Method for foam flotation and enrichment of low-grade boron-containing tailings

A foam flotation, low-grade technology, applied in flotation, solid separation, etc., can solve the problems of high cost, inconvenient on-site operation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

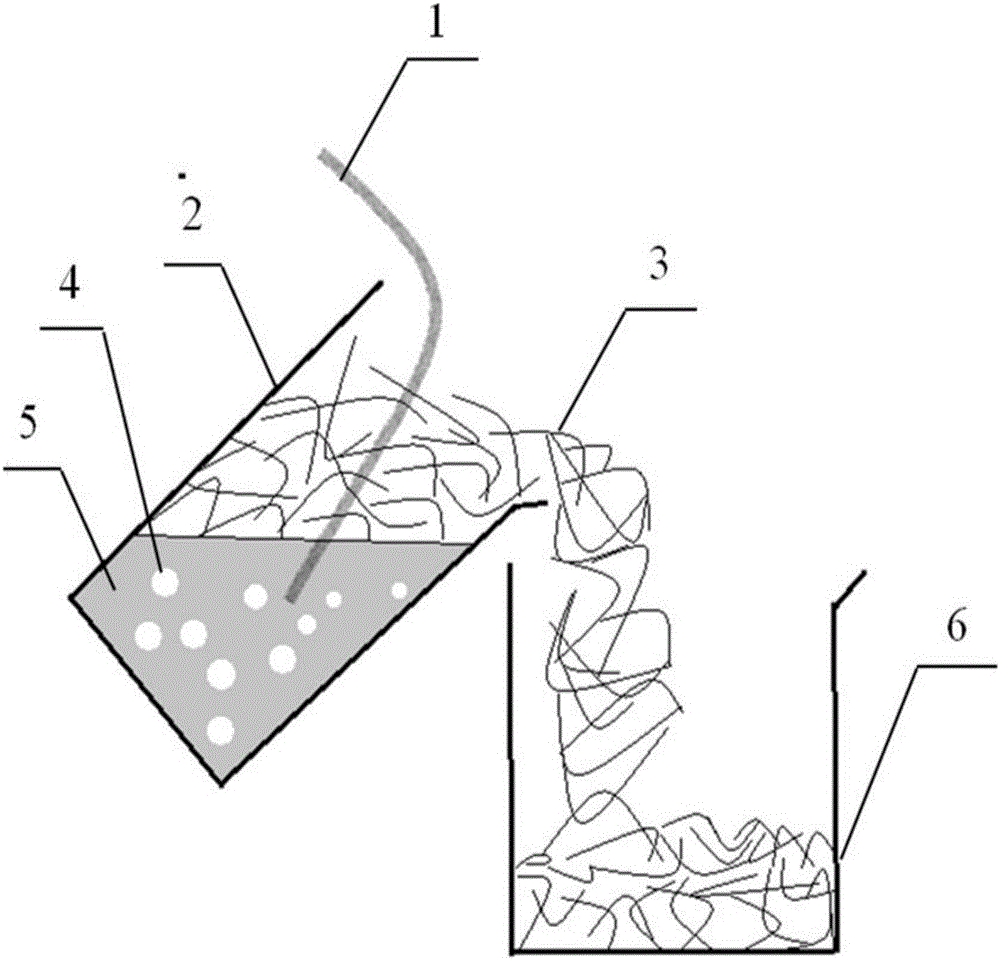

[0046] The particle size of 67.2g is 70 mesh, B 2 o 3 A low-grade boron-containing tailings powder in Dandong, Liaoning, with a mass percentage of 2.76% was added to the flotation device (see attached figure 1 ) in container a 2, add 300mL of water and stir well, adjust the pH of the pulp to 12 with sodium hydroxide and hydrochloric acid, add 0.1008g calcium lignosulfonate to the pulp and stir well, then add 0.0336g to the pulp Sodium oleate powder and fully stirred, and finally use an air compressor to feed air into the pulp through the air duct 1, the air flow rate is 40L / min, the ventilation time is 10min, the foam 3 is collected, and dried at 90°C for 4 hours to obtain the refined boron ore. The analysis results show that: B in the refined boron ore 2 o 3 The mass percentage reaches 7.79%.

Embodiment 2

[0048] The particle size of 67.2g is 85 mesh, B 2 o 3 A low-grade boron-containing tailings powder in Dandong, Liaoning with a mass percentage of 2.76% was added to container a 2 of the flotation device, 300mL of water was added and fully stirred, and the pH value of the pulp was adjusted to 10 with sodium hydroxide and hydrochloric acid, and the Add 0.1008g of calcium lignosulfonate to the pulp and stir thoroughly, then add 0.0470g of sodium oleate powder to the pulp and stir thoroughly, and finally use an air compressor to feed air into the pulp through air duct 1, and the air flow rate is 35L / min , the aeration time is 12min, the foam 3 is collected and dried at 80°C for 5 hours to obtain boron concentrate. The analysis results show that: B in the refined boron ore 2 o 3 The mass percentage reaches 6.63%.

Embodiment 3

[0050] The particle size of 67.2g is 93 mesh, B 2 o 3 A low-grade boron-containing tailings powder in Dandong, Liaoning with a mass percentage of 2.76% was added to container a 2 of the flotation device, 300mL of water was added and fully stirred, and the pH value of the pulp was adjusted to 10 with sodium hydroxide and hydrochloric acid, and the Add 0.0336g of calcium lignosulfonate to the pulp and stir well, then add 0.0336g of sodium oleate powder to the pulp and stir well, and finally use an air compressor to feed air into the pulp through air duct 1, and the air flow rate is 30L / min , the aeration time is 15 minutes, the foam 3 is collected and dried at 100° C. for 3 hours to obtain boron concentrate. The analysis results show that: B in the refined boron ore 2 o 3 The mass percentage reaches 7.16%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com