Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54 results about "Boron ores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special composite organic fertilizer for mangnolia officinalis and preparation method of special composite organic fertilizer

The invention discloses a special composite organic fertilizer for mangnolia officinalis and a preparation method of the special composite organic fertilizer, wherein the special composite organic fertilizer for mangnolia officinalis consists of the following ingredients in parts by weight: 10 to 20 parts of soybean meal, 30 to 40 parts of plant straws, 10 to 13 parts of cabbage slag, 0.5 to 2 parts of composite strains, 15 to 20 parts of potassium sulfate, 0.3 to 0.8 part of manganese sulfate, 0.4 to 0.9 part of ferrous sulfate, 10 to 25 parts of ammonium sulfate, 2 to 5 parts of borax, 10 to 15 parts of diammonium phosphate, 2 to 5 parts of fulvic acid, 1 to 4 parts of soluble chitosan, 2 to 5 parts of trace boron ore, 0.04 to 0.08 part of dipterex, 0.03 to 0.05 parts of chlorothalonil and 25 to 32 parts of filling materials. According to the growth rule of the mangnolia officinalis, the fertilizer provided by the invention adopts a great number of biological organic nitrogenous fertilizers, the physical properties of the soil can be obviously improved after a great number of fertilizers are utilized, the effective void content of the soil is increased, and the survival rate of the young seedlings of the mangnolia officinalis is improved.

Owner:HUBEI FUSOURCE BIOLOGY OF BIOLOGICAL TECH CO LTD

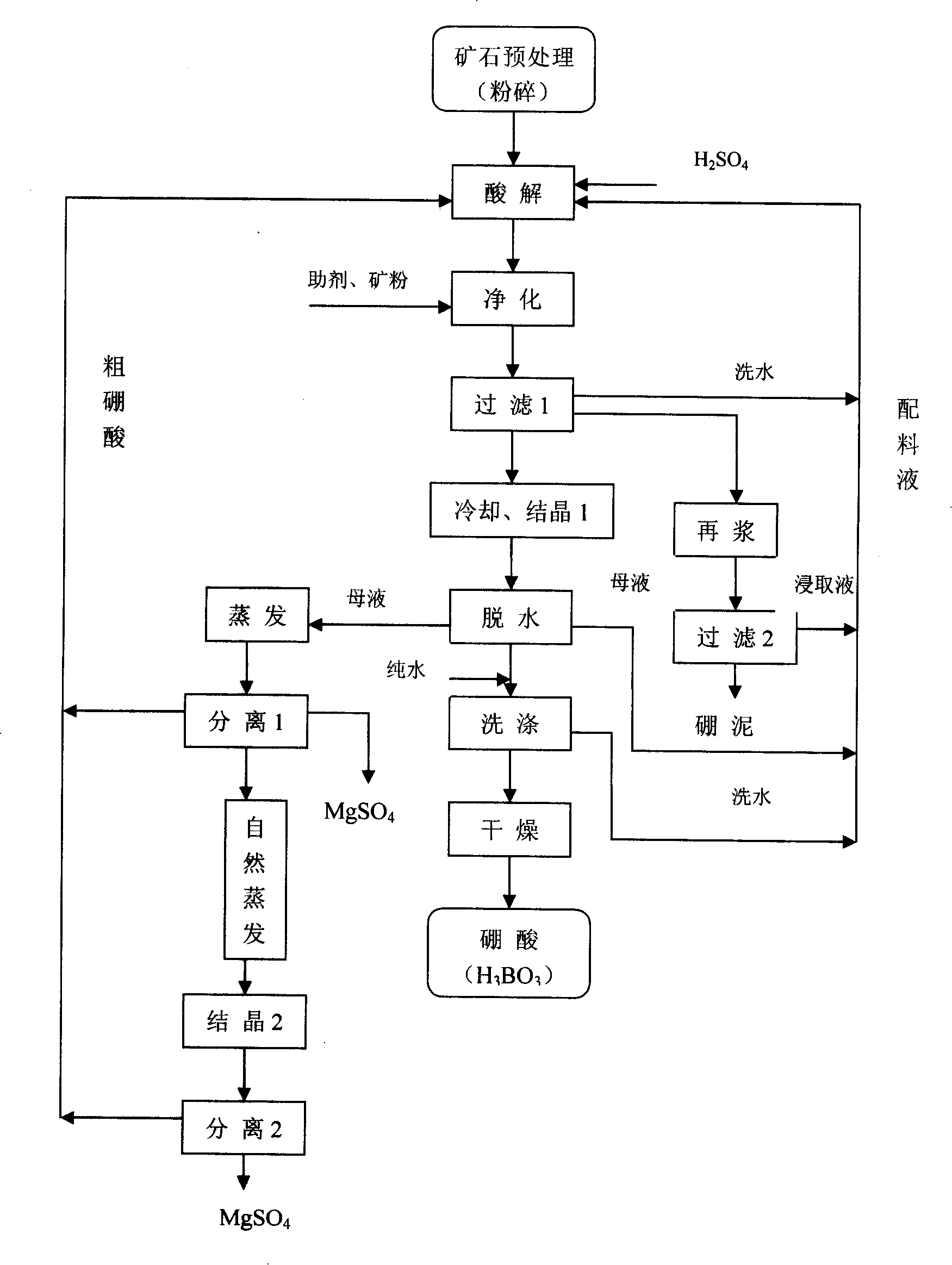

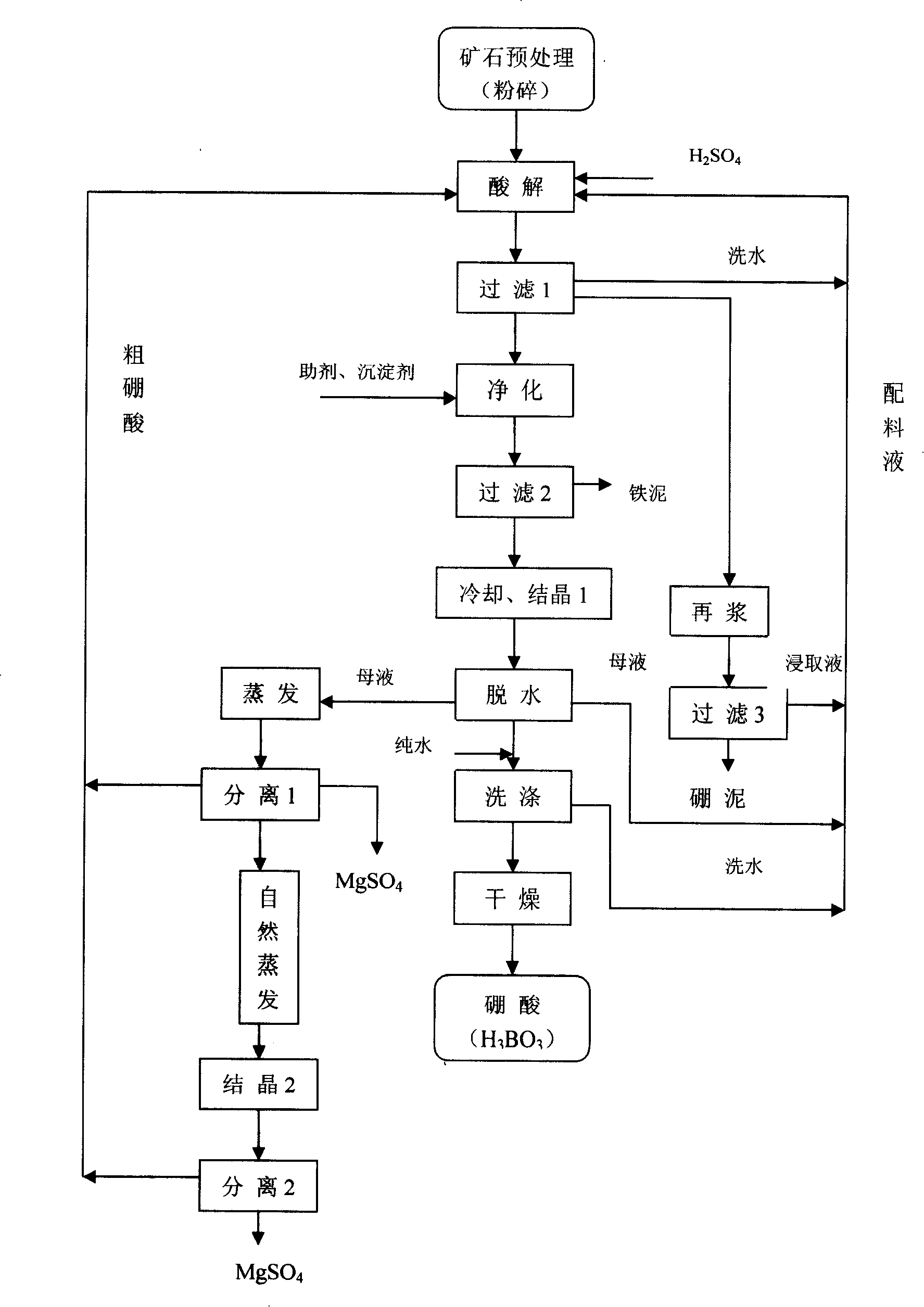

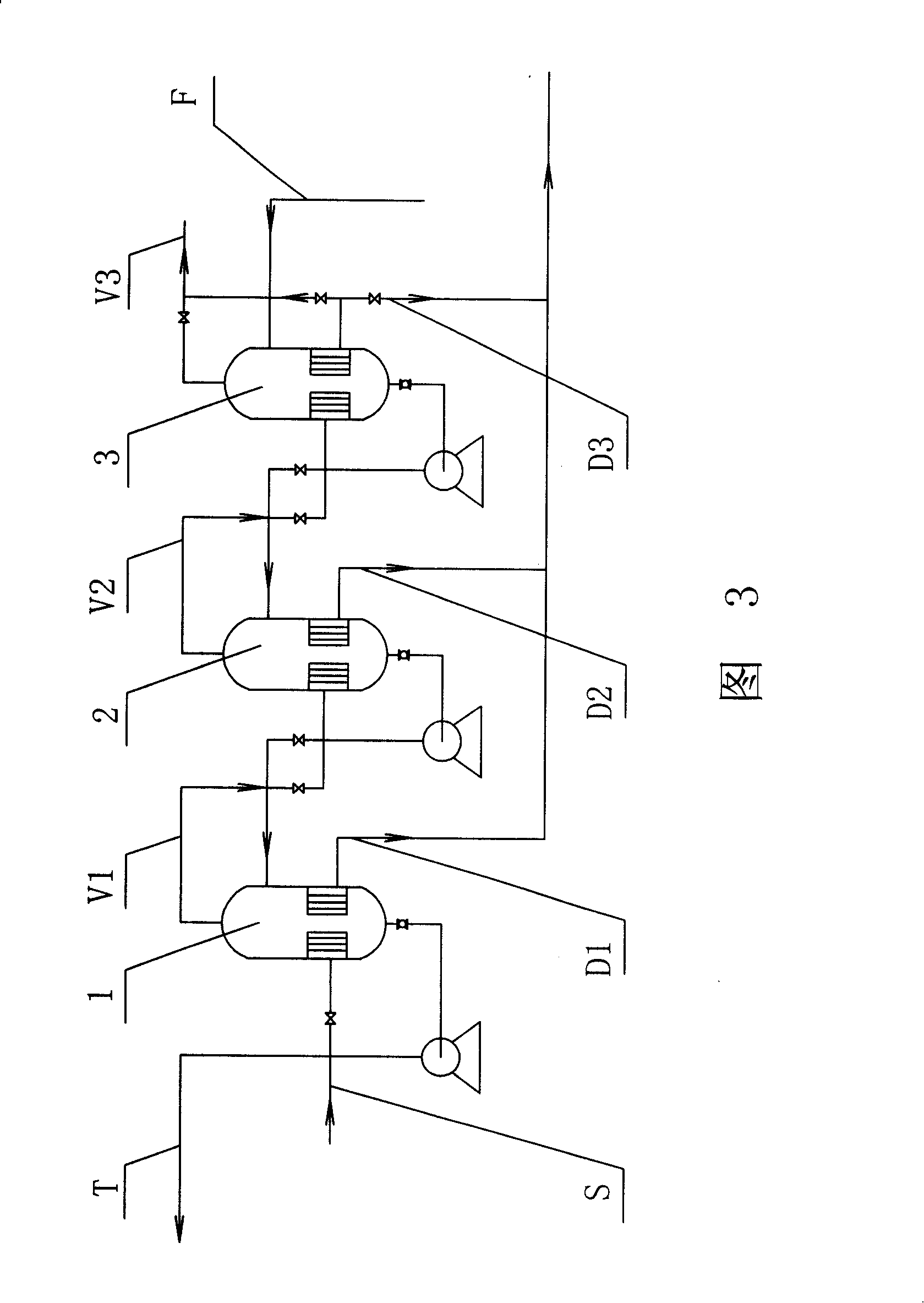

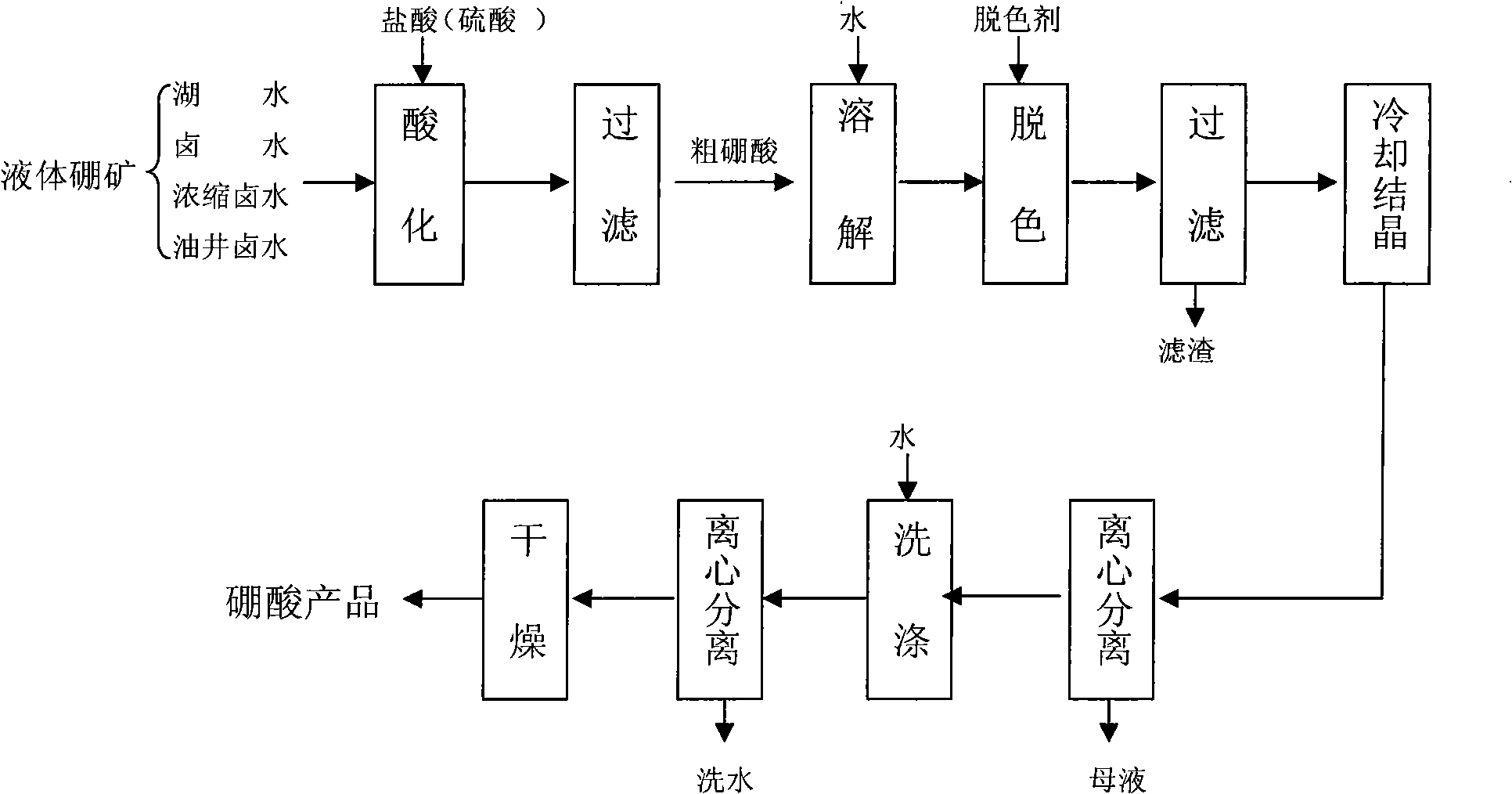

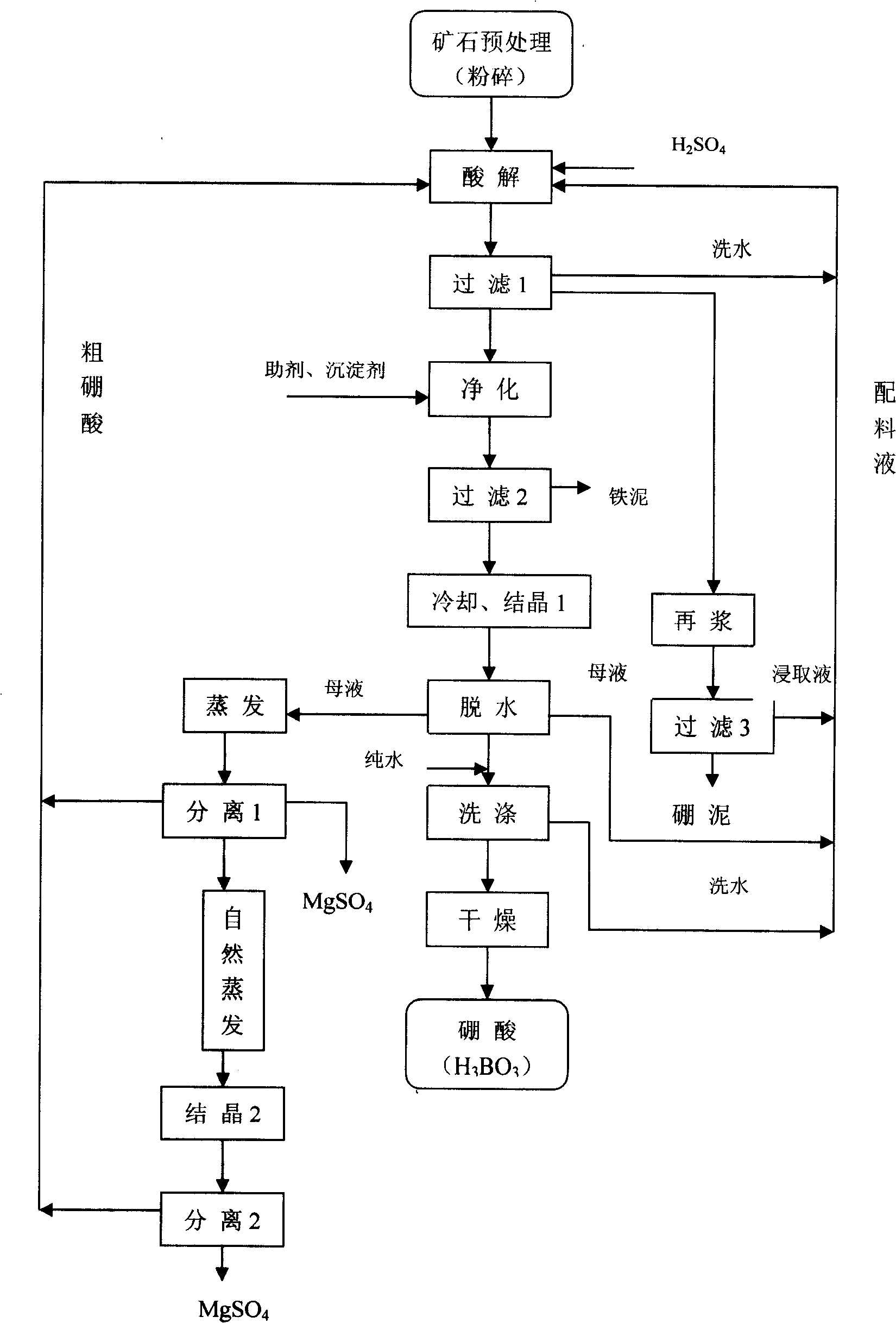

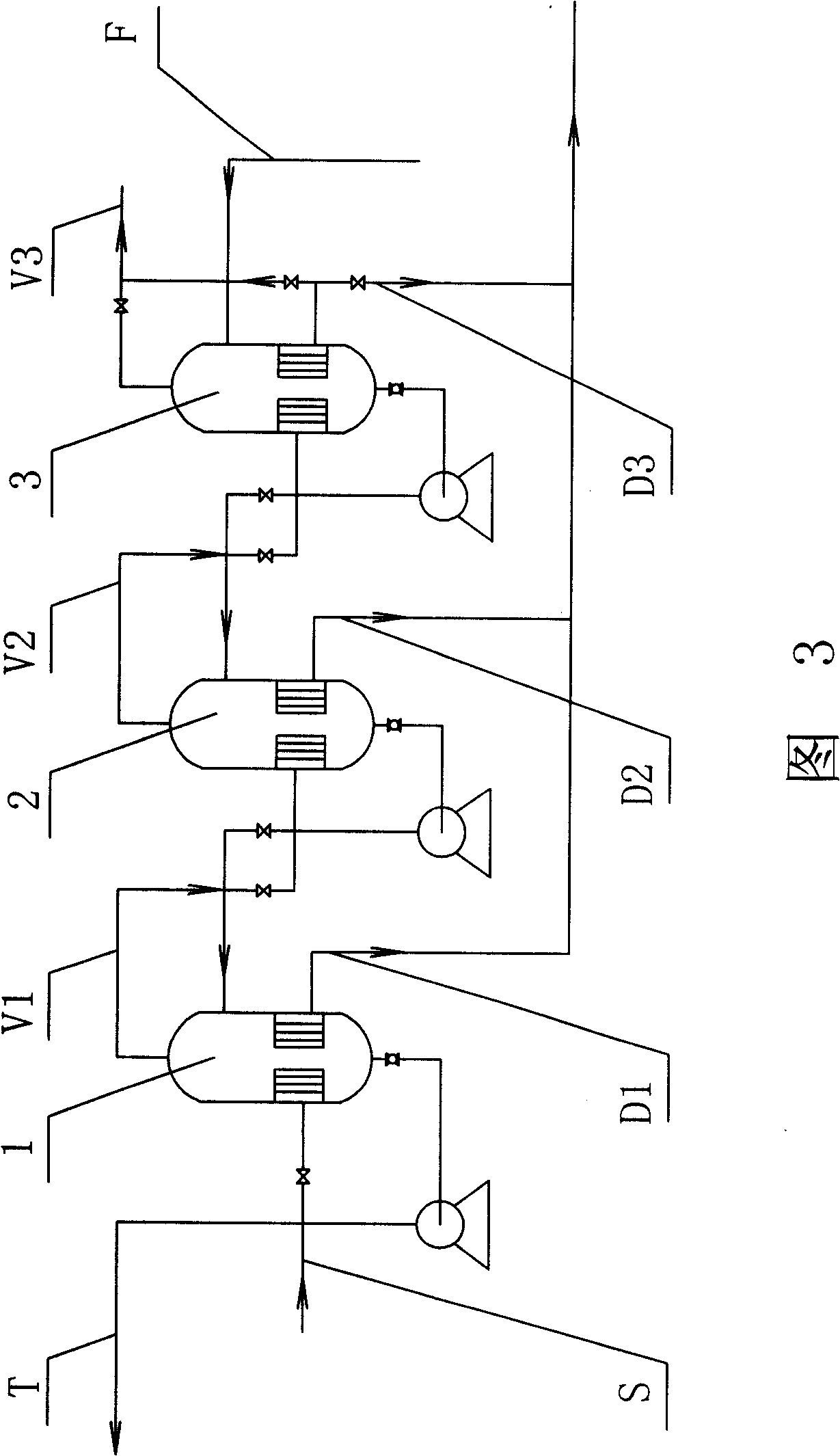

Technique for preparing high quality boric acid from salt lake type boron ore by one-step method

InactiveCN101209844AEasy to separateAchieve the purpose of separationBoron-oxygen compoundsHigh energySludge

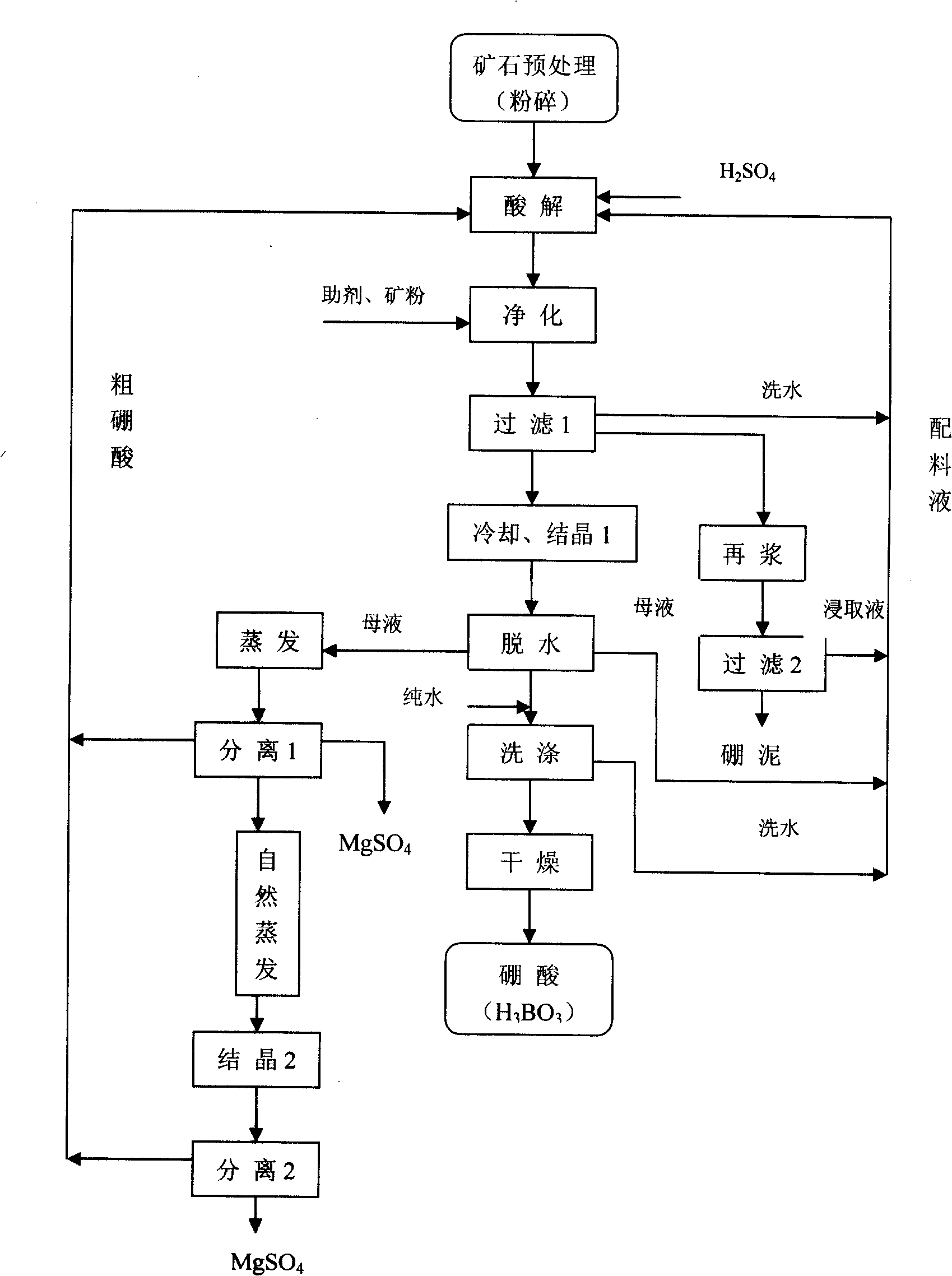

The invention relates to the technical field of extracting boracic acid, in particular to a technological method for preparing boracic acid from a saline boron rock in one-step. On the base of preliminary treatment of ore-acidolysis-filtering-crystallization-dehydration-washing-drying- boracic acid, the invention adds a purification process, namely, impurity removal through chemical oxidation between the acidolysis and crystallization processes. The invention has beneficial effects that: compared with activated carbon absorption method, the oxidizing impurity removal and decoloring techniques of the invention has the advantages of thorough impurity removal, complete decoloring, simple flow process, low operation cost and stronger operability; the product yield is further improved by that boric sludge is leached and then treated with slurry, in which rudimental boron is collected; an independent design of a three-way counter current concentration boron and magnesium separating technique for the technical process overcomes the disadvantages of high energy consumption, inefficiency and incomplete separation in a technique of atmospheric concentrate, decompression single-effect concentration and boron and magnesium separation, which saves energy source and reduces cost. The invention can be widely applied for preparing boracic acid from a saline boron rock.

Owner:肖莹

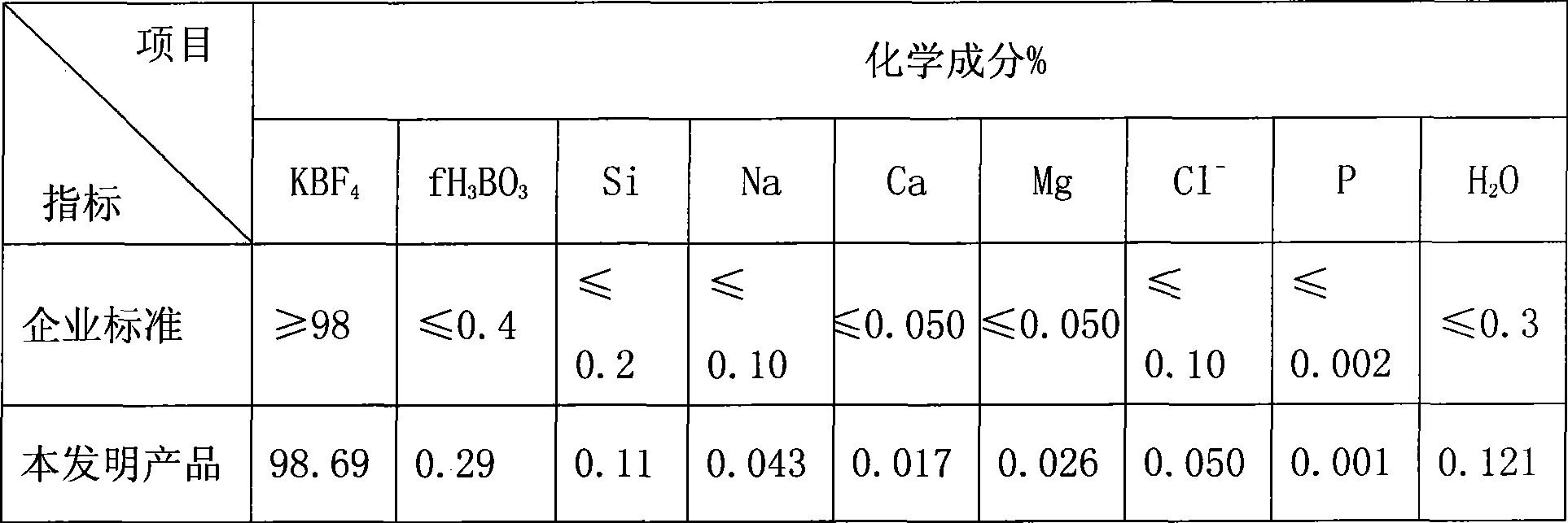

Potassium borofluoride preparation method based on fluosilicic acid and boron rock

InactiveCN101423224AEase of industrial productionReduce manufacturing costBoratesBoron oresFiltration

The invention relates to a preparation method of potassium fluoroborate based on fluosilicic acid and boron ore. The leaching of the boron ore is carried out by using the fluosilicic acid, a potassium fluoroborate product is synthesized by filtering, removing impurities and refining; the steps are as follows: I the fluosilicic acid and the boron ore are selected to produce leaching solution; II the leaching solution is filtered, the residues are removed and filtrate is remained; III an N-type impurity removal agent is added in the filtrate to remove the impurities, the impurities are removed by filtration and refining solution is remained; IV potassium chloride is added in the refining solution to carry out synthesis reaction; V the solution is filtered to obtain a potassium fluoroborate ointment; and VI the potassium fluoroborate ointment is dried to obtain the product. The prepration method adopts the technical proposal of: leaching the boron ore from the fluosilicic acid, filtering, removing the impurities, refining and finally synthesizing the potassium fluoroborate product by using the refining solution and the potassium chloride solution, thereby overcoming the shortcomings that the traditional production process of the potassium fluoroborate uses the non-renewable strategic reserve-fluorspar, borax and boric acid are in short supply, the price is higher, the production cost of the traditional production process is high, and the like. The preparation method is applicable for preparing prepare inorganic fluoride and especially applicable for preparing the potassium fluoroborate by using the fluosilicic acid and the boron ore.

Owner:HUNAN NONFERROUS FLUORIDE CHEM

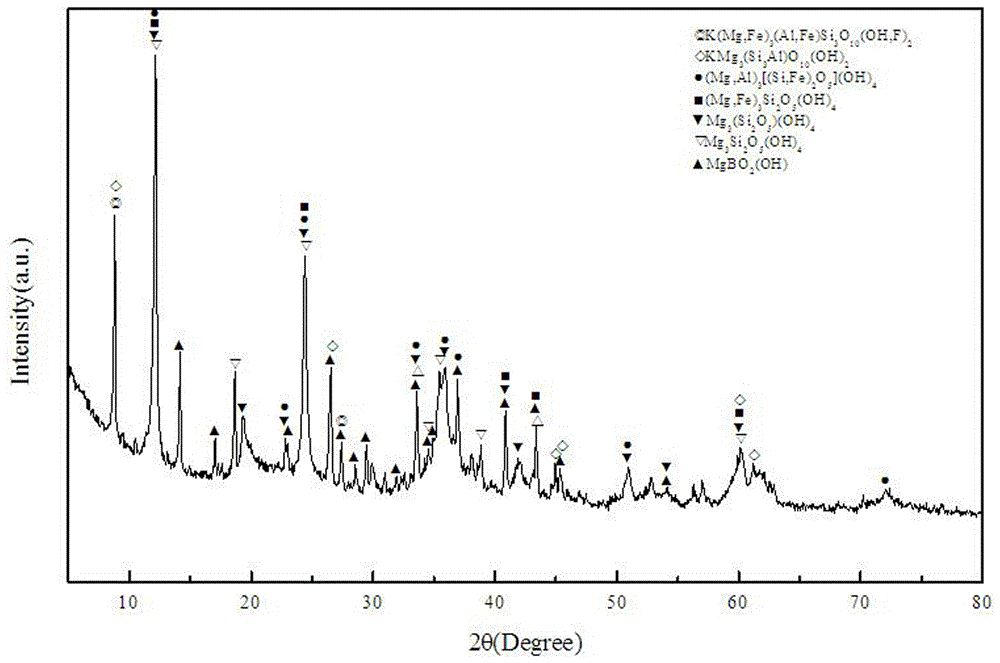

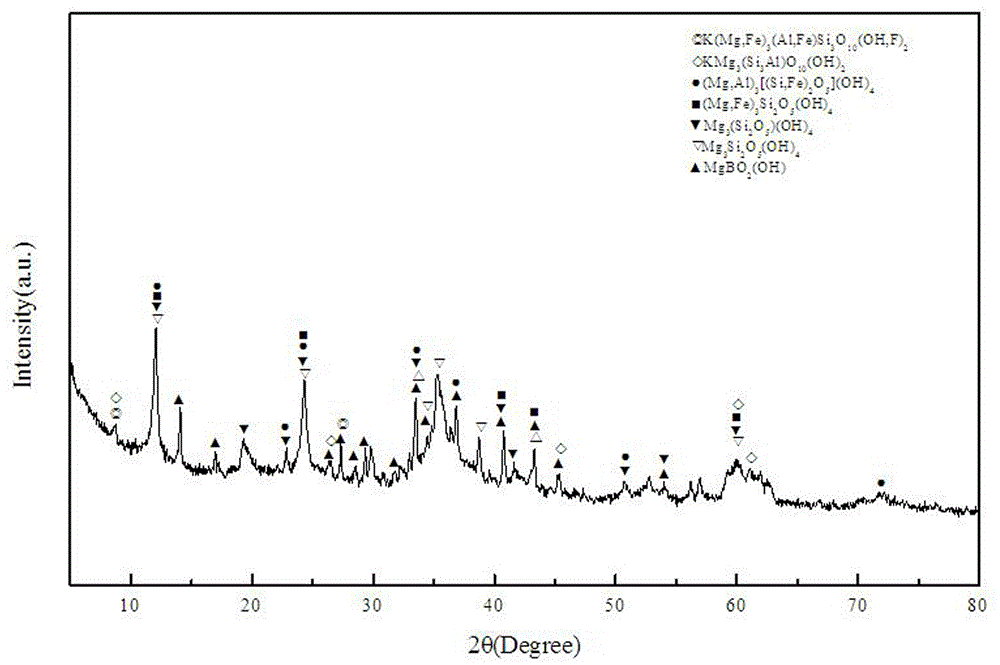

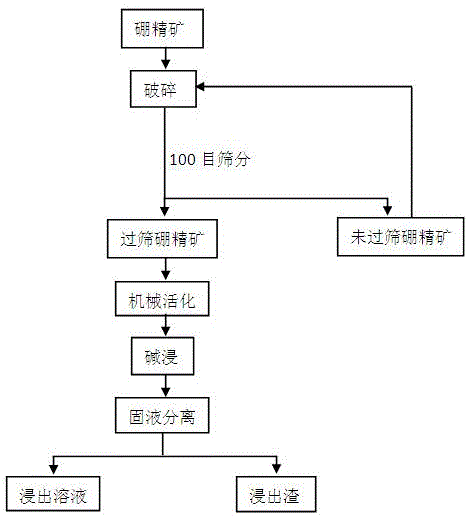

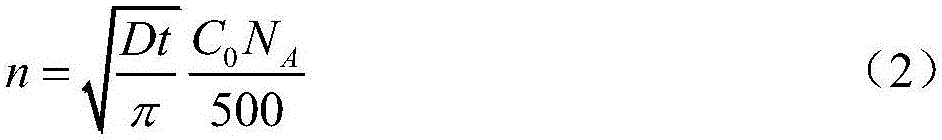

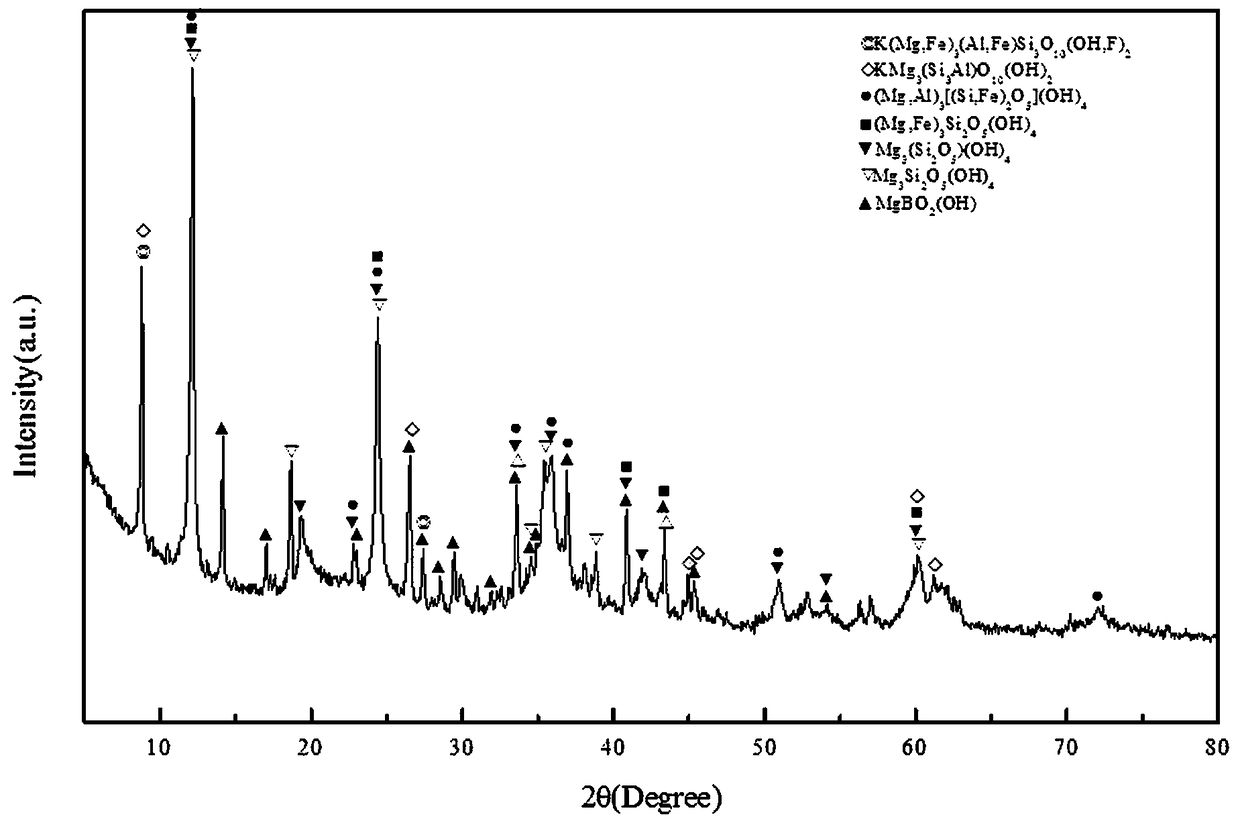

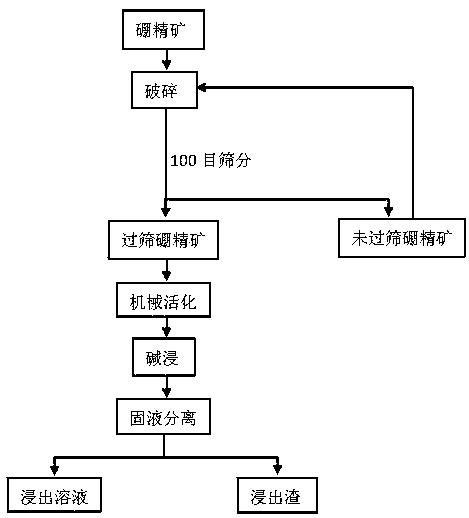

A process of increasing the boron leaching rate of a boron concentrate through mechanical activation

ActiveCN106492940AImprove leaching rateReduce dependenceGrain treatmentsBoron compoundsResource utilizationHigh energy

The invention belongs to the field of boron ore resource utilization, and particularly relates to a process of increasing the boron leaching rate of a boron concentrate through mechanical activation. The process includes firstly mechanically crushing the boron concentrate, keeping the crushed boron concentrate as a raw material for later use, adding the crushed boron concentrate raw material into a high-energy ball mill, performing mechanical activation to obtain a mechanically activated boron concentrate with the mass ratio of grinding balls to the boron concentrate raw material being (4-16):1, the diameter of the grinding balls being 3-10 mm, the filing ratio of the grinding balls and the boron concentrate in a ball milling tank is 30-70%, a ball milling rotary speed being 100-300 r / min and ball milling time being 10-120 min, stirring with a sodium hydroxide solution, heating the mixture, and leaching the mechanically activated boron concentrate to obtain a boron-containing leachate and leaching slag. The boron leaching rate is 73.1% or above. The process in which mechanical activation and alkali soaking are combined for enhancing boron leaching from the boron concentrate is a simple, safe, economical, environment friendly, efficient and novel process. The process can improve activity of the boron concentrate, and therefore the high boron leaching rate at a low alkalinity and temperature is expected to be acquired.

Owner:NORTHEASTERN UNIV

Self-hydrating, self-crosslinking guar compositions and methods

InactiveUS20070281871A1Fast hydrating guarEasy to operateFlushingDrilling compositionBoron oresAntimony compounds

A self-hydrating, self-crosslinking dry composition is used to prepare a hydrated, crosslinked fracturing fluid upon addition of water, the composition comprising (A) guar powder or a guar derivative powder; (B) crosslinker selected from the group consisting of boric acid, borax, borate ore, boron ore, antimony compounds, aluminum compounds, zirconium compounds, and titanium compounds; and (C) slow dissolving alkaline buffer, wherein the crosslinker (B) is non-encapsulated.

Owner:RHONDIA INC

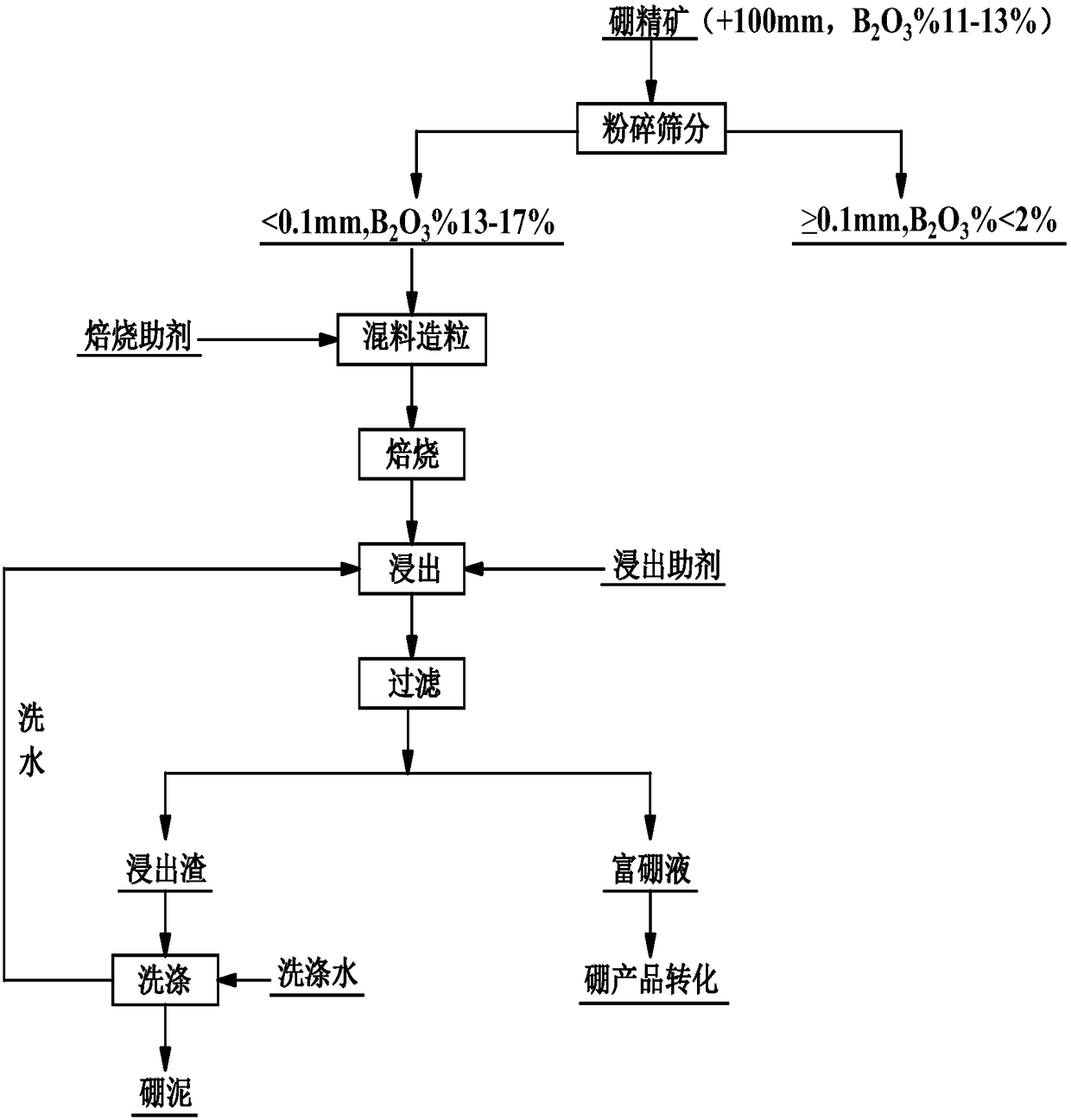

Boron extracting method

ActiveCN108069434AHigh reactivityImprove leaching rateProcess efficiency improvementBoratesActivated carbonBoron ores

The invention provides a boron extracting method, which comprises the following steps of (1) mixing a compound containing boron ore and calcium, roasting at 650 to 900 DEG C, and obtaining a roasted product; (2) after mixing the roasted product and activated carbon, carrying out carbonate decomposition and boron extraction to obtain a boron-rich liquid and a leaching residue. According to the boron extracting method, the energy consumption for a roasting pretreatment process is reduced, meanwhile, the reaction activity of a boron concentrate is improved, high leaching efficiency of the boron-containing component is ensured, a boron component in the boron concentrate can be high-efficiently extracted, the reaction activity of cooked boron ore after roasting achieves more than 90 percent, the leaching efficiency of carbonate decomposition and boron extraction is larger than 90 percent by weight, the content of B2O3 in boron mud is smaller than 2 percent by weight, and the boron-rich liquid is low in impurity content and can be further used for producing boron compounds such as borax and sodium metaborate.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

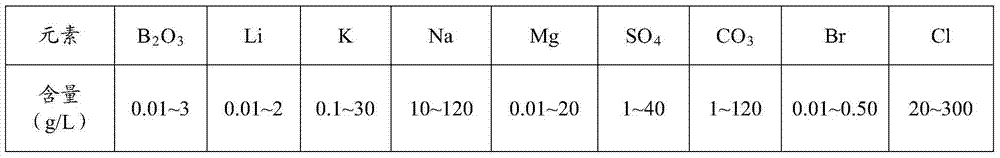

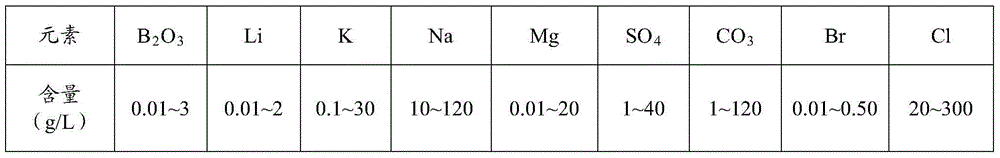

Method for separating elemental boron from boron-containing brine by nanofiltration

ActiveCN109205635ALow costHigh efficiency removalLithium halidesAlkali metal chloridesIon exchangeChemistry

In the process of comprehensive utilization of brine resources, especially in the process of lithium extraction from brine, boron in the brine is usually removed as an impurity. Traditional boron removal technologies include a method of dilution for salt formation, a method of acidification for boron removal, a method of ion exchange for boron removal, a method of extraction for boron removal, etc., and have the limitations of high cost for impurity removal, low efficiency, great loss of lithium ions, a narrow application scope, incapability of realizing comprehensive utilization of boron resources, etc. Although China is rich in boron resources, boron rock products cannot meet the needs of domestic economic construction, and boron products rely heavily on imports. The invention relates toa membrane-process boron removal technology which can remove elemental boron in brine at low cost and high efficiency, improve the yield of lithium ions and realizes the comprehensive utilization ofboron resources.

Owner:QINGHAI TUS QINGYUAN NEW MATERIAL CO LTD

Method for foam flotation and enrichment of low-grade boron-containing tailings

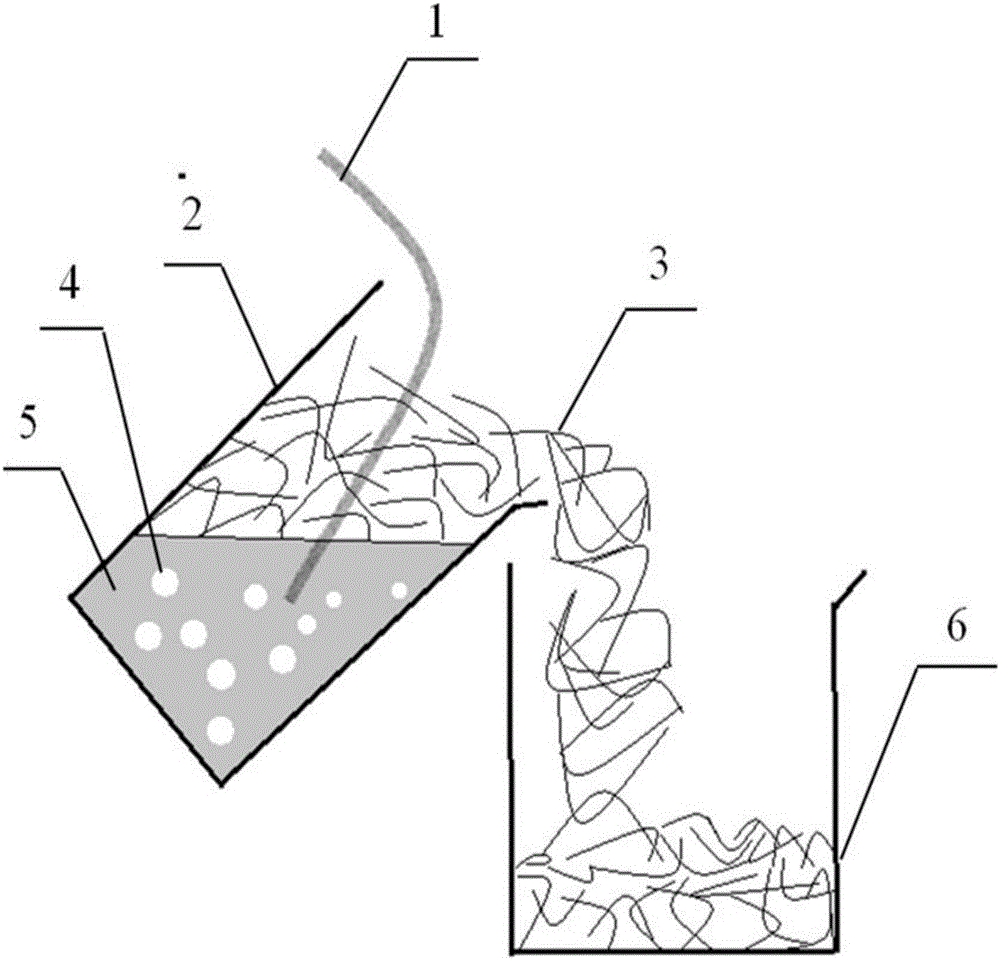

The invention discloses a method for foam flotation and enrichment of low-grade boron-containing tailings and belongs to the technical field of beneficiation techniques of boron ore. The method comprises the technological steps of ore crushing, ore grinding, water adding for pulp conditioning, flotation, bubble scraping and drying. The technique is different from the flotation study by predecessors that flotation is conducted on a special flotation machine; and by the adoption of the technique, a simple flotation device can be made by a user according to the flotation principle, so that the flotation cost is greatly reduced, and the technological process is simple and efficient. After low-grade boron ore is subjected to flotation through the technique, the grade of diboron trioxide is increased to 140% or over, and a novel approach is provided for efficient utilization of boron ore resources with the grade decreased increasingly; and waste of boron resources is reduced, and the method is extremely suitable for rough flotation in site.

Owner:BEIJING UNIV OF TECH

Method for preparing boron ore from mixed brine by using natural energy

The invention provides a method for preparing boron ore from mixed brine by using natural energy. The method comprises the following steps: orderly subjecting a carbonate brine to evaporation, freezing and evaporation treatment, and obtaining brine A when Li in the brine is lower than or equal to 2.5g / L or the content of lithium carbonate in solid ore separated out from the brine is lower than or equal to 0.5%; orderly subjecting a sulfate brine to evaporation, freezing and evaporation treatment, and obtaining brine B when Mg in the brine is greater than or equal to 10g / L; mixing the brine A with the brine B for reacting to obtain brine C; naturally evaporating the brine C to a certain degree to obtain brine D; freezing the brine D to obtain brine E; evaporating the brine E to a certain degree to obtain brine F; evaporating the brine F until a mineral containing lithium is separated out to obtain brine G; mixing the brine G with high-magnesium brine to obtain brine H; reacting the brine H with mirabilite, and obtaining brine I when the ratio of Mg to Li is lower than or equal to 8:1; evaporating the brine I, proportionally mixing the brine I with fresh water or a sulfate original brine, and evaporating to separate out the boron ore.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

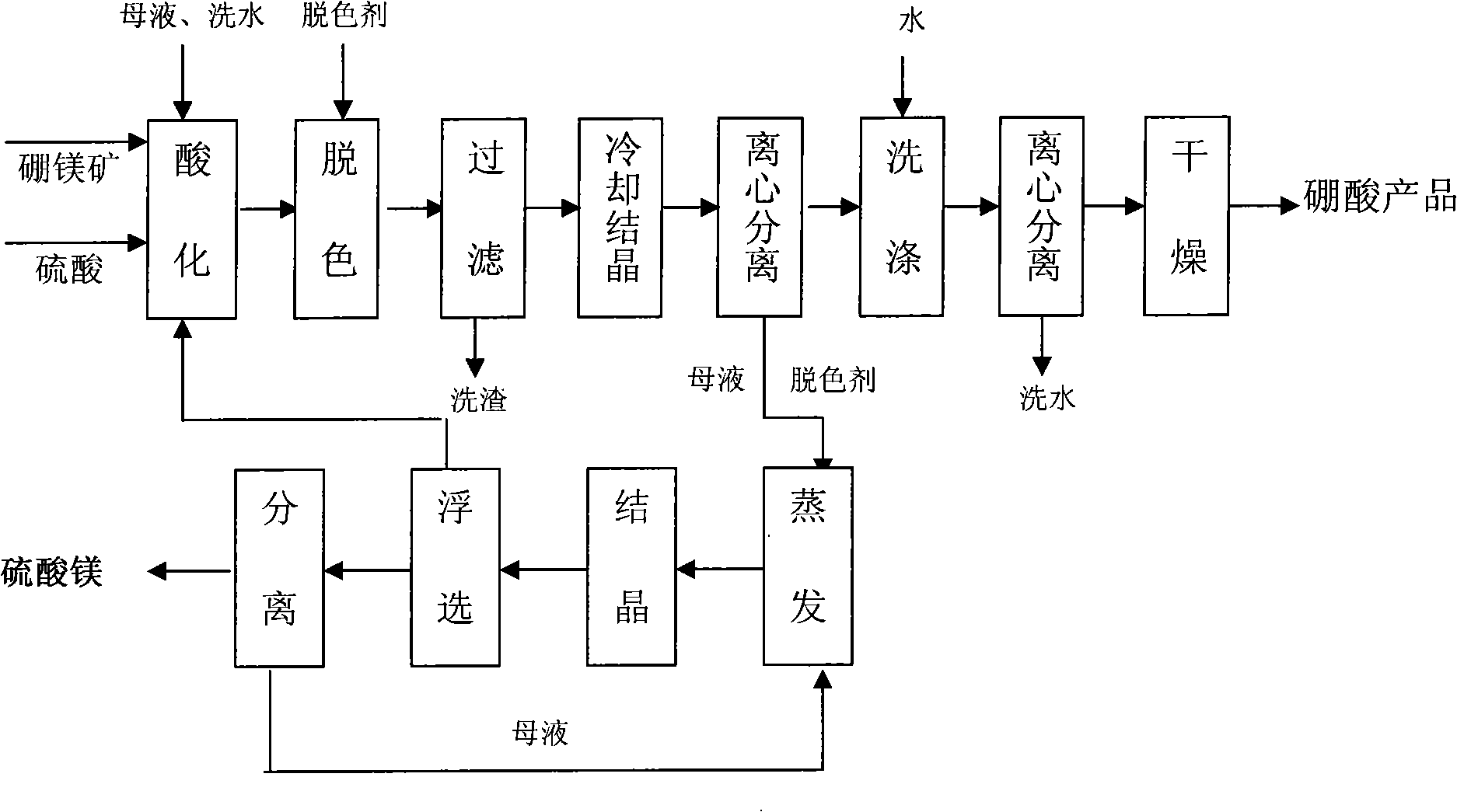

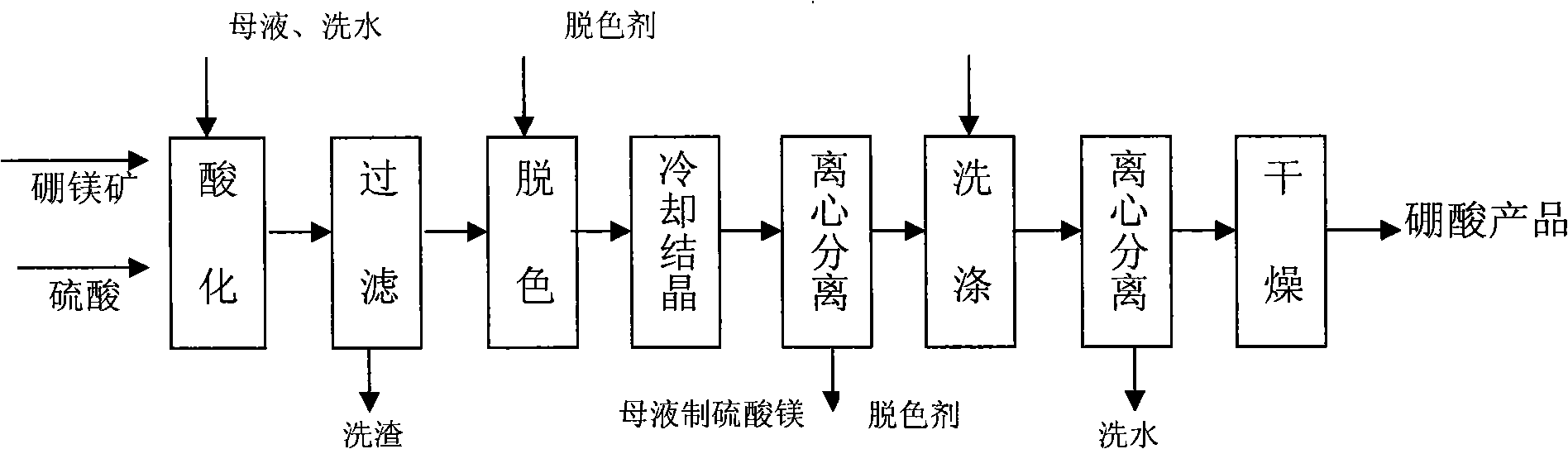

Crystallization control and whitening control method for producing boric acid and magnesium sulfate by salt lake type solid boron ore liquid boron ore

ActiveCN101254926AImprove crystal stateImprove filtering effectMagnesium sulfatesBoron-oxygen compoundsChemical industryFiltration

The invention belongs to the technology field of chemical industry and relates particularly to a crystallization and whitening control method of preparing boric acid and magnesium sulfate based on the salt lake type solid boron ore and liquid boron ore. The original technological process for preparing the boric acid from the salt lake type solid boric acid includes using acidifying szaibelyite, water, boron-containing mother liquor and boron-containing wash water as the material, acidificating with sulfuric acid, filtering, cooling and crystallizing, centrifugalizating, washing, further centrifugalizating, drying and obtaining the boric acid. Based on the process, the method adds the operational process of repeatedly adjusting the acidity to strictly control the pH value range to the process of chemical decolorization and cooling and crystallizing, heat preservation chemical decolorization of the acidified slurry or the acidified and filtered filtrate and repeatedly adjusting the acidity to strictly control the pH value range of the cooled and crystallized solution. The chemical decolorizer is employed to remove the colored ferric iron, algae, and organic matter in solution and improve the crystalline state, and the pH value of the cooled and crystallized solution is controlled by repeatedly adjusting acid to obtain the white boric acid granular crystals. The white boric acid granular crystals have good filtering property, washing property and high yield. The method can be widely used in the production of boric acid from the salt lake type boron ore.

Owner:青海利亚达化工有限公司

Proppant prepared by utilizing industrial tailings and preparation method thereof

InactiveCN103173203AEfficient use ofTake advantage ofFluid removalCeramic materials productionSoft clayExpanded clay aggregate

The invention relates to a proppant. Preparation raw materials of the proppant comprise magnesium ore tailings, iron ore tailings and soft clay, or further comprise boron ore tailings or comprise the boron ore tailings, silica and the soft clay, or further comprise the magnesium ore tailings or comprise the boron ore tailings, the iron ore tailings and the soft clay. A preparation method of the proppant comprises the following steps: firstly respectively performing light burning treatment on the magnesium ore tailings, the boron ore tailings and the silica, and further respectively performing powder grinding through a ball grinder; respectively performing drying treatment on the iron ore tailings and the soft clay, and further respectively performing powder grinding through the ball grinder; then weighing the raw materials according to a mixture ratio, and uniformly mixing to get a premix; performing granulation and screening on the premix; then sending into a rotary kiln, firing and performing heat preservation; and firing to get ceramisite, and screening to get the proppant. The proppant disclosed by the invention has the characteristics of high temperature resistance, high pressure resistance, corrosion resistance, high strength, high diversion capacity, low breaking rate and the like, and the preparation method has the advantages of low energy consumption and large capacity.

Owner:杨松

Magnesium-aluminum spinel-BN-Sialon multiphase refractory raw material and preparation method thereof

The invention discloses a magnesium-aluminum spinel-BN-Sialon multiphase refractory raw material and a preparation method thereof. According to the preparation method, low-grade magnesium borate boron ore or tailings thereof, low-grade bauxite or bauxite tailings thereof and coke powder are used as main raw materials, carbon thermal reduction nitridation reaction is performed at an appropriate temperature according to requirements of needed refractory materials by virtue of component design, and the product is crushed and ground after cooling to obtain MgAl2O4-BN-Sialon multiphase refractory raw material powder. The magnesium-aluminum spinel-BN-Sialon prepared by the method provided by the invention mainly comprises the composition phases of beta-Sialon, Mg-Sialon, BN, MgAl2O4 (magnesium-rich or aluminum-rich magnesium-aluminum spinel) and a small amount of Al6O3N4, Fe3Si and the like; and the preparation method disclosed by the invention has the significant advantages of high solid waste resource utilization degree, low cost and low energy consumption.

Owner:铜陵博雅渡业新材料科技有限公司

Method of preparing lithium borate ores from mixed brine by utilizing natural energy

ActiveCN103553088BControl sulfate concentrationEasy extractionBoron-oxygen compoundsLithium sulfates/sulfitesHigh magnesiumSulfate radicals

The invention discloses a method of preparing lithium borate ores from mixed brine by utilizing natural energy. The method comprises the following steps: evaporating, freezing and evaporating carbonate brine until Li content is less than or equal to 2.5g / L or content of lithium carbonate in solid ores separated out in the brine is less than or equal to 0.5% to obtain brine A; collecting an alkaline mixture generated in the freezing process; evaporating, freezing and evaporating sulfate brine until Mg content is greater than or equal to 10g / L to obtain brine B; mixing and reacting the brine A and the brine B to obtain brine C; evaporating the brine C until sulfate radical content is 5g / L-40g / L to obtain brine D; freezing and nitrifying the brine D to obtain brine E; evaporating the brine E to a certain degree to obtain brine F; naturally evaporating the brine F to separate out sylvine ores and brine G; mixing and reacting the brine G and high-magnesium brine to obtain brine H; reacting the brine H with mirabilite to obtain brine I; evaporating the brine I to concentrate and separate out lithium sulfate ores and brine J; mixing and evaporating the brine J with fresh water or sulfate type original brine to separate out boron ores.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Method of preparing lithium borate ores from mixed brine by utilizing natural energy

ActiveCN103553088AControl sulfate concentrationEasy extractionBoron-oxygen compoundsLithium sulfates/sulfitesHigh magnesiumSulfate radicals

The invention discloses a method of preparing lithium borate ores from mixed brine by utilizing natural energy. The method comprises the following steps: evaporating, freezing and evaporating carbonate brine until Li content is less than or equal to 2.5g / L or content of lithium carbonate in solid ores separated out in the brine is less than or equal to 0.5% to obtain brine A; collecting an alkaline mixture generated in the freezing process; evaporating, freezing and evaporating sulfate brine until Mg content is greater than or equal to 10g / L to obtain brine B; mixing and reacting the brine A and the brine B to obtain brine C; evaporating the brine C until sulfate radical content is 5g / L-40g / L to obtain brine D; freezing and nitrifying the brine D to obtain brine E; evaporating the brine E to a certain degree to obtain brine F; naturally evaporating the brine F to separate out sylvine ores and brine G; mixing and reacting the brine G and high-magnesium brine to obtain brine H; reacting the brine H with mirabilite to obtain brine I; evaporating the brine I to concentrate and separate out lithium sulfate ores and brine J; mixing and evaporating the brine J with fresh water or sulfate type original brine to separate out boron ores.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI +1

Proppant prepared from tailings of magnesium ore, boron ore and iron ore and preparation method thereof

ActiveCN103193461AEfficient use ofTake advantage ofFluid removalCeramic materials productionExpanded clay aggregateHigh pressure

The invention relates to a proppant. The proppant is prepared from magnesium ore tailings, boron ore tailings, iron ore tailings and mild clay. The preparation method of the proppant comprises the following steps of: firstly respectively carrying out soft burning treatment on the magnesium ore tailings and the boron ore tailings, and then, respectively milling through a ball mill; respectively carrying out drying treatment on the iron ore tailings and the mild clay, and then, respectively milling through a ball mill; weighing and uniformly mixing the raw materials according to a proportioning ratio so as to obtain a premixture; granulating and sieving the premixture; feeding the premixture into a rotary kiln, and carrying out heat preservation after firing; and sieving fired ceramsite, thereby obtaining the proppant. The proppant disclosed by the invention has the characteristics of high temperature resistance, high pressure resistance, corrosion resistance, high strength, high flow guide capability, low broken rate and the like, and the preparation method of the proppant is low in energy consumption and high in productivity.

Owner:杨松

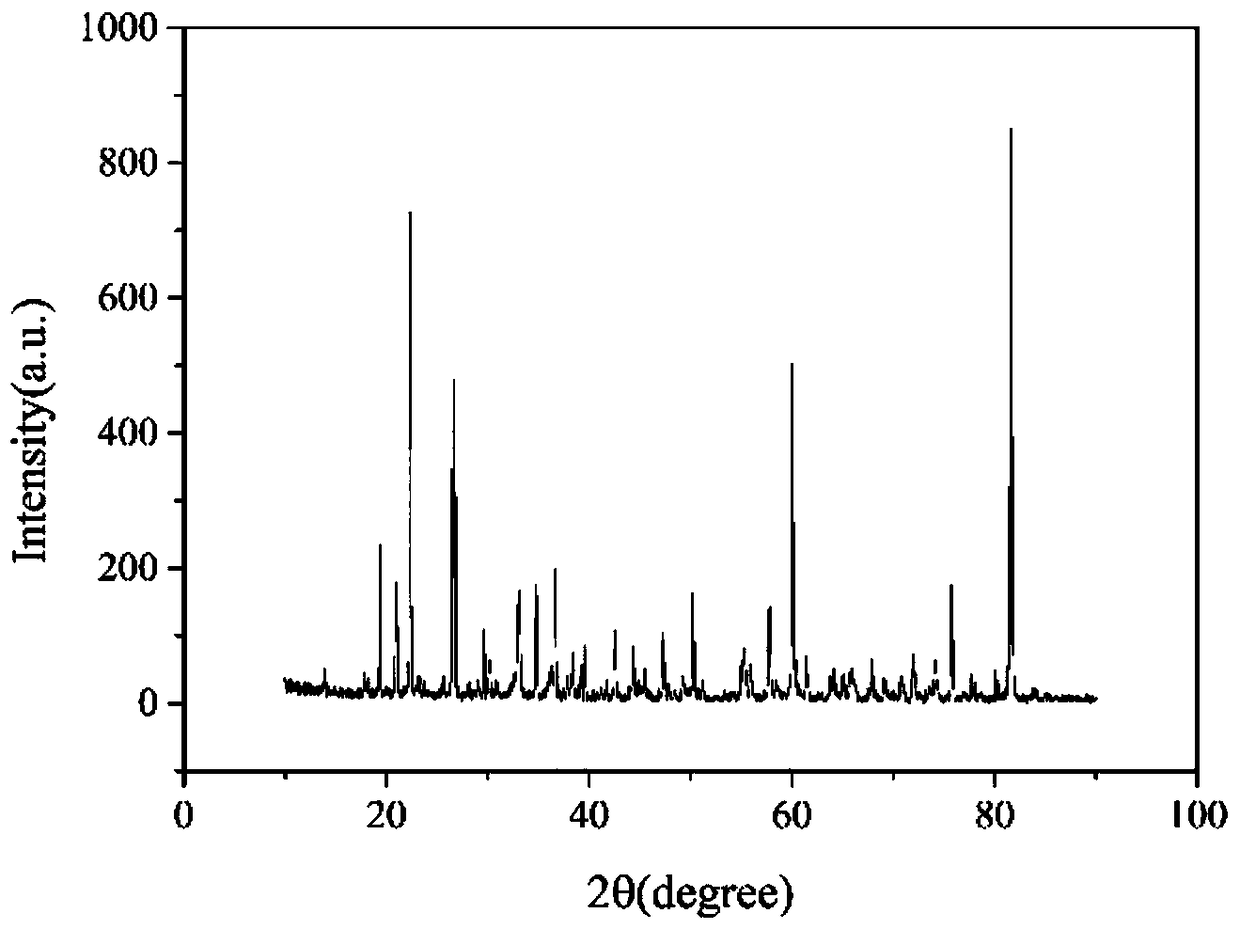

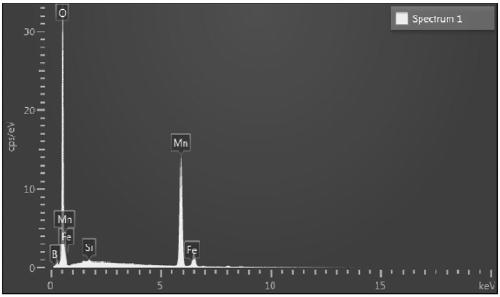

Nano porous boron ore loaded iron-manganese composite deep treatment catalyst applied to ozone catalytic oxidation

PendingCN109364937AGood decolorization effectHigh catalytic efficiencyMetal/metal-oxides/metal-hydroxide catalystsWater/sewage treatment by oxidationChemical oxygen demandCatalytic oxidation

The invention relates to a nano porous boron ore loaded iron-manganese composite deep treatment catalyst applied to ozone catalytic oxidation. The catalyst takes porous boron ore as a carrier; Mn2O3,Fe2O3 and FeMnO3 are loaded on the porous boron ore; and in the catalyst, the content of the Mn2O3 is 20 to 50 percent, the content of the Fe2O3 is 1 to 15 percent, the content of the FeMnO3 is 1 to 15 percent and the balance is the carrier. According to the catalyst provided by the invention, manganese, iron and boron are compounded so that the catalytic efficiency of the catalyst is greatly improved and ozone can be induced to produce more hydroxyl free radicals (.OH); the utilization rate of the ozone is high and the COD (Chemical Oxygen Demand) value removal efficiency is high; a degradedproduct has a smaller molecule and is more easy to biodegrade; and the catalyst still has a removal effect on ammonia nitrogen and has the advantages of low cost, simple technological flow and operation and convenience for realizing industrialization.

Owner:W STARTECH BEIJING ENVIRONMENTAL TECH

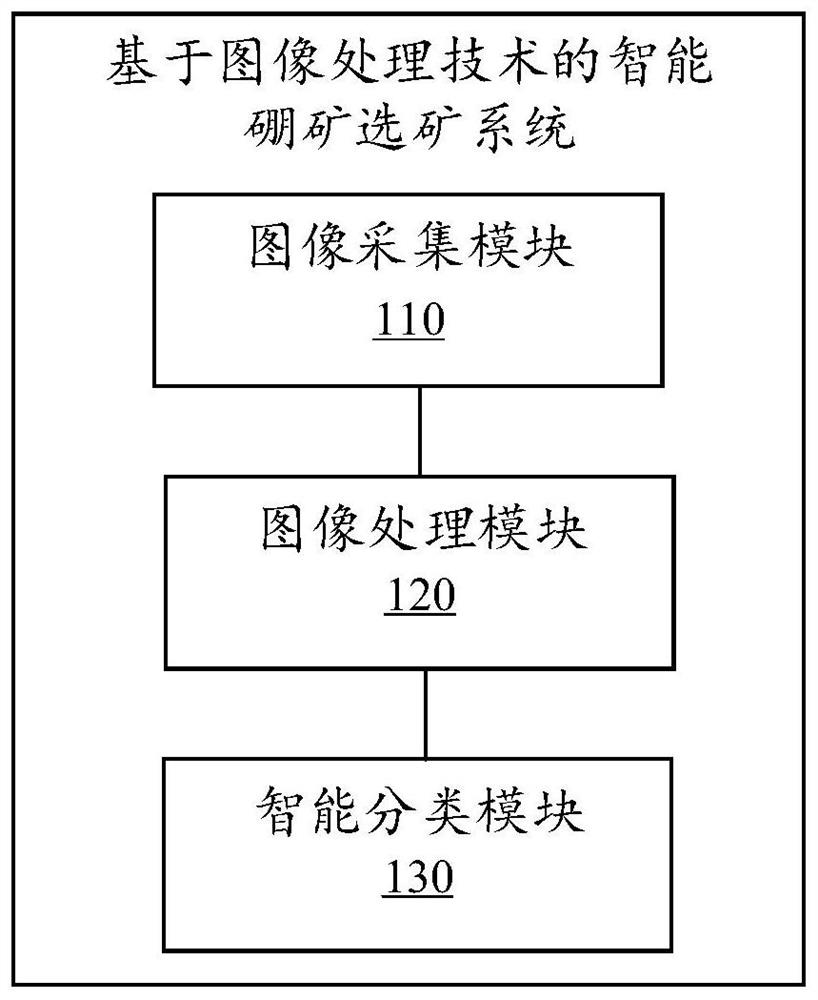

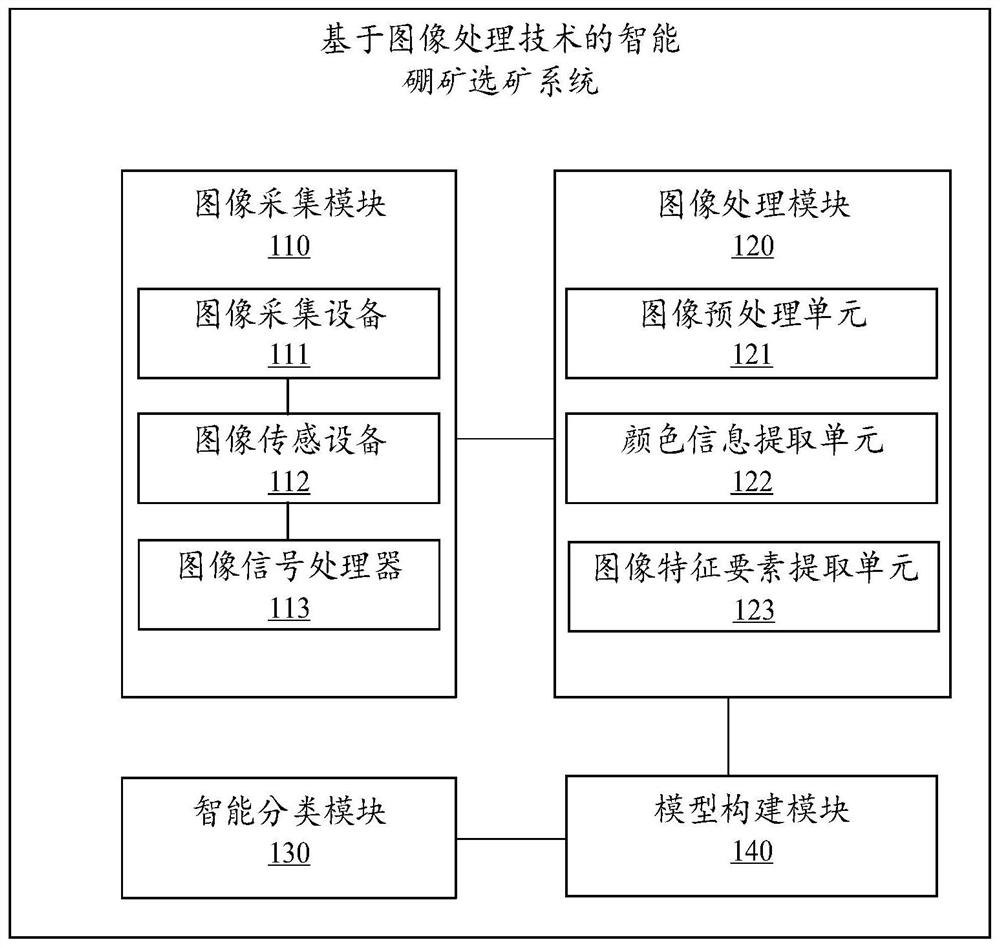

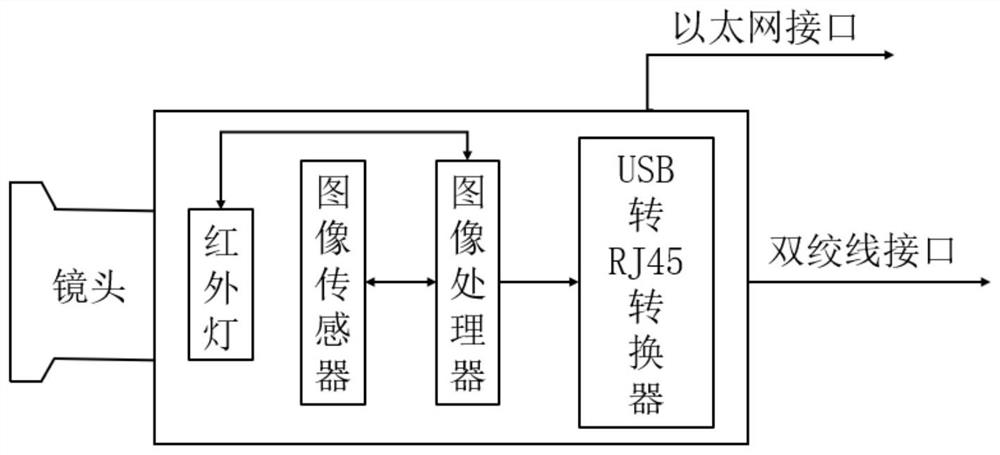

Intelligent boron ore beneficiation system and method

PendingCN113591583AImplement automatic detectionEasy to detectCharacter and pattern recognitionNeural architecturesData ingestionImaging processing

The invention provides an intelligent boron ore beneficiation system and method, and the system comprises: an image collection module, which is used for obtaining image data of at least one boron ore and storing the image data to an image database; an image processing module, which is used for carrying out image preprocessing on the image data in the image database to select effective image data and extracting color information and image feature elements corresponding to the effective image data; and an intelligent classification module, which is used for inputting the color information and the image feature elements corresponding to any effective image data into a pre-trained target boron ore classification model, and performing boron ore classification on the boron ore corresponding to the effective image data by using the target boron ore classification model to obtain the boron ore type of the boron ore. In the boron ore beneficiation process, flow, modularization, automation and high-efficiency boron ore type identification is achieved, the accuracy of boron ore type detection is improved, and manpower and time cost is saved.

Owner:沈阳科来沃电气技术有限公司

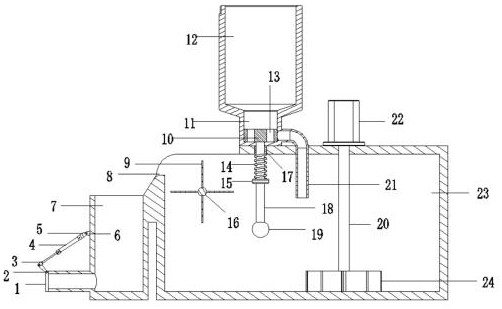

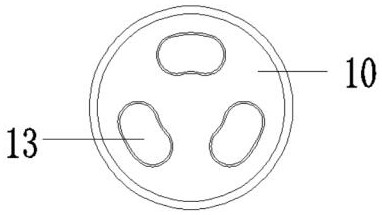

Flotation separation device for preparing boric acid from boron ore

The invention discloses a flotation separation device for preparing boric acid from boron ore. The flotation separation device comprises a flotation bin, a cover plate, an overflow port, a centrifugalassembly, a collecting bin, a foam scraping assembly, an overturning assembly, a liquid storage bin and a feeding assembly, and the centrifugal assembly comprises a rotating shaft, an impeller and amotor. The flotation separation device has the beneficial effects that the collecting bin is arranged, and foam scraped out by the foam scraping assembly is scraped into the collecting bin to be collected; the overturning assembly is arranged, the sealing cover plate is driven by the overturning assembly to overturn, and the sealing cover plate does not need to be opened manually; the liquid storage bin is arranged, and a flotation agent needed in the flotation operation process can be stored; the communication between a communicating pipe and a communicating bin is controlled by the feeding assembly, so that the flotation agent can enter the communicating pipe from the communicating bin and then flow into the flotation bin; and in conclusion, compared with flotation equipment in the priorart, the flotation separation device has the advantages that the functions are diversified, the operation is convenient and fast, and the working efficiency is further improved.

Owner:衡阳市大宇锌业有限公司

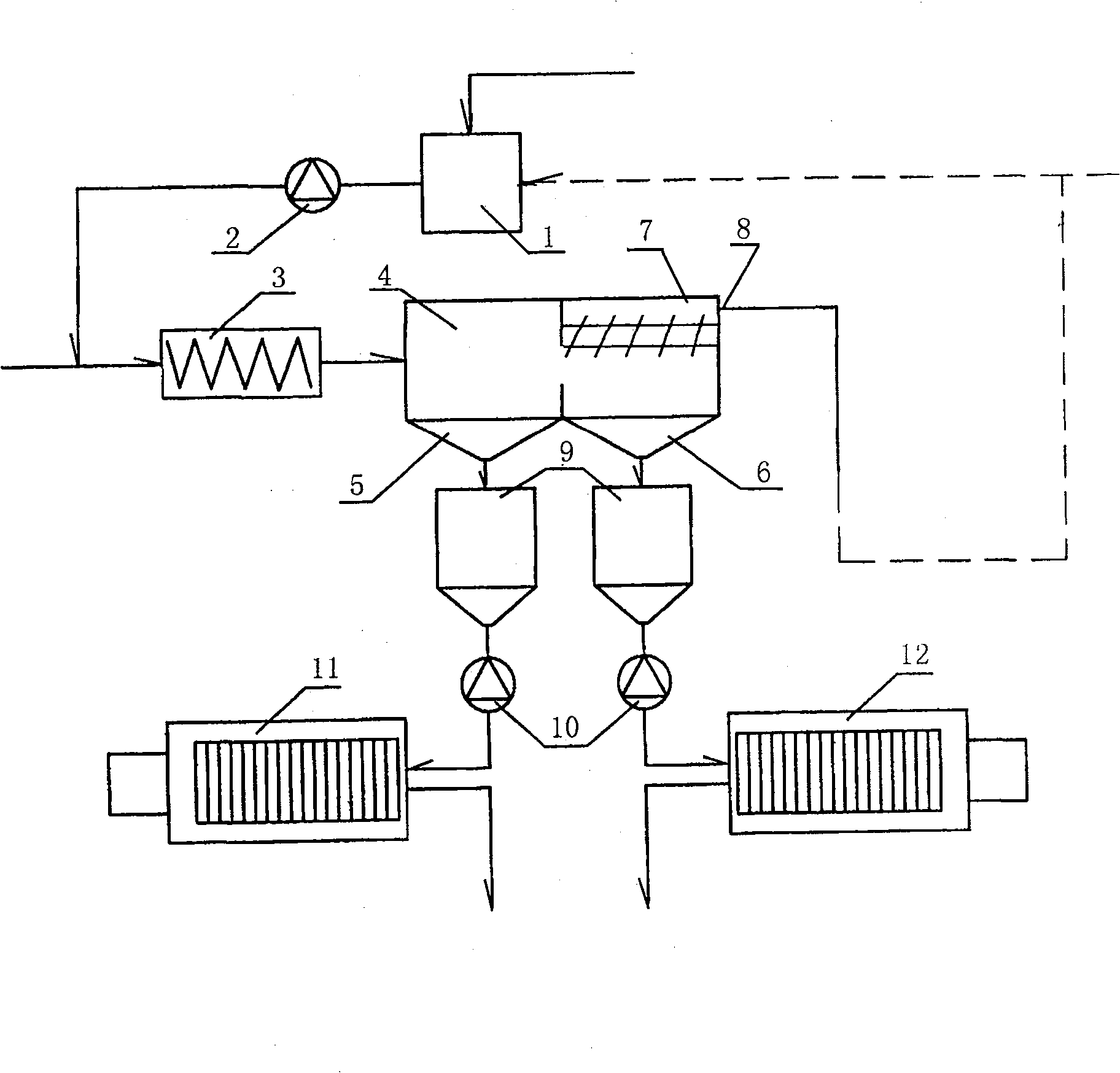

Calcination process of boron ore powder

The invention provides a technique for calcining powdery lagonite; the technique process comprises the following steps: lagonite is added into a drier, then the lagonite is broken into powder for drying, then the powdery lagonite and the air are fed into a semi-finished product gas-solid separator to make gas-solid separation, wherein, the gas is emitted out as waste gas and the dried solid is fed into an calcinator for calcination; at the same time, hot air is fed as a heat source, and the calcined lagonite and air are fed into a finished product gas-solid separator to make gas-solid separation, wherein, the hot gas are recovered to the drier as a heat source after the gas-solid separation, and the calcined solid is fed into a wind cooler for cooling, and finally the finished product can be obtained for storage. During the technical process, the water content of the lagonite fed into the drier is 15 to 30 percent and the grade is 6 to 10 percent; the calcination temperature is 1000 to 12000 DEG C and the calcination period is 1 to 15s. The technical flow is simple and short with high energy utilization ratio; meanwhile, the product quality is good and the activation rate of the powdery lagonite can be improved to 85 percent at least.

Owner:辽宁东大粉体工程技术有限公司

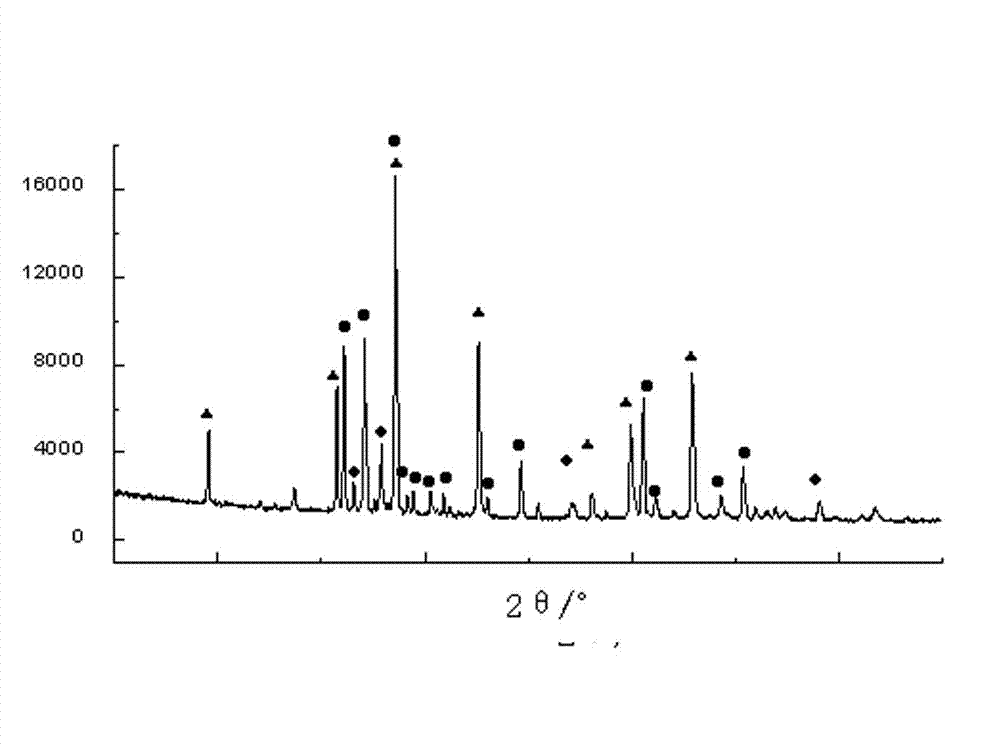

Method for preparing sodium metaborate with sodium perborate byproduct from low-grade ludwigite

The invention discloses a method for preparing sodium metaborate with a sodium perborate byproduct from low-grade ludwigite. The method comprises the following steps: (1) boron ore concentrate powderis obtained through a mineral processing process; (2) sodium hydroxide and water are added according to the mass ratio of the sodium hydroxide to the boron ore concentrate powder to the water of 1:(1-1.2):(3-4); (3) alkaline hydrolysis is performed on the boron ore concentrate powder at the pressure of 0.5-0.6 MPa and the temperature of 155-160 DEG C, a reaction is performed for 2 h, and thereforea sodium metaborate solution is obtained; (4) after the reaction is completed, plate frame filtration is performed, and a crystallization liquid enters a crystallization tank; and plate frame filtration is performed, and a filtrate returns to the crystallization tank; (5) activated carbon is added into the filtrate, the filtrate is subjected to heat exchange and cooling through a heat exchanger,and the obtained filtrate is sent to a material preparing tank in the preparation process of the sodium perborate; and (6) a preparation process of the sodium perborate is performed: finally, materials are mixed according to a ratio after the sodium perborate product is crystallized so to improve the product stability. The method provided by the invention has the advantages of shortening an overall production process and saving a large amount of costs; and impurity removal of the product is more thorough, and the comprehensive utilization rate of the low-grade ludwigite is improved compared with a usual process.

Owner:LIAONING SHOUGANG BORON IRON

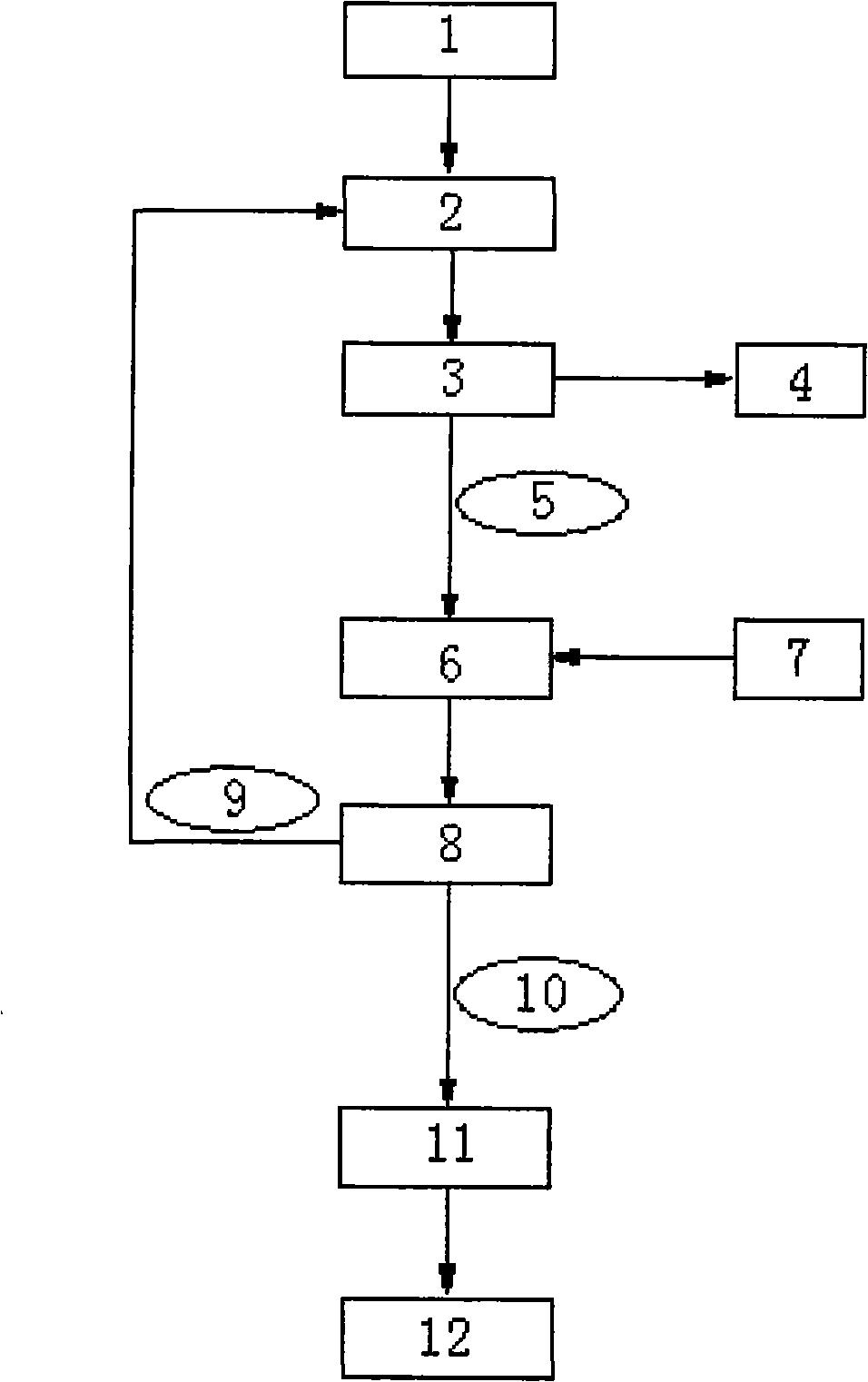

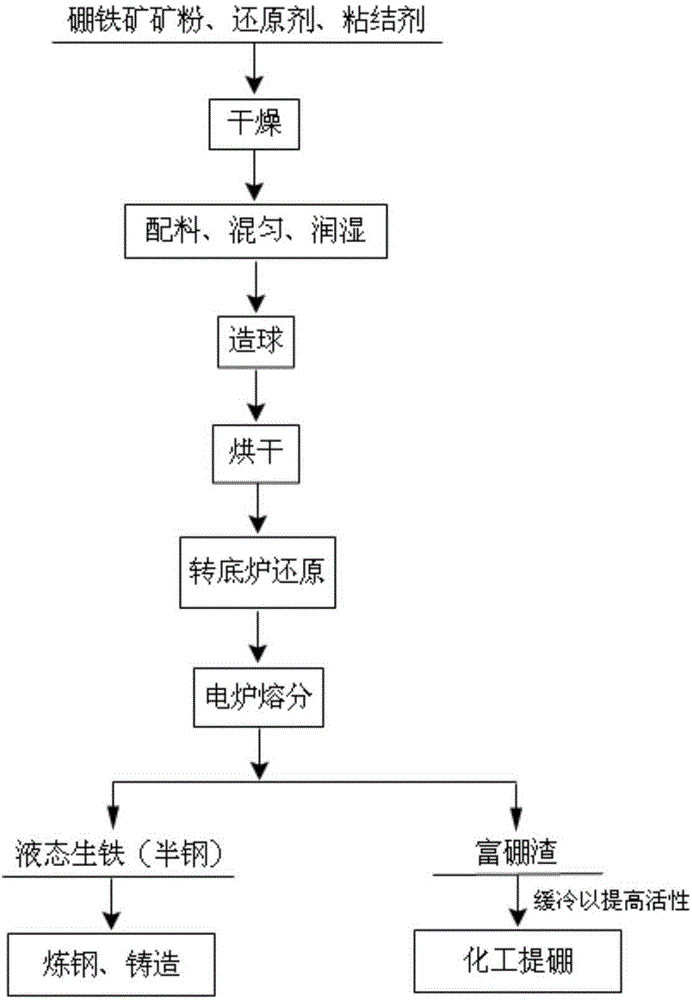

Method for comprehensive utilization of paigeite through direct reduction-electric furnace melting separation of rotary hearth furnace

The invention discloses a rotary hearth furnace direct reduction-electric furnace melting method for comprehensive utilization of boron ore, which belongs to the field of ironmaking and resource comprehensive utilization. The invention relates to a method for separating and enriching boron and iron in boron-iron ore, and is used for the development and utilization of boron-iron ore. It is characterized in that it uses boron iron ore powder, carbonaceous reducing agent, and binder as raw materials to prepare liquid pig iron (or semi-steel) and High-quality boron-rich slag with a B2O3 content of 10-22%. The produced liquid pig iron (or semi-steel) can be used as raw material for steelmaking, and the boron-rich slag can replace boronite ore to produce boric acid or borax, so that boron and iron resources can be fully utilized to realize the comprehensive utilization of boronite ore. The method has the advantages of simple process, short process, complete separation of boron and iron, and high efficiency. The separated product can meet the needs of boron industry and iron and steel industry at the same time, and has good social and economic benefits.

Owner:UNIV OF SCI & TECH BEIJING

Medium trace element compound fertilizer as well as preparation method and application thereof

InactiveCN111574307AMeet needsReduce pollutionCalcareous fertilisersFertilizer mixturesSoil scienceBoron ores

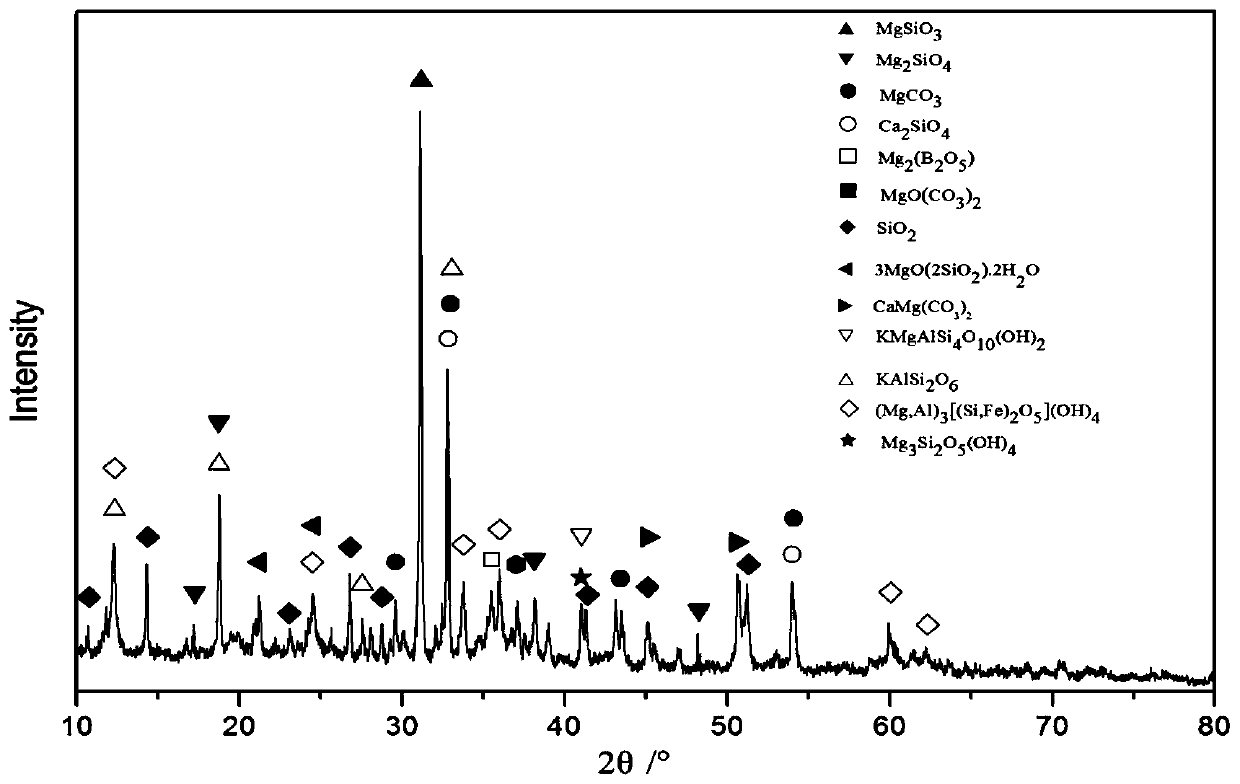

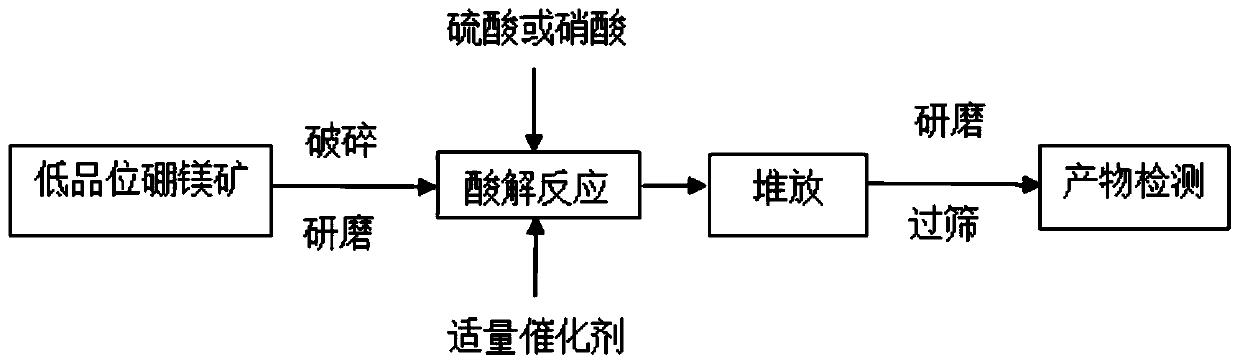

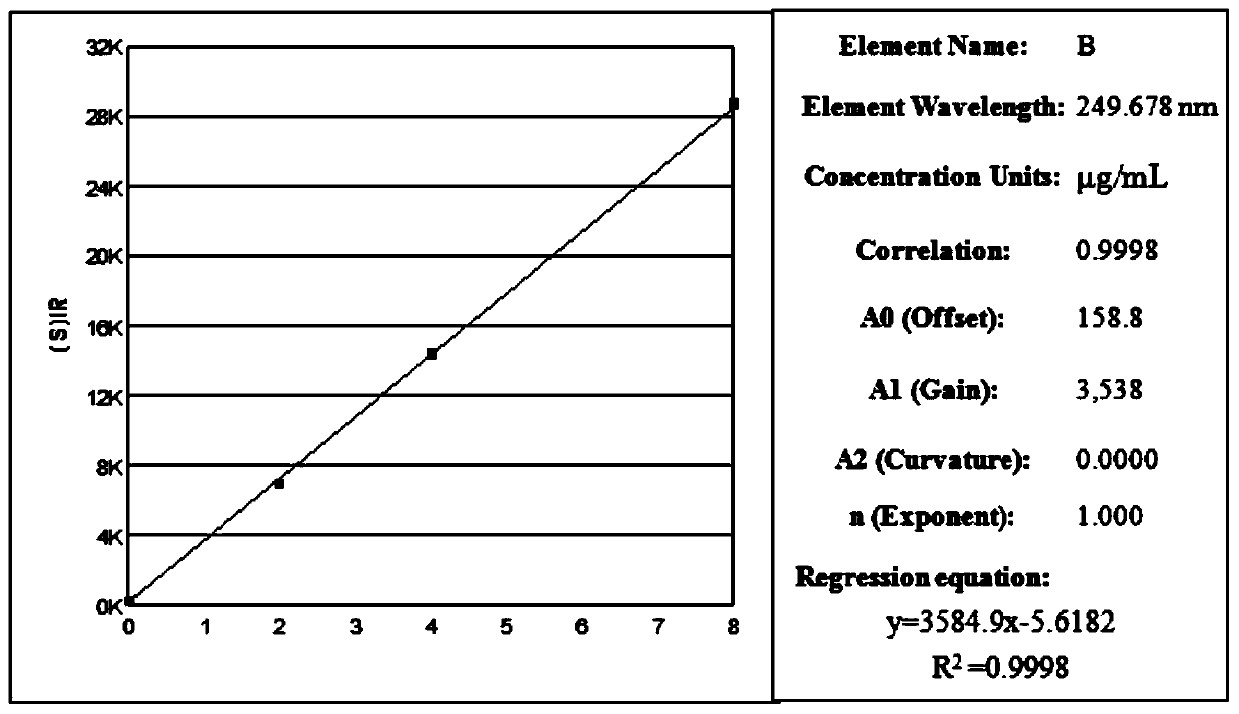

The invention relates to the technical field of inorganic fertilizers, in particular to a medium-trace element compound fertilizer and a preparation method and application thereof. The medium-trace element compound fertilizer is prepared by taking low-grade boron-magnesium ore as a raw material, performing acidolysis reaction in concentrated acid liquor at 60-80 DEG C after crushing to obtain a fertilizer intermediate, and stacking and curing the fertilizer intermediate, wherein the concentrated acid solution is concentrated sulfuric acid or concentrated nitric acid, and the concentrated acidsolution is concentrated sulfuric acid. According to the invention, low-grade boron ore powder and concentrated acid liquor are used as raw materials; the acidic medium trace element compound fertilizer with the pH value of 3-5 is prepared, low-grade boron-magnesium ore resources can be fully utilized, the problem of environmental pollution can be effectively solved; no waste gas, fertilizer residues or wastewater is generated, and the prepared acidic medium trace element compound fertilizer can be applied to improvement of alkaline soil.

Owner:武汉吴教授农业科技有限公司

Proppant prepared from tailings of magnesium ore and boron ore and preparation method thereof

InactiveCN103194203AEfficient use ofTake advantage ofFluid removalHigh pressureTemperature resistance

The invention relates to a proppant. The proppant is prepared from magnesium ore tailings, boron ore tailings, silica and mild clay. The preparation method of the proppant comprises the following steps of: firstly respectively carrying out soft burning treatment on the magnesium ore tailings, the boron ore tailings and the silica, and then, respectively milling through a ball mill; carrying out drying treatment on the mild clay, and then, milling through a ball mill; weighing and uniformly mixing the raw materials according to a proportioning ratio so as to obtain a premixture; granulating and sieving the premixture; feeding the premixture into a rotary kiln, and carrying out heat preservation after firing; and sieving fired ceramsite, thereby obtaining the proppant. The proppant disclosed by the invention has the characteristics of high temperature resistance, high pressure resistance, corrosion resistance, high strength, high flow guide capability, low broken rate and the like, and the preparation method of the proppant is low in energy consumption and high in productivity.

Owner:杨松

Technique for preparing high quality boric acid from salt lake type boron ore by one-step method

InactiveCN101209844BImprove evaporation efficiencyImprove efficiencyBoron-oxygen compoundsSludgeFiltration

Owner:肖莹

Smelting method of high-chromium and high-titanium iron ores

InactiveCN107400744AEarly precipitationReduce concentrationBlast furnace detailsBoron oresSmelting process

The invention provides a smelting method of high-chromium and high-titanium iron ores. The smelting method comprises the steps of sintering high-chromium and high-titanium iron ores so as to obtain sintered ores, and smelting the sintered ores, lump ores, high-chromium and high-titanium pellets, boron ores and a reducing agent in a blast furnace, so as to obtain molten iron containing chromium and titanium. According to the smelting method, by adding the boron ores in a smelting process of the high-chromium and high-titanium iron ores, the viscosity of slag is reduced, the smooth operation of the blast furnace is guaranteed, the molten iron containing chromium and titanium is produced, and resources containing chromium and titanium are adequately utilized, and the method meets the requirements of the nation on strategic materials such as chromium and titanium; and meanwhile, considerable economic benefit can be further created.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

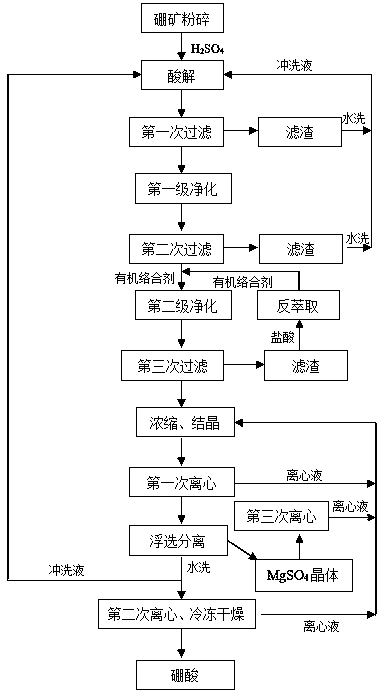

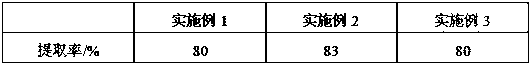

Method for preparing boric acid from boron ore

InactiveCN109110775AReduce extraction costsHigh extraction rateBoron-oxygen compoundsAluminum IonBoron ores

The invention discloses a method for preparing boric acid from boron ore. The method comprises the following steps: ore smashing, acidolysis, first filtering, first purification, secondary filtering,concentrating, crystallizing, first centrifugation, flotation separation, secondary centrifugation and freeze-drying, thereby obtaining the boric acid product. The method is characterized in that thesecondary purification is added between the secondary filtering and the concentrating; an organic complexing agent is adopted for complexing iron ions and aluminum ions during the secondary purification; the organic complexing agent is used for precipitating iron ions and aluminum ions, so as to form an iron-organic complexing sediment and an aluminum-organic complexing sediment. The method can beused for effectively removing iron ions, is capable of eliminating the influence of iron ions on the glossiness of the finished product of boric acid and has simple process, high operability, high cyclic utilization rate of filtrate, low cost and high extraction ratio of boric acid.

Owner:衡阳市大宇锌业有限公司

Boron-ore-slurry solid-liquid separation method

InactiveCN100534572CHigh recovery rateNo pollutionSedimentation separationFiltration circuitsLiquid layerBoron ores

Owner:吉林市恒昌过滤机械有限公司

Special composite organic fertilizer for mangnolia officinalis and preparation method of special composite organic fertilizer

InactiveCN102617246BIncrease concentrationIncrease profitOrganic fertilisersFertilizer mixturesCompound organicSlag

The invention discloses a special composite organic fertilizer for mangnolia officinalis and a preparation method of the special composite organic fertilizer, wherein the special composite organic fertilizer for mangnolia officinalis consists of the following ingredients in parts by weight: 10 to 20 parts of soybean meal, 30 to 40 parts of plant straws, 10 to 13 parts of cabbage slag, 0.5 to 2 parts of composite strains, 15 to 20 parts of potassium sulfate, 0.3 to 0.8 part of manganese sulfate, 0.4 to 0.9 part of ferrous sulfate, 10 to 25 parts of ammonium sulfate, 2 to 5 parts of borax, 10 to 15 parts of diammonium phosphate, 2 to 5 parts of fulvic acid, 1 to 4 parts of soluble chitosan, 2 to 5 parts of trace boron ore, 0.04 to 0.08 part of dipterex, 0.03 to 0.05 parts of chlorothalonil and 25 to 32 parts of filling materials. According to the growth rule of the mangnolia officinalis, the fertilizer provided by the invention adopts a great number of biological organic nitrogenous fertilizers, the physical properties of the soil can be obviously improved after a great number of fertilizers are utilized, the effective void content of the soil is increased, and the survival rate of the young seedlings of the mangnolia officinalis is improved.

Owner:HUBEI FUSOURCE BIOLOGY OF BIOLOGICAL TECH CO LTD

A process of mechanical activation to improve boron leaching rate of boron concentrate

ActiveCN106492940BImprove leaching rateReduce dependenceGrain treatmentsBoron compoundsEnvironmental resistanceHigh energy

The invention belongs to the field of boron ore resource utilization, and particularly relates to a mechanical activation process for improving the boron leaching rate of boron concentrate. In the present invention, the boron concentrate is first mechanically crushed and used as raw material for later use. The crushed boron concentrate raw material is placed in a high-energy ball mill for mechanical activation. The mass ratio of the grinding ball to the boron concentrate raw material is (4~16):1. The diameter of the grinding ball is 3~10mm, the filling rate of the grinding ball and boron concentrate in the ball mill tank is 30%~70%, the ball milling speed is 100~300r / min, the ball milling time is 10~120min, and the mechanically activated boron concentrate is obtained , and finally stir and heat the mechanically activated boron concentrate with sodium hydroxide solution to obtain boron-containing leach liquid and leaching residue. The boron leaching rate reaches more than 73.1%. The present invention applies the method of combining mechanical activation and alkali leaching to strengthen the leaching of boron in boron concentrate, which is a simple, safe, economical, environmentally friendly and efficient new process. This new process can improve the activity of boron concentrate, Therefore, it is expected to obtain higher boron leaching rate at lower alkalinity and temperature.

Owner:NORTHEASTERN UNIV LIAONING

Method for preparing MgAION/SiAION ceramic composite material by utilizing lagonite milltailings

A method for preparing magnesia-alon / cyaalon ceramic composite materials using boron ore beneficiation tailings, which belongs to the field of material technology and is carried out according to the following steps: grind the boron ore beneficiation tailings to obtain tailings powder; Powder, bauxite and carbon black are mixed to make a mixed material; after wet mixing, it is dried, then dry mixed, and then pressed into a green body; a normal pressure sintering is performed under nitrogen protection conditions; the carbon removal powder is obtained by heating and insulation. Mix it with additives and press it into shape; cover it with nitride mixed powder and perform secondary normal pressure sintering. The method of the present invention adopts low raw material cost and simple process, and the prepared magnesium Alon / Sialon ceramic composite material has the characteristics of good creep resistance, thermal shock resistance and excellent high-temperature mechanical properties.

Owner:NORTHEASTERN UNIV LIAONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com