Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

201 results about "Sodium metaborate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium metaborite (NaBO₂) is a colorless solid chemical compound.

Method of generating hydrogen gas from sodium borohydride

ActiveUS7306780B1Rapid and complete reactionEliminate needPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesChemical/physical/physico-chemical microreactorsClosed loopCobalt

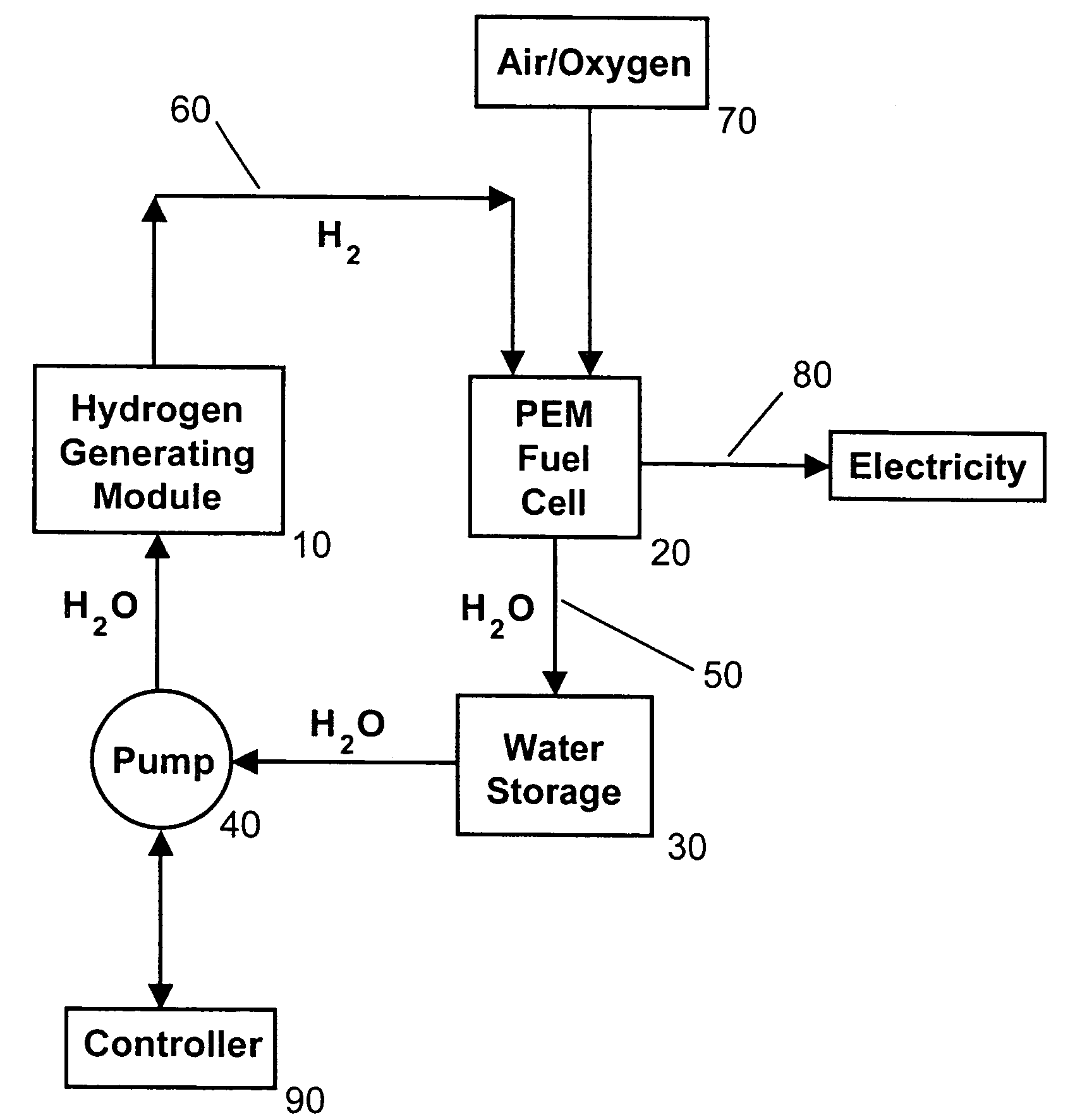

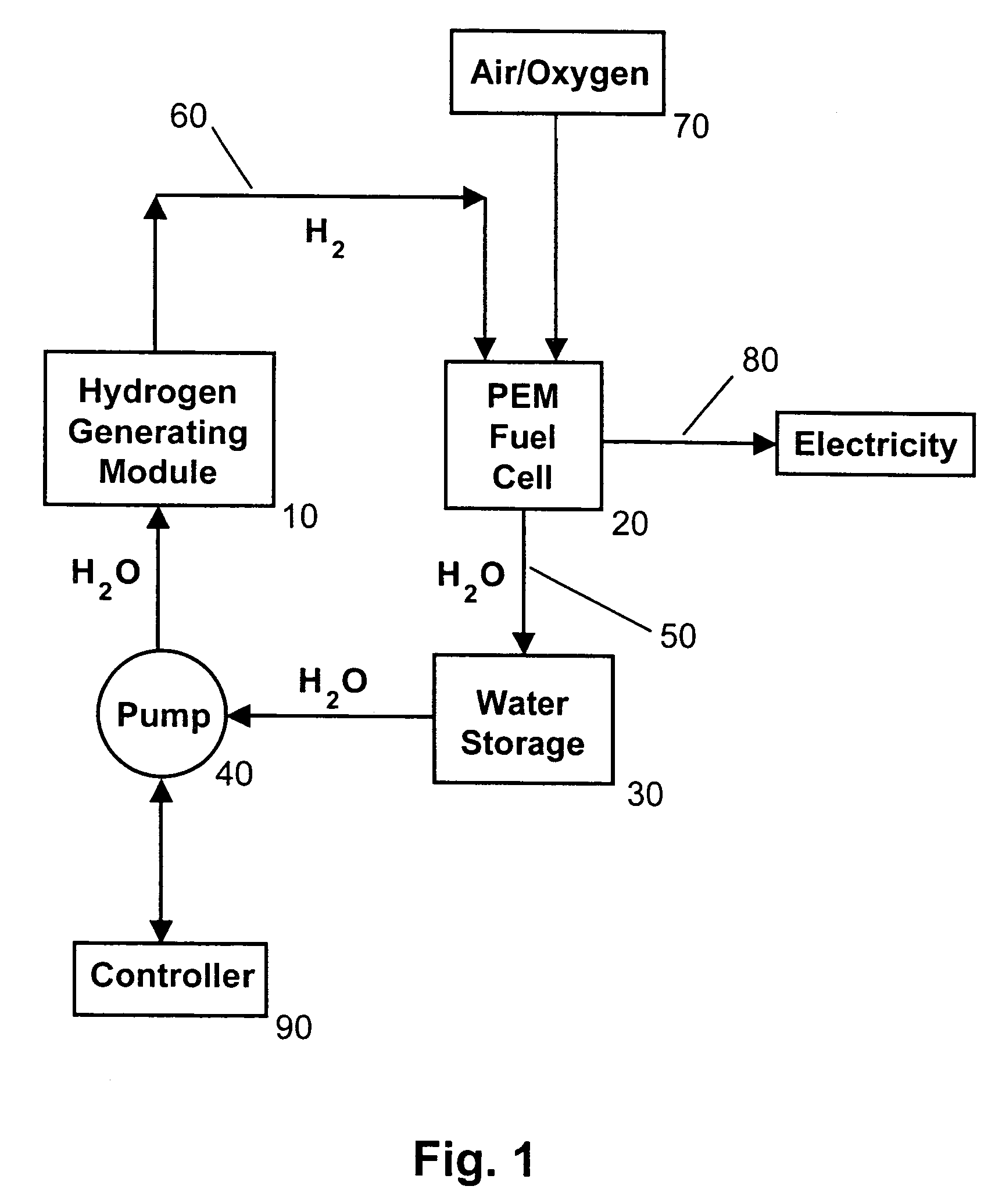

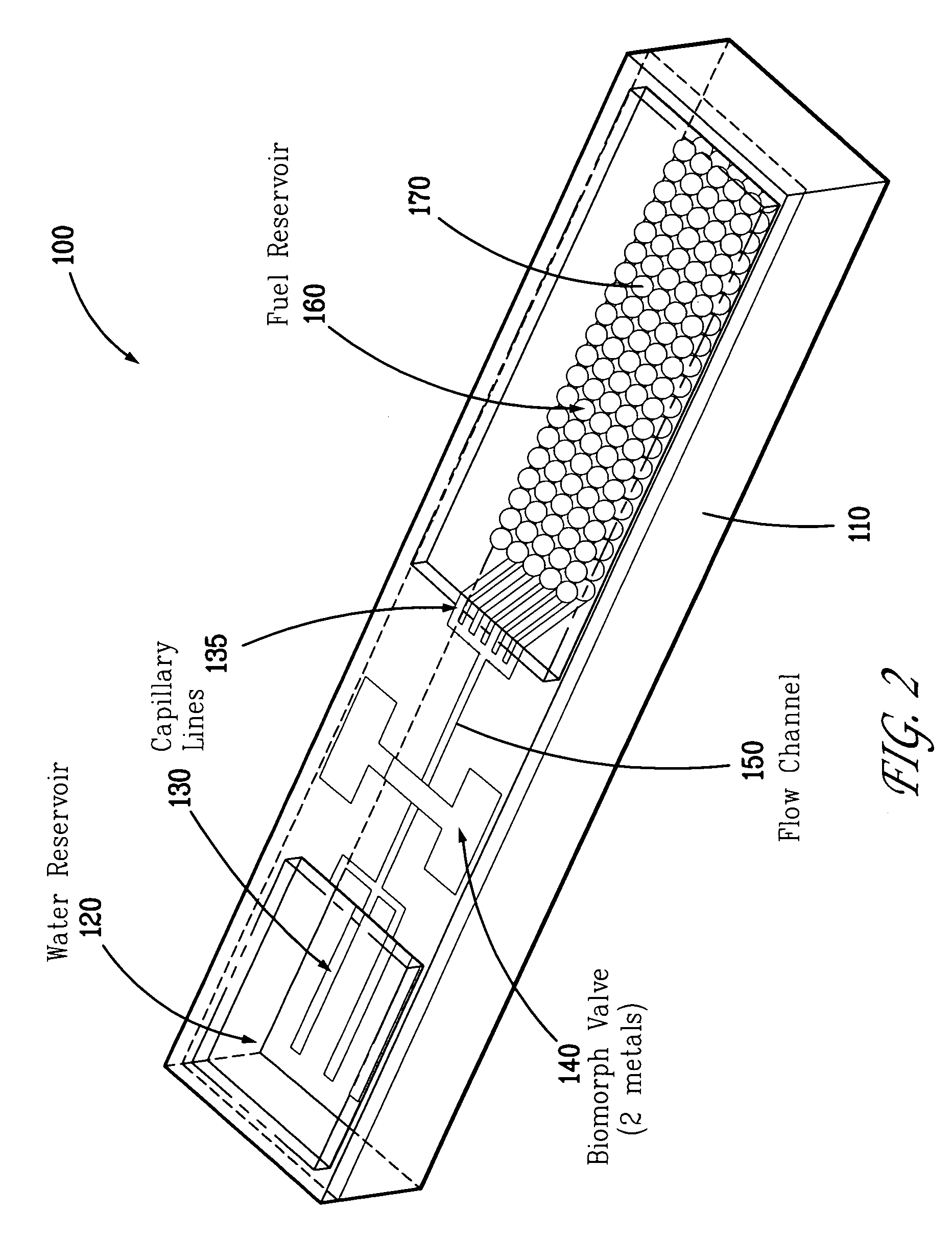

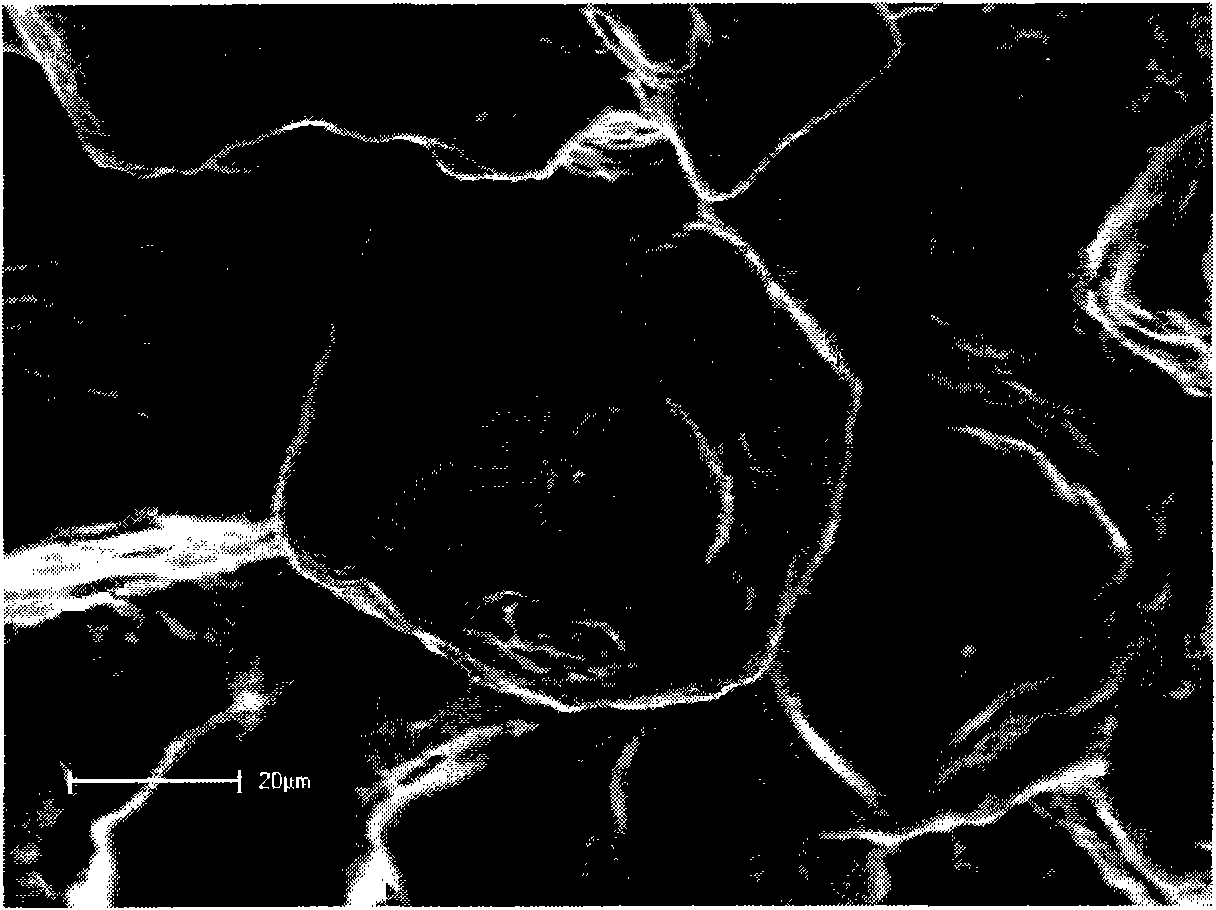

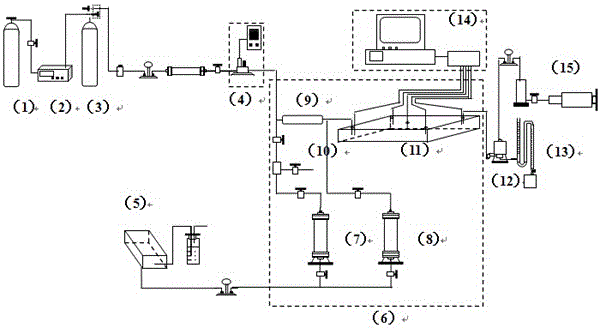

A compact solid source of hydrogen gas, where the gas is generated by contacting water with micro-disperse particles of sodium borohydride in the presence of a catalyst, such as cobalt or ruthenium. The micro-disperse particles can have a substantially uniform diameter of 1-10 microns, and preferably about 3-5 microns. Ruthenium or cobalt catalytic nanoparticles can be incorporated in the micro-disperse particles of sodium borohydride, which allows a rapid and complete reaction to occur without the problems associated with caking and scaling of the surface by the reactant product sodium metaborate. A closed loop water management system can be used to recycle wastewater from a PEM fuel cell to supply water for reacting with the micro-disperse particles of sodium borohydride in a compact hydrogen gas generator. Capillary forces can wick water from a water reservoir into a packed bed of micro-disperse fuel particles, eliminating the need for using an active pump.

Owner:NAT TECH & ENG SOLUTIONS OF SANDIA LLC

Method for preparing sodium borohydride by recycling sodium metaborate

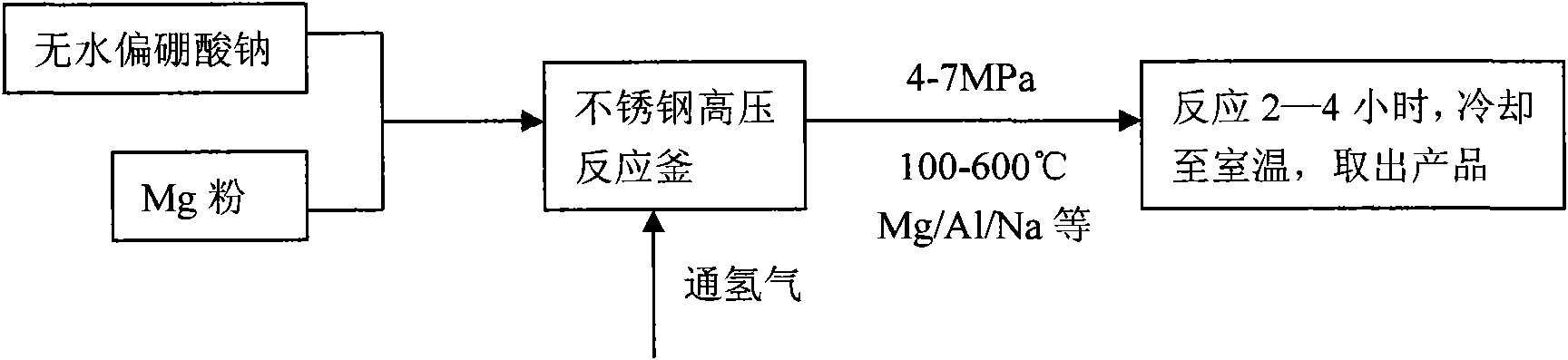

The invention relates to a method for preparing alkali metals hydroboron, in particular to a method for preparing sodium borohydride by recycling sodium metaborate, which solves the problem of recycling a byproduct sodium metaborate after the sodium borohydride is hydrolyzed to prepare hydrogen in the prior art, and is a novel method for preparing the sodium borohydride. The method takes magnesiumhydride as a hydrogen source and the sodium metaborate as a boron source, and prepares the sodium borohydride through mechanical and chemical reaction. In the presence of the hydrogen, magnesium powder is hydrogenated at certain temperature and pressure to prepare magnesium hydride; and the sodium metaborate and the magnesium hydride in a certain ratio are put into a ball mill, certain argon or hydrogen pressure, ratio of grinding media to material and grinding time are maintained, and the sodium metaborate can be reduced into the sodium borohydride. The method has the advantages of simple, convenient and safe process, no environmental pollution and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Foam oil displacement system with ultralow interfacial tension and use method of foam oil displacement system

ActiveCN105154055AReduce interfacial tensionImprove oil washing efficiencyFluid removalDrilling compositionCelluloseCocamidopropyl dimethylamine

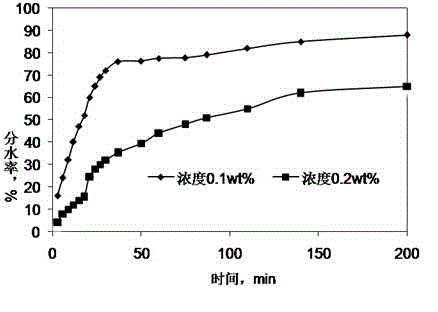

The invention provides a foam oil displacement system with ultralow interfacial tension and a use method of the foam oil displacement system. The oil displacement system is formed by mixing raw materials in percentage by weight as follows: 0.1%-0.3% of a foaming agent, 0.05%-0.15% of an inorganic reagent, 0.01%-0.10% of a foam stabilizer and the balance of water, wherein the foaming agent is dodecyl dimethyl betaine, dodecyl hydroxysulfobetaine, dodecyl hydroxypropyl sulphobetaine, lauramide propyl hydroxysulfobetaine, lauramide propyl betaine, cocamidopropyl dimethylamine oxide, gemini oxidized tertamine, polyoxyethylene dodecanol ether sulfate or sodium dodecyl sulfate; the inorganic reagent is sodium hydroxide, anhydrous sodium carbonate or sodium metaborate; the foam stabilizer is partially HPAM (hydrolyzed polyacrylamide), acrylamide copolymer, PACHV (high-viscosity polyanionic cellulose) or HPMC (hydroxypropyl methyl cellulose).

Owner:CHINA PETROLEUM & CHEM CORP +1

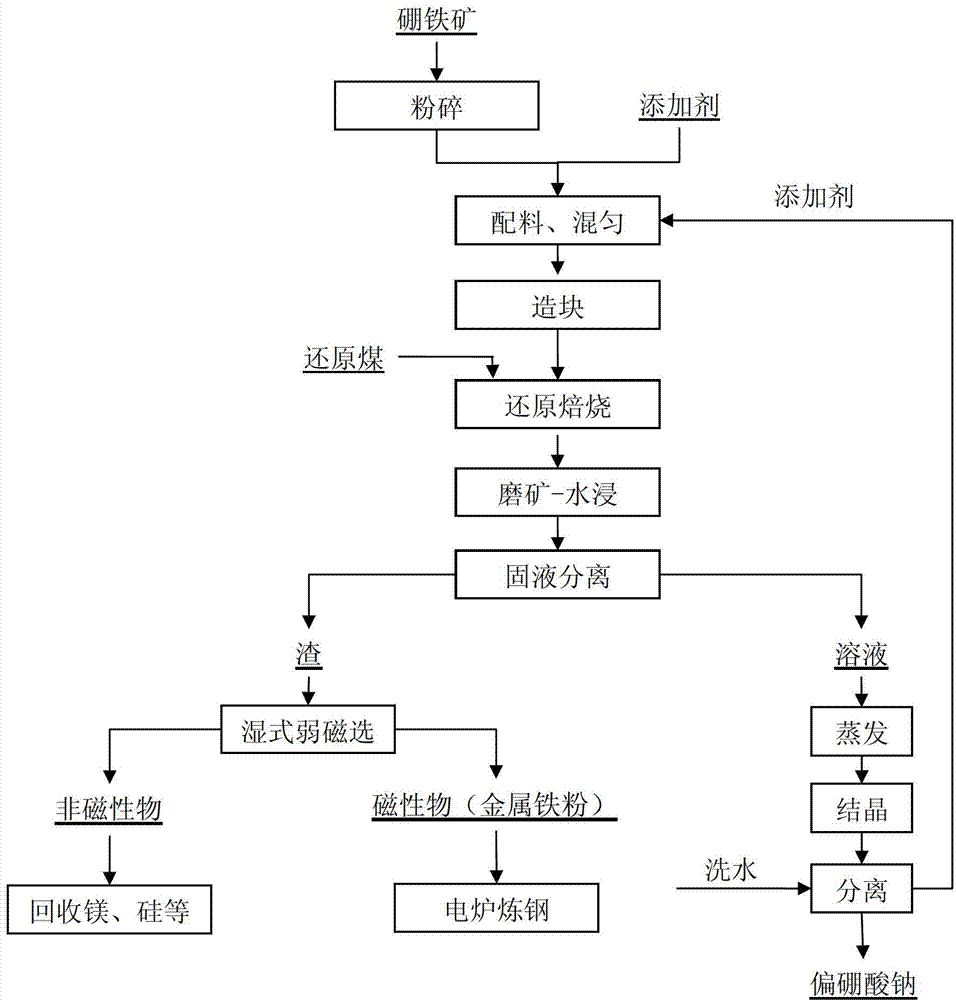

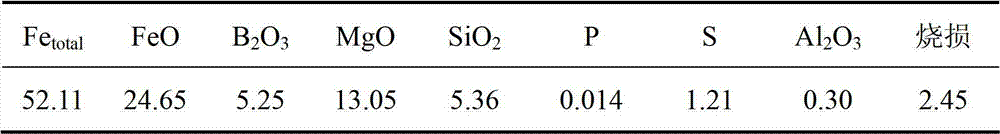

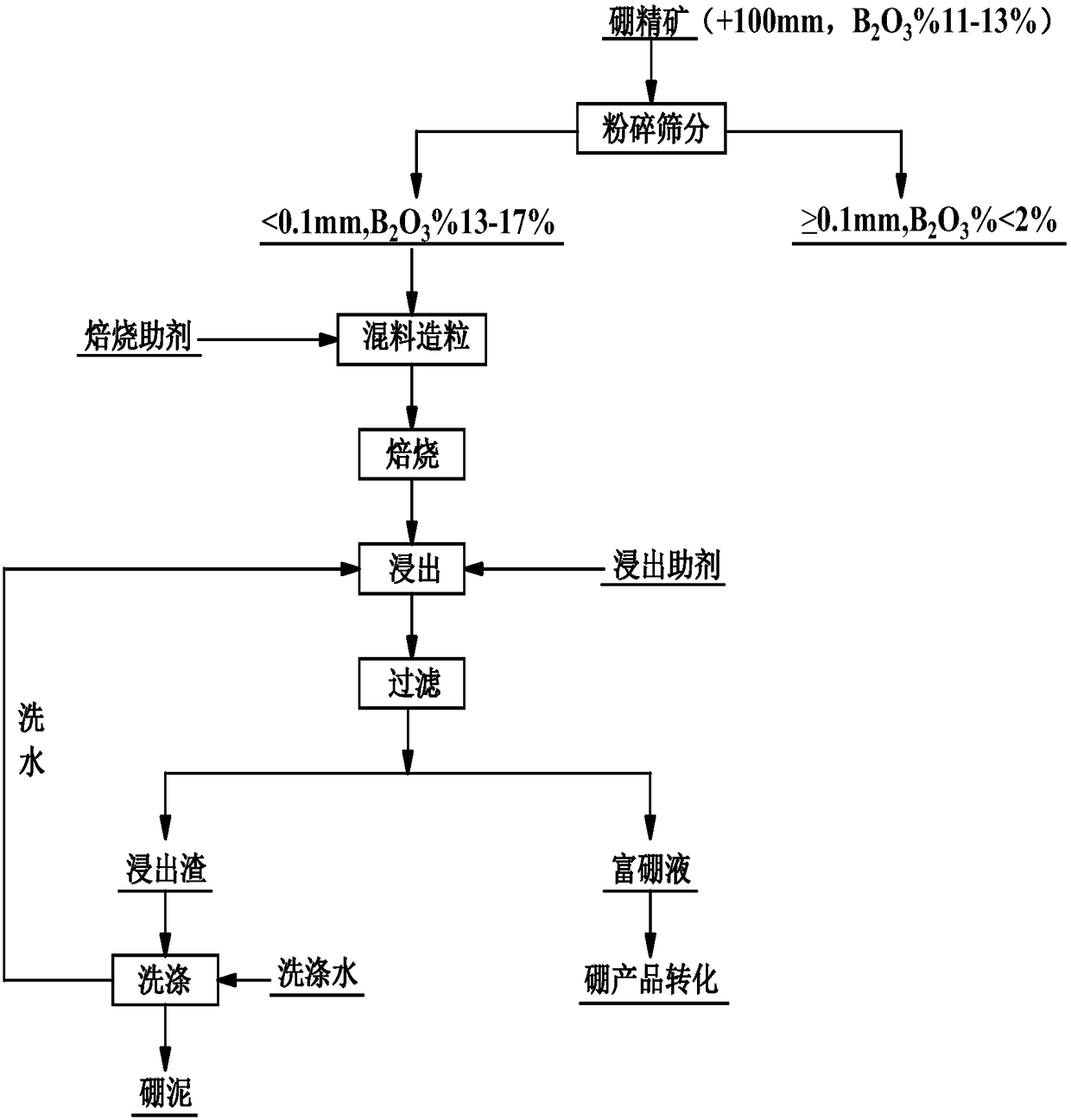

Method for synchronously extracting boron and iron in paigeite

ActiveCN102899434AHigh reactivitySolve the shortcomings of insignificant separation effectChemical industryProcess efficiency improvementSteelmakingSodium sulfate

The invention provides a method for synchronously extracting boron and iron in paigeite. The method comprises the following steps: fully mixing a paigeite powder and an additive composed of sodium carbonate, sodium sulfate, natrium humate, sodium fulvate and sodium oxalate by mixing, agglomerating, performing reduction roasting on dried paigeite agglomerates which take coal as a reducing agent, cooling the roasting agglomerates and placing in a bowl mill, synchronously grinding ore and leaching by water, performing solid-liquid separation on a pulp to obtain a filtrate containing sodium metaborate and filter residues containing metallic iron powder, evaporating and crystallizing a filtrate to obtain the sodium metaborate crystals; employ a wet type weak magnetic separation on the filter residue to obtain the directly reduced metallic iron powder with iron grade greater than 90%, wherein the metallic iron powder is a high-quality furnace material used for making steel of an electric furnace; and treating the magnetic separation nonmagnetic products to recover the valuable components such as magnesium and silicon. The method has the advantages of strong raw material adaptability, simple process flow, high production efficiency, less energy consumption, low cost, good comprehensive recovery effect of ferroboron and high product added value. The method provided by the invention can provide technical support for efficiently using the paigeite with abundant reserve volume for our country, and has wide popularization and application prospects.

Owner:CENT SOUTH UNIV

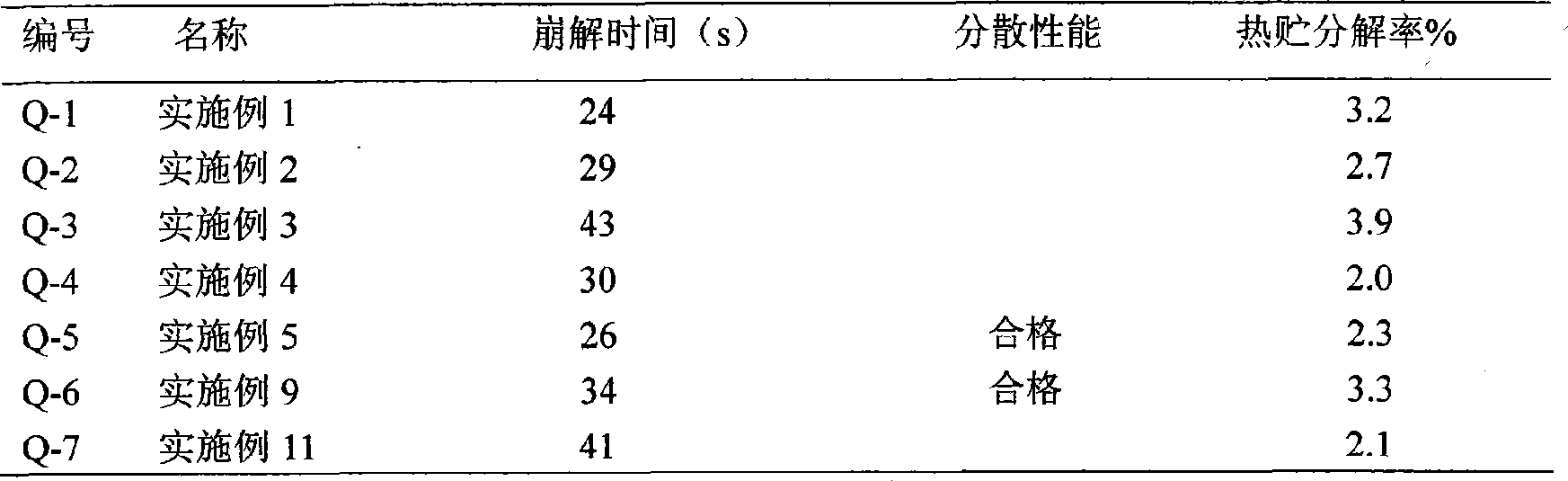

Boric fertilizer water dispersing granule and preparing method thereof

InactiveCN101531550AFast disintegrationDissolve (disperse) completelyFertiliser formsFertilizer mixturesMagnesium phosphatePotassium

The invention belongs to a new boric fertilizer, referring to a boric fertilizer water dispersing granule and preparing method thereof. The invention comprises one or more than one boric fertilizers and at least one surfactant; the materials are processed as the regular or irregular granules water dispersing granule; the weight part of the boric fertilizer is 5-95 parts; the rest is the assistant. The preferable solution of the invention is following: the boric fertilizer comprises one of the boric acid, boron oxide, boric acid ammonium, sodium tetraborate, calcium borate side, partial sodium borate, sodium borate tetrahydrate, magnesium diboride, sodium perborate, zinc borate, boric acid manganese, high-sodium borate, partial acid potassium, boron and magnesium fertilizer, boron and magnesium phosphate and boron mud or the mixture of the two or more than two of the above. The preparing method of the invention is scaling the prescription, mixing, crushing, and granule and drying to obtain the product. The boric fertilizer water dispersing granule of the invention has a fast disintegration, dissolving (dispersing) completely, not plugging the nozzle and the dropping pipe lines, no heating while using, easy to absorb moisture, packaging, storage and transportation, measurement, the use of low cost, widely used in food crops, cash crops, horticulture, lawns and urban greening; the market prospect is very broad.

Owner:SHENZHEN LANGTAI BIOTECH

Multifunctional extreme-pressure antiwear cutting fluid and preparation method thereof

InactiveCN103666733AStrong extreme pressureImprove wear resistanceLubricant compositionRapeseedSebacic acid

A multifunctional extreme-pressure antiwear cutting fluid is prepared form the following raw materials: by weight, 1-2 parts of diethanolamine, 3-4 parts of boric acid ester, 2-3 parts of borax, 4-5 parts of sebacic acid, 1-2 parts of petroleum sodium sulfonate, 2-3 parts of molybdenum disulfide, 2-3 parts of methylparaben, 1-2 parts of sodium metaborate, 0.8-1.2 parts of fatty alcohol polyoxyethylene ether, 0.05-0.1 part of lanthanum acetate, 12-14 parts of rapeseed oil, 6-8 parts of an additive and 200 parts of water; the multifunctional extreme-pressure antiwear cutting fluid, by use of the boric acid ester, the molybdenum disulfide, the lanthanum acetate and the rapeseed oil, has good extreme pressure property, wear resistance and lubricity, the service life of the cutting fluid and a machine tool is prolonged, and the multifunctional extreme-pressure antiwear cutting fluid has good rust resistance to ferrous metals and copper and other non-ferrous metals, is wide in use, is a multifunctional cutting fluid, and at the same time has strong inhibitory effects on bacteria and mould.

Owner:MAANSHAN HENGYI MACHINERY MFG

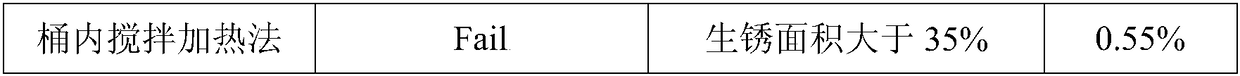

Efficient multipurpose metal cleaning agent

The invention discloses an efficient multipurpose metal cleaning agent, which is prepared from alkylphenol polyoxyethylene, fatty alcohol-polyoxyethylene ether, alkylolamide, oleic acid, triethanolamine, ethylene glycol monobutyl ether, anhydrous sodium metasilicate, sodium metaborate, sodium molybdate, organic silicon defoamer and water according to certain percentage by weight. The cleaning agent has quick oil removing and stain removing speed, and the cleaned surface has better corrosion inhibition capability, thus the cleaning agent is a low-foaming and basically non-toxic green product. When the aqueous solution, for which the working temperature is 60-80 DEG C and the dosage of the cleaning agent is 5%, is used for washing a steel piece for 3-5 minutes, the surface of the steel piece is clean, and the rust-free cycle of the steel piece is not less than 7 days.

Owner:郭良生 +1

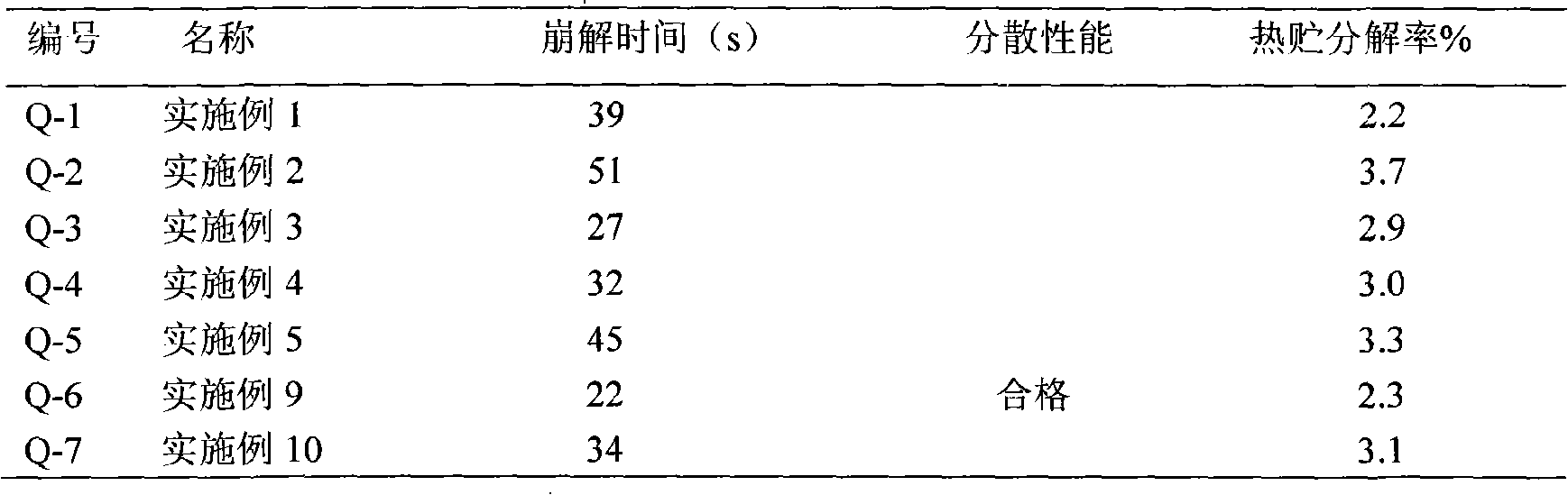

Boron fertilizer effervescence granule and method of producing the same

InactiveCN101550040AFast disintegrationImprove solubilityFertilizer mixturesMagnesium phosphateManganese

The invention relates to a boron fertilizer effervescence granule and method of producing the same, pertaining to a novel boron fertilizer. The boron fertilizer effervescence granule includes one or more boron fertilizer and one or more compounds contacted with water to generate gas, wherein, the weight part scope of the boron fertilizer is from 61 to 95. The preferred scheme of the invention is that the boron fertilizer includes one of boric acid, boron oxide, ammonium pentaborate, sodium tetraborate, calcium metaborate, sodium metaborate, tetrahydate octa sodium borate, magnesium diboride, sodium perborate, zinc borate, manganese borate, sodium perborate, potassium metaborate, boron magnesium fertilizer, boron and magnesium phosphate, and boron mud, or a mixture of two or more of the above. The preparation method of the invention includes: weighing the formulation material, mixing, grinding, granulating, and drying to obtain. The inventive boron fertilizer effervescence granule has a fast disintegrating velocity in the water; completely dissolving(dispersing); non-clogging of nozzle and drip irrigation pipeline; no need of heating when in use; no absorption of moisture; low packaging, storage and transportation, measurement and use cost; wide application in food crops, cash crops, horticulture, lawns and urban greening; and very broad market prospect.

Owner:SHENZHEN LANGTAI BIOTECH

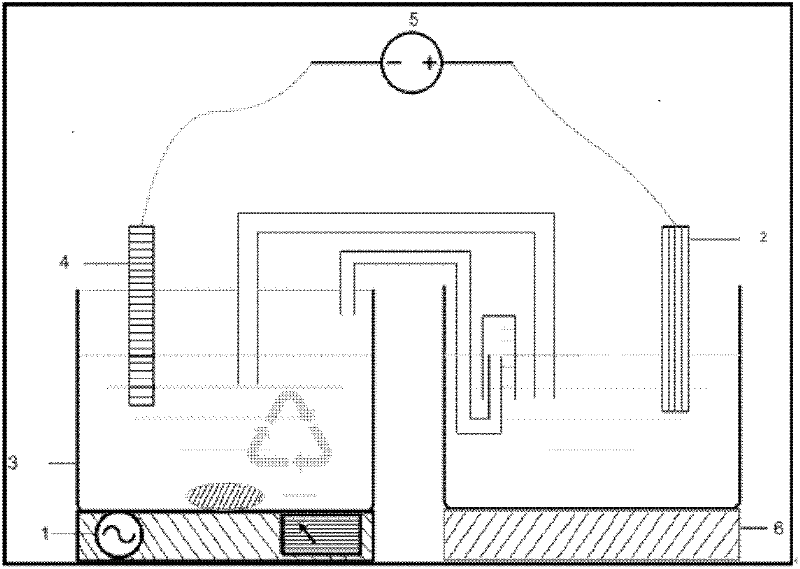

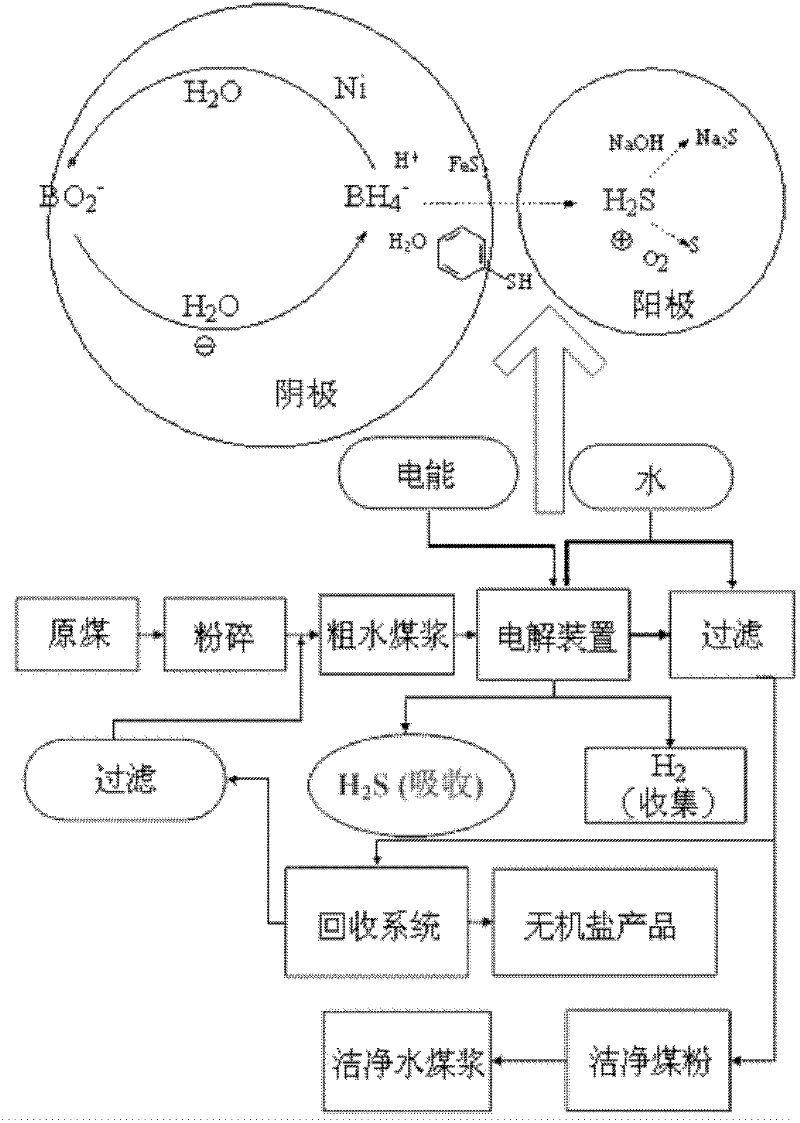

Method for electrolysis, reduction and desulfurization of coal water slurry

The invention relates to a method for electrolysis, reduction and desulfurization of coal water slurry, which comprises the following steps: a, adding sodium metaborate and sodium hydroxide solution into a cathode electrolysis cell, adding raw coal water slurry powder, and uniformly mixing; b, adding sodium hydroxide solution into an anode electrolysis cell; c, leading the voltage into the anode electrolysis cell and the cathode electrolysis cell, and simultaneously mixing the solution in the electrolysis cells for electrolysis; and d, filtering and washing products in the cathode electrolysis cell after the electrolysis, thus completing the electrolysis, reduction and desulfurization of the coal water slurry. The sodium metaborate is used as the main electrolyte, a small amount of sodium hydroxide is added as the auxiliary electrolyte, the electrochemical reduction reaction is carried out under alkaline conditions, the sulfur in the coal water slurry is converted into hydrogen sulfide, and the hydrogen sulfide is absorbed by alkali solution in the anode cell. Meanwhile, a small amount of metal Ni2+ catalyst is added into the cathode electrolysis cell, so that the desulfurization effect can be improved greatly. The reaction of the green electrochemical desulfurization process is mild, the operation is simple, the desulfurization efficiency is high, and the cost is low.

Owner:SHANGHAI JIAO TONG UNIV

Method for activating ludwigite

The invention provides a method of activating ludwigite. Firstly, ludwigite powders and Na2CO3 are mixed evenly at a certain rate, wherein, the ludwigite powders have a particle size of 80 to 350 meshes, and contain7 to 18 percent of B2O3, 7 to 32 percent of TFe, and 22 to 44 percent of MgO. After activating reaction under high temperature, the B2O3 in the ludwigite is changed into a water-soluble boric acid sodium salt, with reactivity up to 90 to 96 percent; then, adding water into milled material, heating and leaching, a boric acid sodium salt solution is filtered out, finally sodium metaborate, borax, or the boric acid sodium salt can be obtained through vaporization-concentration, cooling, crystallization or carbonation. The invention is characterized in that the reactivity liveness of boron-iron ore containing the ludwigite can be increased from less than 60 percent to 90 to 96 percent; and the magnetic performance of the obtained filter cake can be increased by 10 to 90 percent compared with raw ore, thereby improving the utilization value of slag (boron mud).

Owner:DALIAN UNIV OF TECH

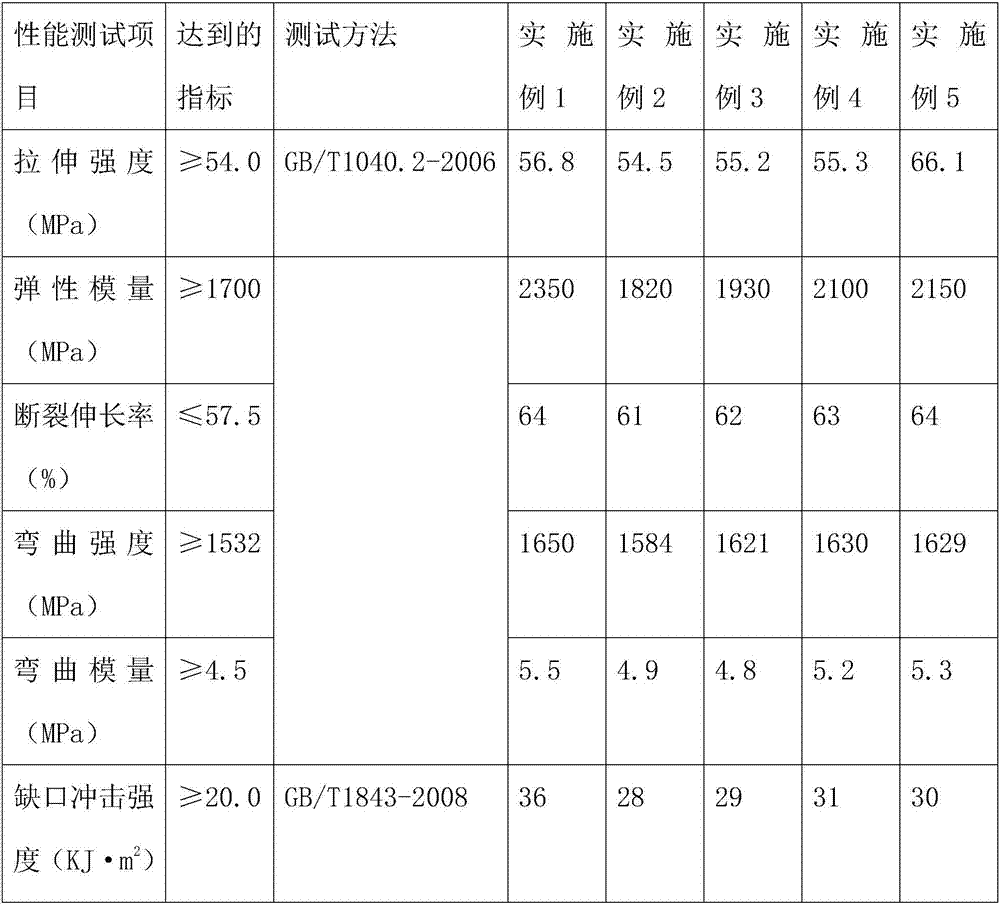

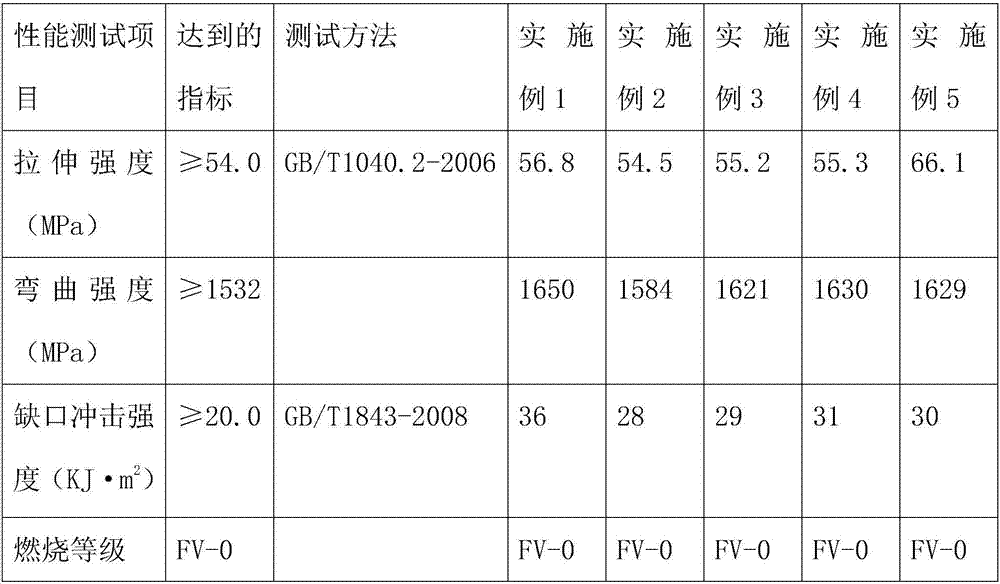

Medical corrosion-resistance high-toughness 3D printing material

The invention discloses a medical corrosion-resistance high-toughness 3D printing material which is prepared from the raw materials of ABS resin, SAN resin, butadiene rubber, chloroprene rubber, epoxy acrylic resin, polymethyl methacrylate, polycarbonate, polyolefin elastomer, sulphur, sulfur dichloride, chlorinated paraffin, dimethicone, zinc borate, isocyanate, nano graphite, carbon black, barite powder, nano aluminum hydroxide, polyphosphoric acid, nano silicon dioxide, mica powder, talcum powder, a silane coupling agent KH-560, sodium metaborate, pentaerythritol, polylactic acid, polycaprolactone, sodium stearate, sodium dodecyl benzene sulfonate, an antioxidant, a degassing agent, dimethicone, an anticorrosion additive, a modified filler and a toughening and modifying agent. The 3D printing material disclosed by the invention has excellent corrosion resistance and toughness.

Owner:HEFEI SKE INTELLIGENT TECH

Glass powder, preparation method of glass powder, conductive silver slurry and preparation method of conductive silver slurry

ActiveCN102674696AImprove photoelectric conversion efficiencyEasy to prepareNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteBismuth telluride

The invention provides glass powder which contains 5-30% of sodium stannate, 1-20% of sodium metaborate, 1-20% of sodium silicate and 40-70% of bismuth telluride by mass. The glass powder overcomes the traditional shortcomings, does not require processes such as high temperature melting and quenching and can be obtained by simply directly mixing components evenly. A preparation method of the glass powder is simple, and the glass powder is excellent in performance. Conductive silver slurry is further provided. The conductive silver slurry contains 65-90% of the glass powder, 1-10% of sliver powder and 5-30% of organic carrier by mass.

Owner:BYD CO LTD

High-temperature-resistant tensile control cable material

The invention discloses a high-temperature-resistant tensile control cable material. The high-temperature-resistant tensile control cable material is prepared from phenolic resin, silicon rubber, butadiene rubber, alkyd resin, chloroprene rubber, epoxy resin, coumarone resin, trimethyl phosphate, zinc borate, carbon black, vermiculite, zinc borate, nano silicon carbide, glass fibers, nano magnesium oxide, sodium metaborate, wood fiber powder, antimonous oxide, nano aluminium hydroxide, isocyanate, polysiloxane, diisooctyl phthalate, a silane coupling agent KH-550, chlorinated paraffin, ammonium polyphosphate, styrene, a vulcanizing agent DTDM, a plasticizer, high-temperature-resistant modification additives and tensile modification additives. The control cable material has excellent high temperature resistance and tensile performances.

Owner:安徽华海特种电缆集团有限公司

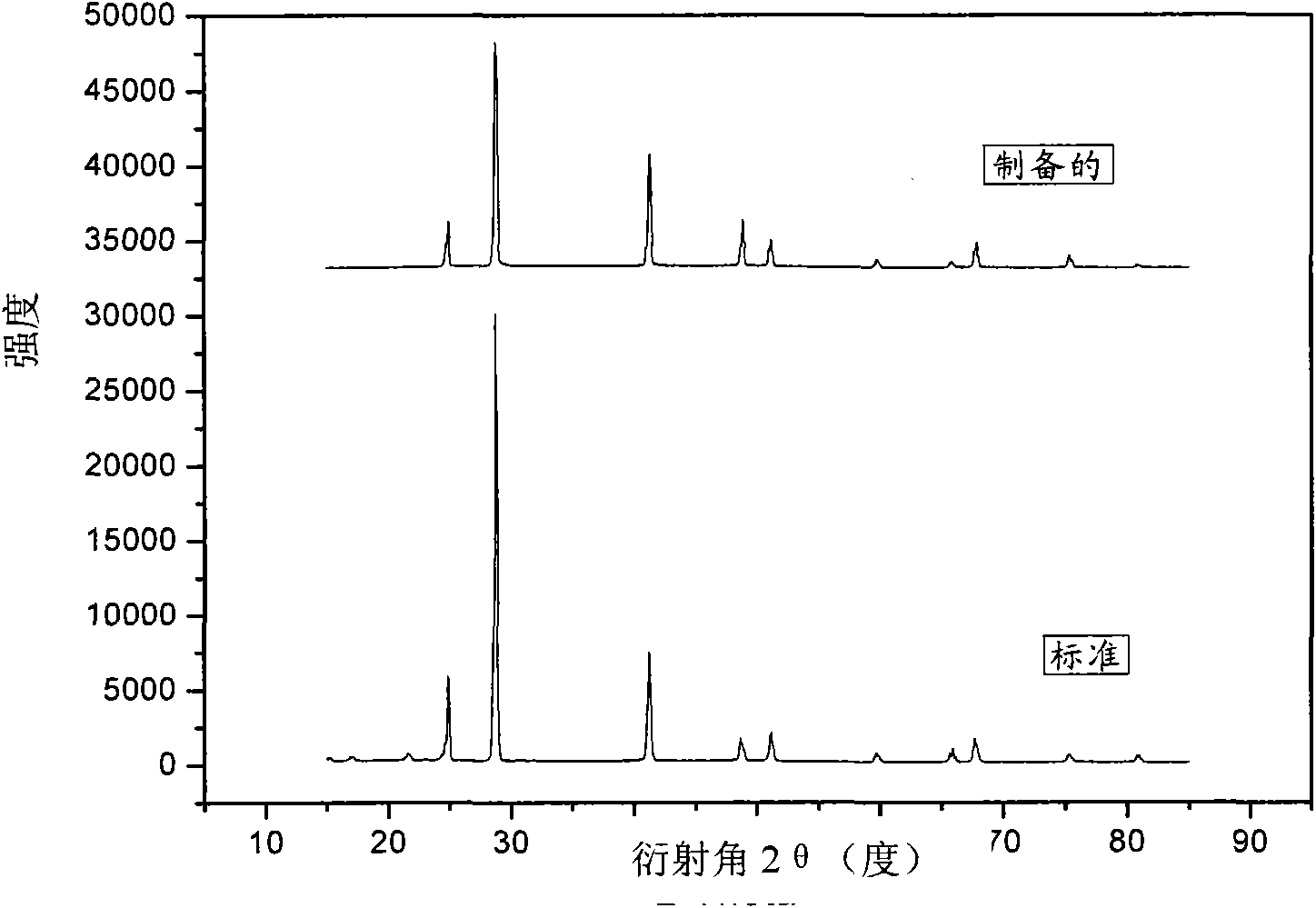

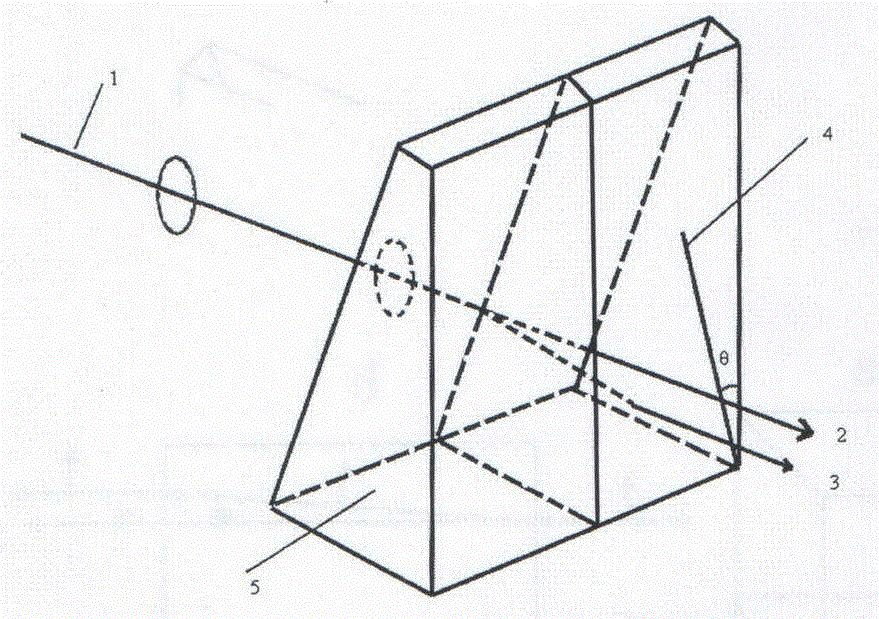

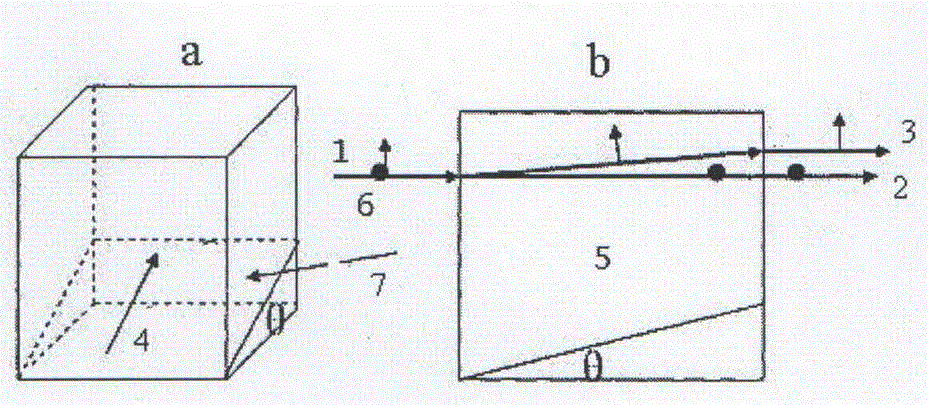

Compound sodium metaborate birefringent crystal and preparing method and application thereof

ActiveCN106149055APromote growthCut wellPolycrystalline material growthFrom frozen solutionsCongruent meltingSpace group

The invention relates to a compound sodium metaborate birefringent crystal and a preparing method and application thereof, in particular to a sodium metaborate birefringent crystal with a molecular formula of NaBO2 used in the deep-ultraviolet-infrared waveband. The chemical formula of the crystal is NaBO2, molecular weight is 65.8, the crystal belongs to a trigonal system, space group is shown in the description, and cell parameters a=11.8617angstroms, b=11.8617angstroms, c=6.3957angstroms, V=590.93 cubic angstroms, and Z=4; light-pervious range is 180-3500 nm, and birefringence is between 0.09(3500 nm) and 0.23(180 nm). Crystal growth is conducted with a high-temperature melt method or high-temperature solution method. The crystal is moderately hard and easy to process, growth is easy due to congruent melting, and birefringence is high; the crystal has a high application value in the optical and communication fields and can be used for preparing optoisolators, circulators, light beam displacers, optical polarizers or optical modulators.

Owner:XINJIANG TECHN INST OF PHYSICS & CHEM CHINESE ACAD OF SCI

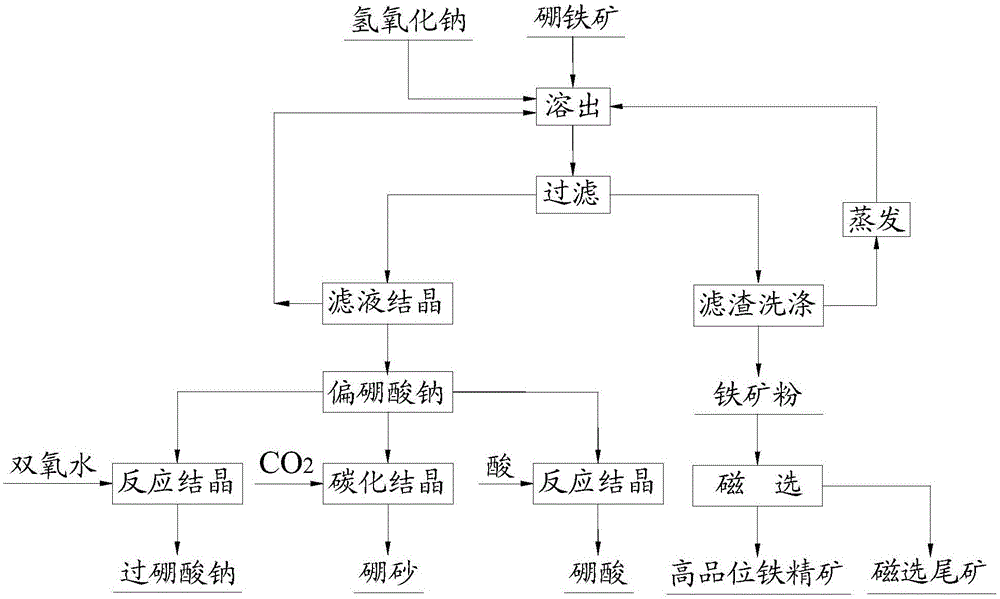

Method for separating boron and iron from ludwigite

InactiveCN106319198ALess investmentMild operating conditionsPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesProcess efficiency improvementSteelmakingDissolution reaction

The invention relates to a method for separating boron and iron from ludwigite. The method comprises the steps of dissolving out ludwigite by using a sodium hydroxide solution in an autoclave, after carrying out solid-liquid separation, enabling sodium metaborate to enter a dissolution fluid, and cooling a crystal after concentrating to obtain sodium metaborate, wherein sodium metaborate is used for preparing sodium perborate, borax and boric acid; and cleaning first filter residues, and carrying out magnetic separation to obtain a high-grade iron ore concentrate and realize boron and iron separation. According to the method for separating boron and iron from ludwigite, the ludwigite is not needed to be subjected to high-temperature activated roasting treatment, the operation condition for dissolution reaction is relatively mild, and the dissolution rate of boron oxide can reach 88-93% and above; the method can be used for reducing energy consumption and high-temperature roasting equipment investment and is easy to control in operation; the iron grade of the obtained iron ore concentrate is increased by 7-15% or above, so that the steelmaking and ironmaking requirements are met; and sodium metaborate obtained by separation is used for further preparing sodium perborate, borax, boric acid and the like which have high added values, so that the utilization value of boron is increased.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

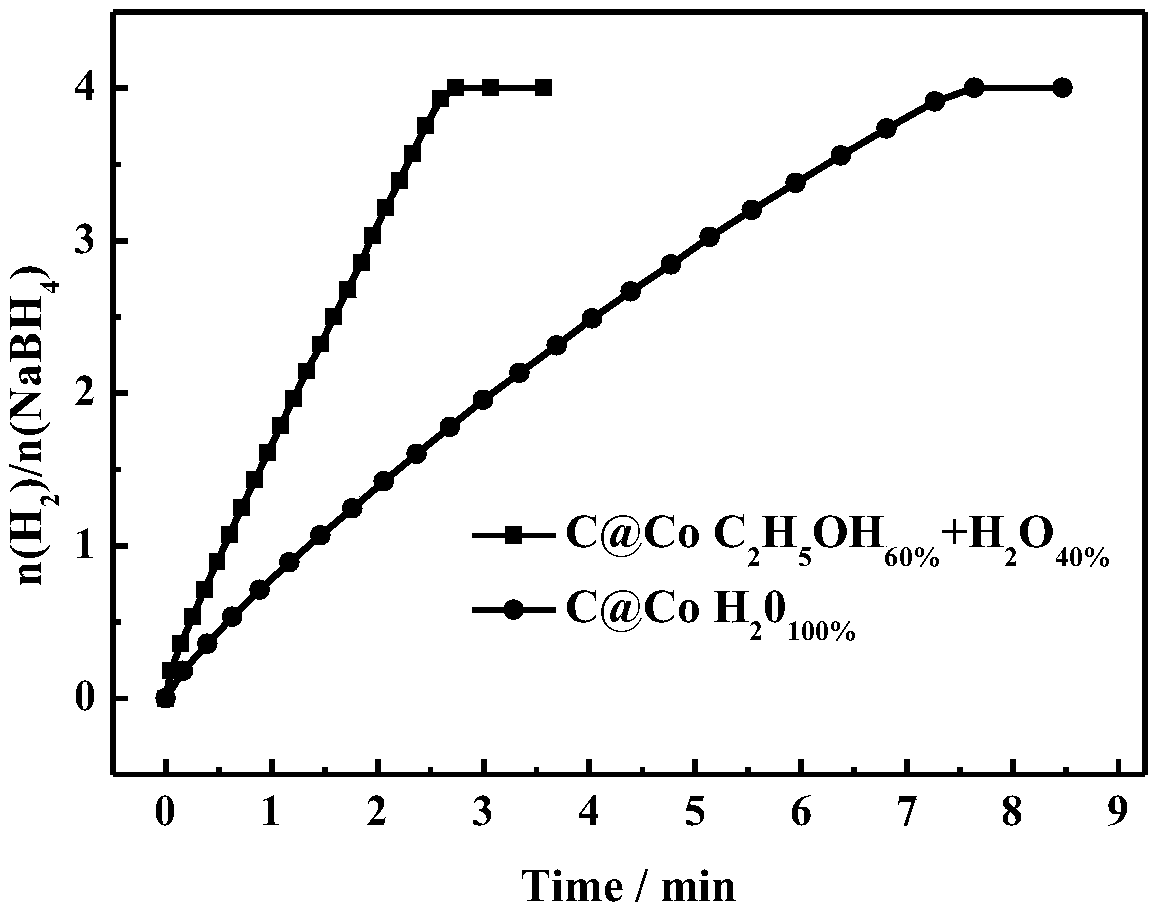

Non-noble metal catalyst and preparation method

ActiveCN108906058AHigh catalytic activityGood dispersionCatalyst activation/preparationHydrogen productionPtru catalystNanoparticle

The invention provides a preparation method of a non-noble metal catalyst, and the preparation method includes the following steps: mixing an ethanol-water solvent, a carrier material and a non-noblemetal salt to obtain a non-noble metal salt dispersion solution; mixing the non-noble metal salt dispersion solution with a sodium borohydride solution, and performing reducing and water washing to obtain the non-noble metal catalyst. The preparation method adopts the ethanol-water solvent to control the solubility of sodium metaborate generated in the reduction reaction process, the sodium metaborate precipitates accompanied by non-noble metal formation in the reduction process, non-noble metal nanoparticles are isolated, the agglomeration growth of the non-noble metal nanoparticles is significantly inhibited, the particle size of the non-noble metal nanoparticles is effectively reduced, and at the same time the catalytic activity of the non-noble metal catalyst is greatly improved.

Owner:YANSHAN UNIV

Heat-resistant and high-strength 3D printing material for chemical engineering manufacturing industry

InactiveCN107312331AImprove heat resistanceImprove mechanical propertiesAdditive manufacturing apparatusPolyethylene terephthalate glycolPolymethyl methacrylate

The invention discloses a heat-resistant and high-strength 3D printing material for chemical engineering manufacturing industry. Raw materials for the 3D printing material include modified polyphenylene sulfide, ABS resin, nylon 66, epoxy acrylic resin, ethylene propylene diene monomer, epoxy resin, ethylene-octene copolymer, polymethyl methacrylate, polyethylene, polypropylene, high-density polyethylene, polyethylene terephthalate, arylene ether nitrile, polysulfone, carbon fiber, basalt fiber, nano calcium carbonate, nano silica, dimethyl silicone oil, chlorinated paraffin, isocyanate, sodium metaborate, ammonium polyphosphate, polysiloxane, sodium stearate, sodium dodecyl benzene sulfonate, antioxidant, defoamer, compatilizer, silane coupling agent KH-570, modified filler and performance additive. The 3D printing material has excellent heat resistance and strength.

Owner:HEFEI SKE INTELLIGENT TECH

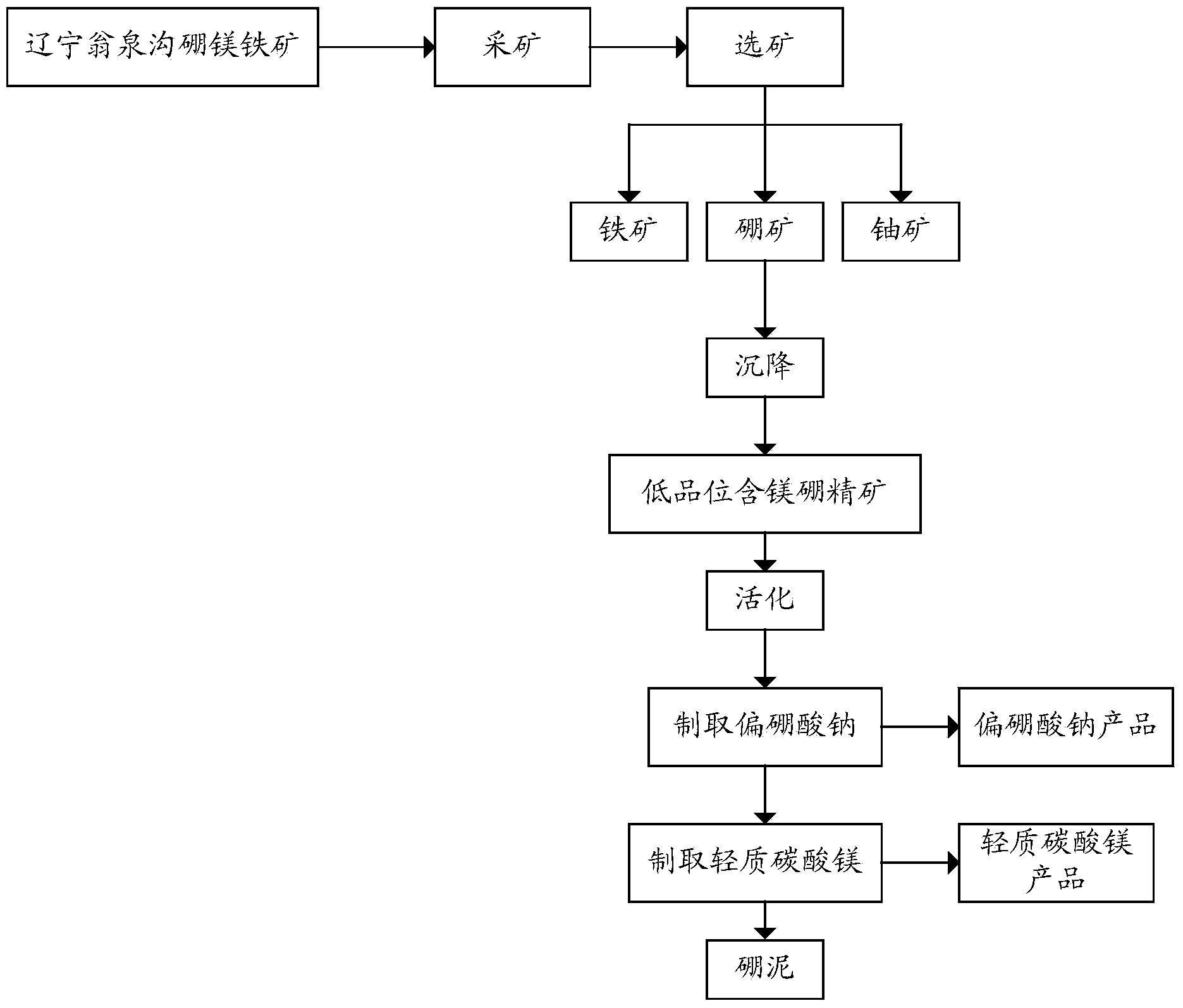

Method for preparing sodium metaborate with coproduct of light magnesium carbonate from low-grade ores containing magnesium and boron

InactiveCN104386705ARealize cleaner productionReduce alkalinityMagnesium carbonatesBoratesDecompositionLower grade

The invention provides a method for preparing sodium metaborate with a coproduct of light magnesium carbonate from low-grade ores containing magnesium and boron. The method comprises the following steps: activating the ores containing magnesium and boron to obtain an activated ore concentrate containing magnesium and boron; performing sodium modification on the activated ore concentrate containing magnesium and boron to obtain a sodium metaborate solution and alkaline hydrolysis boron mud; performing concentration crystallization on the sodium metaborate solution to obtain hydrated sodium metaborate; mixing the alkaline hydrolysis boron mud with water to obtain an alkaline hydrolysis boron mud mixture, and carbonizing the alkaline hydrolysis boron mud mixture by adopting a carbon decomposition gas to obtain a heavy magnesium solution and boron mud; and pyrolyzing the heavy magnesium solution to obtain light magnesium carbonate. According to the method, the low-grade ore concentrate containing magnesium and boron is activated at first so as to improve the activity of boron and ensure that borne can be fully extracted; meanwhile, ores containing magnesium are decomposed to generate magnesium hydroxide, which creates a condition for subsequent extraction of magnesium compounds; and by virtue of sodium modification and carbon decomposition, the extraction of boron and magnesium from the activated ore concentrate containing magnesium and boron is realized.

Owner:LIAONING SHOUGANG BORON IRON

Polyvinyl chloride resin with high abrasion resistance and preparation method of polyvinyl chloride resin

The invention discloses polyvinyl chloride resin with high abrasion resistance, and belongs to the technical field of resin preparation. The polyvinyl chloride resin with high abrasion resistance comprises the following raw materials: ABS resin, polyvinyl chloride resin, low-density polyethylene, epoxy resin E-51, triallyl isocyanurate, methyl methacrylate, nano ceramic powder, aluminum powder, nano montmorillonite, multiwalled carbon nano tubes, nano graphite, pine tar, polyethylene glycol, tetraethoxysilane, dibutyltin dilaurate, sodium dodecyl benzene sulfonate, sodium metaborate, calcium stearate, calcium sulfate whiskers, activated calcium silicate, chlorinated paraffin, nano silicon dioxide, carbon black, a silane coupling agent KH-560 and a wear-resistant modifying aid. The polyvinyl chloride resin with high abrasion resistance is prepared by the following steps: preparing base materials, preparing modified materials, mixing the base materials and the modified materials, and thelike. The polyvinyl chloride resin prepared by the preparation method provided by the invention has excellent wear resistance.

Owner:HWASU

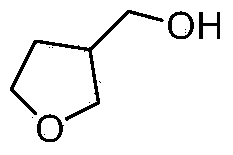

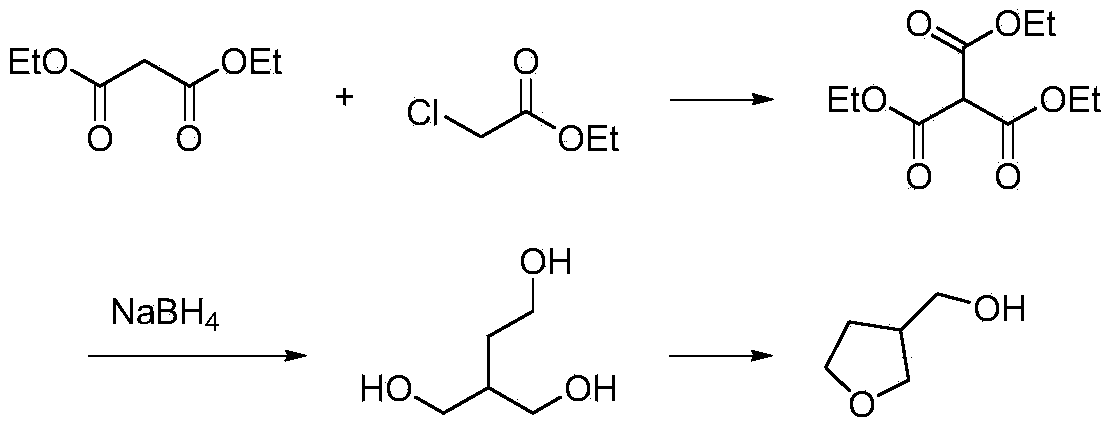

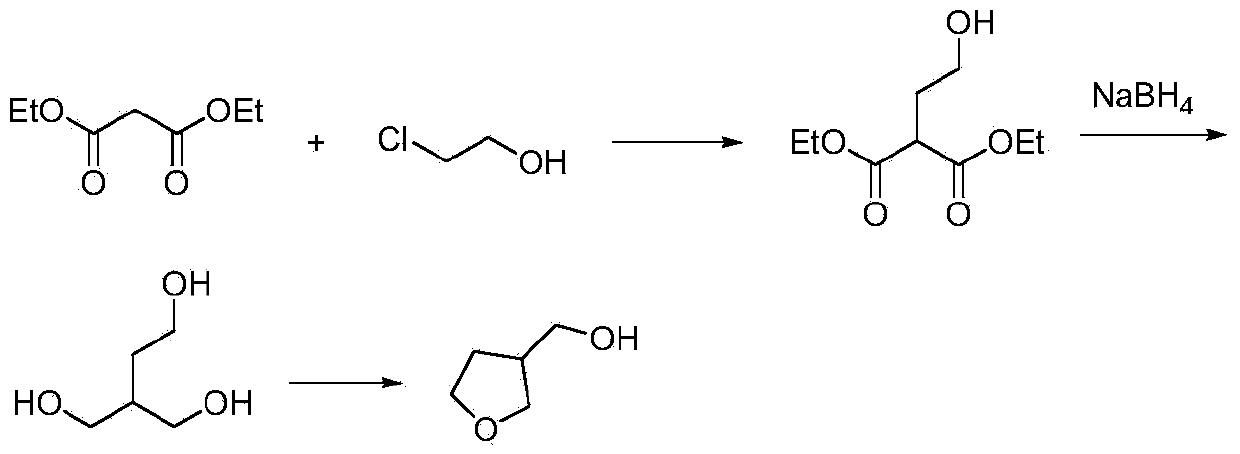

Synthetic method for 3-hydroxymethyl tetrahydrofuran

The invention discloses a synthetic method for 3-hydroxylmethal tetrahydrofuran. The synthetic method comprises the following steps: with 2-chloroethanol and diethyl malonate as raw materials, reacting under the action of alkaline in the presence of an organic solvent or in absence of a solvent to obtain an intermediate 2-ethoxy-diethyl succinate; then, reducing the intermediate 2-ethoxy-diethyl succinate by virtue of metal borohydride to obtain 2-hydroxymethyl-1,4-butanediol; and finally, producing 3-hydroxylmethal tetrahydrofuran under the action of a dehydrating agent. According to the synthetic method, the usage amount of the reducing agent metal borohydride is remarkably lowered, and yield of a byproduct sodium metaborate is reduced at the same time. The invention provides the synthetic method for the drug intermediate 3-hydroxylmethal tetrahydrofuran.

Owner:XIAN MODERN CHEM RES INST

Catalytic desulphurization aqua for cement kiln flue gas

InactiveCN107261825ANo emissionsImprove sulfur fixation efficiencyGas treatmentDispersed particle separationFlue gasSulfur

The invention provides a catalytic desulphurization aqua for cement kiln flue gas. The catalytic desulphurization aqua is prepared through mixing, by mass, 1-10% of urea or ammonia water, 1-10% of sodium carbonate or potassium carbonate, 0.5-5% of sodium bicarbonate or potassium bicarbonate, 0.001-0.1% of potassium permanganate, 3-5% of sodium metaborate, and the balance of tap water, and the desulphurization aqua is used for cement kiln sulfur fixation. The catalytic sulfur fixation aqua adopting an amino group and sodium metaborate as a combined catalyst, potassium permanganate as an oxidant and sodium carbonate and potassium bicarbonate as sulfur fixation reaction groups has the advantages of simplicity in use, high sulfur fixation efficiency, small occupied area, small device investment, suitable running cost, low energy consumption, and low concentration of SO2 in a flue gas outlet.

Owner:董小军

Gasoline desulfurization method

InactiveCN102925199ATo achieve the purpose of removing sulfur compounds in gasolineHydrocarbon oils refiningElectrochemistrySodium hydroxide

The invention discloses a gasoline desulfurization method, relating to a method for refining hydrocarbon oil by use of hydrogen or hydrogen generation compounds. The gasoline desulfurization method comprises the following steps of: adding 100mL of 1mol / L H2SO4 solution into an anode slot of a diaphragm electrolytic cell; adding 100mL of saturated sodium metaborate ethanol solution and 3g of sodium hydroxide into a cathode slot; performing electrolysis at normal temperature under normal pressure by taking lead electrodes as a cathode and an anode, and reducing to obtain catholyte; adding 10mL of nickel sulfate methanol saturated solution into 30mL of gasoline, and then adding the catholyte; stirring for reaction and standing; and after layering, fetching the gasoline layer. According to the invention, sodium metaborate is used as a basic substance, and sodium borohydride is generated by an electrochemical reduction method; and a metal compound is added so that the sodium borohydride and the metal compound react together with sulfide in the gasoline to generate precipitates to realize separation from gasoline and achieve the aim of removing sulfides from gasoline.

Owner:SHAANXI HI TECH ENERGY DEV

Process for preparing monohydrated sodium perborate

InactiveCN1369430AScope of innovation and improvementInnovation improves appearancePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesInorganic ChemicalPhosphate

A process for prepared monohydrated sodium perborate from the solution of sodium metaborate and the solution of H2O2 includes adding phosphate to the solution of sodium metaborate, adding polycarboxylic acid or its salt to the solution of H2O2, dripping them into reactor, reaction to obtain tetrahydrated sodium perborate crystal, and baking. Its advantages are hith improved stack specific weight range and particle appearance, and high wet stability.

Owner:陶华西

Boron extracting method

ActiveCN108069434AHigh reactivityImprove leaching rateProcess efficiency improvementBoratesActivated carbonBoron ores

The invention provides a boron extracting method, which comprises the following steps of (1) mixing a compound containing boron ore and calcium, roasting at 650 to 900 DEG C, and obtaining a roasted product; (2) after mixing the roasted product and activated carbon, carrying out carbonate decomposition and boron extraction to obtain a boron-rich liquid and a leaching residue. According to the boron extracting method, the energy consumption for a roasting pretreatment process is reduced, meanwhile, the reaction activity of a boron concentrate is improved, high leaching efficiency of the boron-containing component is ensured, a boron component in the boron concentrate can be high-efficiently extracted, the reaction activity of cooked boron ore after roasting achieves more than 90 percent, the leaching efficiency of carbonate decomposition and boron extraction is larger than 90 percent by weight, the content of B2O3 in boron mud is smaller than 2 percent by weight, and the boron-rich liquid is low in impurity content and can be further used for producing boron compounds such as borax and sodium metaborate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Tear-resistant heat-insulating rubber cable material and preparation method thereof

PendingCN105585754AImprove heat resistanceImprove corrosion resistanceRubber insulatorsPolymer scienceButadiene-styrene rubber

The invention discloses a tear-resistant heat-insulating rubber cable material which is prepared from the following raw materials in parts by weight: 20-30 parts of epoxidized natural rubber, 40-60 parts of styrene-butadiene rubber, 30-50 parts of ethylene propylene diene monomer rubber, 50-80 parts of modified montmorillonite, 25-35 parts of dioctyl phthalate, 25-35 parts of epoxy soybean oil, 20-40 parts of aluminum hydroxide, 10-15 parts of melamine, 10-15 parts of sodium metaborate, 1-3 parts of bis-[gamma-(triethoxysilyl)propyl]tetrasulfide, 1-2 parts of sulfur, 0.6-0.8 part of accelerator M, 0.4-0.6 part of accelerator D, 2-4 parts of Ca / Zn composite stabilizer, 1-2 parts of bis-butyl tin dichloride, 0.2-0.4 part of antioxidant BHT, 0.1-0.2 part of anti-aging agent and 2-4 parts of montanin wax. The invention also discloses a preparation method of the tear-resistant heat-insulating rubber cable material. The tear-resistant heat-insulating rubber cable material has the advantages of favorable tear resistance and favorable heating insulating property.

Owner:繁昌县菲德通讯材料设计有限公司

High-toughness corrosion-resistant rubber sealing element and preparation method thereof

InactiveCN106700367AImprove bindingImprove anti-corrosion performanceLow-density polyethylenePolymer science

The invention discloses a high-toughness corrosion-resistant rubber sealing element. The rubber sealing element comprises the following raw materials: silicone rubber, cis-1,4-polybutadiene rubber, chloroprene rubber, epoxy acrylic resin, modified high chlorinated polyethylene resin, coumarone resin, low-density polyethylene, ethylene propylene diene monomer rubber, sulfur, sulfur dichloride, chlorinated paraffin wax, styrene, dimethyl silicon oil, zinc borate, isocyanate, nano graphite, carbon black, barite powder, nano aluminum hydroxide, aluminum polyphosphate, nano silicon dioxide, mica powder, talcum powder, a silane coupling agent KH-570, sodium metaborate, pentaerythritol, ammonium polyphosphate, polysiloxane, sodium stearate, sodium dodecyl benzene sulfonate and an antioxidant. The invention also discloses a preparation method of the high-toughness corrosion-resistant rubber sealing element. The rubber sealing element has excellent toughness and favorable corrosion resistance.

Owner:安徽亚兰密封件股份有限公司

A disinfectant specially used for aquaculture and preparation thereof

InactiveCN107467084APromote growthSimple preparation processBiocideOther chemical processesPhosphoniumMass ratio

A disinfectant specially used for aquaculture and preparation thereof are provided. The disinfectant includes an A agent and a B agent in a mass ratio of 3:1.2-1.6. The A agent includes tetrakis(hydroxymethyl)phosphonium sulfate, potassium peroxymonosulfate, sodium metaborate, glacial acetic acid and water. The B agent includes a traditional Chinese medicine extract liquid, maifan stone, allicin, citric acid and water. A preparing process is simple. Compared with traditional disinfectants prepared from chlorine, the disinfect prepared by the method is safe and environmentally friendly, has good disinfection effects, improves water quality and growth of aquatic products to a certain extent and increases economic benefit of aquaculture essentially.

Owner:ANHUI HUANGHUAI VETERINARY MEDICINE

Concrete aggregate prepared by utilizing coal gangue and preparation method thereof

The invention relates to concrete aggregate prepared by utilizing coal gangue and a preparation method thereof. The concrete aggregate is prepared from the following raw materials in parts by weight: 110-150 parts of broken coal gangue, 50-70 parts of foundry waste sand, 10-20 parts of copper sludge, 10-20 parts of red mud, 50-70 parts of regenerated diatomite broken pieces, 5-9 parts of additives, 6-10 parts of calcium hydroxide and 5-9 parts of sodium hydroxide solution with the mass concentration of 0.5mol / L, wherein the regenerated diatomite broken pieces are prepared from the following components in parts by weight: 40-60 parts of waste diatomite slurry, 20-30 parts of modified steel slag micro-powder, 6-11 parts of a surface modifier and 0.04-0.06 part of a foaming agent; and the modified steel slag micro-powder is prepared from steel slag and sodium metaborate which accounts for 1 / 10 to 1 / 2 of the weight of the steel slag. According to the invention, a large-scale application direction is found for the coal gangue, foundry waste sand, copper sludge, red mud, steel slag and waste diatomite, the waste materials are changed into things of value, and the environmental pollution and land occupation caused by solid wastes are reduced, so that the resources are further utilized, and energy conservation and environment friendliness are achieved.

Owner:重庆交院和瑞工程检测技术有限公司

Method for preparing metal soft magnetic powder through inorganic insulation coating

InactiveCN108461247AImprove toughnessImprove insulation performanceInorganic material magnetismInductances/transformers/magnets manufactureSODIUM METAPHOSPHATENano al2o3

The invention discloses a method for preparing metal soft magnetic powder through inorganic insulating coating, and belongs to the technical field of preparation of metal soft magnetic powder materials. The method comprises the following steps that 1, sodium metaborate, sodium metaphosphate, nanometer magnesia and nanometer aluminium oxide are weighed in proportion, and dissolved into distilled water, the mixture is fully stirred to be mixed to be uniform, and a coating agent is obtained; 2, the soft magnetic powder is weighed in proportion and put into a stirrer, the coating agent is added into the mixture, stirring and mixing are conducted, and primary pulp is obtained; 3, the primary pulp is subjected to flash drying, and a product is obtained. The method has the advantages that continuous production can be achieved, and the production efficiency is greatly improved; meanwhile, the adopted inorganic coating agent has the advantages of being high in toughness, high in insulating property and good in rust-resisting property.

Owner:HEFEI ECRIEE TAMURA ELECTRIC

Automotive cleaning fluid

InactiveCN104371839AGood dirt removal effectEasy to cleanInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium phosphatesSilicic acid

The invention provides an automotive cleaning fluid. The automotive cleaning fluid comprises the following components in parts by weight: 1.2-1.6 parts of sodium dodecyl sulfonate, 2.3-2.6 parts of nonylphenol polyoxyethylene ether, 0.3-0.5 part of polyoxyethylene lauryl ether, 0.2-0.3 part of sodium xylene sulfonate, 0.1-0.2 part of sodium gluconate, 0.4-0.6 part of sodium phosphate, 0.2-0.3 part of dodecyldiethanolamide, 0.1-0.2 part of sodium metaborate, 0.5-0.8 part of potassium silicate, 0.01-0.03 part of benzotriazole and 300-320 parts of deionized water. The automotive cleaning fluid provided by the invention has a good effect of removing dirt and a relatively good effect of removing light dirt and heavy dirt, and can well clean a vehicle body, vehicle windows and other parts of an automobile without damaging the automobile.

Owner:LIUZHOU ERHE AUTO PART

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com