Method for preparing polysilicate ferro-aluminum sulfate composite flocculant from red mud waste

A technology of polysilicon aluminum ferric sulfate and composite flocculant, which is applied in the fields of ferric sulfate, chemical instruments and methods, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of complex preparation process and high cost, and achieve simple process and low production cost Low, low residual aluminum content effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

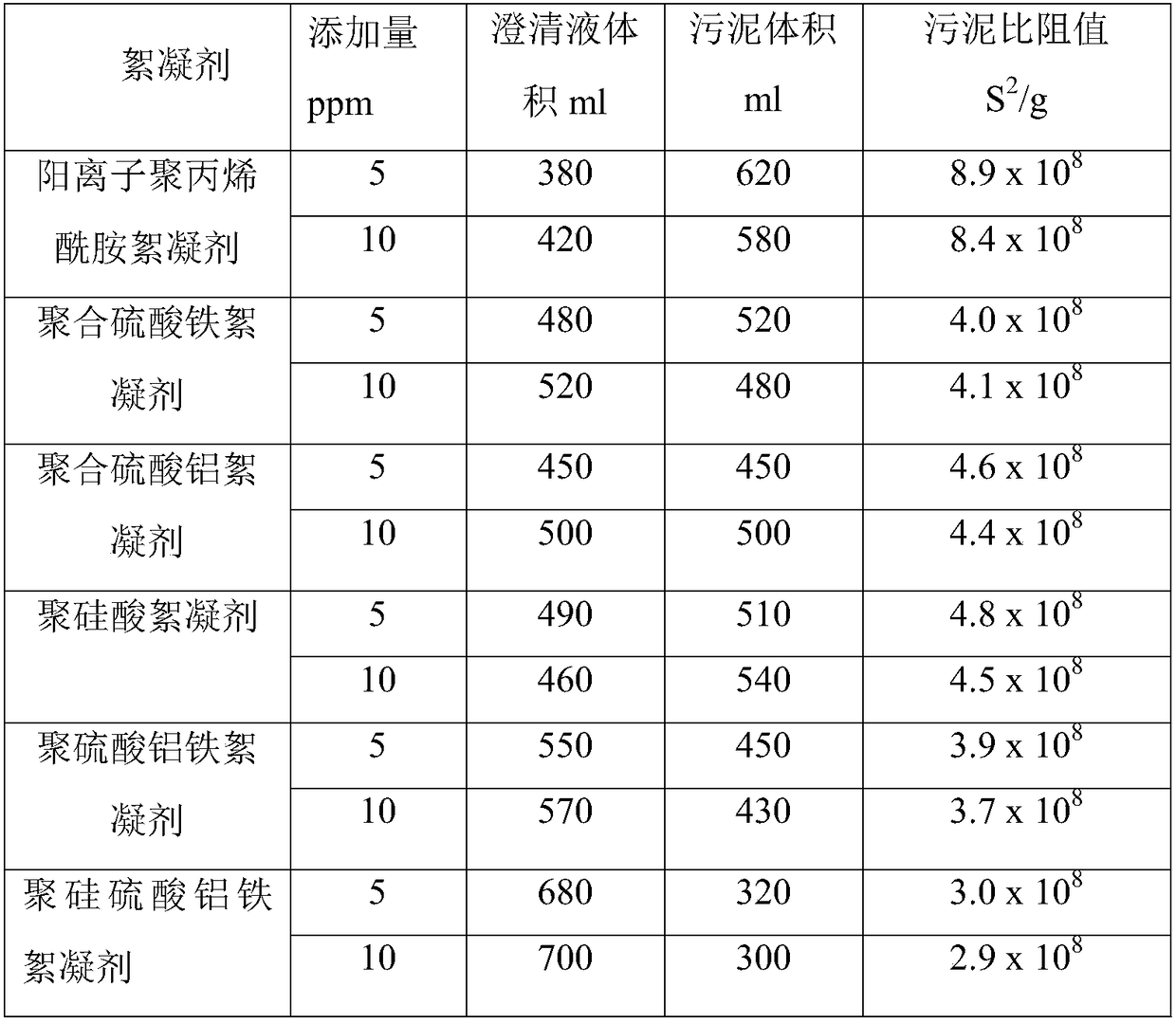

Examples

Embodiment 1

[0054] The method for preparing the polysilicon-aluminum-ferric-sulfate composite flocculant using red mud waste in this embodiment comprises the following steps:

[0055] (1) Put the red mud waste containing silicon, aluminum and iron and the activator sodium carbonate in a muffle furnace for calcination, the calcination temperature is 550°C, and the calcination time is 4.5h; then the red mud waste is ground and passed through 300 Mesh sieve to obtain activated red mud powder with a particle size of 48 μm; the quality of the activator sodium carbonate is 2% of the red mud waste quality;

[0056] (2) Put the activated red mud powder into a sulfuric acid solution with a mass fraction of 80% for reaction, add hydrogen peroxide to increase the leaching rate, the amount of hydrogen peroxide is 0.2% of the mass of red mud waste, the reaction temperature is 90°C, and the reaction time is 1.5h, The solid-to-liquid ratio is 8ml / g;

[0057] (3) Add calcium oxide and aluminum silicate ...

Embodiment 2

[0060] The method for preparing the polysilicon-aluminum-ferric-sulfate composite flocculant using red mud waste in this embodiment comprises the following steps:

[0061] (1) Put the red mud waste containing silicon, aluminum and iron and the activator sodium fluoride in a muffle furnace for calcination, the calcination temperature is 550°C, and the calcination time is 4.5h; 300 mesh sieves to obtain activated red mud powder with a particle size of 48 μm; the quality of the activator sodium fluoride is 2% of the red mud waste mass;

[0062] (2) Put the activated red mud powder into a sulfuric acid solution with a mass fraction of 80% for reaction, add hydrogen peroxide to increase the leaching rate, the amount of hydrogen peroxide is 0.2% of the mass of red mud waste, the reaction temperature is 90°C, and the reaction time is 1.5h, The solid-to-liquid ratio is 8ml / g;

[0063] (3) Add calcium oxide and aluminum silicate to the solution of step (2), adjust the molar ratio of F...

Embodiment 3

[0066] The method for preparing the polysilicon-aluminum-ferric-sulfate composite flocculant using red mud waste in this embodiment comprises the following steps:

[0067](1) Put the red mud waste containing silicon, aluminum and iron and the activator sodium fluoride in a muffle furnace for calcination, the calcination temperature is 550°C, and the calcination time is 4.5h; 300 mesh sieves to obtain activated red mud powder with a particle size of 48 μm; the quality of the activator sodium fluoride is 3% of the red mud waste mass;

[0068] (2) Put the activated red mud powder into a sulfuric acid solution with a mass fraction of 80% for reaction, add hydrogen peroxide to increase the leaching rate, the amount of hydrogen peroxide is 0.2% of the mass of red mud waste, the reaction temperature is 90°C, and the reaction time is 1.5h, The solid-to-liquid ratio is 8ml / g;

[0069] (3) Add calcium oxide and aluminum silicate to the solution of step (2), and adjust the molar ratio o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com