Method for preparing sodium borohydride by recycling sodium metaborate

A technology of sodium borohydride and sodium metaborate, which is applied in chemical instruments and methods, metal hydrides, inorganic chemistry, etc., can solve the problem of reusing by-products, etc., and achieve the effects of easy control of reaction, simple and safe process, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

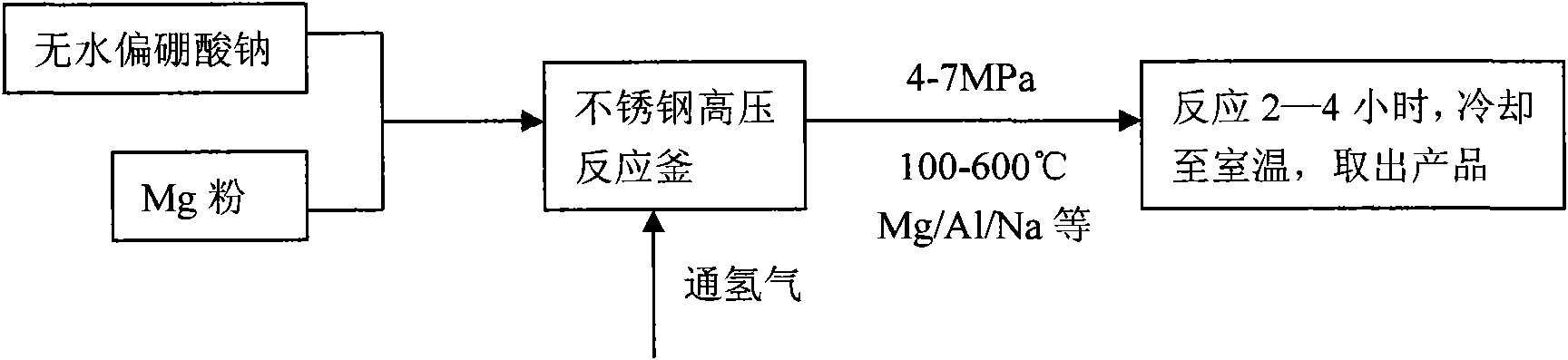

[0019] 1. Raw material handling

[0020] Sodium metaborate tetrahydrate is treated in a vacuum oven at 120-220°C, dried for more than 4 hours, and the crystal water is removed to obtain anhydrous sodium metaborate for later use.

[0021] 2. Synthesis of magnesium hydride

[0022] Weigh 60g of magnesium powder (passed through a 200 mesh sieve) and add it to an autoclave (GCF-1 autoclave), seal the autoclave, fill it with argon to vacuumize, and repeat 3 times, then turn on the power and heat the autoclave to 300°C, and then fill the autoclave. Hydrogen to 6.0MPa, react for 24h. After the reaction, stop heating, cool to room temperature, release the pressure to normal pressure, and fill with argon to protect the product.

[0023] 3. Synthesis of sodium borohydride

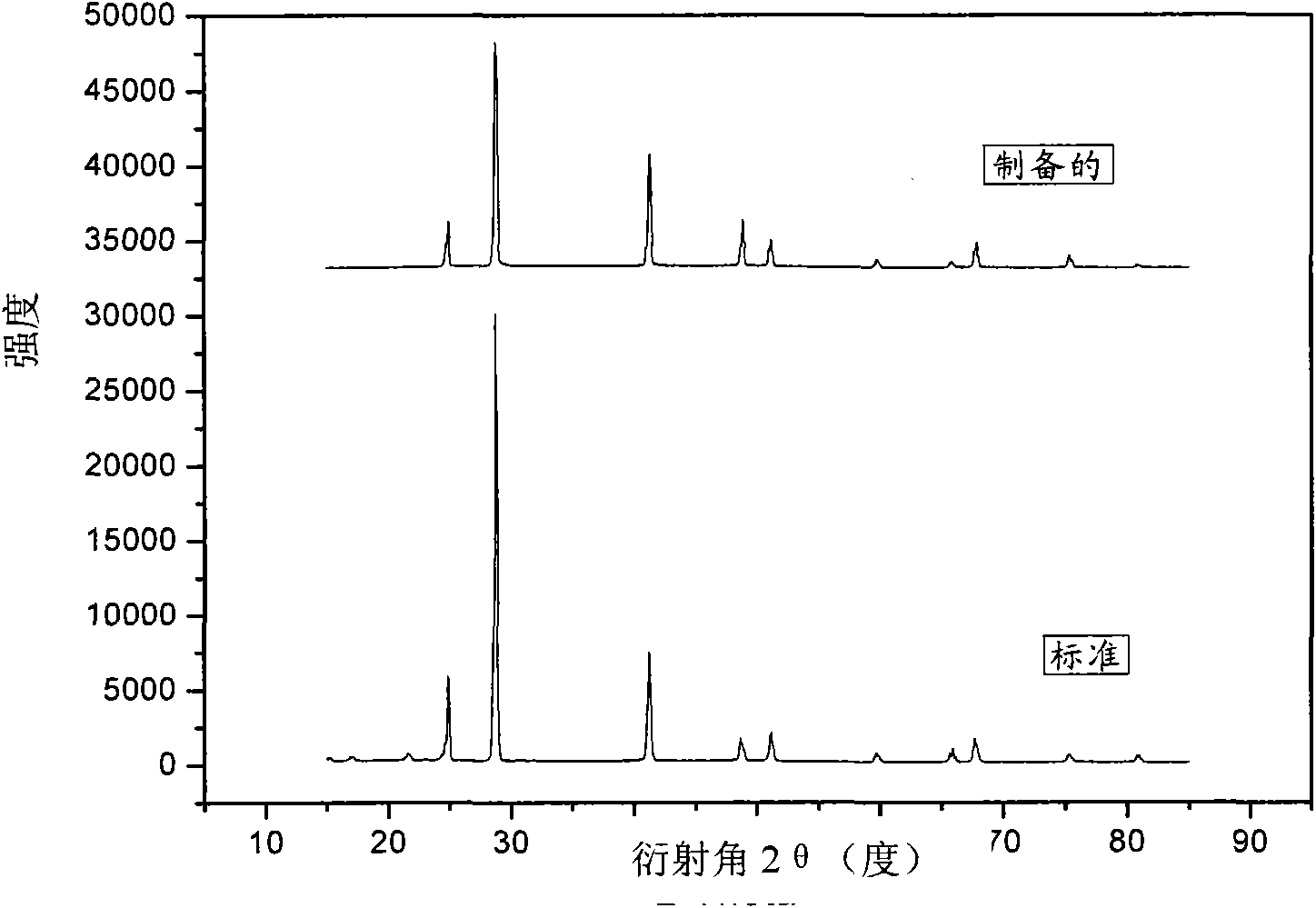

[0024] Weigh 1.32g of anhydrous sodium metaborate and 1.4g of magnesium hydride, put them into a ball mill tank (QM-3A high-speed vibrating ball mill), put steel balls into them according to a certain charging rat...

Embodiment 2

[0027] 1. Raw material handling

[0028] Sodium metaborate tetrahydrate is treated in a vacuum oven at 120-220°C, dried for more than 4 hours, and the crystal water is removed to obtain anhydrous sodium metaborate for later use.

[0029] 2. Synthesis of magnesium hydride

[0030] Weigh 60g of magnesium powder (over 200 mesh) into the autoclave (GCF-1 autoclave), seal the autoclave, fill it with argon and vacuumize, repeat 3 times, then turn on the power and heat the autoclave to 200°C, then fill it with hydrogen To 4.5MPa, react for 24h. After the reaction, stop heating, cool to room temperature, release the pressure to normal pressure, and fill with argon to protect the product.

[0031] 3. Synthesis of sodium borohydride

[0032] Weigh 1.32g of anhydrous sodium metaborate and 1.4g of magnesium hydride, put them into a ball mill tank (QM-3A high-speed vibrating ball mill), put steel balls in a certain charging ratio (mass ratio of ball to material: 30:1), and then vacuumiz...

Embodiment 3

[0034] 1. Raw material handling

[0035] Sodium metaborate tetrahydrate is treated in a vacuum oven at 120-220°C, dried for more than 4 hours, and the crystal water is removed to obtain anhydrous sodium metaborate for later use.

[0036] 2. Synthesis of magnesium hydride

[0037] Weigh 60g of magnesium powder (over 200 mesh) into the autoclave (GCF-1 autoclave), seal the autoclave, fill it with argon and vacuumize, repeat 3 times, then turn on the power and heat the autoclave to 300°C, then fill it with hydrogen To 6.0MPa, react for 24h. After the reaction, stop heating, cool to room temperature, release the pressure to normal pressure, and fill with argon to protect the product.

[0038] 3. Synthesis of sodium borohydride

[0039] Weigh 1.32g of anhydrous sodium metaborate and 1.0g of magnesium hydride, put them into a ball mill tank (QM-3A high-speed vibrating ball mill), put steel balls into them according to a certain charging ratio (mass ratio of ball to material: 50:1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com