining catalyst and application thereof

InactiveCN106268871AUniform particle sizeImprove hydrogenation activityPhysical/chemical process catalystsRefining to eliminate hetero atomsVulcanizationMolybdate

The invention relates to the field of hydro-refining catalysts, in particular to a supported Co-MoS2 / LDHS hydro-refining catalyst prepared by ionic liquid. A compound material has the structures and the performance advantages of cobalt-molybdenum disulfide and hydrotalcite; in a synthetic system, the vulcanization processes of a vulcanizing agent and a molybdate precursor are eliminated, and the dispersing property of molybdenum disulfide is directly improved from raw material control together with solvent effect; the catalyst has good heat resistance, compression resistance and thermal stability.

Owner:朱晨迪

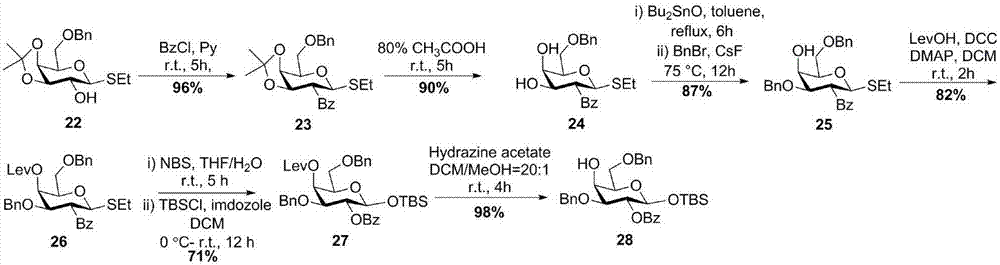

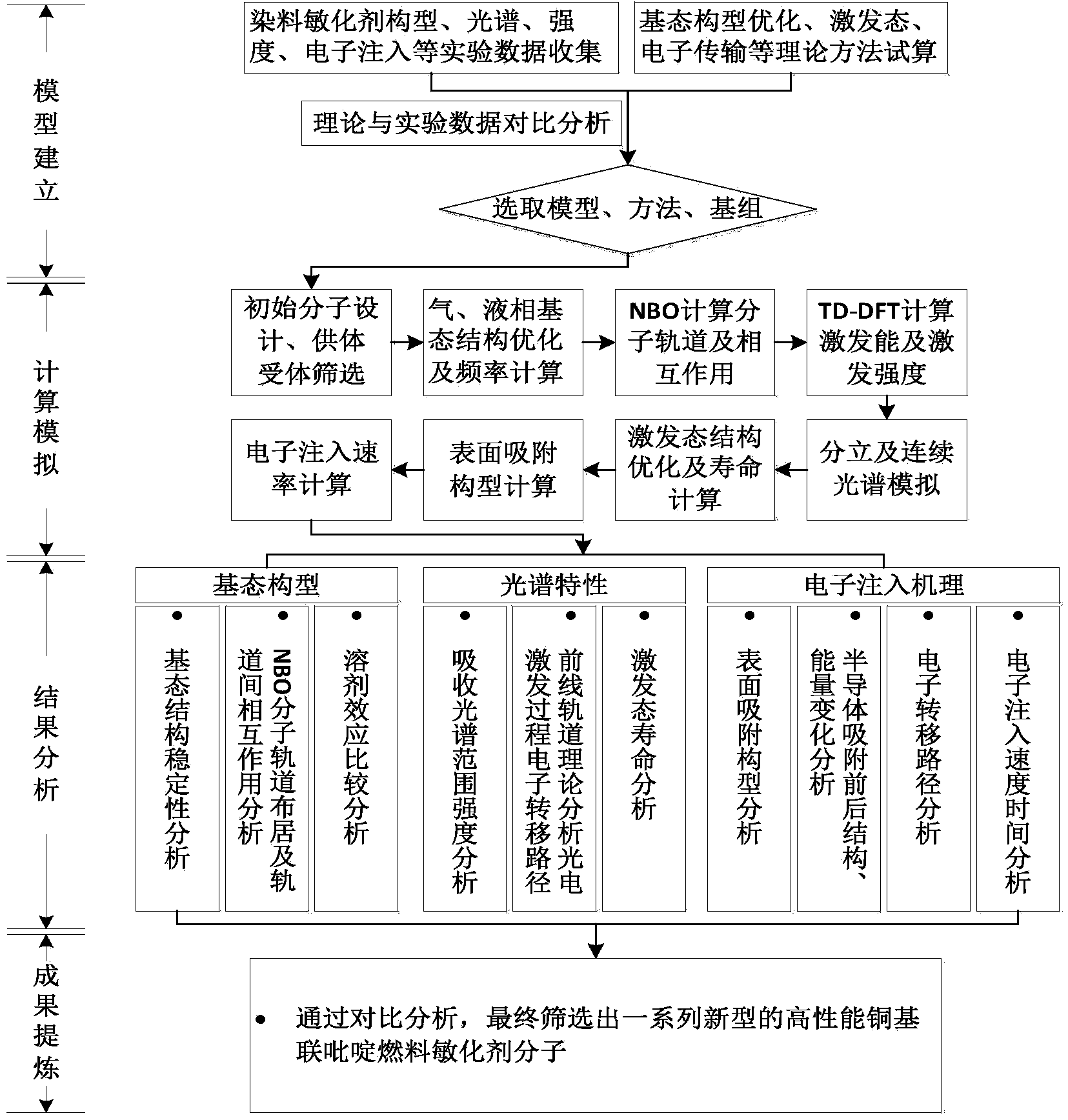

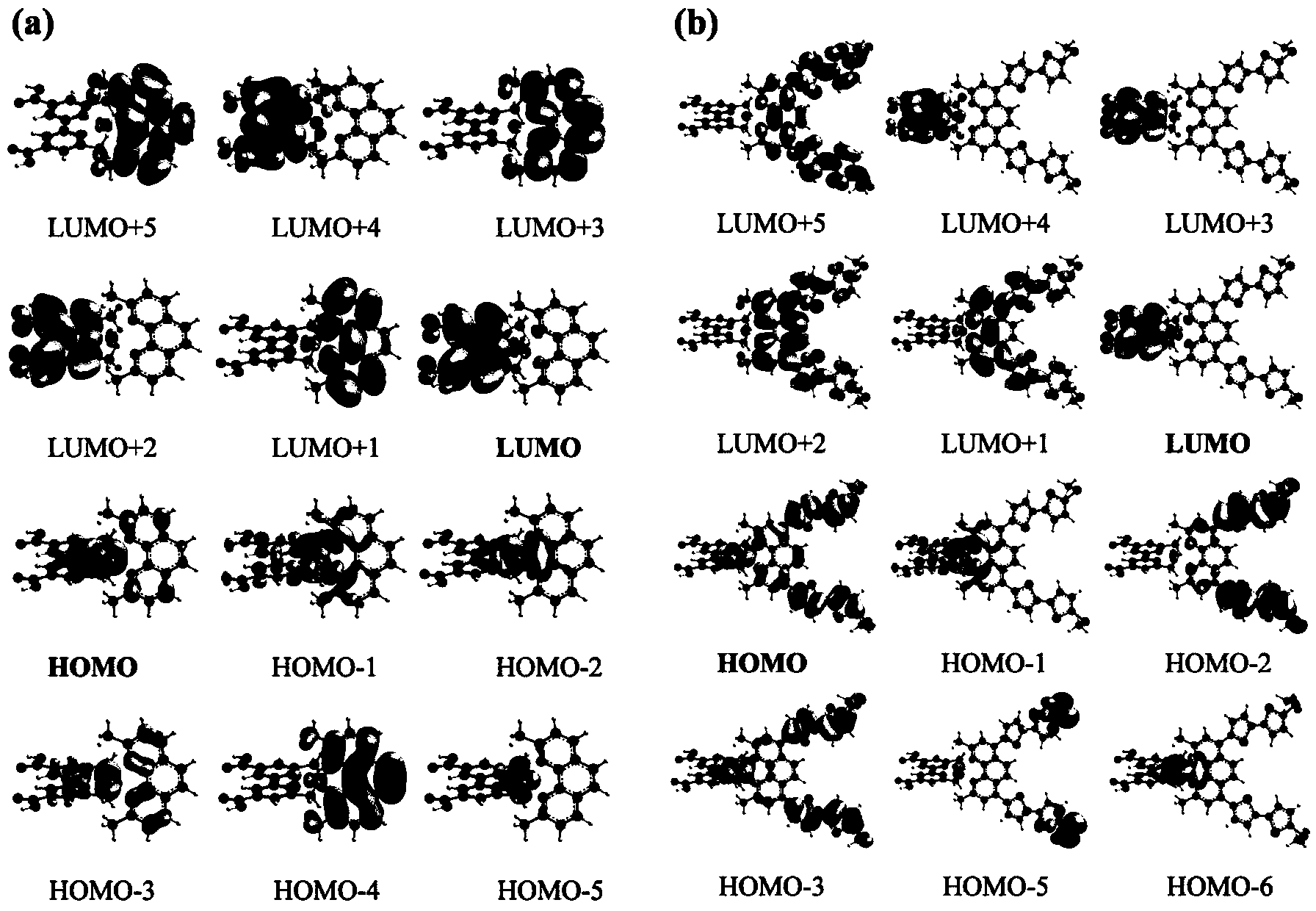

Method for designing and screening copper-based bipyridine dye sensitizer

InactiveCN103955588AAccurate R&D cycleShorten the development cycleLight-sensitive devicesPhotovoltaic energy generationElectronic transmissionUltraviolet

The invention discloses a method for designing and screening a copper-based bipyridine dye sensitizer. The method utilizes a density functional theory (DFT) to structurally design and characterize copper-based bipyridine dye sensitizer molecules; utilizing a natural valence bond theory (NBO) and a frontier molecular orbital theory to analyze the orbit and energy level information of the dye sensitizer molecules; utilizing a time-dependent density functional theory (TD-DFT) to study the Ultraviolet-Visible (UV-VIS) absorption spectroscopy and excited-state lifetime of the dye sensitizer molecules; utilizing the first-principles to optimize the semiconductor adsorption configuration of the dye sensitizer molecules, and analyze electronic excitation and transfer paths; utilizing a Tomasi's Polarized Continuum Model (PCM) to study the solvent effect, the electronic transmission process and the electronic injection rate. The study and development cycle of new materials is shortened, the study and development cost is reduced, the material waste is reduced, a direct theoretical guidance is provided for industrial selection, and design of novel copper-based bipyridine dye sensitizer, and meanwhile, a lot of manpower, material and financial resources can be saved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

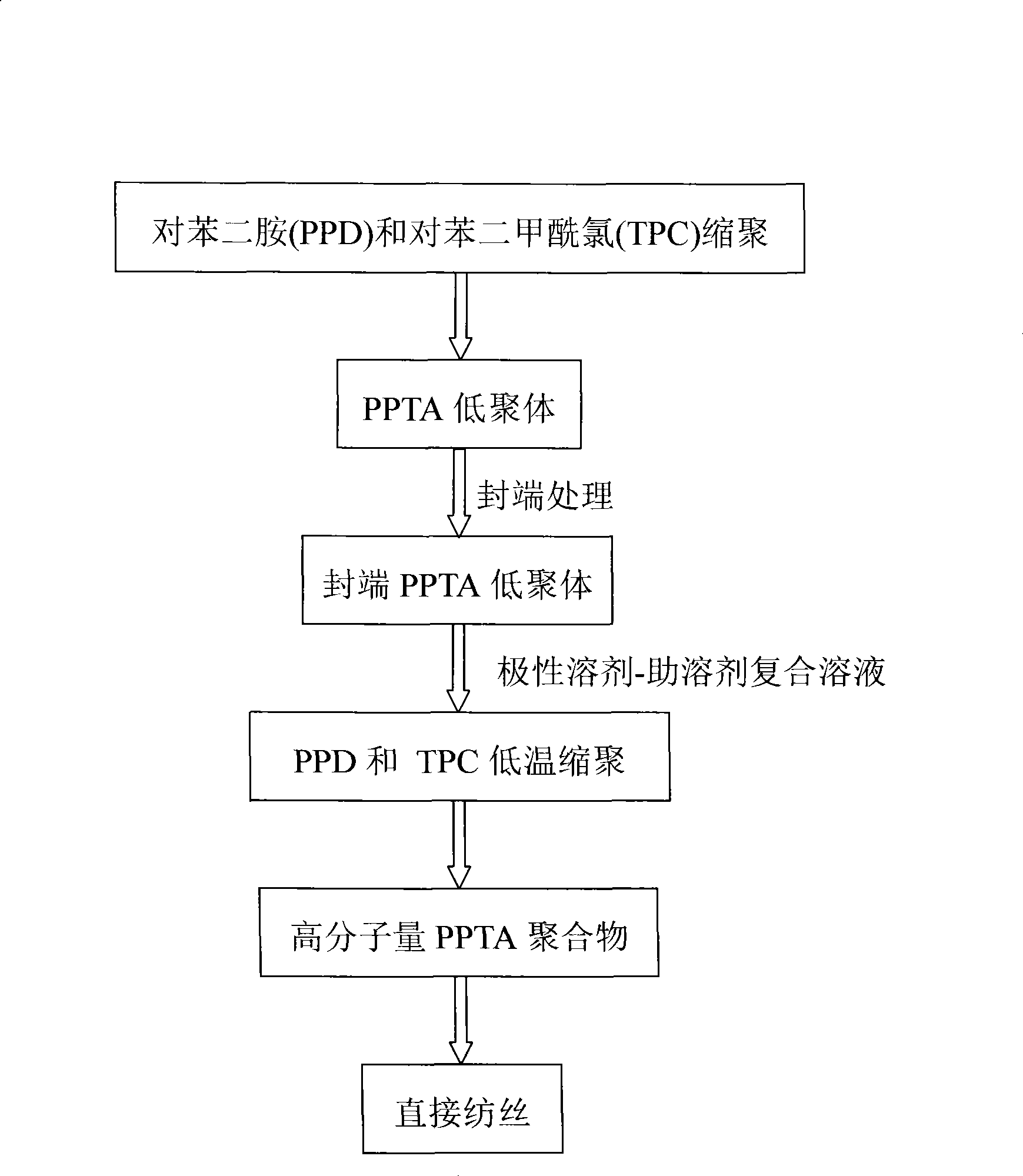

Direct spinning process for preparing PPTA fibre by end capping resin method

InactiveCN101476173AReduce pollutionIncrease productivitySpinning solutions preparationMonocomponent polyamides artificial filamentAramidStock solution

The invention provides a direct spinning technique for preparing polyphenylene terephthalamide by using end capping oligomer. The method includes steps as follows: firstly, polyesterification of phthaloyl chloride and phenylene diamine for obtaining PPTA oligomer with low molecular weight, passivating two ends of molecule using end-capping reagent for forming end capping PPTA resin; secondly, adding polar solvent and latent solvent into the resin for confecting a composite solution; finally, processing solution polyesterification in the composite solution for obtaining PPTA polymer with high molecular weight, and processing stock solution spinning preparing PPTA fibre. The method makes PPTA polymer giant molecule dissolving into the composite solution associated with polar solvent and latent solvent by using reaction inertia and solvent effect of end capping PPTA resin that is convenient for spinning. The method breaches technique difficult problem that the prior liquid crystal spinning technique for preparing aramid fiber with high quality must need concentrated sulfuric acid as solvent, avoid usage of concentrated sulfuric acid with causticity and is hoping to become an universality direct spinning technique with high effect and low cost, green and environmental protective.

Owner:赵海鹏 +1

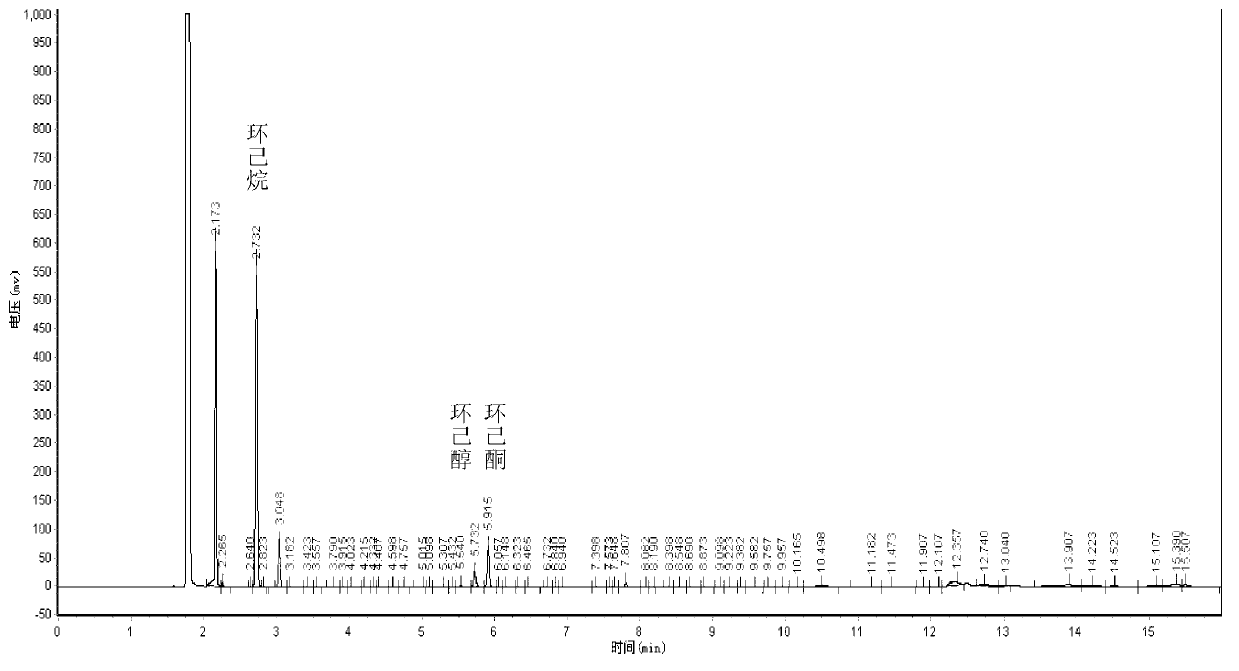

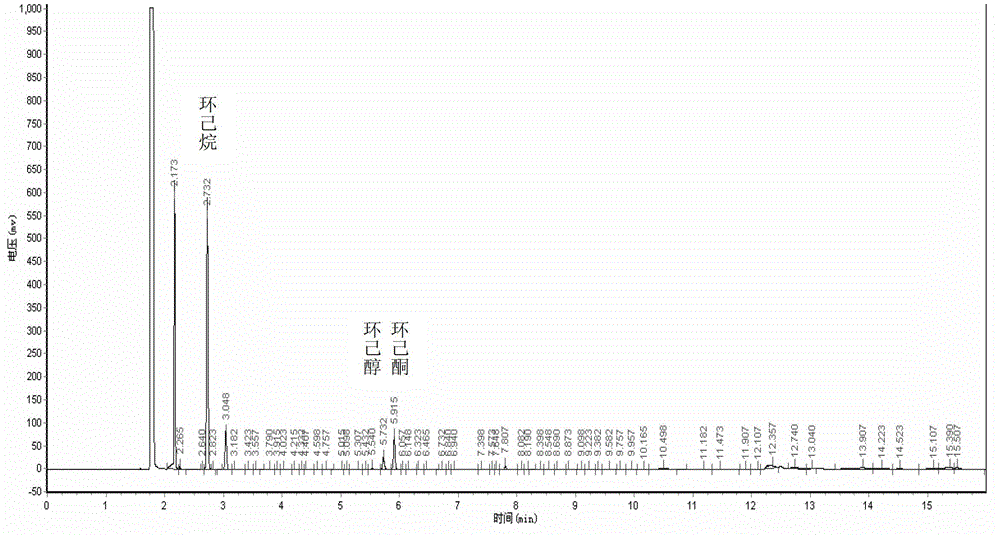

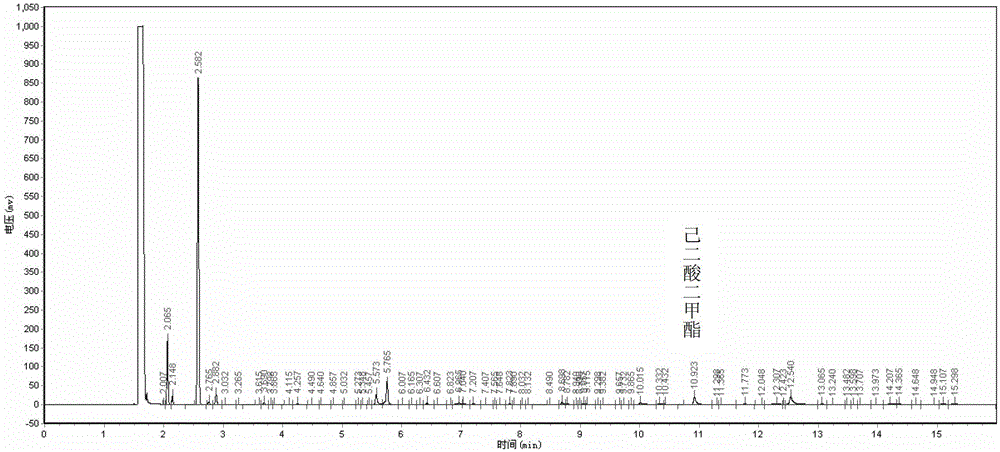

Environment-friendly method for preparing adipic acid by catalytic oxidation

ActiveCN102816054ASimple processSave operating costsOrganic compound preparationCarboxylic compound preparationCyclohexanoneCatalytic oxidation

The invention discloses an environment-friendly method for preparing adipic acid by catalytic oxidation. The method includes: at the beginning of reaction, adding cyclohexane, butanone serving as solvent, cyclohexanone serving as initiators and activated carbon supported nano-gold catalysts into a stainless steel high-pressure reactor; carrying out the catalytic oxidation reaction for 3-14 hours under the pressure of 0.9-2.1MPa at the temperature of 100-150 DEG C; separating after the reaction is completed to obtain the activated carbon supported nano-gold catalysts and reaction liquor, and processing the reaction liquor to obtain adipic acid crystalline solid; collecting the cyclohexanone serving as the initiators by oil-phase vacuum rotary steaming; and washing and drying the activated carbon supported nano-gold catalysts for recycling. By the method, solvent effect of the butanone serving as the solvent is particularly suitable for the nano-gold catalysts to catalyze the cyclohexane to generate the adipic acid by means of selective oxidation, and the problems of low activity and proneness to inactivation of the catalysts in reaction are solved. The method is simple in technological process, convenient for preparing and separating the catalysts, mild in reaction conditions, low in technological cost, economic, efficient and environment-friendly and pollution-free as molecular oxygen substitutes for nitric acid to be used as oxidants.

Owner:ZHEJIANG UNIV

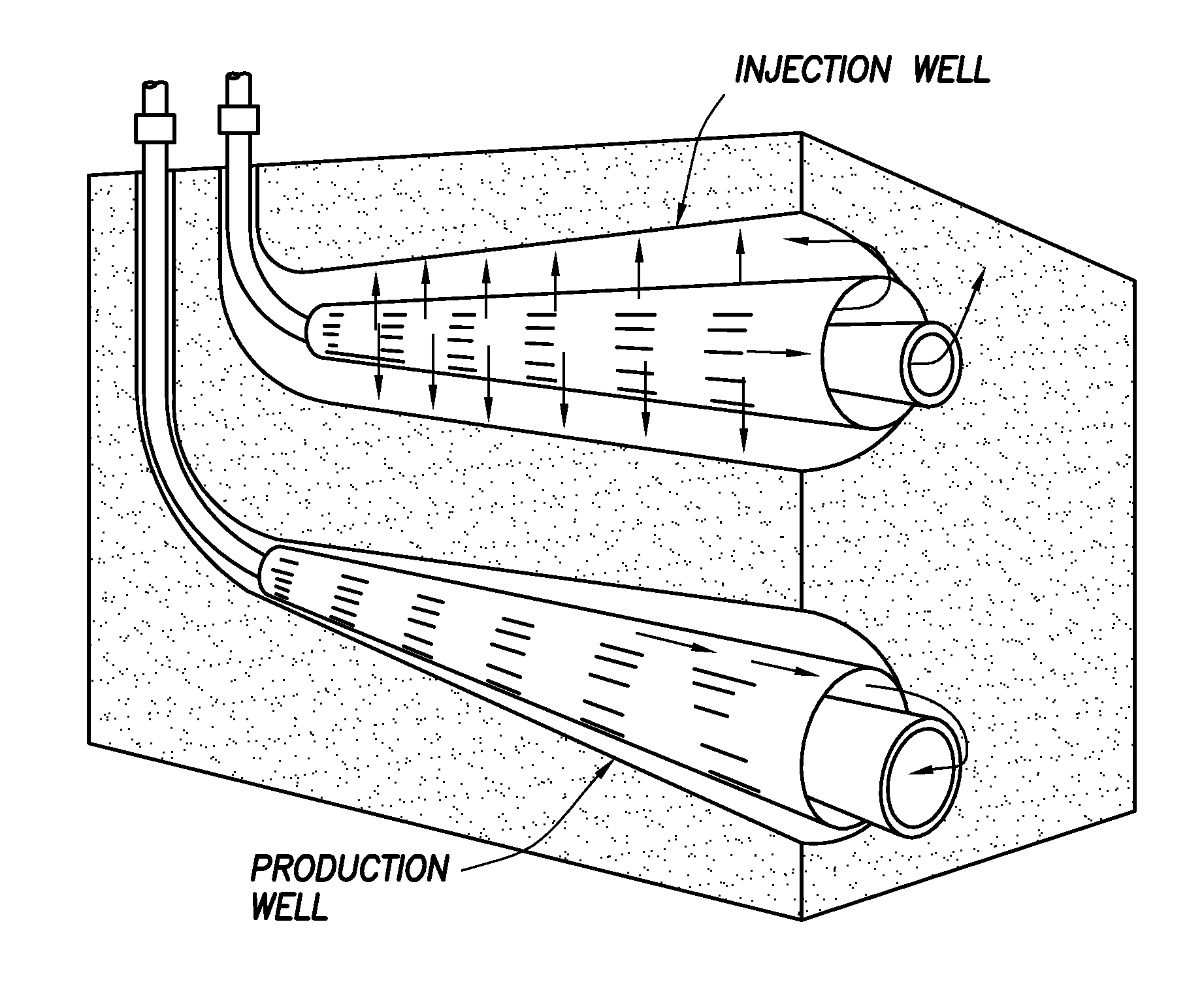

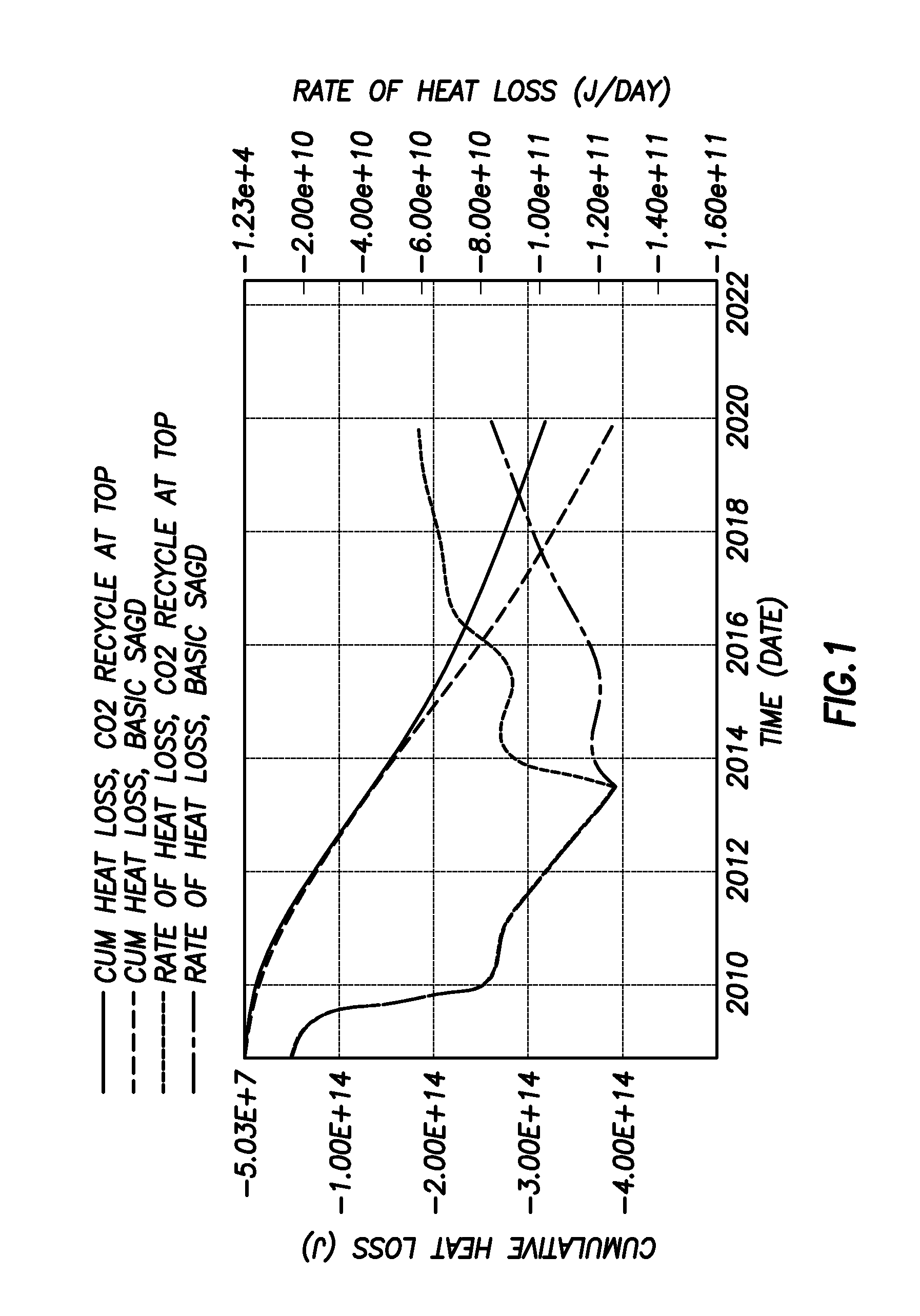

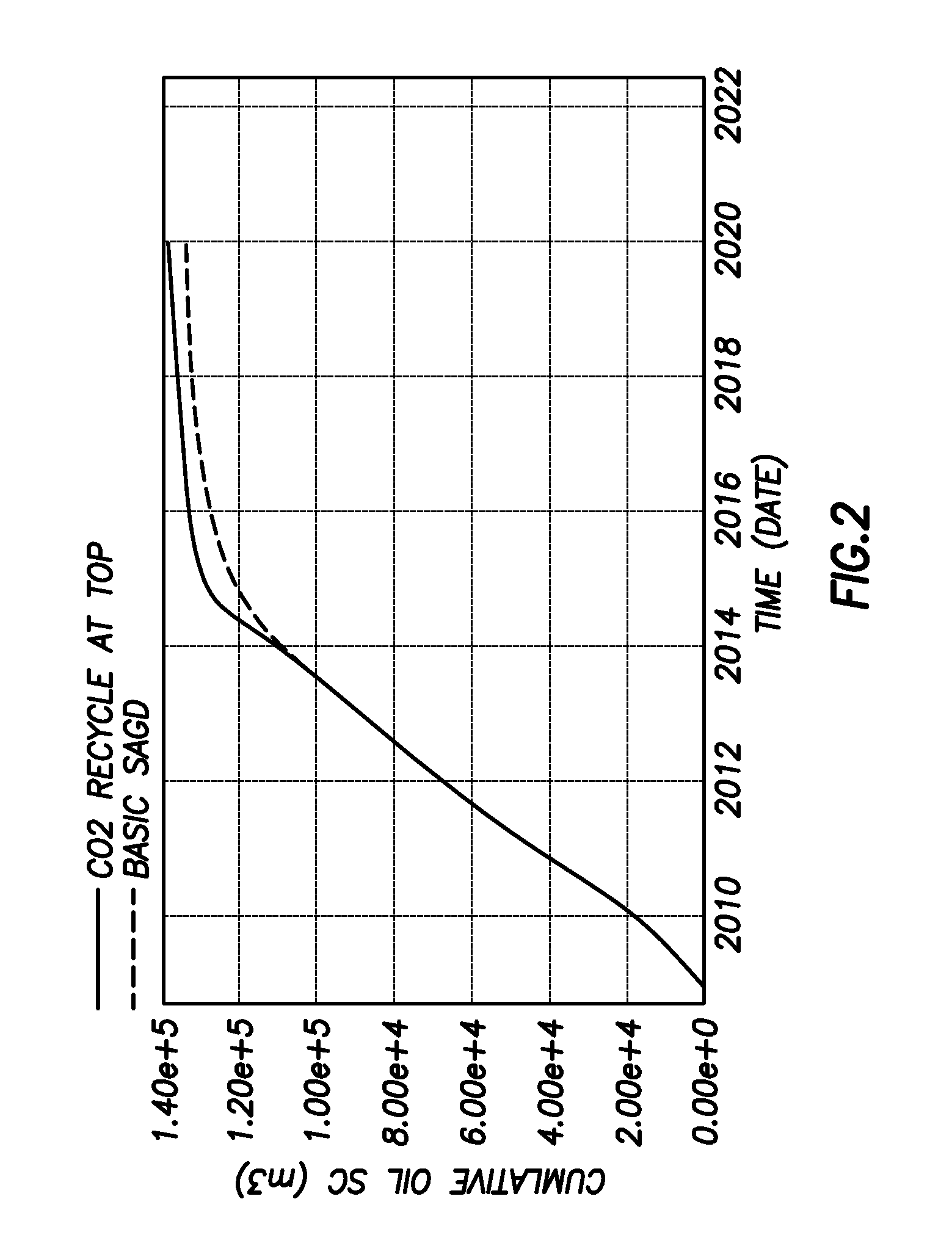

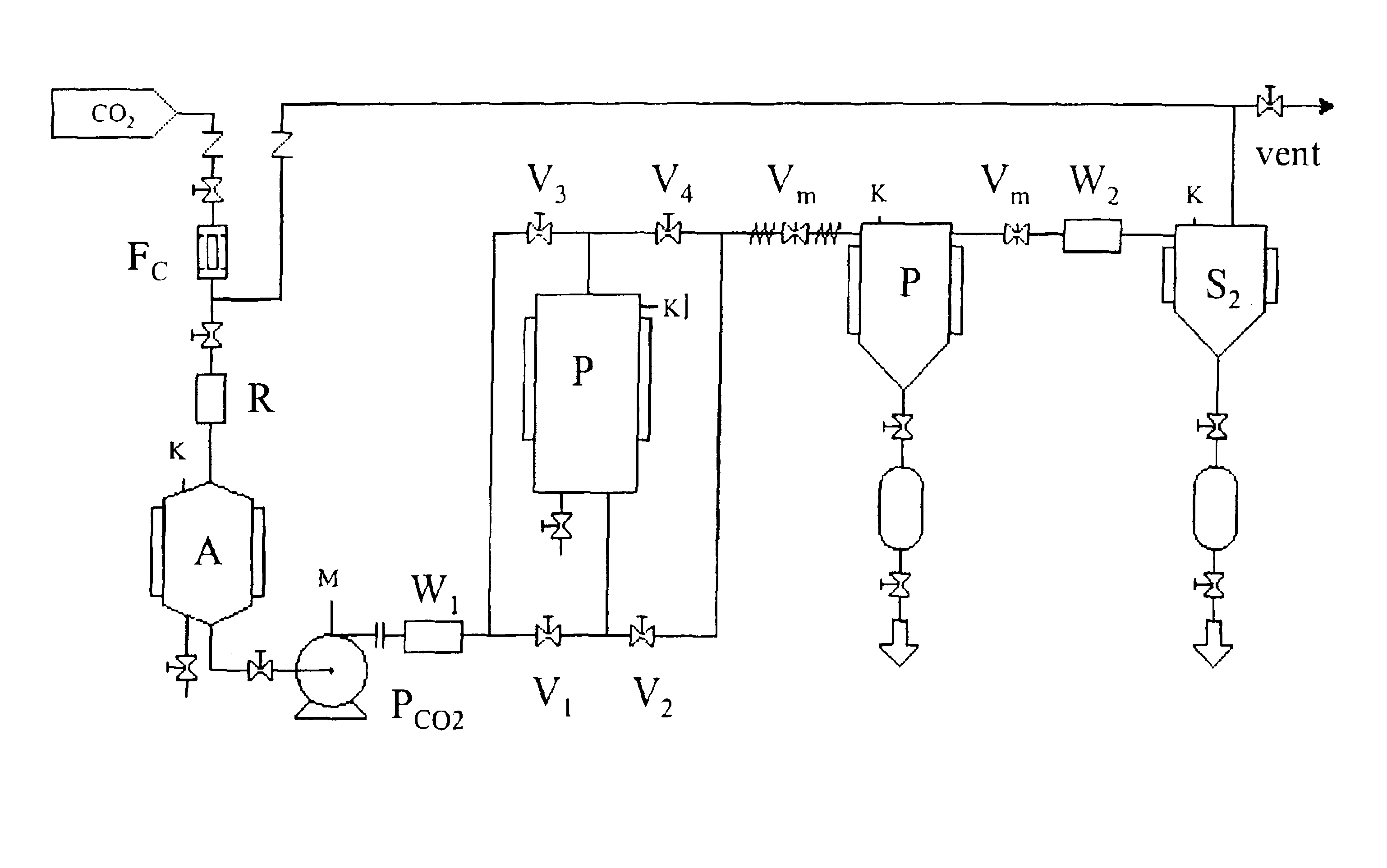

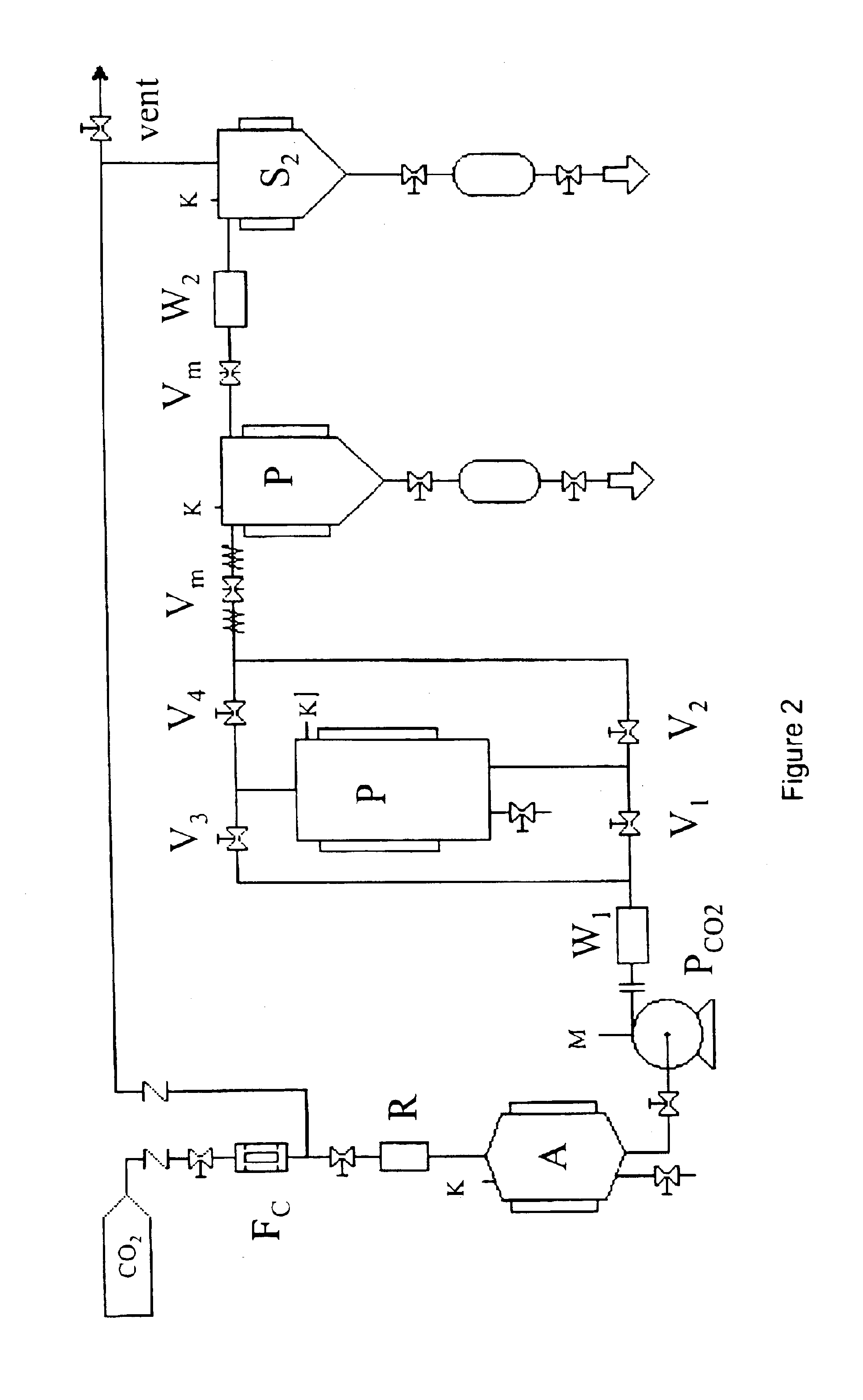

Recycling co2 in heavy oil or bitumen production

ActiveUS20130000897A1Low costMaximize efficiencyOther gas emission reduction technologiesFluid removalProduction rateFuel oil

A method relates to improving production rate and recovery of heavy oil or bitumen and reducing heat loss to over and under burden in a steam-assisted production process. The method includes strategically injecting recycled carbon dioxide into the reservoir between production wells. The heat insulation and solvent effects provided by carbon dioxide dissolved in the oil phase facilitate the desired improvement on oil recovery, and simultaneously sequester the CO2 back into the reservoir.

Owner:CONOCOPHILLIPS CO

Process for the preparation of accelerated release formulations using compressed fluids

The following description refers to a process for the impregnation of cross-linked polymers with an active ingredient. The process is based on the used of compressed fluids, in particular CO2, with antisolvent effect, and involves the steps of impregnating the polymer with an active ingredient solution, adding a compressed fluid until precipitation of the active ingredient caused by the compressed fluid antisolvent effect, removing the solvent and the compressed fluid. The process allows to obtain accelerated release pharmaceutical formulations that, compared with the formulations already known, contain larger quantities of amorphous or nanocrystalline active ingredient.

Owner:ADARE PHARM SRL

Process for the preparation of cyclohexanol

InactiveUS20030018223A1Increase productionPromote recoveryOrganic compound preparationPreparation by hydrogenationSolubilityWater use

A method for producing cyclohexanol by subjecting cyclohexene to a hydration reaction in the presence of water using a solid acid as a catalyst in which as a reaction solvent, there is used an organic solvent having a solubility in water at 25° C. of not higher than 5% by weight, a boiling point which is at least 20° C. higher than that of the cyclohexanol produced, a conversion rate of not more than 3% under the hydration reaction conditions, and a solvent effect index of not less than 1.5 which indicates the effect of making the distribution of cyclohexene into the aqueous phase predominate.

Owner:ASAHI KASEI KK

Process for the preparation of cyclohexanol

InactiveUS6552235B2Increase productionPromote recoveryOrganic compound preparationPreparation by hydrogenationHydration reactionWater use

A method for producing cyclohexanol by subjecting cyclohexene to a hydration reaction in the presence of water using a solid acid as a catalyst in which as a reaction solvent, there is used an organic solvent having a solubility in water at 25° C. of not higher than 5% by weight, a boiling point which is at least 20° C. higher than that of the cyclohexanol produced, a conversion rate of not more than 3% under the hydration reaction conditions, and a solvent effect index of not less than 1.5 which indicates the effect of making the distribution of cyclohexene into the aqueous phase predominate.

Owner:ASAHI KASEI KK

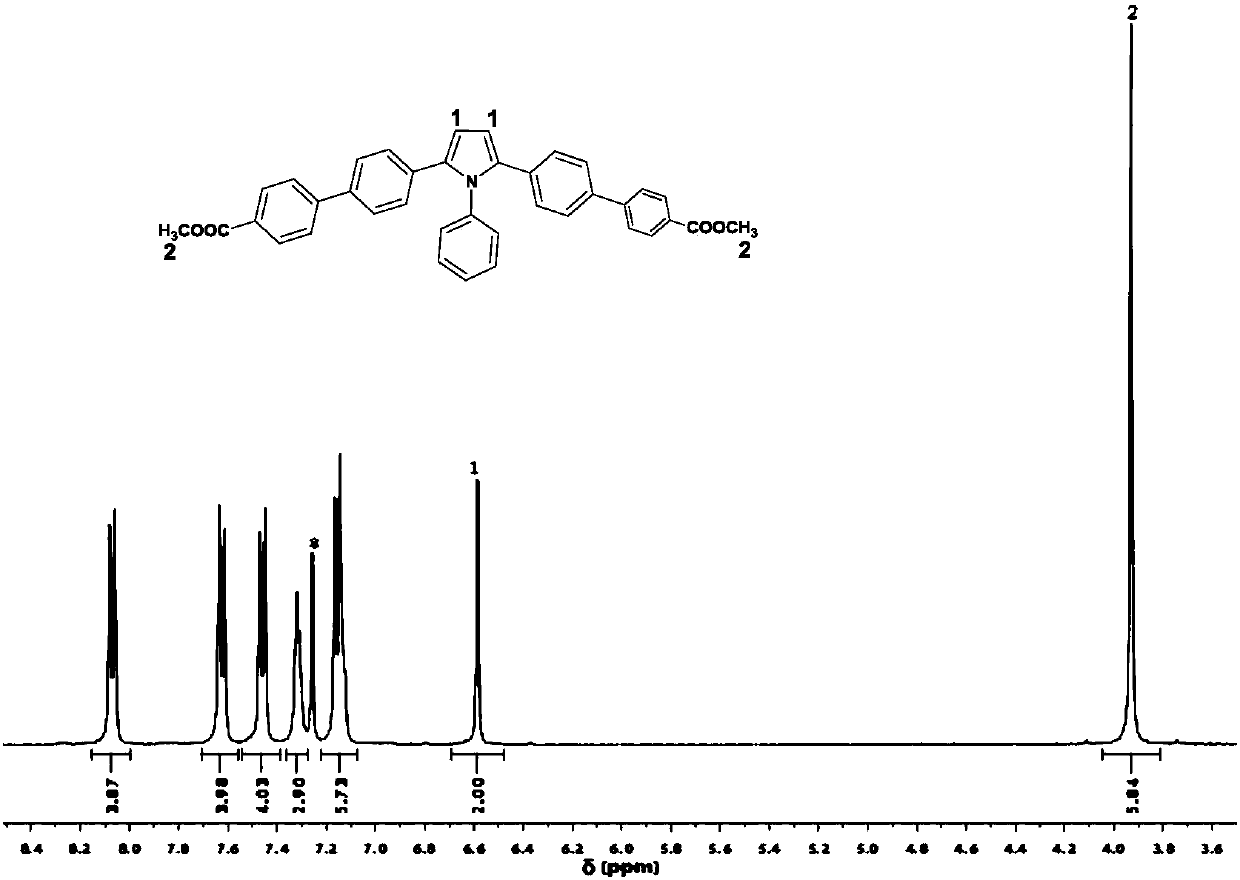

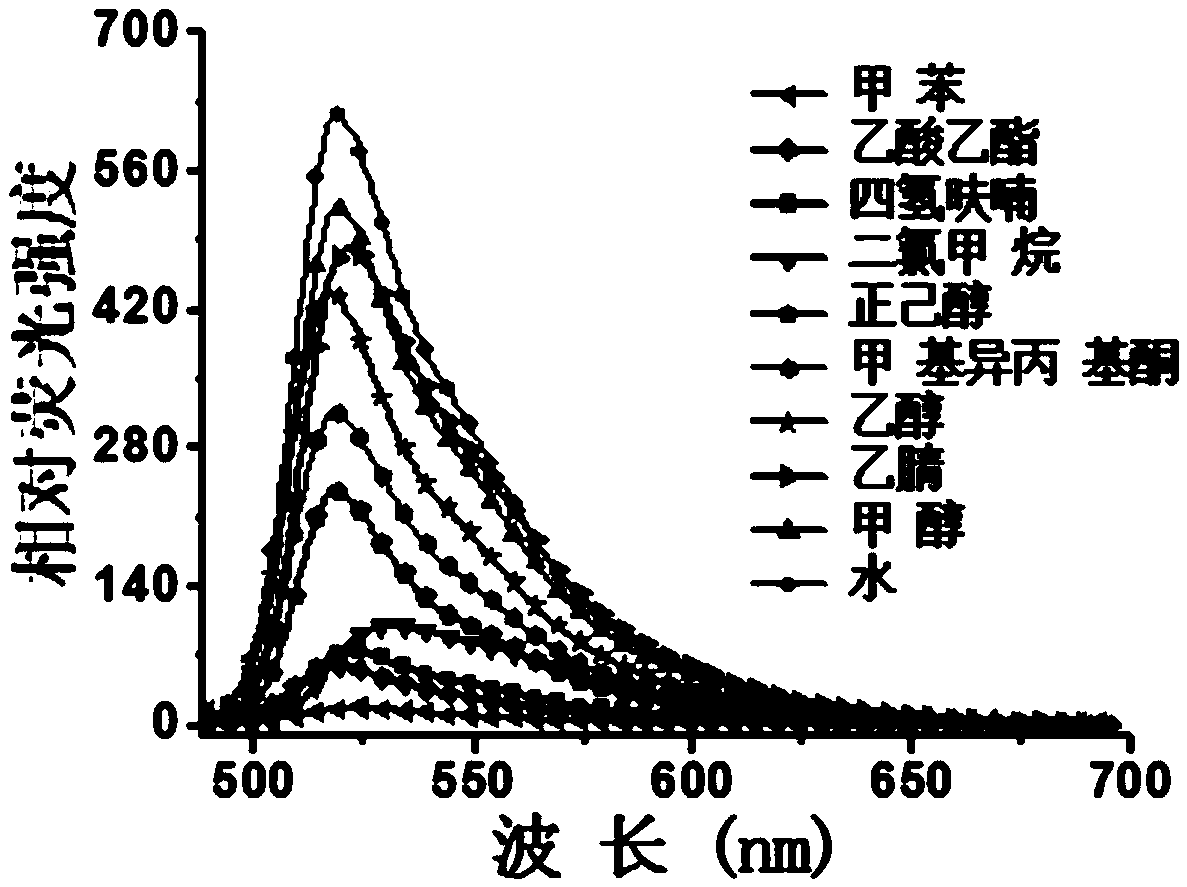

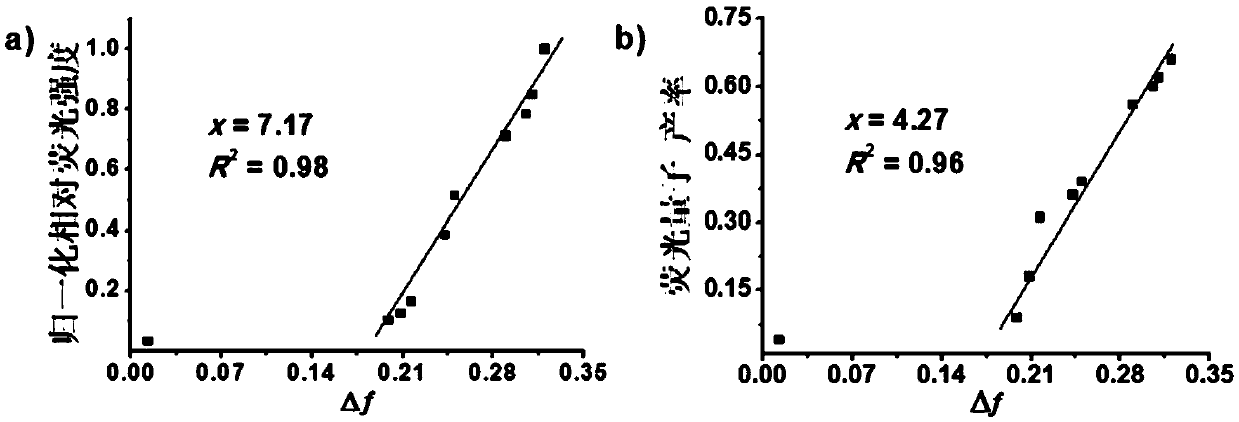

Double-phase organic fluorescent materials with relatively strong fluorescence in solid state and liquid state and preparation method thereof

InactiveCN107759504AStrong fluorescence emissionGood solvent effectOrganic chemistrySolid-state devicesDouble phaseSolution state

The invention provides double-phase organic fluorescent materials with relatively strong fluorescence in the solid state and the solution state and a preparation method and application thereof. Particularly, the invention provides arylpyrrole derivative fluorescent materials shown as a general formula (TPP-R) and having relatively strong solid-state and solution-state two-phase fluorescence emission: FORMULA, wherein R is an electron-withdrawing group, an aldehyde group, cyano or an ester group. The invention further provides a preparation method of the aryl-substituted pyrrole derivative fluorescent materials. The prepared fluorescent materials have relatively high fluorescence quantum efficiency and significant solvent effect in the solid state and the liquid state, and the medium-polarity electron-withdrawing enables one of the fluorescent materials to have light-emitting characteristics in different aggregation morphologies. The fluorescent materials with relatively strong light-emitting characteristics in the solid state and the solution state have a good application prospect in organic light-emitting diodes, chemical detection, biological detection and other aspects.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

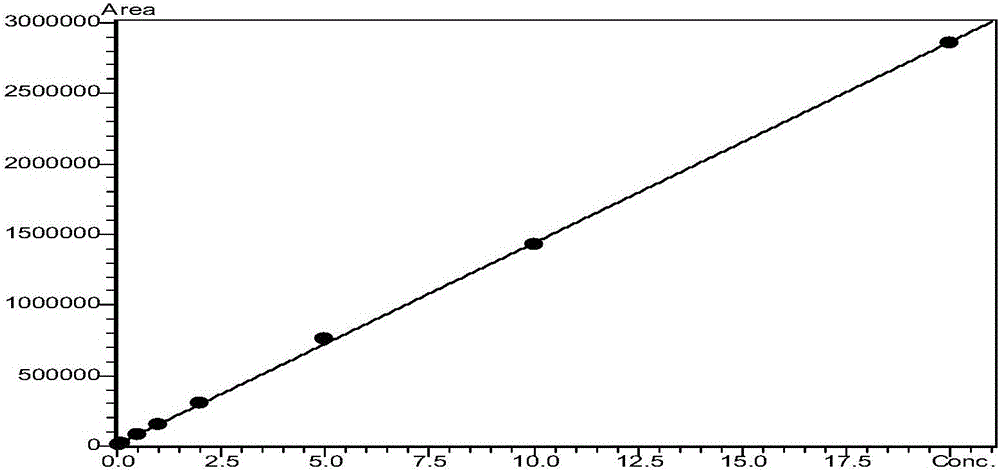

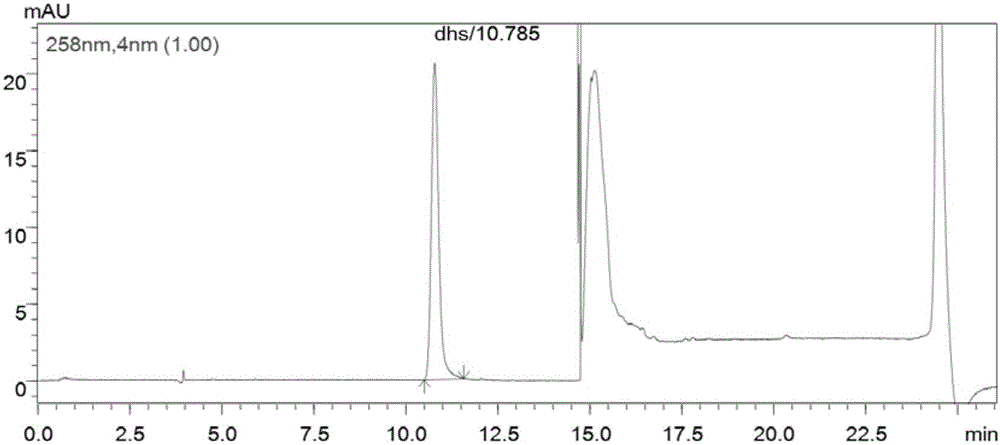

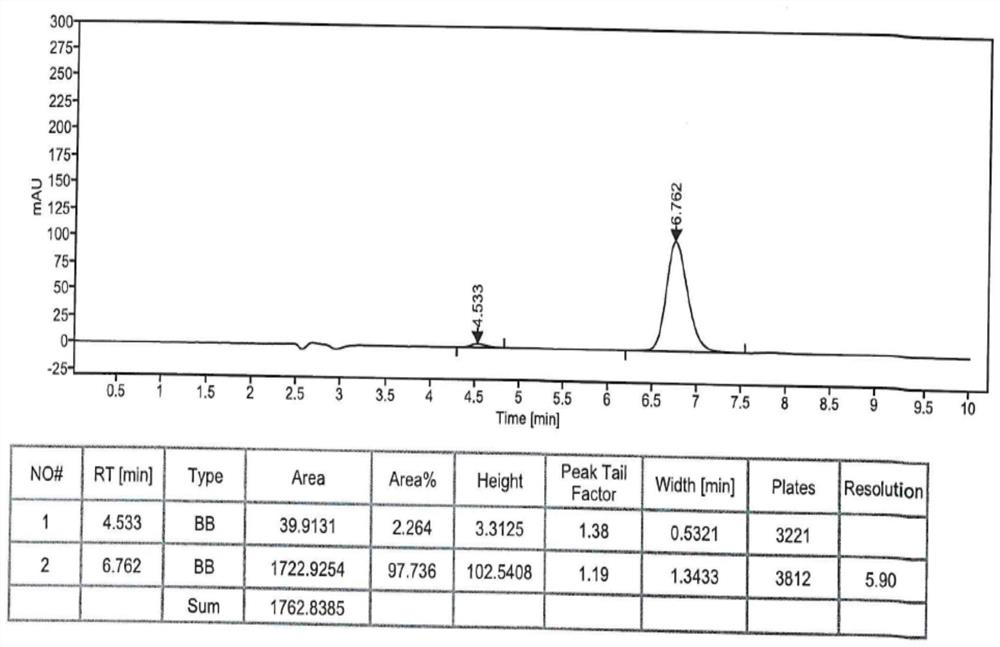

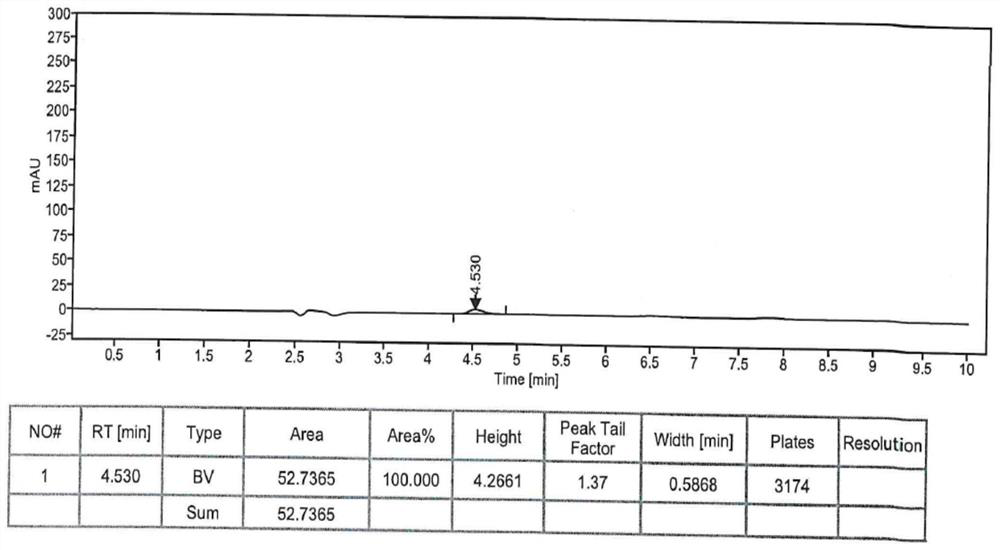

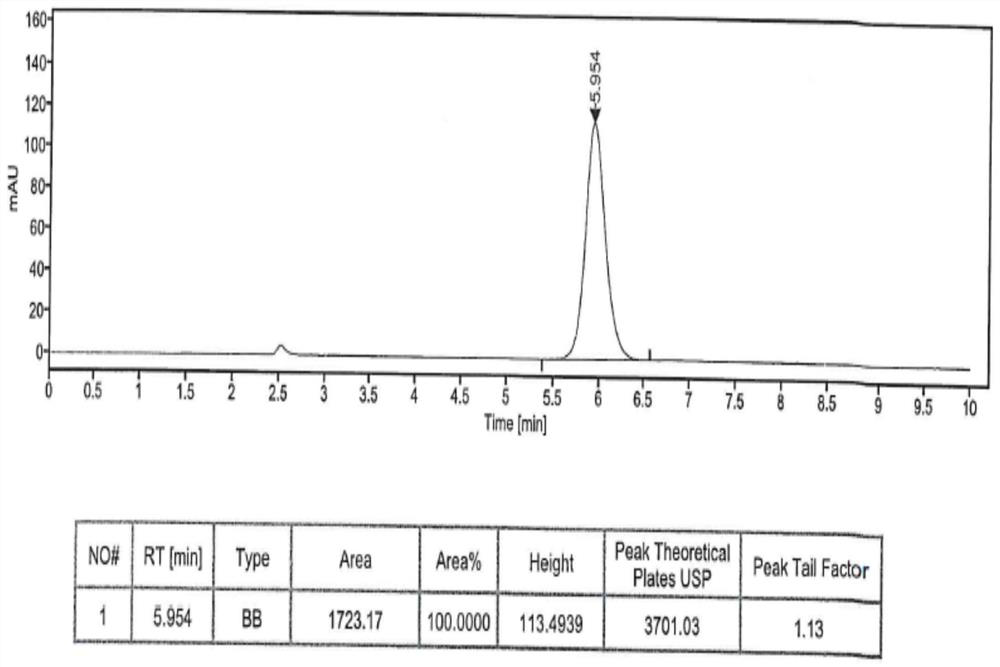

Method for detecting toxoflavin in foodstuff based on multifunctional purifying column-high performance liquid chromatography

InactiveCN105974018AReduce distractionsFully extractedComponent separationLipid formationReversed-Phase Liquid Chromatography

The invention provides a method for detecting a toxoflavin residue in foodstuff based on multifunctional purifying column purification-high performance liquid chromatography. 80mL of acetonitrile and 20mL of water are used for dissolving a foodstuff sample, ultrasonic extraction is carried out, a multifunctional purifying column is used for purifying, 5.0mL of purifying liquid is used, N2 is used for blowing and drying, 1.0mL of water is used for metering the volume, and liquid for testing is obtained. Detection of the toxoflavin residue in the sample is realized, and the method has the advantages of good purifying effects, accurate quantification, and elimination of influences of solvent effect on chromatographic behaviors of toxoflavin. Gradient elution of a mobile phase is carried out by methanol and water, retention of toxoflavin in a reversed phase chromatography column, effective separation between toxoflavin and other interfering substances is realized during sample analysis, so that the purpose of accurate quantification is realized. In the sample purifying process, interferences of lipids, pigments, proteins and other substances are effectively removed from the sample, the purifying effect is good, and the quantitative analysis has good accuracy, high sensitivity, and good result reappearance; and the method is suitable for detection of the toxoflavin residue in a plurality of foodstuffs.

Owner:浙江省产品质量安全检测研究院

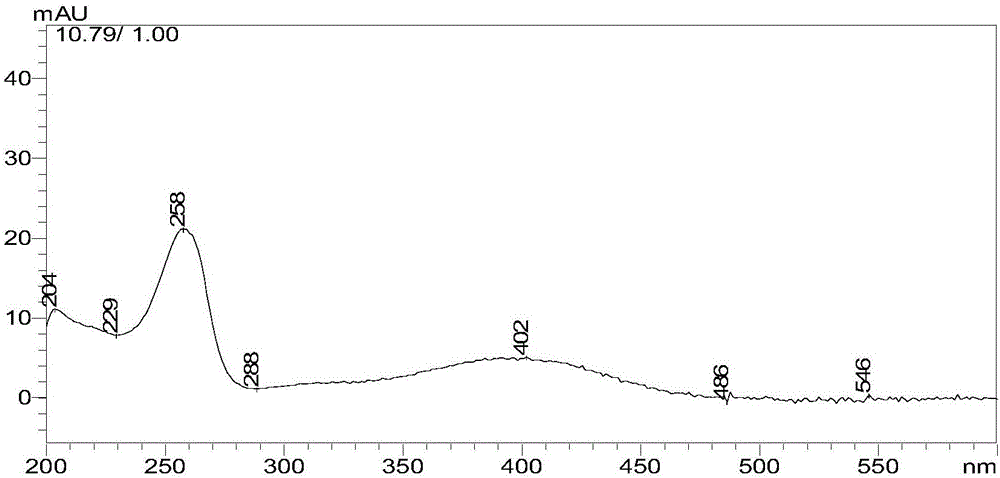

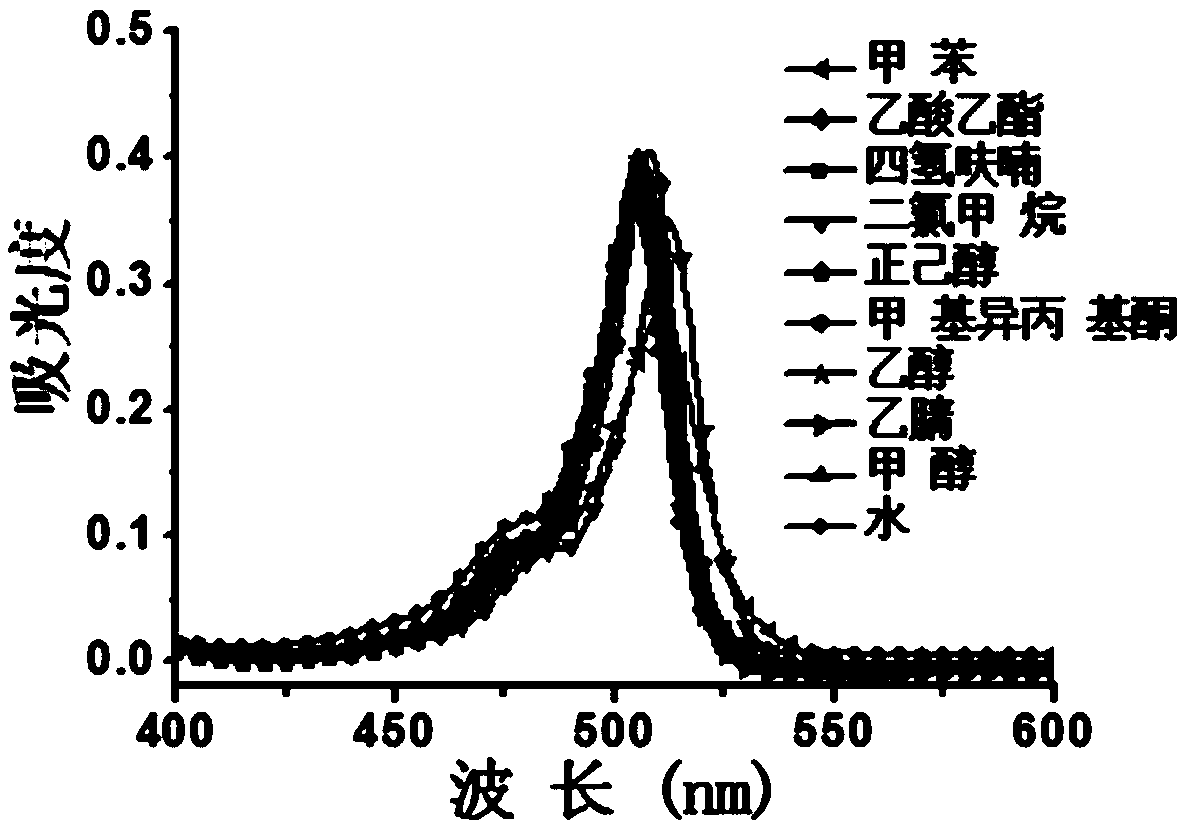

Compound with hemicyanine-naphthalimide structure, and preparation method and application thereof

The invention relates to a compound with a hemicyanine-naphthalimide structure, and a preparation method and an application thereof. The structural formula of the compound is shown in the specification. The dissolvability, the maximum absorption, the optimum fluorescence emission wavelength and the quantum yield of the compound are tested in the spectrum property experiment of the compound; a solvent effect experiment of the fluorescence emission of the compound shows that the fluorescence emission of the compound has a substantial solvent effect; experiments of response of the compound to ions show that the absorption peak nearby 600nm gradually enhances with increase of the trifluoroacetic acid concentration, and the absorption peak at 490nm decreases with the increase of the trifluoroacetic acid concentration until disappearance, so the structure of the compound changes after trifluoroacetic acid is added; and fluorescence spectrum detection finds that the maximum emission spectrum intensity enhances with the addition of trifluoroacetic acid, so the compound can be used as an acidic fluorescence probe. The preparation method of the compound has the characteristics of simple operation, mild conditions and high reaction yield.

Owner:HENAN UNIVERSITY

Synthesis of helicobacter-pylorus O2 serotype O antigen oligosaccharide compound

The invention discloses discloses synthesis of a helicobacter-pylorus O2 serotype O antigen oligosaccharide compound, and belongs to the field of organic synthesis. According to the synthesis, helicobacter-pylorus O2 serotype O-antigen disaccharide to tetraco-saccharide are obtained through chemical synthesis. A chemical synthesis method quite beneficial for generation of glucose alpha glucoside bonds is developed through a protective agent strategy, a temperature effect, a solvent effect and an additive effect, and used for synthesizing the helicobacter-pylorus O2 serotype O-antigen oligosaccharide compound assembled with aminolinks; glycoconjugate can be made of the synthesized helicobacter-pylorus O2 serotype O-antigen oligosaccharide compound assembled with the aminolinks and carrier protein for immunological researching, and an important role is played in the development of prevention and treatment of helicobacter pylori.

Owner:JIANGNAN UNIV

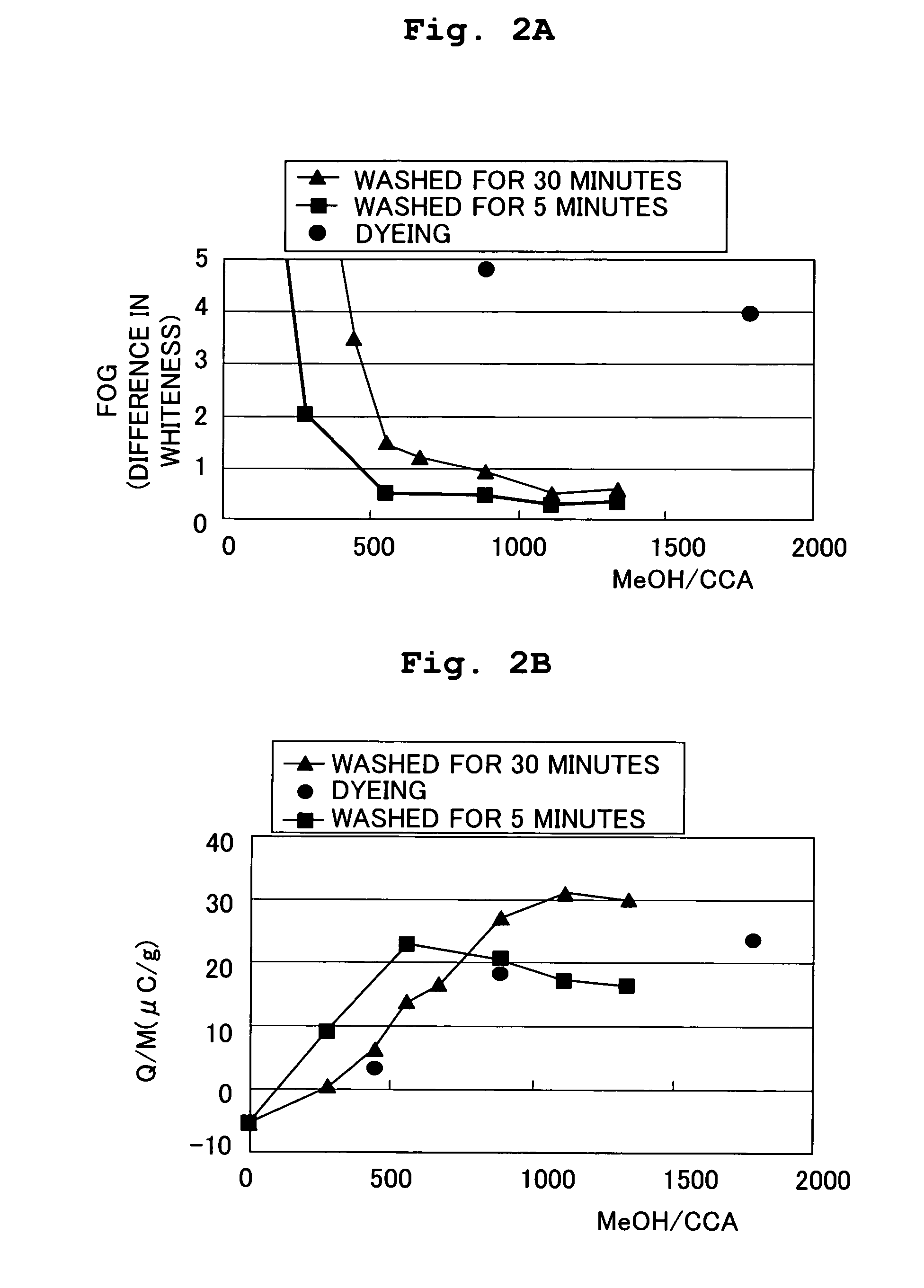

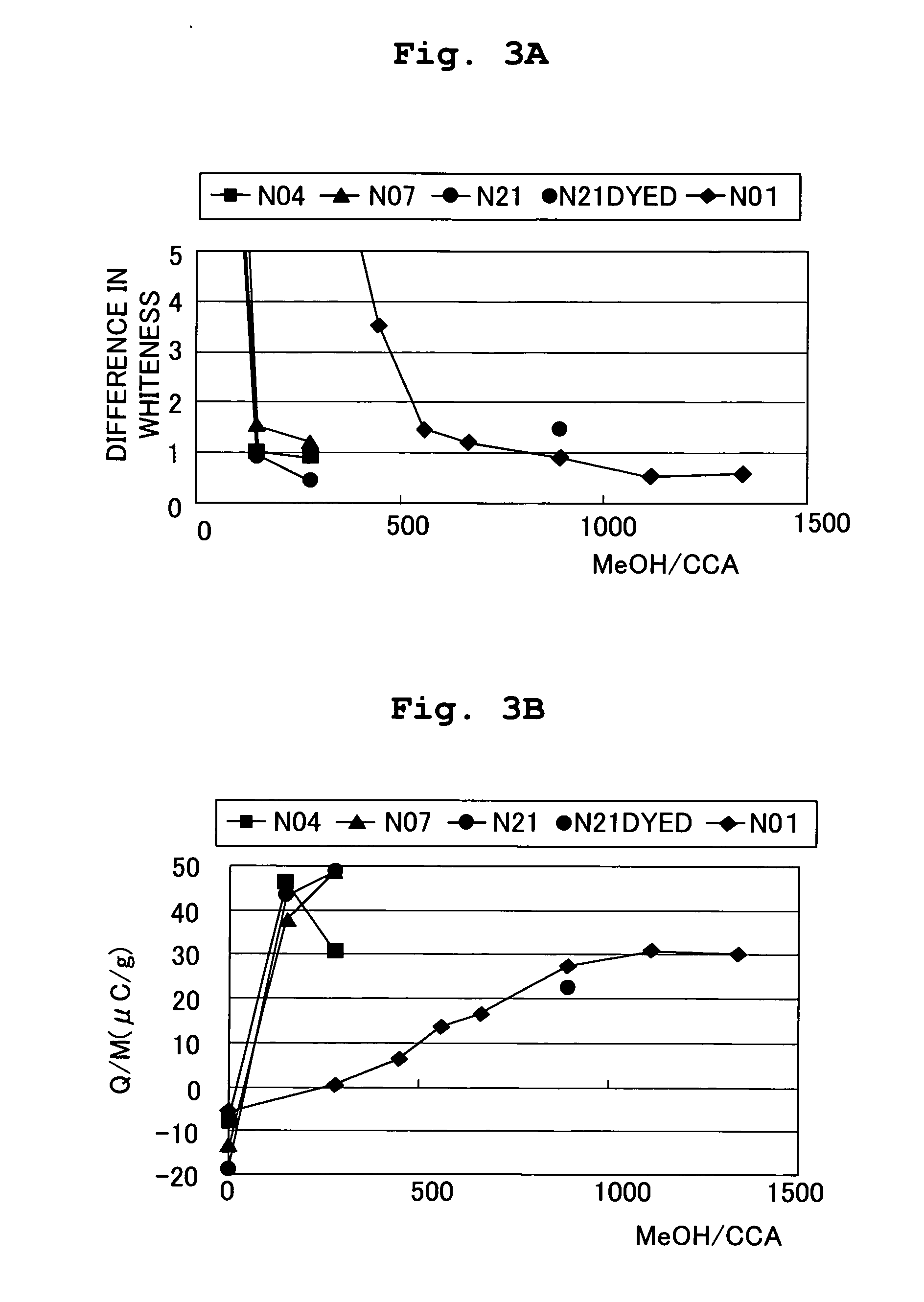

Method of producing toner, and toner

Spherical-shaped liquid droplets are made by dispersing oil phase containing: a resin with an acid group, a first hydrophobic solvent effecting dissolution of the resin, a colorant, and a charge control agent which is positively charged in an aqueous dispersion medium in the presence of a base; and the liquid particles are solidified to be solid particles by removing the first solvent from the liquid droplets. The solid particles obtained in this manner are washed with a second solvent. As the second solvent, a solvent which dissolves the charge control agent and but does not dissolve the resin such as alcohol is selected. Accordingly, the charge control agent in the solid particles are made to elute to the outer surface layer of the solid particles, thereby improving the positive chargeability of the solid particles.

Owner:BROTHER KOGYO KK

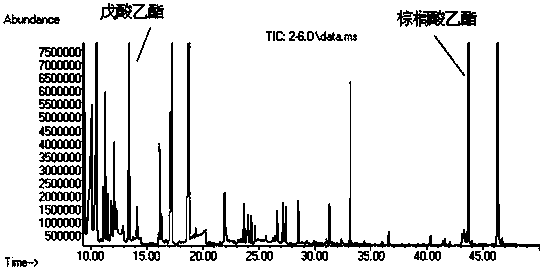

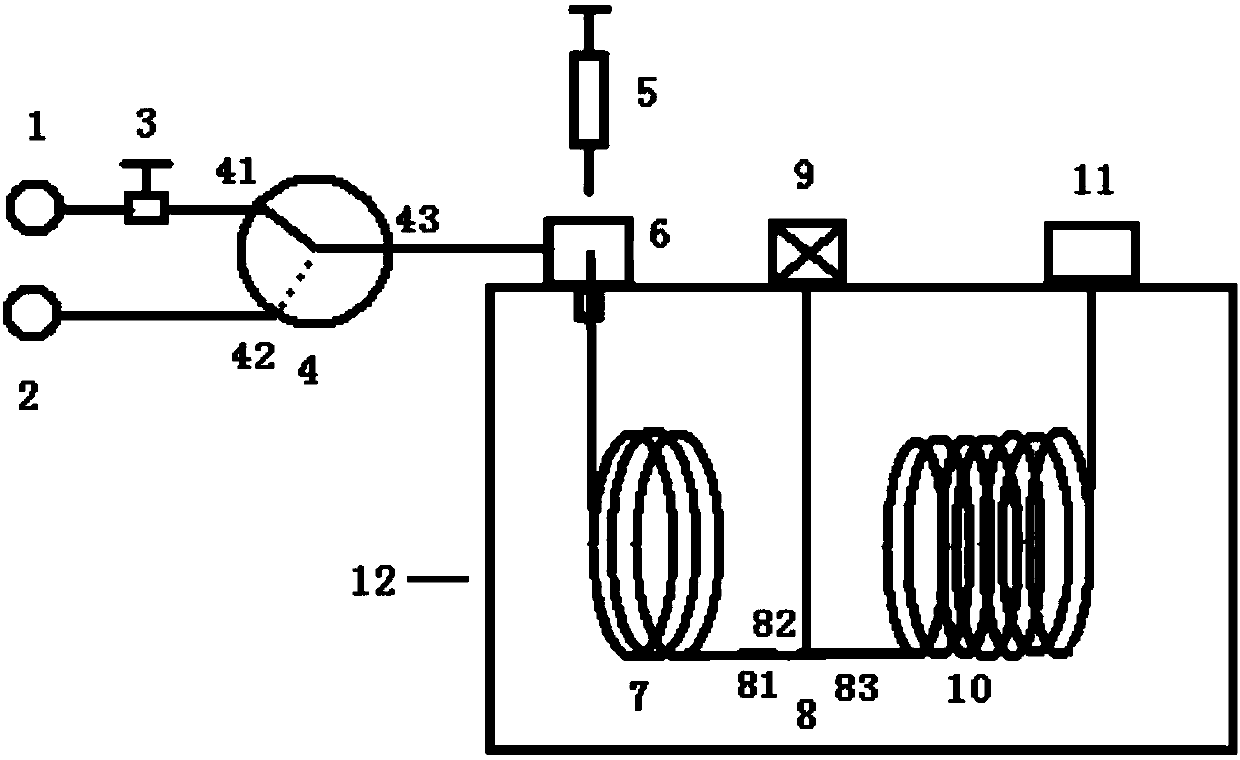

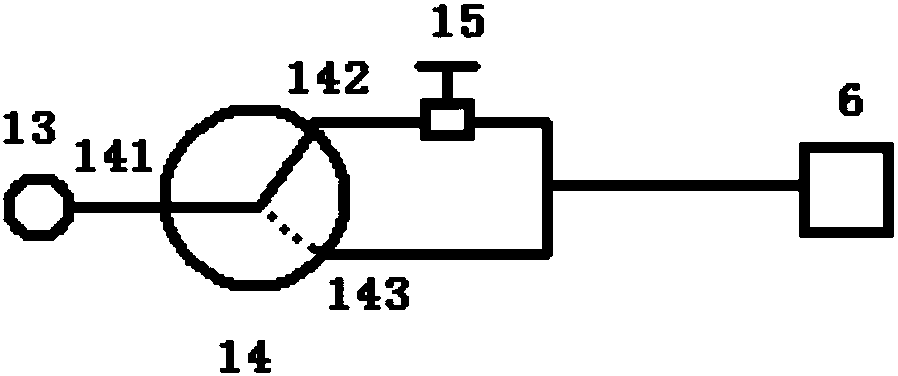

Gas chromatographic column large-volume injection technology and application thereof

ActiveCN107656002AChanging the constant pressure carrier gas evaporation methodImproving Technical Results for Large Volume InjectionsComponent separationInjection portGas phase

The invention belongs to the technical field of gas chromatography and relates to a gas chromatographic column large-volume injection technology and application thereof. The invention provides a gas chromatographic column large-volume injection system, which comprises a carrier gas injection part and a chromatographic injection part. The chromatographic injection part comprises an injection port,a pre-column, a drain valve, a capillary chromatographic column and a chromatographic column box. The carrier gas injection part comprises a constant-current mode carrier gas access and a constant-voltage mode carrier gas access. The invention also further provides application of the gas chromatographic column large-volume injection device and an injection method. The invention provides a gas chromatographic column large-volume injection technology and application thereof. According to the invention, pure pressure control mode is changed into constant current-constant voltage switching mode. Thus, solvent evaporation is faster and more stable, and solvent evaporation end point is easier to control, thus being beneficial to performance of solvent effect and analysis of volatile matter. Thetechnology is widely applied.

Owner:SHANGHAI TOBACCO GRP CO LTD

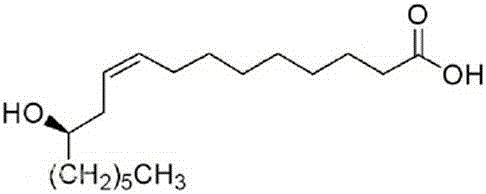

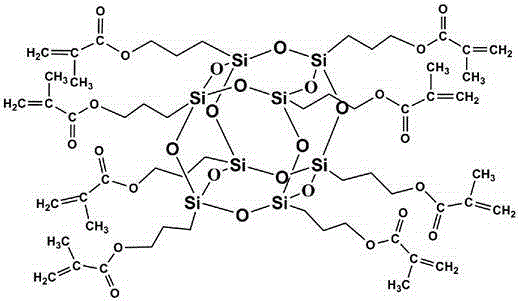

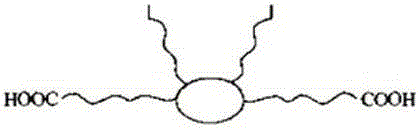

Preparation method of cage-shaped organic silicon hybridized star-shaped polyester soft PVC plasticizer

The invention relates to the technical fields of the preparation and modification of functional macro-molecular materials, and particularly relates to a preparation method of a cage-shaped organic silicon hybridized star-shaped polyester soft PVC plasticizer. The preparation method comprises the following steps: (1) sequentially cracking oxidizing and hydrogenating ricinoleic acid to obtain a mixed product of dihydric alcohol and nonanol acid; (2) facilitating esterolysis reaction of an apex group of 8-methacryloxypropyl cage-shaped silsesquioxane to obtain 8-propanol cage-shaped silsesquioxane; (3) mixing the mixed product obtained in the step (1) and the 8-methacryloxypropyl cage-shaped silsesquioxane obtained in the step (2) with a dimer acid according to a mass ratio to obtain a mixed solution; and (4) adding an esterification catalyst and a dehydration agent into the mixed solution prepared in the step (3), and refluxing to obtain the cage-shaped organic silicon hybridized star-shaped polyester soft PVC plasticizer. The plasticizer has excellent application performance and is high in migration resistance, solvent resistant effect, weather resistance and the like.

Owner:GUANGDONG DAHUA WATER SAVING TECH CO LTD

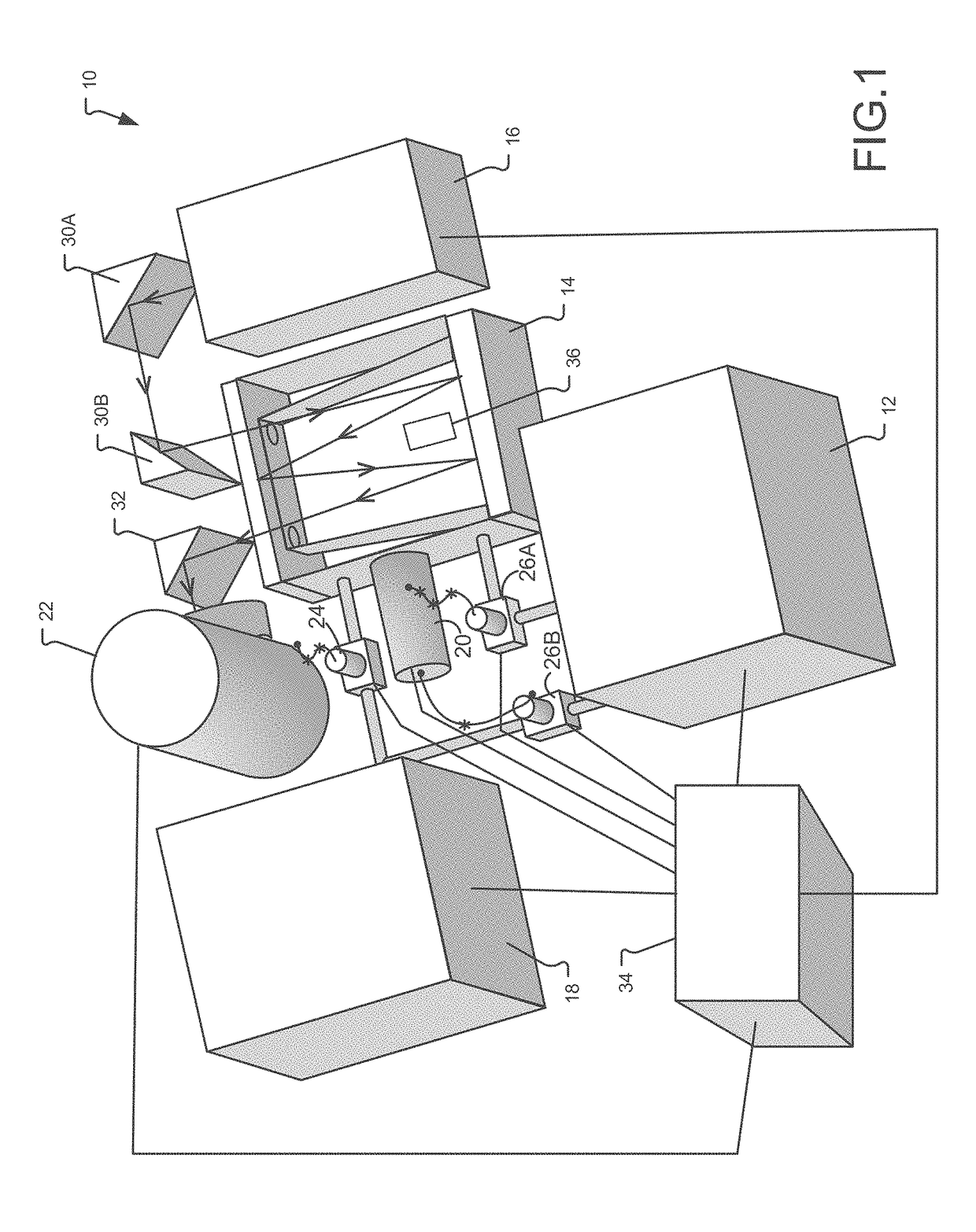

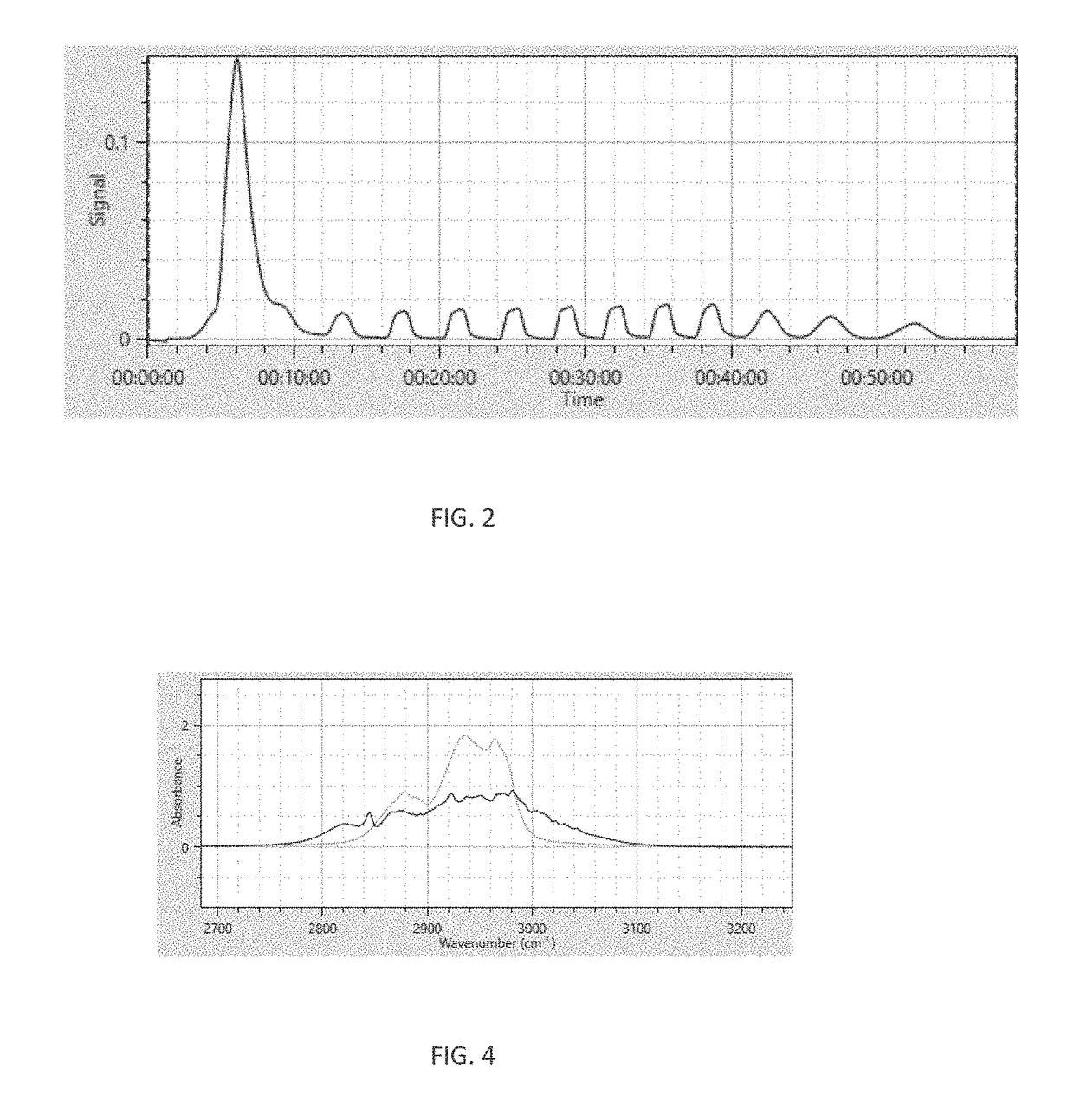

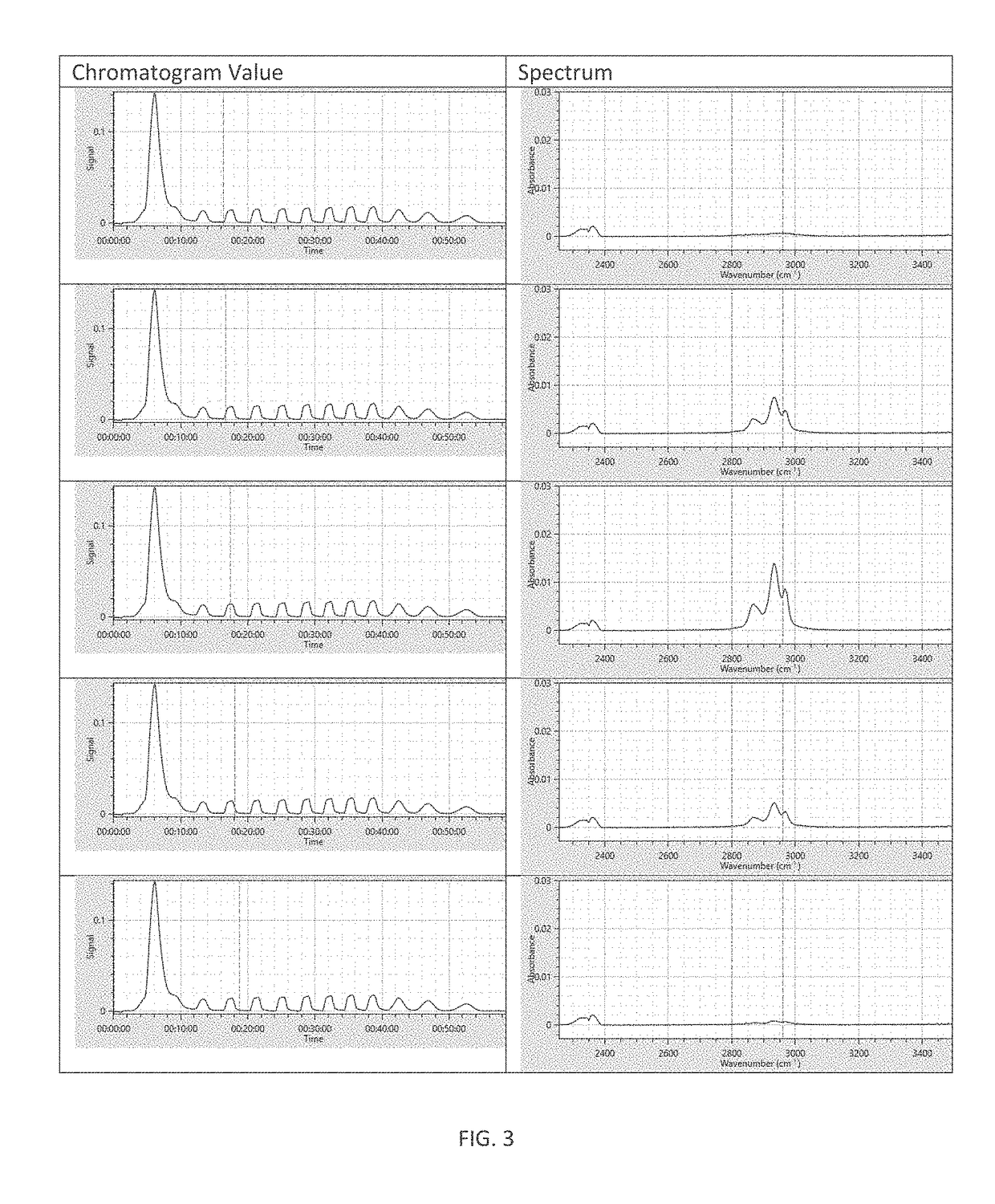

Carbon Ladder Calibration

ActiveUS20190064131A1ConfidenceFacilitate proper identificationComponent separationMaterial analysis by optical meansElutionSpectral fitting

A GC sample carbon ladder is generated with the help of one or more of the following techniques: correction of solvent effects; fit analysis of the spectrum obtained for a target member of the carbon ladder and a reference spectrum; fit analysis of a sample carbon ladder in comparison with reference spectral features; constraints for proper order of elution; and / or inclusion of all members in a selected carbon ladder set.

Owner:MLS ACQ INC

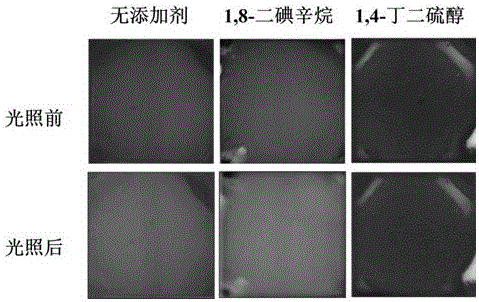

Method for improving photoelectric conversion efficiency and light-heat stability of organic solar device

InactiveCN106848066AInhibit migrationReduces the phenomenon of decomposing donorsSolid-state devicesSemiconductor/solid-state device manufacturingOrganic solar cellHeterojunction

Provided is a method for improving the photoelectric conversion efficiency and the light-heat stability of an organic solar device. A little amount of mercaptan-type solvent additive is added to an organic solar cell light absorption layer solution, appropriate aggregation and separation of a donor and a receptor are achieved through the solvent effect of the solvent additive on the receptor in the light absorption layer spin-coating and film-forming process, the purity of a donor phase is improved, and the light-heat stability of the device is improved while the photoelectric conversion performance is improved. The method is a simple morphological control means, the shortcomings of likely light decomposition of an existing halogen additive are avoided, the donor and the receptor distribution situation at a body heterojunction is also optimized, and the photoelectric conversion efficiency and light-heat stability of the device are effectively improved by adopting the method.

Owner:NANCHANG UNIV

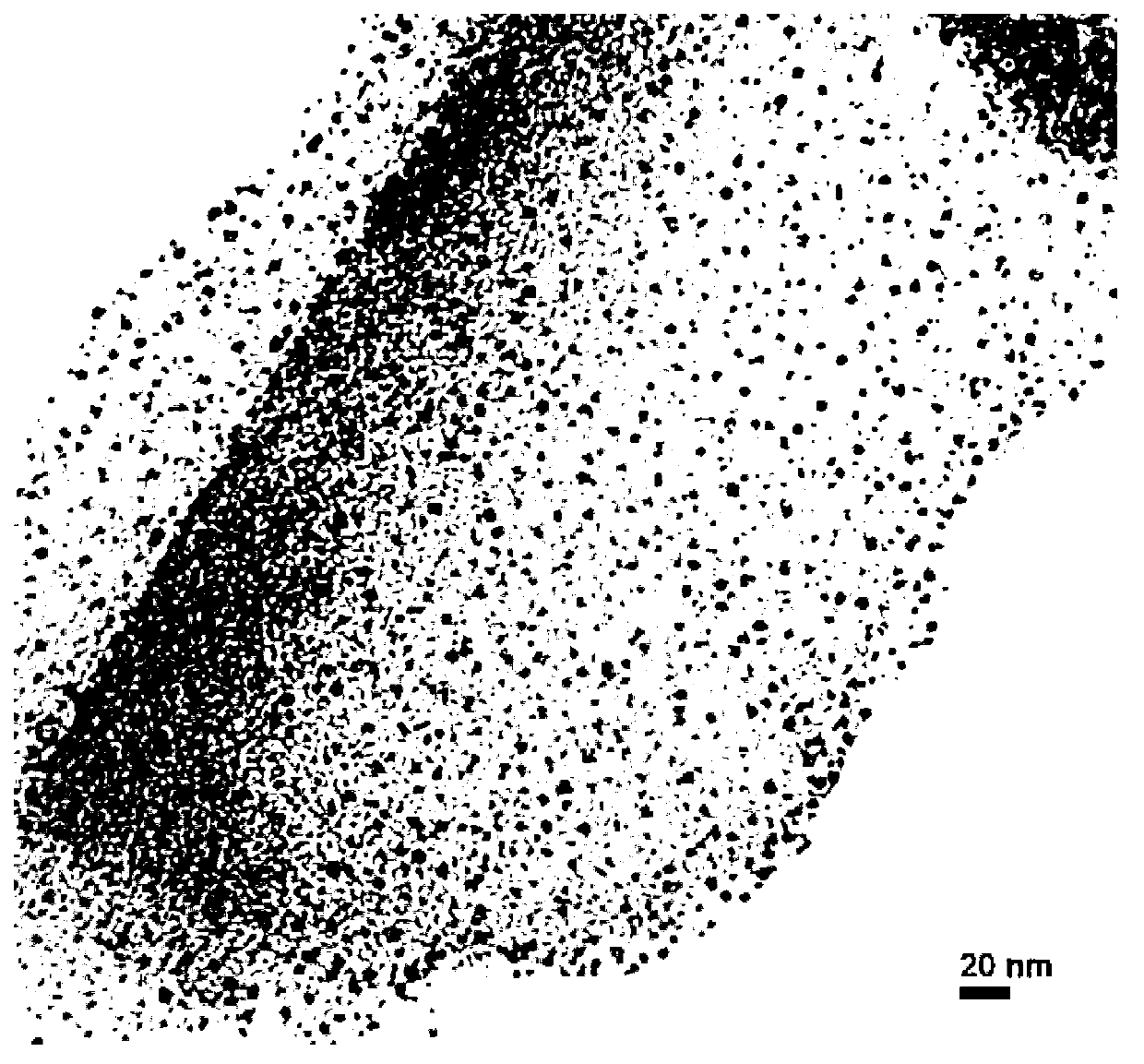

Preparation method and application of Pt-MoS2/LDHS hydrocracking catalyst

InactiveCN109821556AControl of parenthoodLow molybdenum oxide contentCatalyst activation/preparationHydrocarbon oil crackingDispersityVulcanization

The invention relates to the field of hydrocracking catalysis, in particular to a preparation method of a supported Pt-MoS2 / LDHS hydrocracking catalyst. An obtained composite material has the advantages of the structure and performance of platinum-molybdenum disulfide and hydrotalcite, in a synthesis system, the vulcanization process of a vulcanizing agent and molybdate precursor is omitted, the raw materials are controlled directly, and the composite material is assisted by a solvent effect, thereby improving the dispersity of nano molybdenum disulfide, and the catalyst has good heat resistance, crushing resistance, higher cracking rate and heat stability.

Owner:WENZHOU HONGCHENGXIANG TECH

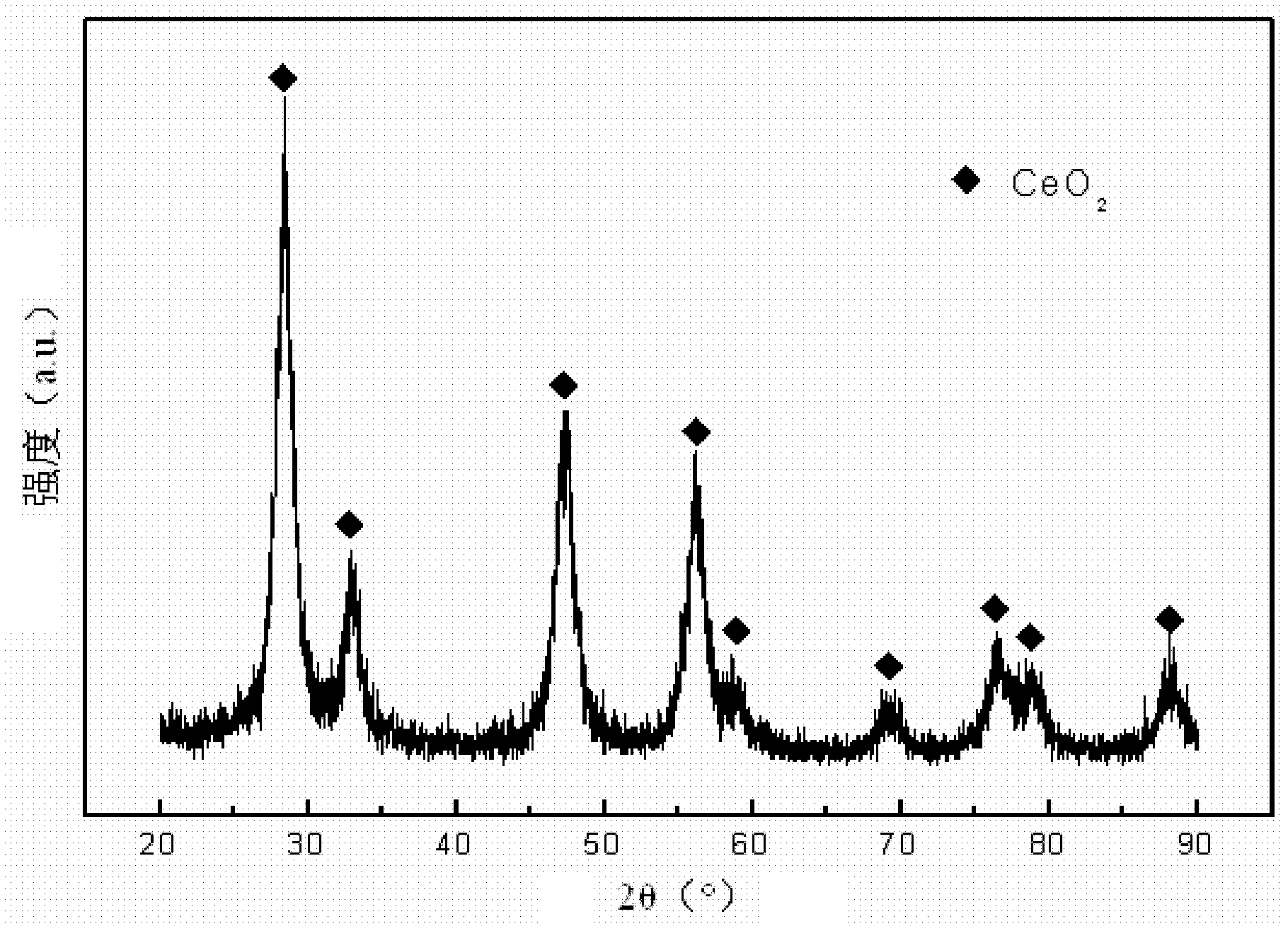

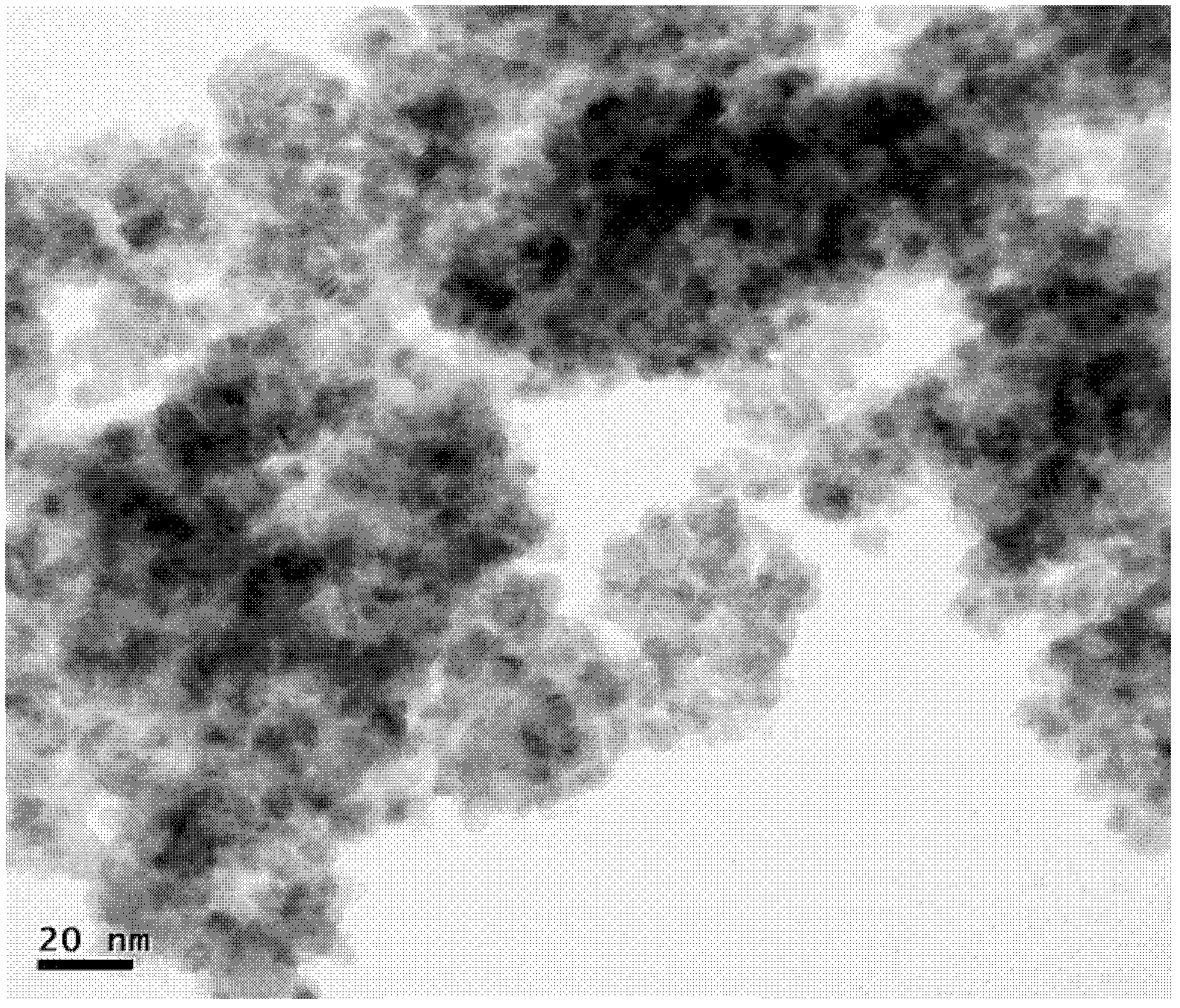

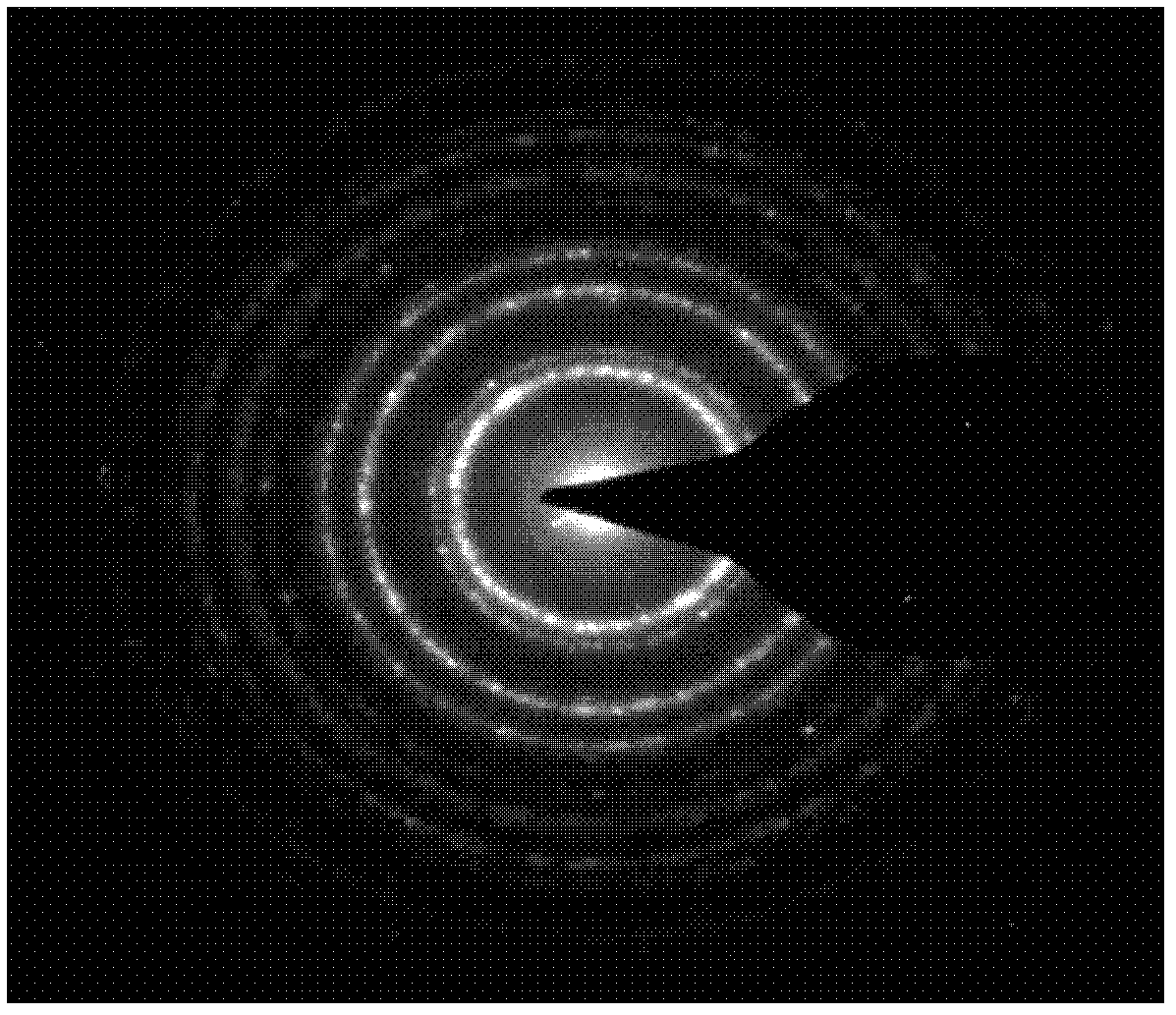

Method for preparing nanometer ceria by solid state reaction at room temperature

InactiveCN102275971ANo pollution in the processHigh purityNanotechnologyRare earth metal compoundsCeriumReaction temperature

The invention discloses a method for preparing nano ceria by solid state reaction at room temperature, which relates to a preparation method of nano ceria. The invention aims to solve the disadvantages of complex process, large amount of organic solvent used, harsh preparation conditions and high cost in the existing preparation of nanometer CeO2. The method of the present invention is as follows: 1. CeCl3.7H2O and alkali metal hydroxide are ground into powder at room temperature and then mixed to obtain a mixture; 2. Grinding; 3. Ultrasonic cleaning with water, suction filtration, and drying to obtain nano-dioxide cerium. Compared with the existing method, the present invention has a simple process, does not use any organic solvent, fundamentally eliminates solvation, does not need high-temperature calcination, has mild reaction conditions, and the whole preparation process has no pollution to the environment, and the production efficiency can be further improved, thereby Reduce production costs; compared with other solid-state reaction methods, the reaction temperature is low, the environment is friendly, and the obtained powder particles are small and uniform in particle size and high in purity.

Owner:HARBIN INST OF TECH

Method for quick detection of toxoflavin in food

InactiveCN106018659AReduce distractionsEffective elutionComponent separationGradient elutionDissolution

The invention discloses a method for quick detection of toxoflavin residues in food based on solid-phase extraction-high performance liquid chromatography. A food sample is subjected to pure water dissolution and ultrasonic extraction, the sample is purified with a solid-phase extraction column (HLB) to achieve enrichment of the target analyte toxoflavin, the solid-phase extraction column is eluted with aqueous methanol of 80% as eluant, blow drying is conducted by means of N2, and supernate is obtained after water dissolution and volume metering. Due to the pretreatment condition, during detection of toxoflavin residues in the sample, influences of disrupting compounds on accurate metering of toxoflavin are effectively reduced, and adverse effects of solvent effect on toxoflavin chromatographic behavior are eliminated. Methyl alcohol and water gradient elution is conducted on the mobile phase, so that reservation of toxoflavin in a reversed phase column is enhanced, effective separation of toxoflavin and other interferents is achieved during chromatographic analysis of the sample, and then accurate metering and analysis are realized. The method is low in detection cost, high in accuracy, sensitivity and result reproducibility and suitable for detection of toxoflavin residues in various food, and no toxic reagent is used so that environment friendliness is realized.

Owner:ZHEJIANG INST OF QUALITY INSPECTION SCI

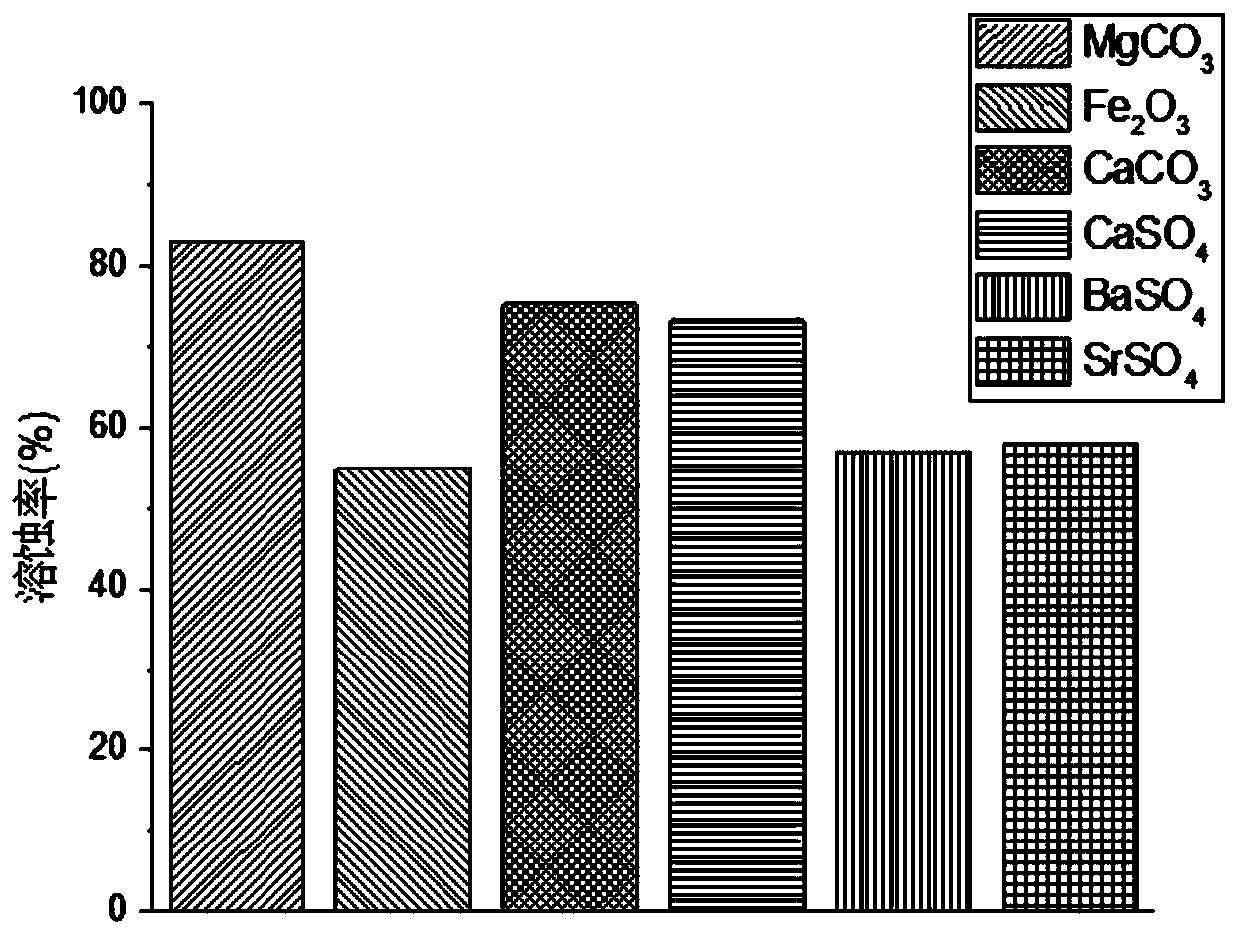

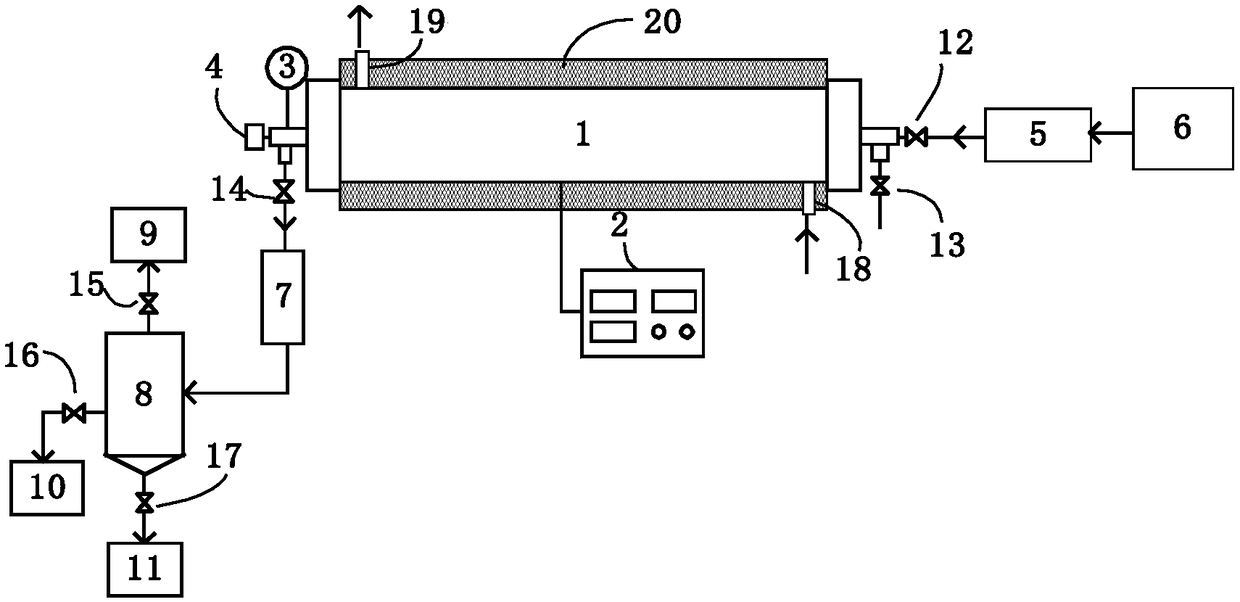

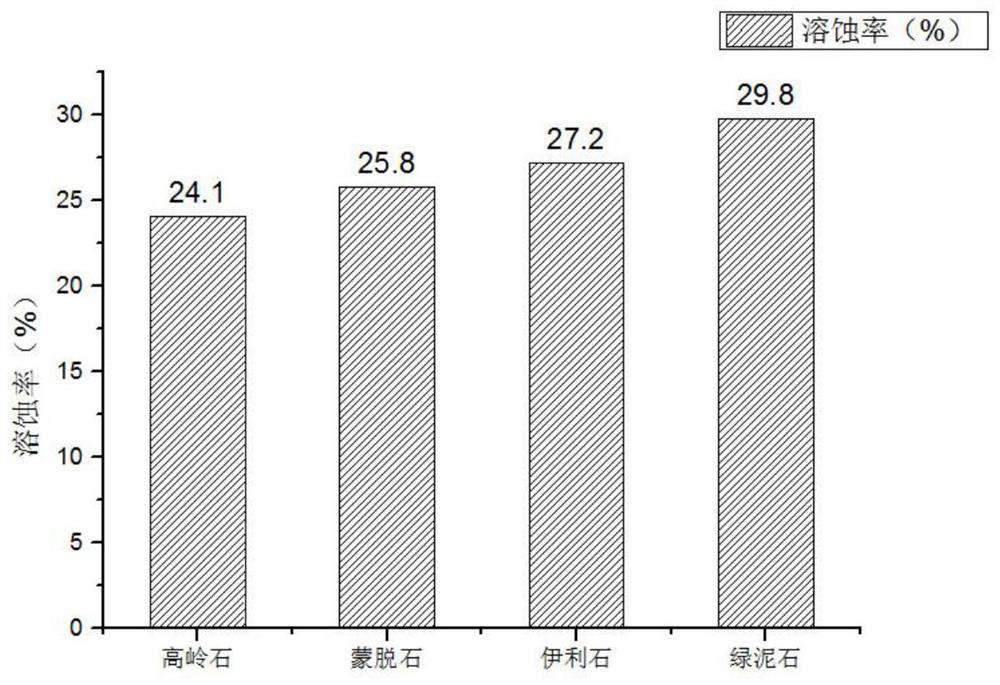

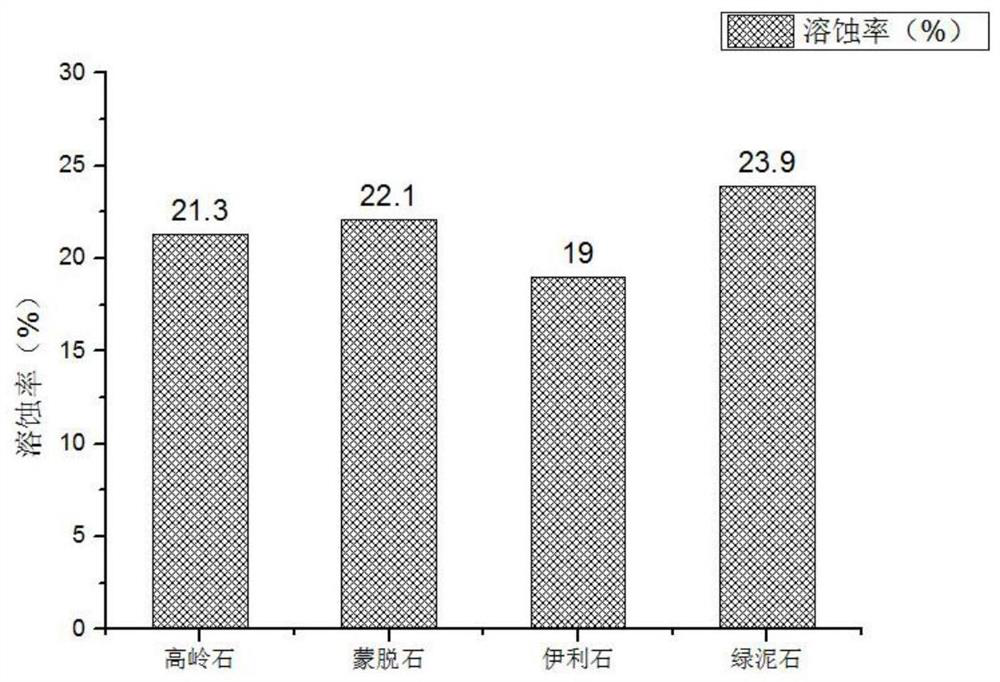

Blocking remover based on deep eutectic solvent and preparation method thereof

ActiveCN111205840AProcess synthesis is simpleEasy to achieve large-scale productionDrilling compositionBulk chemical productionCaffeic acidGlycerol

The invention relates to a blocking remover based on a deep eutectic solvent and a preparation method thereof, and belongs to the technical field of preparation of novel green blocking removers. According to the blocking remover based on the deep eutectic solvent, the blocking remover is composed of a deep eutectic solvent-based blocking remover and a blocking removing functional additive, whereinthe deep eutectic solvent-based blocking remover is prepared from a hydrogen bond acceptor and a hydrogen bond donor according to the ratio of the total mole number of the hydrogen bond acceptor to the total mole number of the hydrogen bond donor of 1:(0.2-10), and the hydrogen bond acceptor is composed of ammonium chloride and choline chloride in a mole ratio of 1:1; the hydrogen bond donor is prepared from the following components in parts by mole: 11-13 parts of polyaspartic acid, 5-7 parts of ethylenediamine tetramethylene phosphonic acid, 5-7 parts of amino trimethylene phosphonic acid,2-4 parts of diglycolamine, 2-3 parts of tris(hydroxymethyl)methylglycine, 2-4 parts of glycerol, 2-3 parts of trehalose and 1-2 parts of caffeic acid. The deep eutectic solvent-based blocking removerprovided by the invention has good affinity with metal ions, the metal ions can be dispersed by utilizing a solvent effect, and the corrosion rate is increased.

Owner:DONGGUAN UNIV OF TECH

Process for producing hydrocarbon oil by performing supercritical hydrothermal treatment on waste plastic and straws

InactiveCN108559543AIncrease productionReduce viscosityLiquid hydrocarbon mixture productionHydrocarbon oils treatmentViscosityHeat treated

The invention relates to a process for producing hydrocarbon oil products by performing supercritical hydrothermal treatment on waste plastic and straws. The straws of farmland waste plants are liableto crack under the supercritical hydrothermal condition to generate active species to trigger cracking of plastic macromolecules, a catalyst is not used, and the problem that the catalyst and the products are difficult to separate is avoided; moreover, the components generated through plant cracking have a solvent effect and can obviously reduce the viscosity of plastic cracking oil. Supercritical water can serve as a solvent and a dispersing agent in the waste plastic cracking process to avoid system coking, the unsaturation degree of the plastic cracking products is reduced through the hydrogen transfer effect, and the stability of the products is improved. By the method, the waste plastic and the farmland waste straws are comprehensively utilized to serve as the raw materials, the costis low, the operation is simple and easy, a hydrogen source is not needed, the yield of the hydrocarbon oil is high and environmental pollution is avoided.

Owner:TIANJIN UNIV

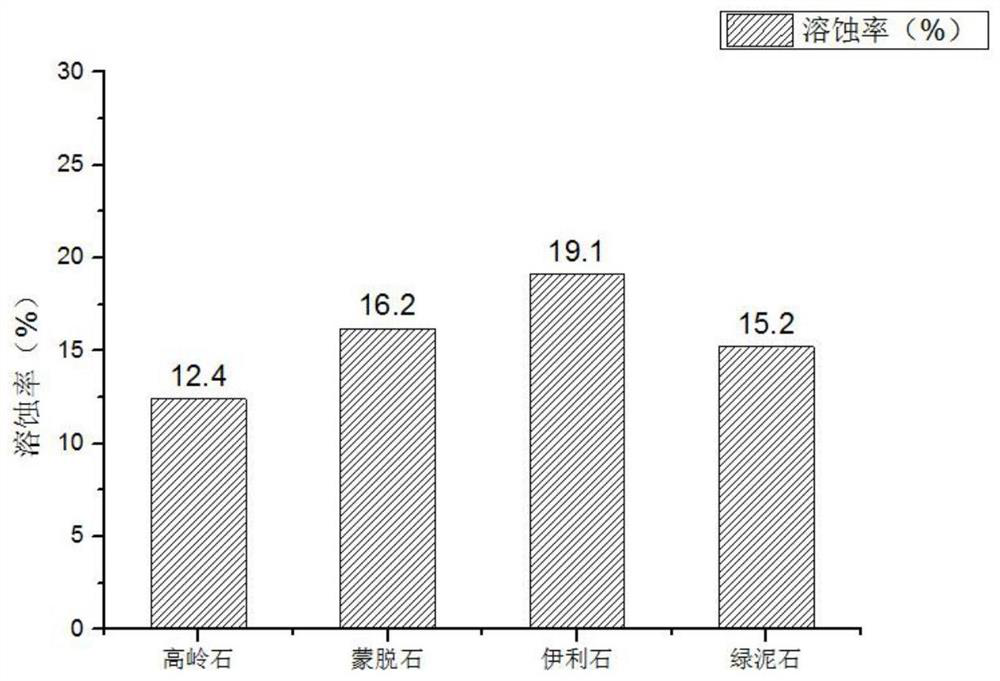

Oil field acidification plug removal system based on deep eutectic solvent

InactiveCN113234427AStable generationThe reaction environment is stableDrilling compositionHexamethylenetetramineSuccinic acid

The invention provides an acidification plug removal system based on a deep eutectic solvent. Specifically, the scale inhibitor is obtained by mixing the following raw materials in parts by mole: 9 to 11 parts of hexamethylenetetramine, 9 to 11 parts of D-sodium gluconate, 9 to 11 parts of sodium polyepoxysuccinate, 9 to 11 parts of polyaspartic acid, 7 to 9 parts of sodium ethylenediamine tetramethylene phosphonate, 6 to 9 parts of ethanol, 4 to 6 parts of rhamnolipid, 4 to 6 parts of benzotriazole and 4 to 7 parts of MA-AA polymer. The scale inhibitor, hydrochloric acid and villiaumite are mixed according to the total mole number ratio of 1: (2-4): (1-2) to form a solute, then the solute formed by mixing the scale inhibitor and the villiaumite is dissolved in a deep eutectic solvent, the novel plug removal system is obtained, and the total mole number ratio of the deep eutectic solvent to the solute formed by the villiaumite, the hydrochloric acid and the scale inhibitor is (0.01-0.5): 1. The deep eutectic solvent can control the strong acidity of hydrochloric acid, delay the intense reaction effect of a rock stratum and an acid liquid system, fully exert the solvent effect of the deep eutectic solvent, reduce the generation of precipitates and improve the plug removal efficiency.

Owner:DONGGUAN UNIV OF TECH

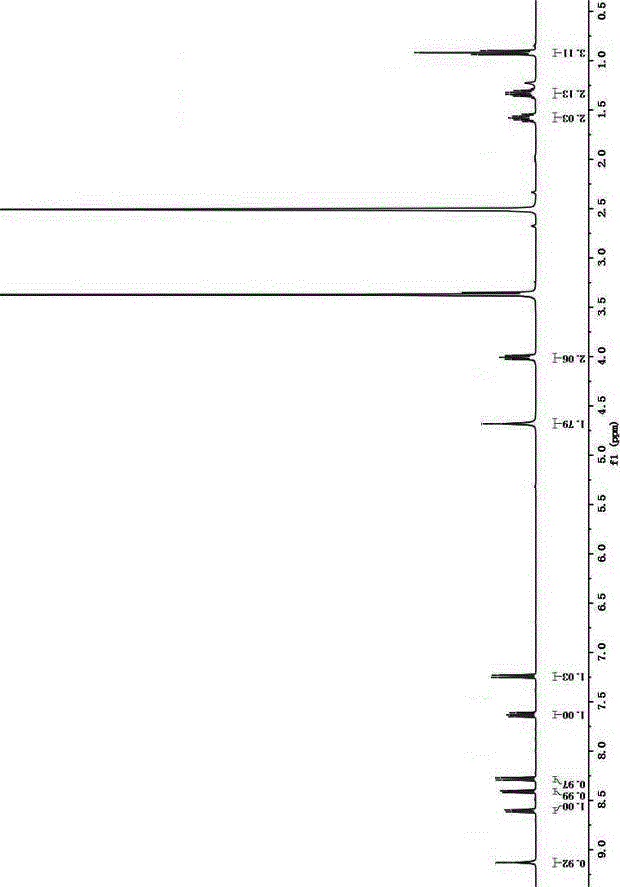

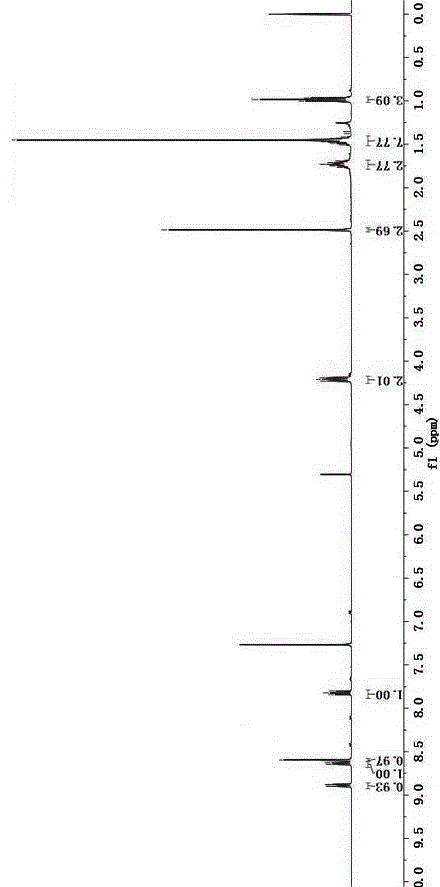

Boron-dipyrrolemethene fluorescent dye and preparation method and application thereof

ActiveCN105503921AGood biocompatibilityEasy to synthesizeMethine/polymethine dyesMicrobiological testing/measurementQuantum yieldStructural formula

The invention provides a boron-dipyrrolemethene fluorescent dye and a preparation method and application thereof. The boron-dipyrrolemethene fluorescent dye has the general structural formula I. The fluorescence property of the boron-dipyrrolemethene fluorescent dye has an obvious solvent effect. The fluorescence is strong in a polar solvent, and the fluorescence is weak in a non-polar solvent. The fluorescent intensity and the fluorescent quantum yield of the fluorescent dye have a good linear relation with solvent polarity. Selectivity is good, the fluorescent dye is not interfered with negative and positive ions, active oxygen, amino acid, nucleic acid, protein, viscosity and pH and can be used for living cell subcellular organelle positioning fluorescence staining, and the molecular formula of the fluorescent dye is as shown in the description.

Owner:DALIAN UNIV OF TECH

Method for detecting lidocaine content in lidocaine gel plaster

ActiveCN113295782AImprove stabilityHigh sensitivityComponent separationAgainst vector-borne diseasesAcetic acidIsocratic elution

The invention relates to a method for detecting the content of lidocaine in a lidocaine gel plaster, which comprises the following steps of: destroying a gel layer and a back lining layer by adopting a methanol soaking and fractional grinding mode so that lidocaine is completely dissolved in methanol, filtering, taking a subsequent filtrate, diluting with a mixed mobile phase to prepare a test solution, and performing high performance liquid chromatography analysis, in the chromatographic analysis process, adopting a 1-10% glacial acetic acid aqueous solution and methanol as a mixed mobile phase for isocratic elution, and optimizing the content and pH of glacial acetic acid in the glacial acetic acid aqueous solution and the proportion of the mobile phase during isocratic elution, so that the stability of lidocaine in a to-be-detected sample is improved, interference caused by a solvent effect is eliminated, the lidocaine content in the lidocaine gel plaster can be accurately determined, and the method is high in specificity, good in repeatability and high in sensitivity.

Owner:NANJING HEALTHNICE MEDICAL TECH +2

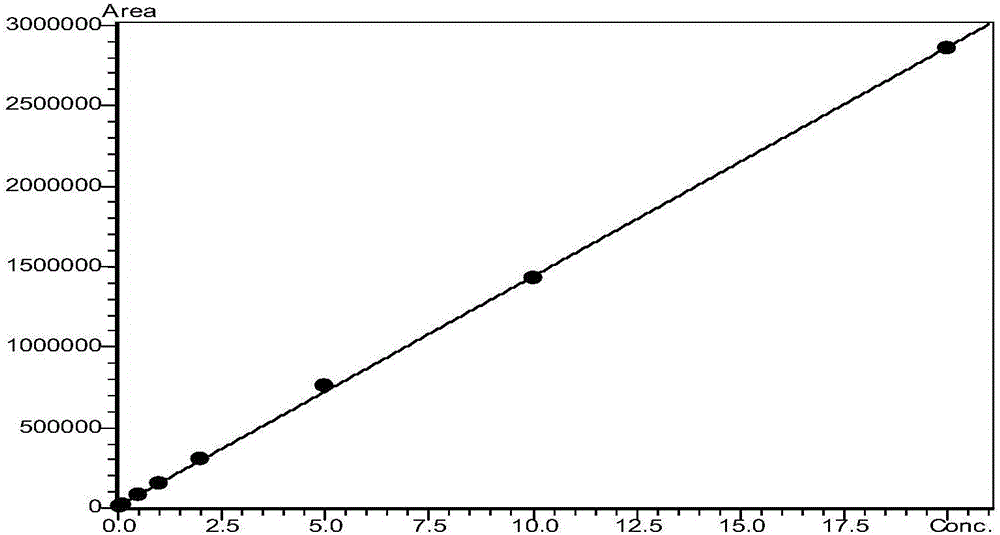

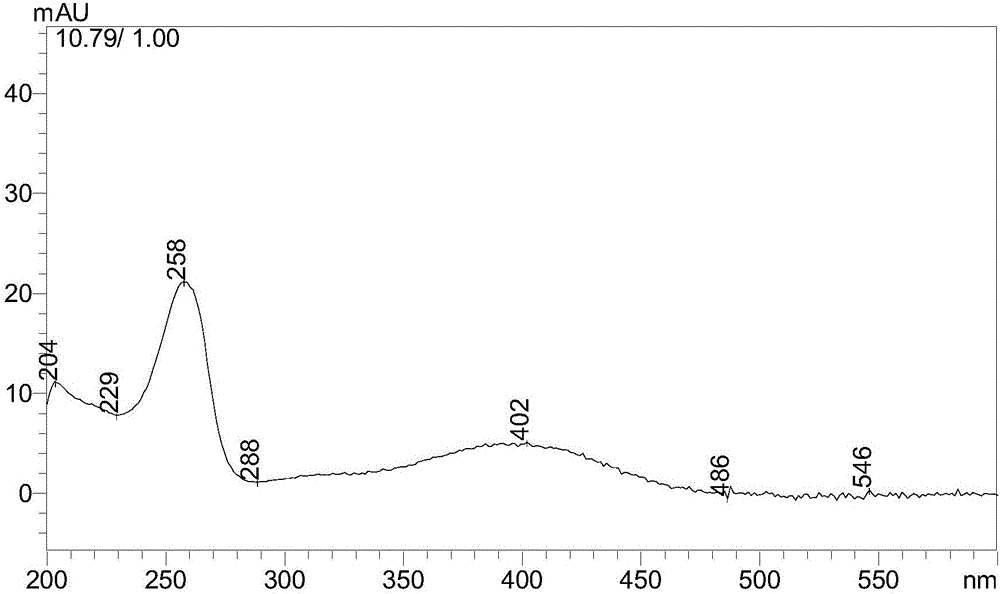

Method for rapidly recovering punicalagin from pomegranate rind extraction waste based on solvent effect

ActiveCN113390988AIncrease the use of added valueSimple methodComponent separationMethanol waterElution

The invention relates to a method for rapidly recovering punicalagin from pomegranate rind extraction waste based on a solvent effect. According to the method, based on a solvent effect, methanol water, acetonitrile water or formic acid water is used as a dispersing solvent to disperse a precipitate (namely pomegranate rind extraction waste) generated in a precipitation pretreatment process of a pomegranate ring extract, and then a sample is injected to a reversed-phase chromatographic column for separation; and a solvent effect is formed in the separation process by controlling the volume and the elution strength of a sample injection solvent and the elution strength of a mobile phase. Large-polarity punicalagin is rapidly eluted at a solvent peak, and small-polarity impurities are retained on a reversed-phase chromatographic column, so that a separation effect is achieved. According to the method, the pomegranate rind waste with the punicalagin content of 12% can be rapidly purified into a punicalagin-rich component with the punicalagin content range of 18-40%. The method provided by the invention is simple and rapid, has high purification efficiency, and provides powerful support for recycling the pomegranate rind extraction waste obtained by precipitation pretreatment in the pomegranate rind extract.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

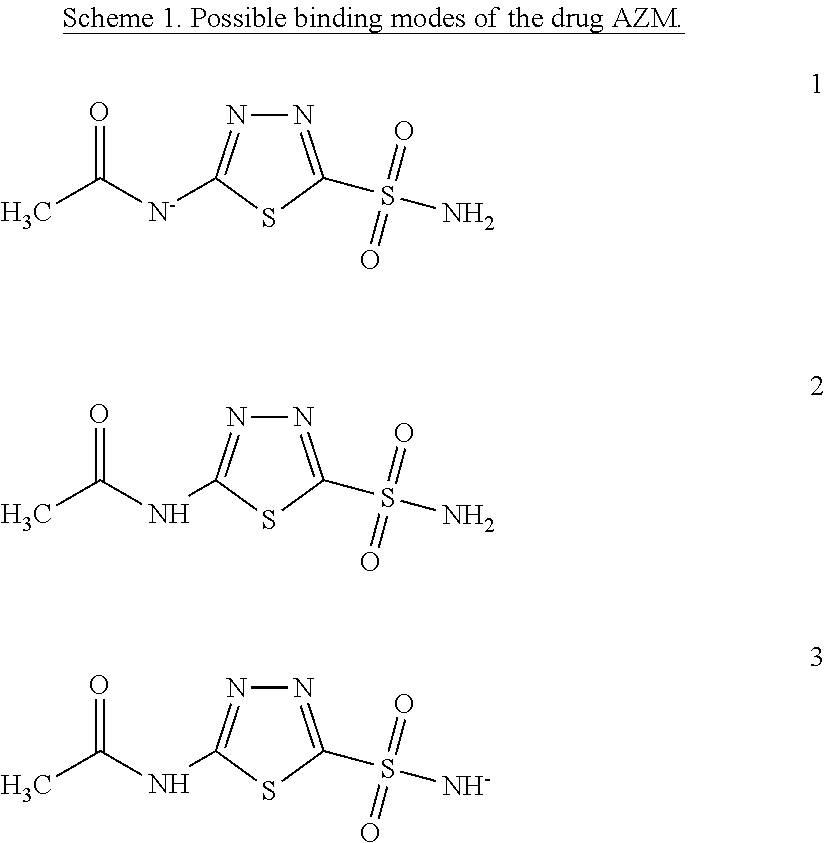

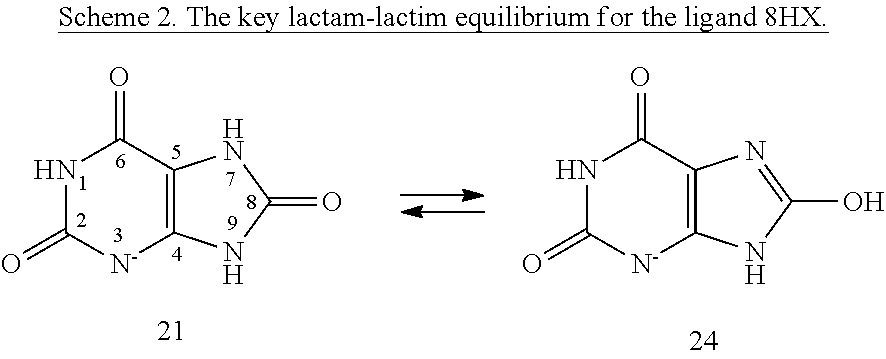

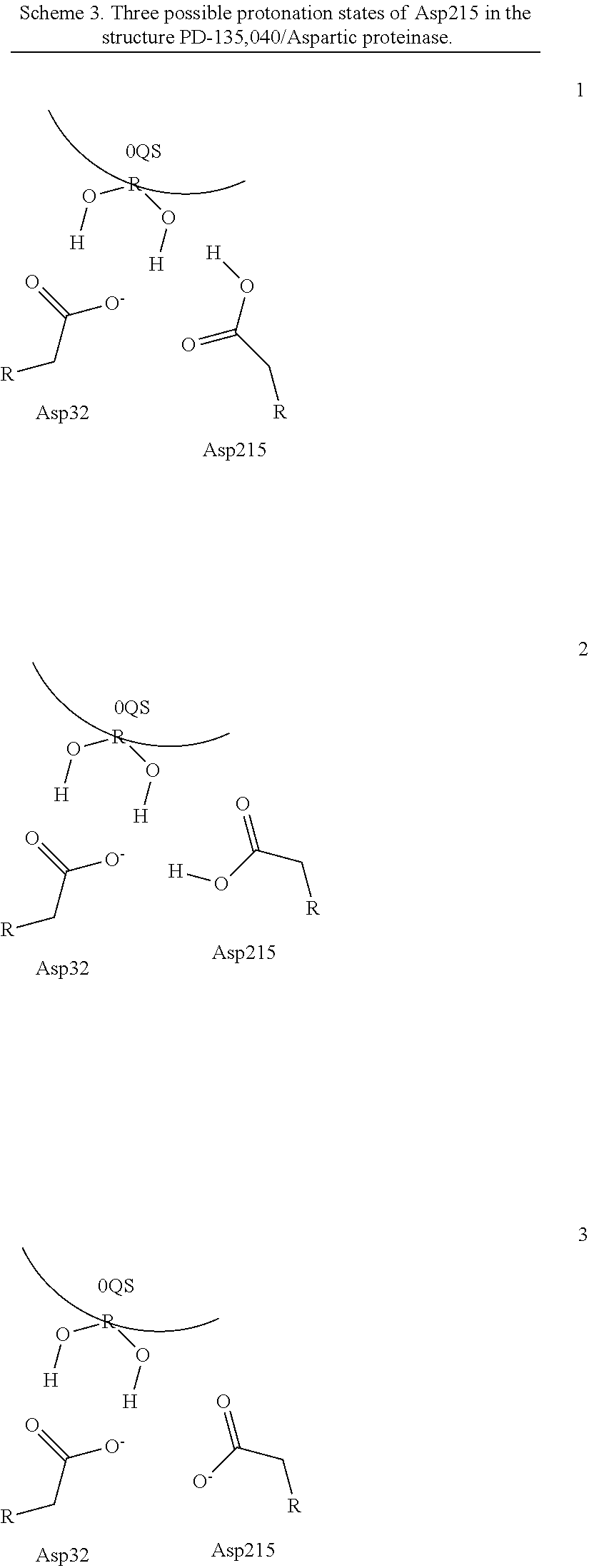

Quantum Mechanical/X-Ray Crystallography Diagnostic for Proteins

ActiveUS20170228495A1Accurate assessmentUseful and reliableProteomicsBiological testingProtonationMedicine

The invention is a diagnostic which overlays quantum mechanical analysis to x-ray crystallography data from one or more proteins to assess and identify the real world conformation, protonation and solvent effects of one or more moieties in said protein. This “overlay” occurs by scoring and identifying the protomer / tautomer states of the moieties using quantum mechanical analysis. The diagnostic results of the present invention accurately identify protein-ligand binding, rendered as an output to a user of a computer in which the x-ray crystallography data is analysed with semi-empirical Hamiltonian quantum mechanics and

Owner:QUANTUMBIO INC

Environment-friendly method for preparing adipic acid by catalytic oxidation

ActiveCN102816054BSimple processLow costOrganic compound preparationCarboxylic compound preparationCyclohexanoneCatalytic oxidation

The invention discloses an environment-friendly method for preparing adipic acid by catalytic oxidation. The method includes: at the beginning of reaction, adding cyclohexane, butanone serving as solvent, cyclohexanone serving as initiators and activated carbon supported nano-gold catalysts into a stainless steel high-pressure reactor; carrying out the catalytic oxidation reaction for 3-14 hours under the pressure of 0.9-2.1MPa at the temperature of 100-150 DEG C; separating after the reaction is completed to obtain the activated carbon supported nano-gold catalysts and reaction liquor, and processing the reaction liquor to obtain adipic acid crystalline solid; collecting the cyclohexanone serving as the initiators by oil-phase vacuum rotary steaming; and washing and drying the activated carbon supported nano-gold catalysts for recycling. By the method, solvent effect of the butanone serving as the solvent is particularly suitable for the nano-gold catalysts to catalyze the cyclohexane to generate the adipic acid by means of selective oxidation, and the problems of low activity and proneness to inactivation of the catalysts in reaction are solved. The method is simple in technological process, convenient for preparing and separating the catalysts, mild in reaction conditions, low in technological cost, economic, efficient and environment-friendly and pollution-free as molecular oxygen substitutes for nitric acid to be used as oxidants.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com