Nano porous boron ore loaded iron-manganese composite deep treatment catalyst applied to ozone catalytic oxidation

A nano-porous, advanced treatment technology, applied in the field of water treatment, can solve the problems of low catalytic efficiency, unstable catalytic effect, and single catalyst effect, and achieve high COD value removal efficiency, easier biodegradation, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

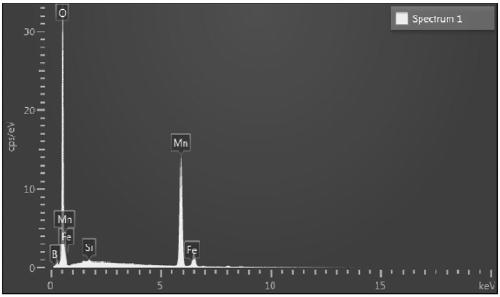

[0053] A nanoporous boron ore-loaded iron-manganese composite advanced treatment catalyst, the catalyst uses porous boron ore as a carrier, nano-Mn 2 o 3 , Fe 2 o 3 , FeMnO 3 The material is supported on porous boron ore.

[0054] Preparation method, the steps are as follows:

[0055] Mix citric acid solution with a concentration of 98g / L, manganese acetate solution with a concentration of 200g / L, and ferric acetate solution with a concentration of 50g / L in a volume ratio of 2.1:2:1, and add porous boron ore. Add 80g of porous boron ore to the mixture, stir for 2 hours, adjust the pH value to 6.0, heat in a water bath to 80°C and stir for 2 hours, filter and dry the solid, and roast at 500°C for 5 hours to obtain a nanoporous boron ore-loaded iron-manganese composite advanced treatment catalyst a.

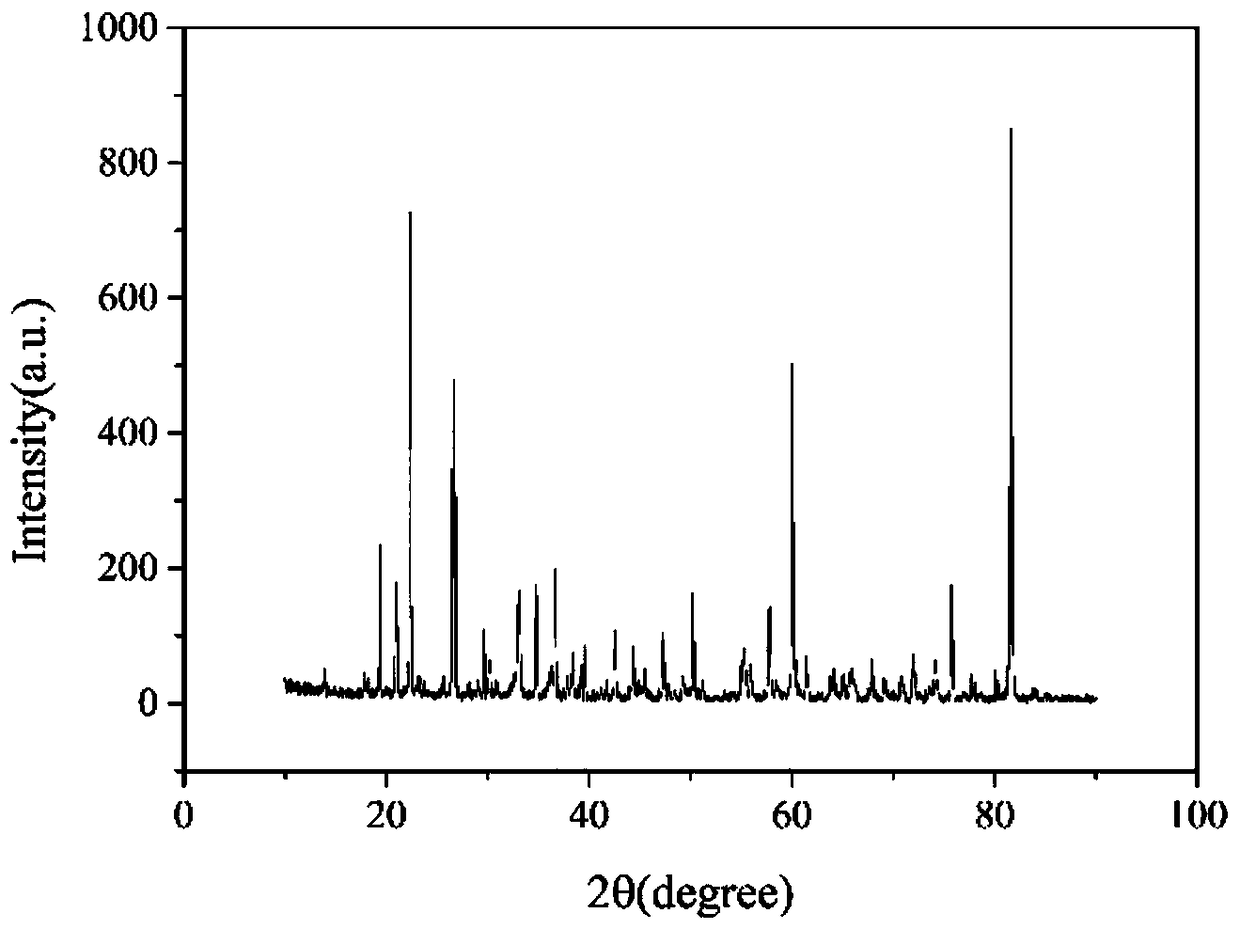

[0056] From figure 1 It can be seen that FeMnO appears at diffraction angles of about 32.8°, 38.3° and 55.35° respectively. 3 (Fe 2 + ) diffraction peaks; Mn appears at d...

Embodiment 2

[0060] A nanoporous boron ore-loaded iron-manganese composite advanced treatment catalyst, the catalyst uses porous boron ore as a carrier, Mn 2 o 3 , Fe 2 o 3 , FeMnO 3 Loaded on porous boron ore.

[0061] Preparation method, the steps are as follows:

[0062] Mix citric acid solution with a concentration of 98g / L, manganese acetate solution with a concentration of 200g / L, and ferric acetate solution with a concentration of 50g / L in a volume ratio of 2:2:1, add porous boron ore, and mix per liter Add 80g of porous boron ore to the solution, stir for 2 hours, adjust the pH value to 6.0, heat in a water bath to 80°C and stir for 2 hours, filter and dry the solid, and roast at 520°C for 5 hours to obtain nano-porous boron ore-loaded iron-manganese composite advanced treatment Catalyst b.

Embodiment 3

[0064] A nanoporous boron ore-loaded iron-manganese composite advanced treatment catalyst, the catalyst uses porous boron ore as a carrier, Mn 2 o 3 , Fe 2 o 3 , FeMnO 3 Loaded on porous boron ore.

[0065] Preparation method, the steps are as follows:

[0066] Mix citric acid solution with a concentration of 98g / L, manganese acetate solution with a concentration of 200g / L, and ferric acetate solution with a concentration of 50g / L in a ratio of 2.25:2:1 by volume, and then add porous boron ore. Add 80g of porous boron ore to the solution, stir for 2 hours, adjust the pH value to 6.0, heat in a water bath to 80°C and stir for 2 hours, filter the solid and dry it, roast it at 550°C for 5 hours, and obtain nano-porous boron ore loaded with iron-manganese composite advanced treatment Catalyst c.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com