Preparation method of cage-shaped organic silicon hybridized star-shaped polyester soft PVC plasticizer

An organosilicon and plasticizer technology, applied in the field of functional polymer material preparation and modification, can solve problems such as increasing low temperature impact resistance, achieve enhanced low temperature impact resistance, good compatibility, and prevent plasticizer migration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation method of cage silicone hybrid star polyester soft PVC plasticizer, its preparation steps are as follows:

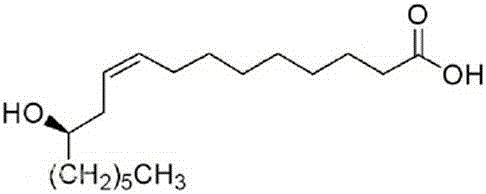

[0033] S1, ricinoleic acid is subjected to cracking and oxidation through ozone oxidation, and Renay-Ni catalytic hydrogenation reaction to obtain nonanol acid and 1,3-dihydroxynonanediol;

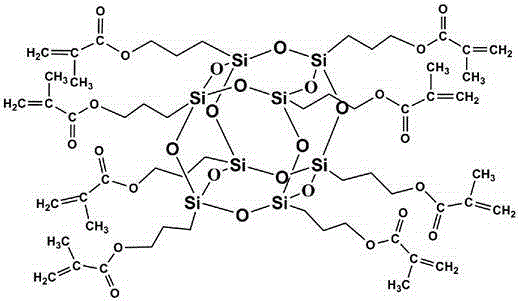

[0034] S2. The vertex group of octamethacryloyloxypropyl cage silsesquioxane undergoes an ester hydrolysis reaction in aqueous sulfuric acid, and stirs and refluxes for 4 hours to obtain octapropanol cage silsesquioxane;

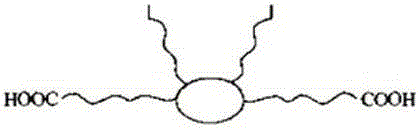

[0035] S3, the nonanol acid obtained in step S1 and 1,3-dihydroxynonanediol and the octapropanol-based cage silsesquioxane obtained in step S2 are 70:10:20 in mass ratio with dimer acid Mix to obtain a mixed solution;

[0036] S4, adding esterification reaction catalyst heteropolyacid PW to the mixed solution prepared in step S3 12 / SiO 2 And dehydrating agent DCC, reflux reaction for 2~6h, to obtain cage silicone hybrid star polyest...

Embodiment 2

[0039] A kind of preparation method of cage silicone hybrid star polyester soft PVC plasticizer, its preparation steps are as follows:

[0040] S1, ricinoleic acid is subjected to cracking and oxidation through ozone oxidation, and Pd / C catalytic hydrogenation reaction to obtain nonanol acid and 1,3-dihydroxynonanediol;

[0041] S2. The vertex group of octamethacryloxypropyl cage silsesquioxane undergoes an ester hydrolysis reaction in aqueous sodium hydroxide solution, and stirs and refluxes for 2 hours to obtain octapropanol cage silsesquioxane ;

[0042] S3, the nonanol acid obtained in step S1 and 1,3-dihydroxynonanediol and the octapropanol-based cage silsesquioxane obtained in step S2 are 70:20:10 in mass ratio with dimer acid Mix to obtain a mixed solution;

[0043] S4, adding esterification reaction catalyst heteropolyacid PW to the mixed solution prepared in step S3 12 / SiO 2 And dehydrating agent DCC, reflux reaction for 2~6h, to obtain cage silicone hybrid star ...

Embodiment 3

[0045] A kind of preparation method of cage silicone hybrid star polyester soft PVC plasticizer, its preparation steps are as follows:

[0046] S1, ricinoleic acid is subjected to cracking and oxidation through ozone oxidation, and Pd / C catalytic hydrogenation reaction to obtain nonanol acid and 1,3-dihydroxynonanediol;

[0047] S2. The vertex group of octamethacryloyloxypropyl cage silsesquioxane undergoes an ester hydrolysis reaction in aqueous sulfuric acid, and stirs and refluxes for 4 hours to obtain octapropanol cage silsesquioxane;

[0048] S3, the nonanol acid obtained in step S1 and 1,3-dihydroxynonanediol and the octapropanol-based cage silsesquioxane obtained in step S2 are 80:10:10 in mass ratio with dimer acid Mix to obtain a mixed solution;

[0049] S4, adding esterification reaction catalyst heteropolyacid PW to the mixed solution prepared in step S3 12 / SiO 2 And dehydrating agent DCC, reflux reaction for 2~6h, to obtain cage silicone hybrid star polyester sof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com