Method of ionic liquid cosolvent effect reinforced enzymatic synthesis of isoquercitrin

An ionic liquid and isoquercitrin technology, applied in the direction of fermentation, can solve the problems of low solubility of rutin and poor enzymatic reaction efficiency, and achieve the effects of good application prospect, increased reaction rate and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

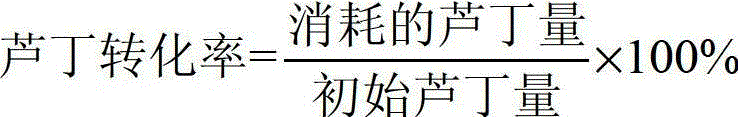

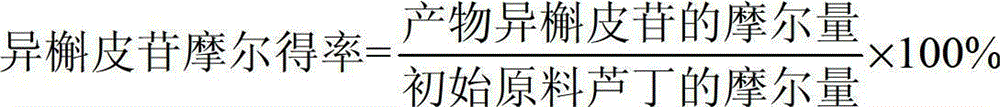

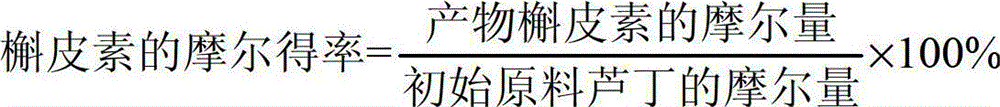

[0024] Prepare 0.26g / L rutin mother liquor with pH=3.0 with disodium hydrogen phosphate-citric acid buffer solution, and use 5% ionic liquid [Emim][BF 4 ], the ratio of anion and cation is 1:1, 90% rutin mother solution and 5% hesperidin enzyme solution constitute the reaction system, and the reaction system is shaken at 300r / min for 1h at 60°C. After the reaction, rutin, isoquercitrin and quercetin were detected by HPLC. The conversion rate of rutin, the molar yield of isoquercitrin and the molar yield of quercetin were 30%, 23% and 0.5% respectively. Compared with the buffer system under the same conditions, the molar yield of isoquercitrin An increase of 0.8%.

Embodiment 2

[0026] Prepare 0.41g / L rutin mother solution with pH=10.0 with disodium hydrogen phosphate-citric acid buffer solution, and use 50% ionic liquid [Bmim][BF 4 ], the ratio of anion and cation is 1:1, 45% rutin mother solution and 5% hesperidin enzyme solution constitute the reaction system, and the reaction system is shaken at 50r / min for 40h at 20°C. After the reaction, rutin, isoquercitrin and quercetin were detected by HPLC. The conversion rate of rutin, the molar yield of isoquercitrin and the molar yield of quercetin were 30%, 15% and 1% respectively. Compared with the buffer system under the same conditions, the molar yield of isoquercitrin increased 2%.

Embodiment 3

[0028]Prepare 0.82g / L rutin mother liquor with pH=5.0 with disodium hydrogen phosphate-citric acid buffer solution, and use 10% ionic liquid [Emim][BF 4 ], the ratio of anions and cations is 1:1, 72% rutin mother liquor and 18% hesperidin enzyme solution constitute the reaction system, and the reaction system is shaken at 120r / min for 7h at 40°C. After the reaction, rutin, isoquercitrin and quercetin were detected by HPLC. The conversion rate of rutin, the molar yield of isoquercitrin and the molar yield of quercetin were 94%, 96% and 11% respectively. Compared with the buffer system under the same conditions, the molar yield of isoquercitrin increased 89%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com