Method for synchronously extracting boron and iron in paigeite

A simultaneous extraction and boronite technology, applied in the direction of borate, boron oxide compound, process efficiency improvement, etc., can solve the problems of low boron comprehensive recovery rate, low product added value, large material handling capacity, etc., to achieve The effect of strong adaptability of raw materials, low cost and low impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

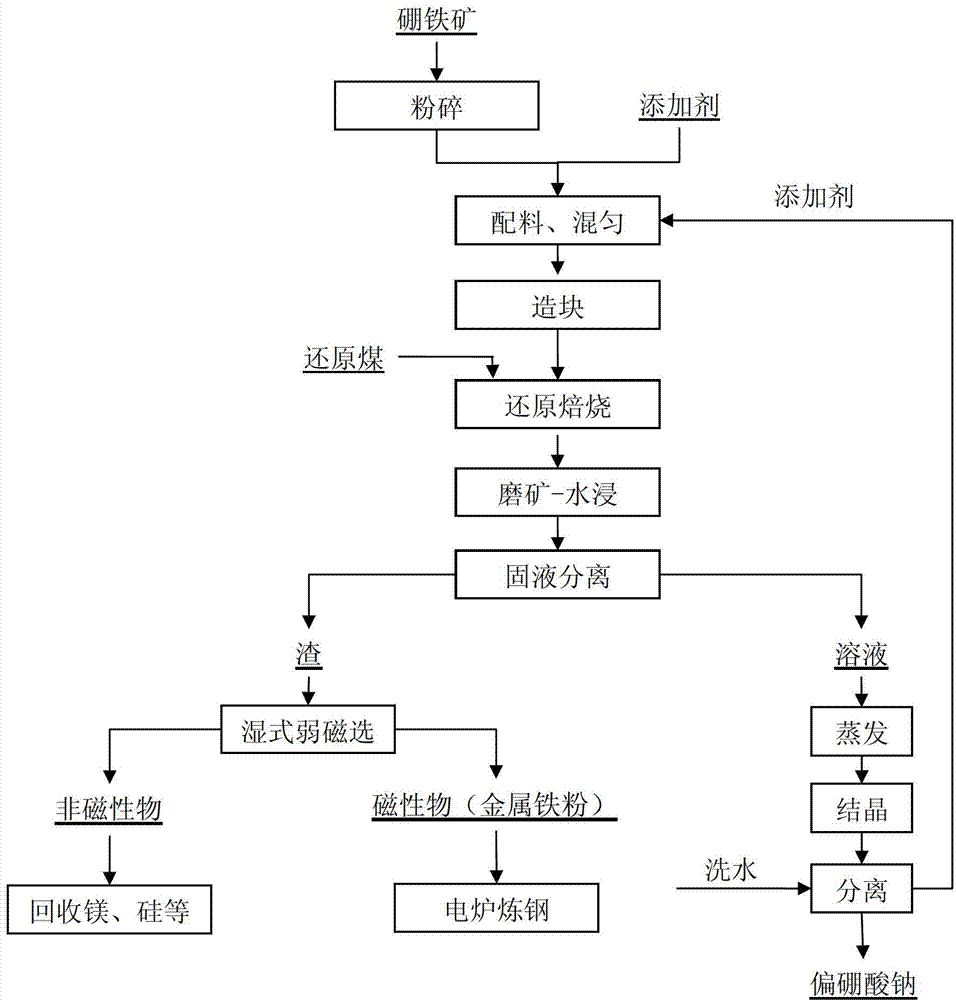

Method used

Image

Examples

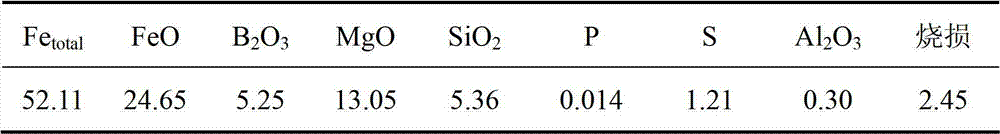

Embodiment 1

[0041] Embodiment 1: 85% sodium carbonate, 5% sodium sulfate, 1% sodium fulvic acid, 4% sodium humate, and 5% sodium oxalate are mixed and formulated as an additive, and boronite powder and its mass fraction are 15% After the above additives are fully mixed, agglomerated, and dried, lignite is used as the reducing agent, and the reduction roasting is carried out at 1000°C for 60 minutes. The mass ratio of the materials was 10:1 for grinding-water leaching for 30 minutes. After the slurry was filtered, the boron leaching rate was 85.54%. The filter residue was sorted by wet weak magnetic separation. The iron grade in the obtained iron concentrate was 86.57%. The rate is 90.81%.

Embodiment 2

[0042] Embodiment 2: 70% sodium carbonate, 20% sodium sulfate, 2% sodium fulvic acid, 4% sodium humate, and 4% sodium oxalate are mixed and formulated as additives, and boronite powder and its mass fraction are 20% After the above additives are mixed, agglomerated, and dried, anthracite is used as a reducing agent, and the reduction roasting is carried out at a temperature of 1100°C for 60 minutes. The mass ratio was 10:1 for grinding-water leaching for 30 minutes. After the slurry was filtered, the boron leaching rate was 87.80%. The filter residue was sorted by wet weak magnetic separation method. 93.67%.

Embodiment 3

[0043] Embodiment 3: 50% sodium carbonate, 25% sodium sulfate, 3% sodium fulvic acid, 10% sodium humate, and 12% sodium oxalate are mixed and formulated as an additive, and boronite powder and its mass fraction are 30% After the above-mentioned additives are mixed, agglomerated and dried, lignite is used as reducing agent, reduced and roasted at 1100°C for 60 minutes, and the reduced product is placed in a ball mill with 60% pulp concentration, balls and ball milled materials The mass ratio is 8:1 for immersion in water for 20 minutes. After the slurry is filtered, the boron leaching rate is 89.21%. The filter residue is sorted by wet weak magnetic separation method. The iron grade in the obtained iron concentrate is 92.46%, and the recovery rate of ferromagnetic separation is 93.85%. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com