Polyethylene terephthalate waste recovery process

A technology of waste recycling and process, which is applied in plastic recycling, recycling technology, carboxylate preparation, etc. It can solve the problems of no steps related to decolorization, difficult recovery of ethylene glycol, and difficulty in process realization, etc., and achieve rotary evaporation recovery Excellent process, improved alcoholysis rate, and low process energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

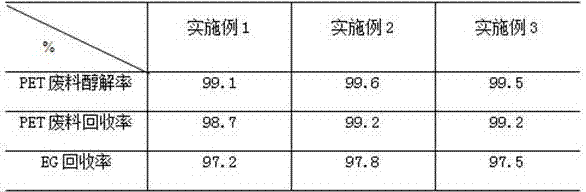

Embodiment 1

[0035] A kind of polyester waste recovery process that present embodiment provides, comprises following raw material:

[0036] PET waste (recycled green beverage bottles) - 100kg;

[0037] Ethylene glycol (AR grade)-200kg-Nanjing Chemical Reagent Co., Ltd.;

[0038] Zinc acetate-0.5kg-Nanjing Chemical Reagent Co., Ltd.;

[0039] Calcium chloride-2kg-Nanjing Chemical Reagent Co., Ltd.;

[0040] Acetone-5kg-Nanjing Chemical Reagent Co., Ltd.;

[0041] Activated carbon-10kg-Nanjing Chemical Reagent Co., Ltd.;

[0042] Specific steps are as follows:

[0043] S1, crushing the PET waste, cleaning and drying;

[0044] S2. Dry and clean PET waste, ethylene glycol (EG) and zinc acetate are added to the reaction kettle together, heated to 196°C, stirred and mixed at a constant temperature for about 3 hours, until the depolymerization reaction is complete;

[0045] S3. After the reaction is completed, the temperature is lowered to 135° C., and rapid hot filtration is obtained to ob...

Embodiment 2

[0053] A kind of polyester waste recovery process that present embodiment provides, comprises following raw material:

[0054] PET waste (recycled green beverage bottles) - 150kg;

[0055] EG (AR grade)-300kg-Nanjing Chemical Reagent Co., Ltd.;

[0056] Zinc acetate-0.75kg-Nanjing Chemical Reagent Co., Ltd.;

[0057] Calcium chloride-3kg-Nanjing Chemical Reagent Co., Ltd.;

[0058] Acetone-7.5kg-Nanjing Chemical Reagent Co., Ltd.;

[0059] Activated carbon-15kg-Nanjing Chemical Reagent Co., Ltd.;

[0060] Specific steps are as follows:

[0061] S1, crushing the PET waste, cleaning and drying;

[0062] S2. Dry and clean PET waste, EG and zinc acetate are added to the reaction kettle together, heated to 196°C, stirred and mixed at a constant temperature for about 2.5 hours, until the depolymerization reaction is complete;

[0063] S3. After the reaction is completed, the temperature is lowered to 125° C., and rapid hot filtration is obtained to obtain the primary filtrate ...

Embodiment 3

[0071] A kind of polyester waste recovery process that present embodiment provides, comprises following raw material:

[0072] PET waste (recycled green beverage bottles) - 200kg;

[0073] EG (AR grade)-400kg-Nanjing Chemical Reagent Co., Ltd.;

[0074] Zinc acetate-2kg-Nanjing Chemical Reagent Co., Ltd.;

[0075] Calcium chloride-4kg-Nanjing Chemical Reagent Co., Ltd.;

[0076] Acetone-10kg-Nanjing Chemical Reagent Co., Ltd.;

[0077] Activated carbon-20kg-Nanjing Chemical Reagent Co., Ltd.;

[0078] Specific steps are as follows:

[0079] S1, crushing the PET waste, cleaning and drying;

[0080] S2. Dry and clean PET waste, EG and zinc acetate are added to the reaction kettle together, heated to 196°C, stirred and mixed at a constant temperature for about 3.5 hours, until the depolymerization reaction is complete;

[0081] S3. After the reaction is completed, the temperature is lowered to 145° C., and the filtrate is quickly heated to obtain a primary filtrate and colo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com