A process of mechanical activation to improve boron leaching rate of boron concentrate

A mechanical activation, boron concentrate technology, applied in inorganic chemistry, boron compounds, chemical instruments and methods, etc., can solve the problems of equipment, energy and resource waste, generation of greenhouse gases, and methods for enhancing the boron leaching process that have not yet been reported, To achieve the effect of reducing the dependence of temperature and solution concentration, increasing the specific surface area, reducing the apparent activation energy and reaction order

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

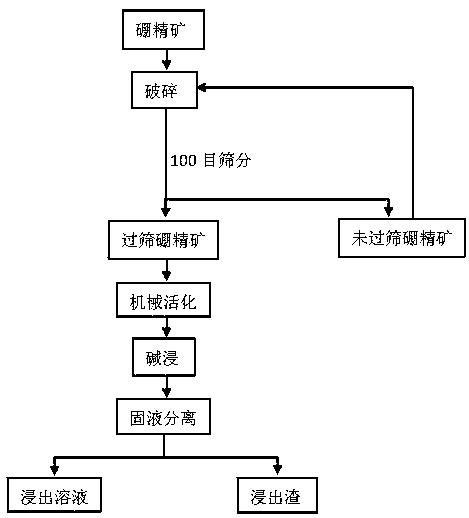

[0030] The mechanical activation of the present embodiment improves the technology of boron concentrate boron leaching rate to carry out according to the following steps:

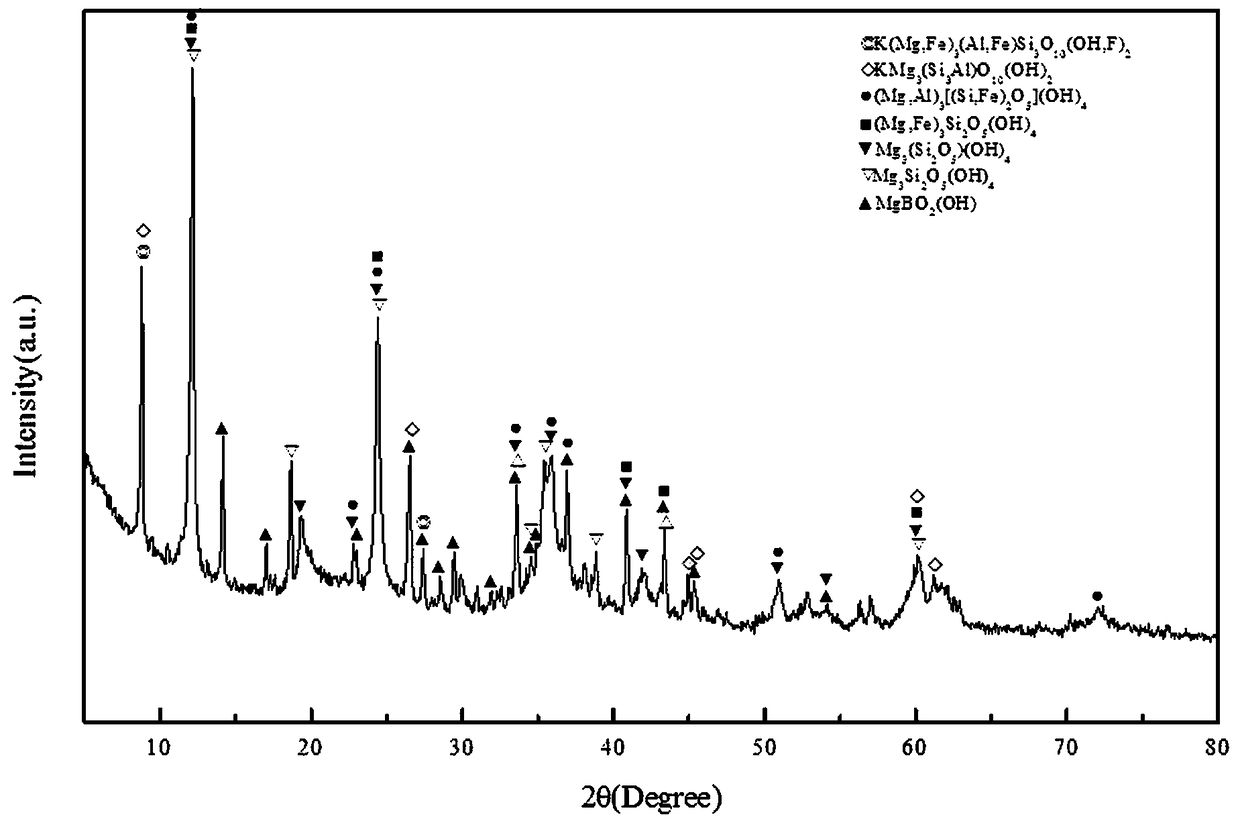

[0031] (1) Raw material preparation: mechanically crush the boron concentrate until the ore sample accounting for more than 95% of the concentrate weight can pass through a 100-mesh screen, and the crushed boron concentrate is used as a raw material for standby;

[0032] (2) Mechanical activation: Place the crushed boron concentrate raw material in a high-energy ball mill for mechanical activation. The mass ratio of the grinding ball to the boron concentrate raw material is 4:1, and the diameter of the grinding ball is 3mm. The filling rate of the ball mill tank is 70%, the ball mill speed is 100r / min, and the ball mill time is 10min to obtain the mechanically activated boron concentrate;

[0033] (3) Leaching: Stir and heat the boron concentrate after mechanical activation with 20% sodium hydroxide solutio...

Embodiment 2

[0035] The mechanical activation of the present embodiment improves the technology of boron concentrate boron leaching rate to carry out according to the following steps:

[0036] (1) Raw material preparation: mechanically crush the boron concentrate until the ore sample accounting for more than 95% of the concentrate weight can pass through a 100-mesh screen, and the crushed boron concentrate is used as a raw material for standby;

[0037] (2) Mechanical activation: Place the crushed boron concentrate raw material in a high-energy ball mill for mechanical activation. The mass ratio of the grinding ball to the boron concentrate raw material is 4:1, and the diameter of the grinding ball is 5mm. The filling rate of the ball mill tank is 50%, the ball mill speed is 200r / min, and the ball mill time is 30min to obtain the mechanically activated boron concentrate;

[0038] (3) Leaching: Stir and heat the boron concentrate after mechanical activation with 20% sodium hydroxide solutio...

Embodiment 3

[0040]The mechanical activation of the present embodiment improves the technology of boron concentrate boron leaching rate to carry out according to the following steps:

[0041] (1) Raw material preparation: mechanically crush the boron concentrate until the ore sample accounting for more than 95% of the concentrate weight can pass through a 100-mesh screen, and the crushed boron concentrate is used as a raw material for standby;

[0042] (2) Mechanical activation: The crushed boron concentrate raw material is placed in a high-energy ball mill for mechanical activation. The mass ratio of the grinding ball to the boron concentrate raw material is 8:1, and the diameter of the grinding ball is 3mm. The filling rate of the ball mill tank is 40%, the ball mill speed is 250r / min, and the ball mill time is 10min to obtain the mechanically activated boron concentrate;

[0043] (3) Leaching: Stir and heat the boron concentrate after mechanical activation with 20% sodium hydroxide solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com