Medical corrosion-resistance high-toughness 3D printing material

A 3D printing and corrosion-resistant technology, applied in the field of 3D printing materials, can solve the problems of unsatisfactory toughness and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

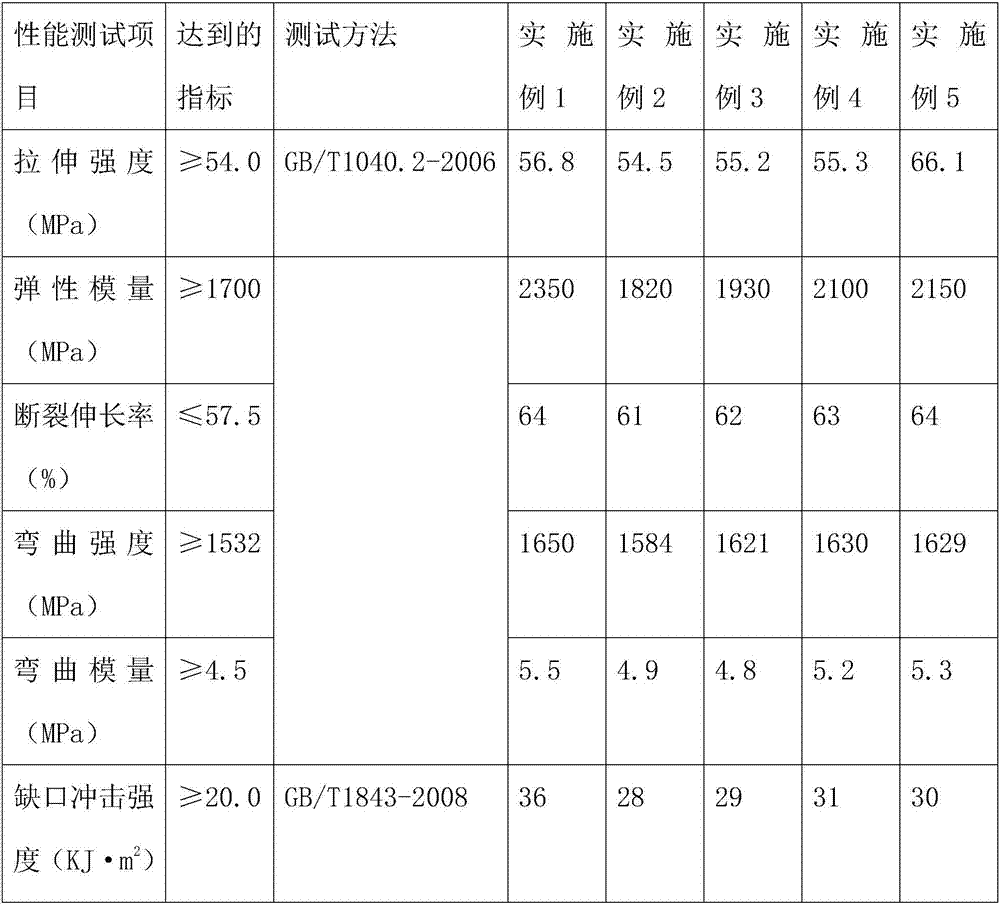

Examples

Embodiment 1

[0016] A corrosion-resistant high-toughness 3D printing material for medical use proposed by the present invention, its raw materials include by weight: 105 parts of ABS resin, 30 parts of SAN resin, 10 parts of butadiene rubber, 4.5 parts of neoprene rubber, and 6 parts of epoxy acrylic resin 4 parts, polymethyl methacrylate 4 parts, polycarbonate 2.5 parts, polyolefin elastomer 4.5 parts, sulfur 3.5 parts, sulfur dichloride 3.5 parts, chlorinated paraffin 2.5 parts, dimethyl silicone oil 3 parts, zinc borate 3 parts, 5.5 parts of isocyanate, 4 parts of nano graphite, 4.5 parts of carbon black, 6 parts of barite powder, 6 parts of nano aluminum hydroxide, 3 parts of aluminum polyphosphate, 3.5 parts of nano silicon dioxide, 4 parts of mica powder, talc 6 parts of powder, 4 parts of silane coupling agent KH-560, 5 parts of sodium metaborate, 2.5 parts of pentaerythritol, 3 parts of polylactic acid, 3.5 parts of polycaprolactone, 4 parts of sodium stearate, dodecylbenzenesulfoni...

Embodiment 2

[0021] A corrosion-resistant high-toughness 3D printing material for medical use proposed by the present invention, its raw materials include by weight: 85 parts of ABS resin, 40 parts of SAN resin, 5 parts of butadiene rubber, 6 parts of neoprene rubber, and 4 parts of epoxy acrylic resin 6 parts, polymethyl methacrylate 6 parts, polycarbonate 1 part, polyolefin elastomer 6 parts, sulfur 2 parts, sulfur dichloride 6 parts, chlorinated paraffin 1 part, simethicone 4 parts, zinc borate 1 part, 8 parts of isocyanate, 2 parts of nano-graphite, 6 parts of carbon black, 4 parts of barite powder, 8 parts of nano-aluminum hydroxide, 1 part of aluminum polyphosphate, 5 parts of nano-silica, 3 parts of mica powder, talc Powder 9 parts, silane coupling agent KH-560 2 parts, sodium metaborate 8 parts, pentaerythritol 1 part, polylactic acid 4 parts, polycaprolactone 1 part, sodium stearate 6 parts, dodecylbenzenesulfonic acid 1 part of sodium, 6 parts of antioxidant, 2 parts of degasser,...

Embodiment 3

[0026]A kind of corrosion-resistant and high-toughness 3D printing material for medical use proposed by the present invention, its raw materials include by weight: 125 parts of ABS resin, 20 parts of SAN resin, 15 parts of butadiene rubber, 3 parts of neoprene rubber, and 8 parts of epoxy acrylic resin 2 parts, polymethyl methacrylate 2 parts, polycarbonate 4 parts, polyolefin elastomer 3 parts, sulfur 5 parts, sulfur dichloride 1 part, chlorinated paraffin 4 parts, dimethyl silicone oil 2 parts, zinc borate 5 parts, 3 parts of isocyanate, 6 parts of nano graphite, 3 parts of carbon black, 8 parts of barite powder, 4 parts of nano aluminum hydroxide, 5 parts of aluminum polyphosphate, 2 parts of nano silicon dioxide, 5 parts of mica powder, talc 3 parts of powder, 6 parts of silane coupling agent KH-560, 2 parts of sodium metaborate, 4 parts of pentaerythritol, 2 parts of polylactic acid, 6 parts of polycaprolactone, 2 parts of sodium stearate, dodecylbenzenesulfonic acid 4 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com