Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78results about How to "Meet the requirements of long-term use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for processing high-temperature alloy furnace tube

ActiveCN101565807AStrong combinationMitigation of catalytic cokingSolid state diffusion coatingProduct gasMetallurgy

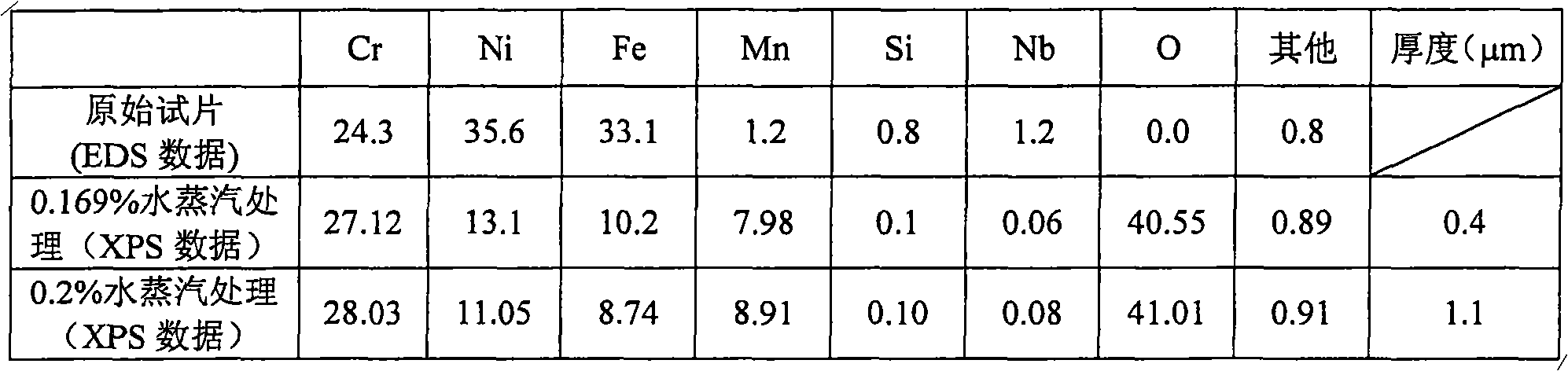

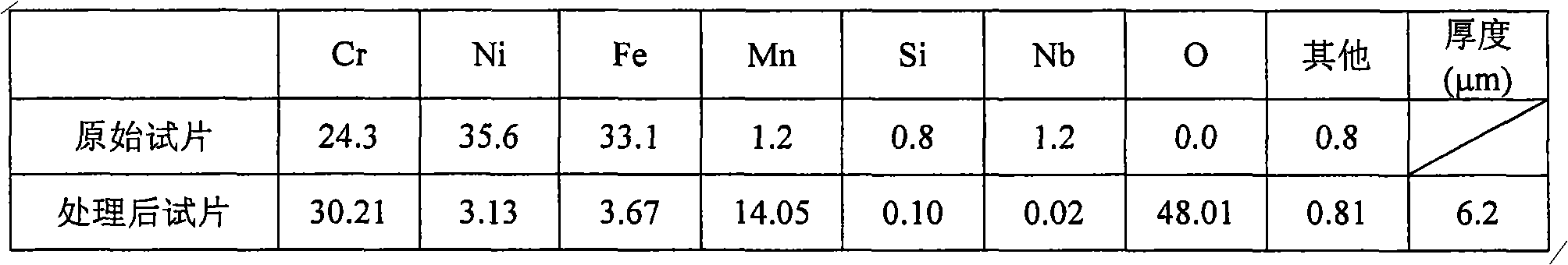

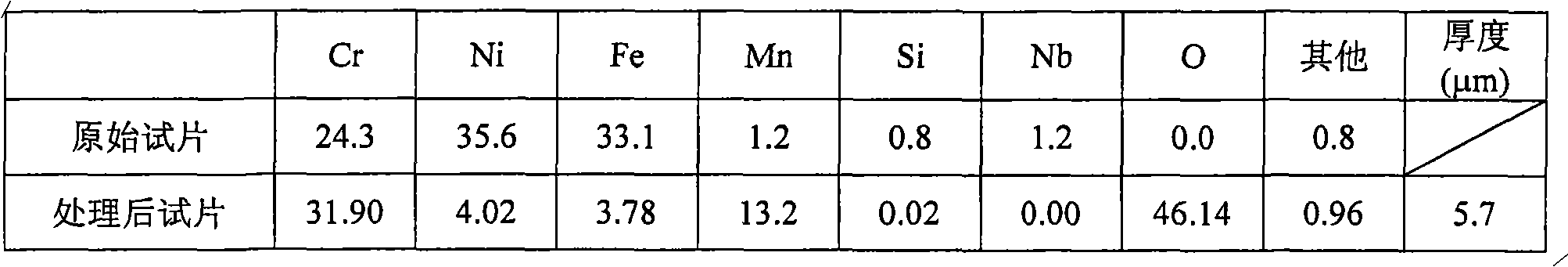

The invention relates to a method for processing a high-temperature alloy furnace tube, which comprises the following steps: controlling the pressure of low-oxygen partial pressure gas to 0-3 atmospheric pressure; introducing the low-oxygen partial pressure gas into an atmosphere furnace provided with the high-temperature alloy furnace tube; raising the temperature to between 600 and 1,100 DEG C; keeping the temperature for 5 to 80 hours; and forming an oxidized protective layer on the surface of the high-temperature alloy furnace tube to obtain the processed high-temperature alloy furnace tube, wherein the low-oxygen partial pressure gas comprises one or two kinds of H2 and CO, and water vapor accounting for 0.17 to 2 percent of the volume fraction of the low-oxygen partial pressure gas. The method for processing the high-temperature alloy furnace tube is adopted to process a furnace tube of a hydrocarbon cracking furnace and the like, so that the compact and stable oxidized protective layer on the surface of the furnace tube, and the requirement for long-term use can be met; and the method can inhibit or retard the phenomena of catalysis and coking, reduces the carburization degree of the furnace tube, and prolongs the decoking cycle and the service life of the furnace tube.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

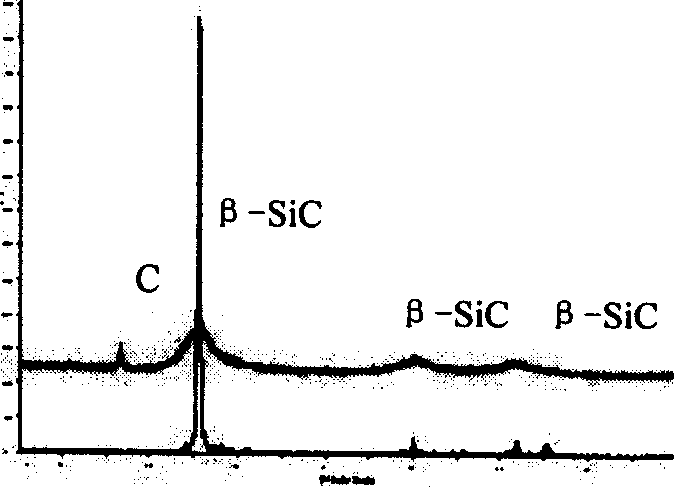

Carbon-fiber reinforced silicon carbide composite material antioxidation coating layer and its preparation method

InactiveCN1718560AImproves Antioxidant ProtectionReduce the rate of oxidation weight lossCarbide siliconCarbon fibers

An antioxidizing coated layer of carbon fibre reinforced SiC material is composed of adhesive layer, self-healing layer and impact and corrosion resistant layer. It is prepared through isothermal chemical vapor deposition (CVD) for preparing adhesive layer, coating sludge and sintering for preparing self-healing layer, and isothermal CVD for preparing the impact and corrosion resistant layer.

Owner:NAT UNIV OF DEFENSE TECH

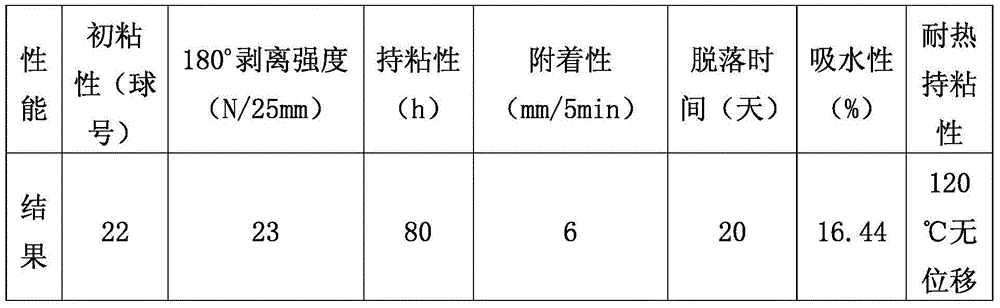

Preparation method of emulsion type polyacrylate pressure-sensitive adhesive for reflecting film

ActiveCN104449485AHigh bond strengthImprove aging resistanceFilm/foil adhesivesEster polymer adhesivesChemistryEmulsion

The invention relates to a preparation method of an emulsion type polyacrylate pressure-sensitive adhesive for a reflecting film. Hard monomers (5-15 parts of vinyl acetate and 5-15 parts of methyl methacrylate) and soft monomers (30-50 parts of ethylhexyl acrylate and 10-30 parts of ethyl acrylate) are subjected to quaternary monomer copolymerization, and consequently, the bonding strength of the pressure-sensitive adhesive is improved obviously. In addition, 0.3-1 part of lauryl sodium sulfate and 1-3 parts of sodium allyloxyhydroxypropyl sulfonate are taken as emulsifying agents; a substance with a surfactant is polymerized to a macromolecular chain to take the place of a part of the micromolecular emulsifying agent lauryl sodium sulfate, and therefore, the aging resistance and the water resistance of the pressure-sensitive adhesive are improved. The emulsion type pressure-sensitive adhesive prepared by use of the preparation method is high in permanent adhesion, high in peel strength, and high in combination properties such as aging resistance, high temperature resistance, water resistance and acid rain resistance, and capable of meeting the requirement on long-term use of the reflecting film. In addition, the preparation method is simple in process, free from environment pollution, low in cost, and suitable for large-scale industrial production.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

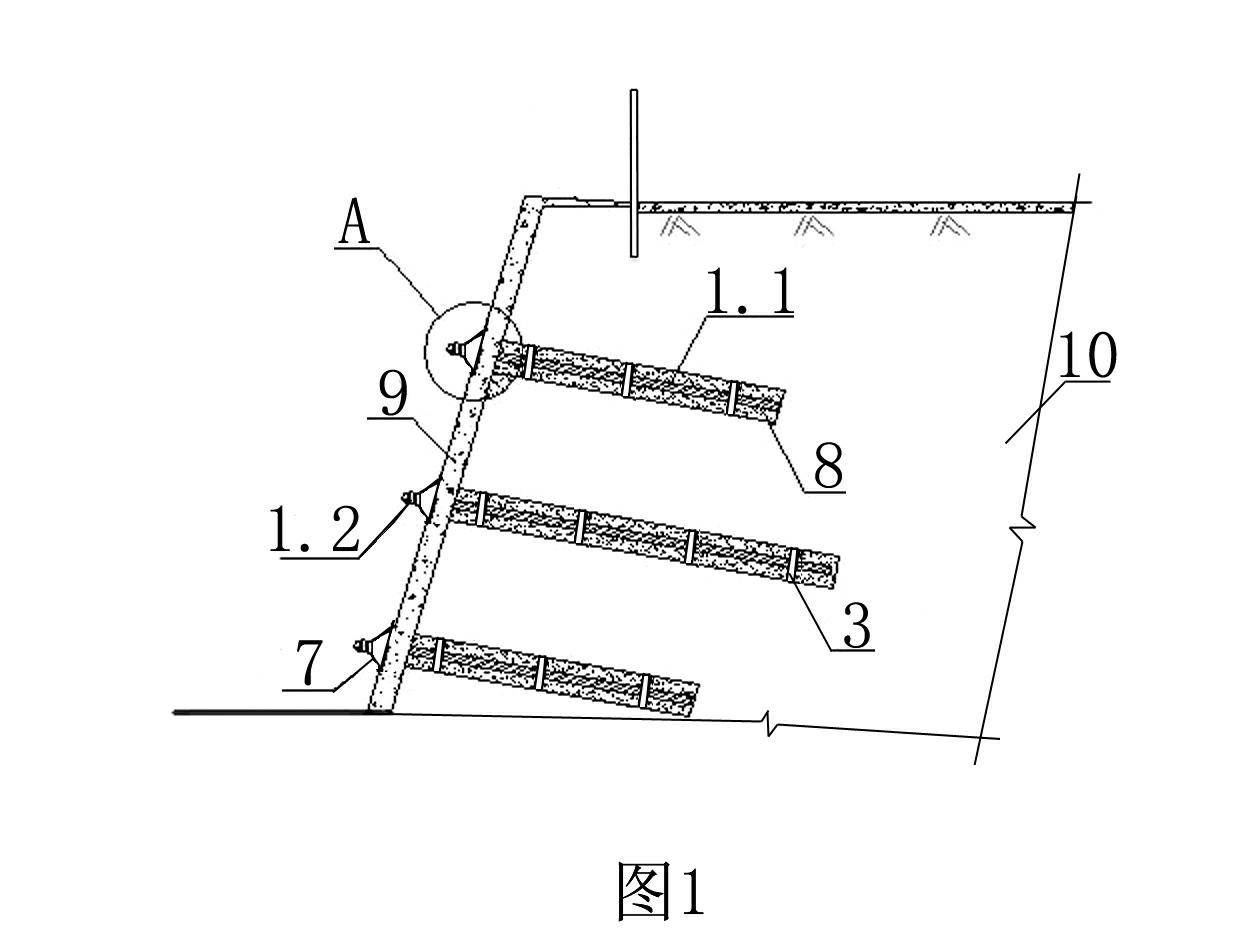

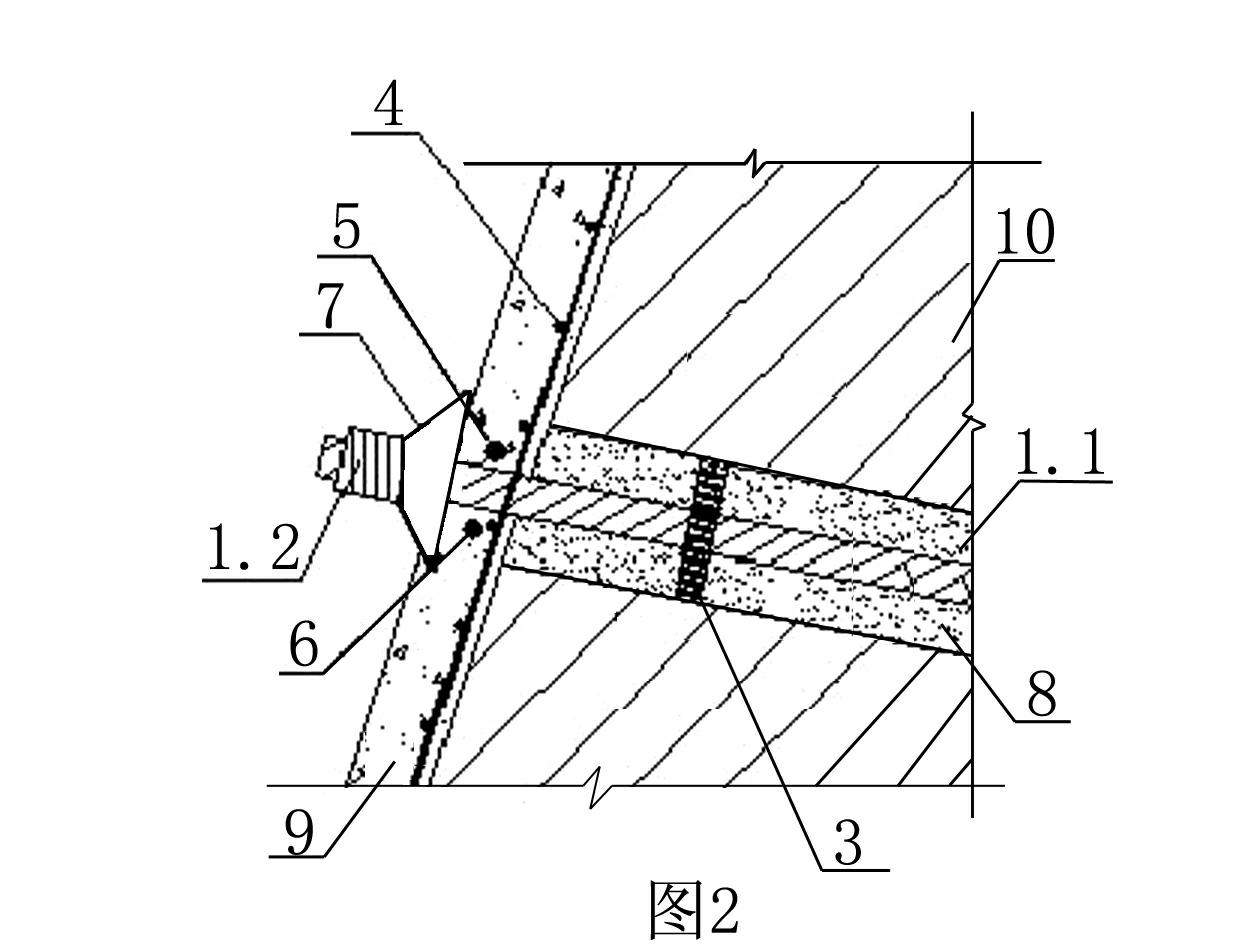

Full-thread fiber resin rod body soil nailing wall and construction method thereof

InactiveCN102352630ACorrosion resistantEasy to resist corrosionExcavationsBulkheads/pilesFiberSoil nailing

The invention relates to a full-thread fiber resin rod body soil nailing wall and a construction method thereof; a soil nail rod body of a soil nailing wall is a full-thread fiber resin rod body, auxiliary reinforcement ribs are arranged at positions situated on the upper part of an interior segment of a concentrate surface layer of the soil nail rod body, and continuous cross pressing ribs are arranged on the lower part thereof; the fastening nut is a resin nut; the lining plate is a resin lining plate injected by a resin material and is fastened on the outer surface of the concentrate surface layer; and ring locators are sleeved on the parts stretched into the side slope soil of the full-thread fiber resin rod body at intervals. Compared with the present soil nailing wall, the invention has the advantages of simple and convenient construction, energy saving, consumption reduction and larger application range of resin rod body; and the nut and lining plate situated on the end part of the rod body are situated at the outside of the concentrate surface layer, so the stress is more reasonable. Meanwhile, an expanding head is arranged at a position situated in the side slope of the rod body according to the actual engineering to form a reinforced expanding head soil nail, so that the plasticity is strong. The invention can be extensively applied in the construction of side slope soil nailing wall technique.

Owner:CHINA XINXING CONSTR & DEV CO LTD

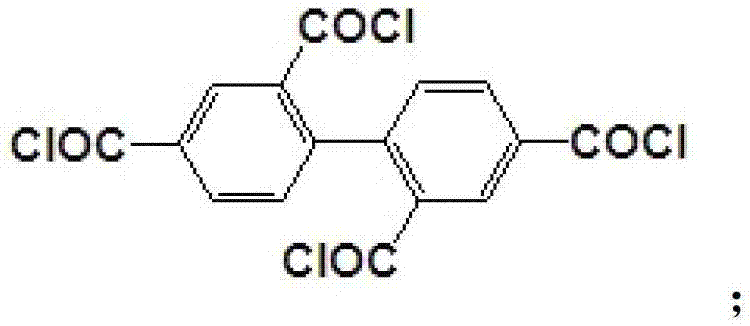

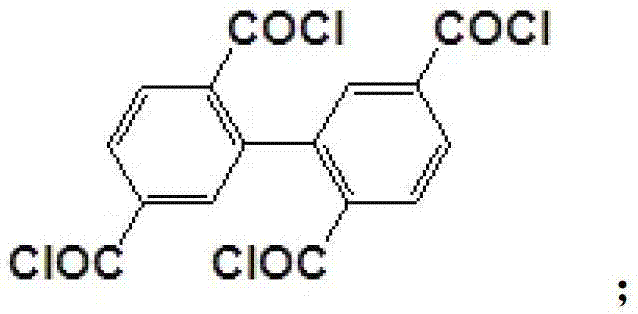

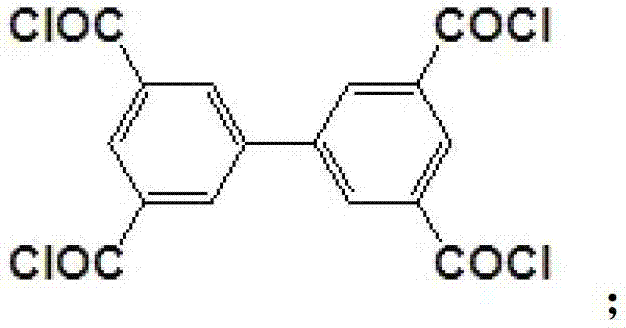

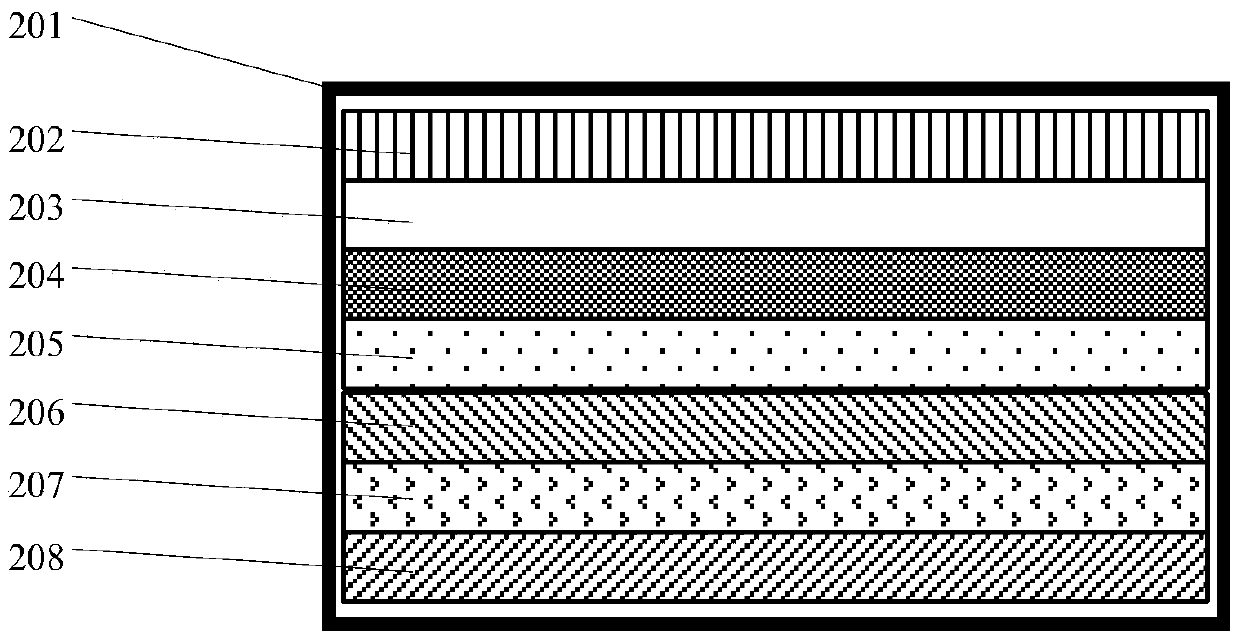

Hydrophilic reverse osmosis composite membrane and preparation method thereof

InactiveCN103157388AIncrease contentGuaranteed Salt RejectionSemi-permeable membranesHydrophilic coatingReverse osmosis

The invention relates to a hydrophilic reverse osmosis composite membrane and a preparation method of the hydrophilic reverse osmosis composite membrane, which relates to the field of membrane separation. In order to solve the problems of poor hydrophilicity and low pollution resistance of the existing reverse osmosis composite membrane prepared by metaphenylene diamine and trimesic acyl chloride, the invention provides the hydrophilic reverse osmosis composite membrane with strong hydrophilicity and pollution resistance and high salt rejection rate and water flux and the preparation method of the hydrophilic reverse osmosis composite membrane. The hydrophilic reverse osmosis composite membrane comprises a porous polysulfone supporting layer, an active separating layer and a hydrophilic coating layer, wherein the molecular weight cut-off of the porous polysulfone supporting layer is 20000-50000; the active separating layer is composited on the surface of the porous polysulfone supporting layer and is a polymer obtained by metaphenylene diamine and biphenyl multielement acyl chloride through interfacial polymerization; and the hydrophilic coating layer is coated on the surface of the active separating layer and is a hydrophilic polymer. The hydrophilic reverse osmosis composite membrane has the advantages that the hydrophilicity is strong, the pollution resistance is strong, the desalting rate reaches to be 99.83%, the water flux reaches to be 56.8L / m<2>h, and the comprehensive performance is obviously improved.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Formula for high-heat-resistant plastic material

InactiveCN107474423AGood weather resistanceImprove anti-aging propertiesProcedure AgentsPlastic materials

The invention relates to a formula for a high-heat-resistant plastic material. The plastic material is prepared from the following components, by weight: 60-80 parts of polyvinyl chloride resin; 20-40 parts of chlorinated polyvinyl chloride resin; 2.5-5 parts of a heat stabilizer; 1-10 parts of a heat resistant modifier; 5-10 parts of an impact resistant modifier; 1-6 parts of a processing auxiliary agent; 0.5-1.6 parts of a lubricant; 5-20 parts of a filler; 0.5-5 parts of a light stabilizer; 0.2-1 part of an anti-aging agent; and 0.01-0.03 part of a coloring agent. According to the invention, the plastic material has good molding performance, high dimensional stability and impact resistant strength, good heat resistance and weathering resistance, high corrosion resistance, and can meet requirements of long-term usage of a building industry.

Owner:XINJIANG CORPS MODERN GREEN CHLOR ALKALI CHEM ENG RES CENT LTD +1

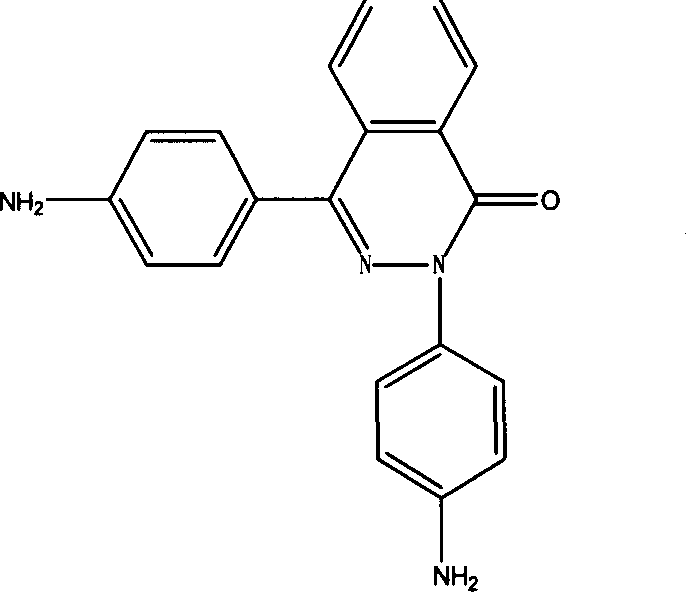

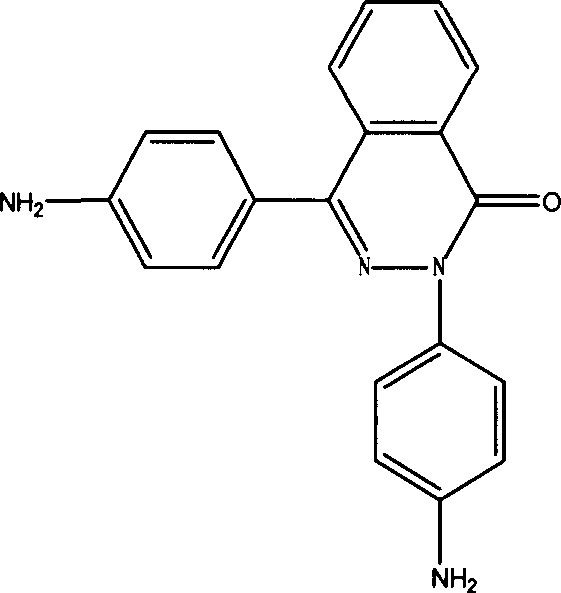

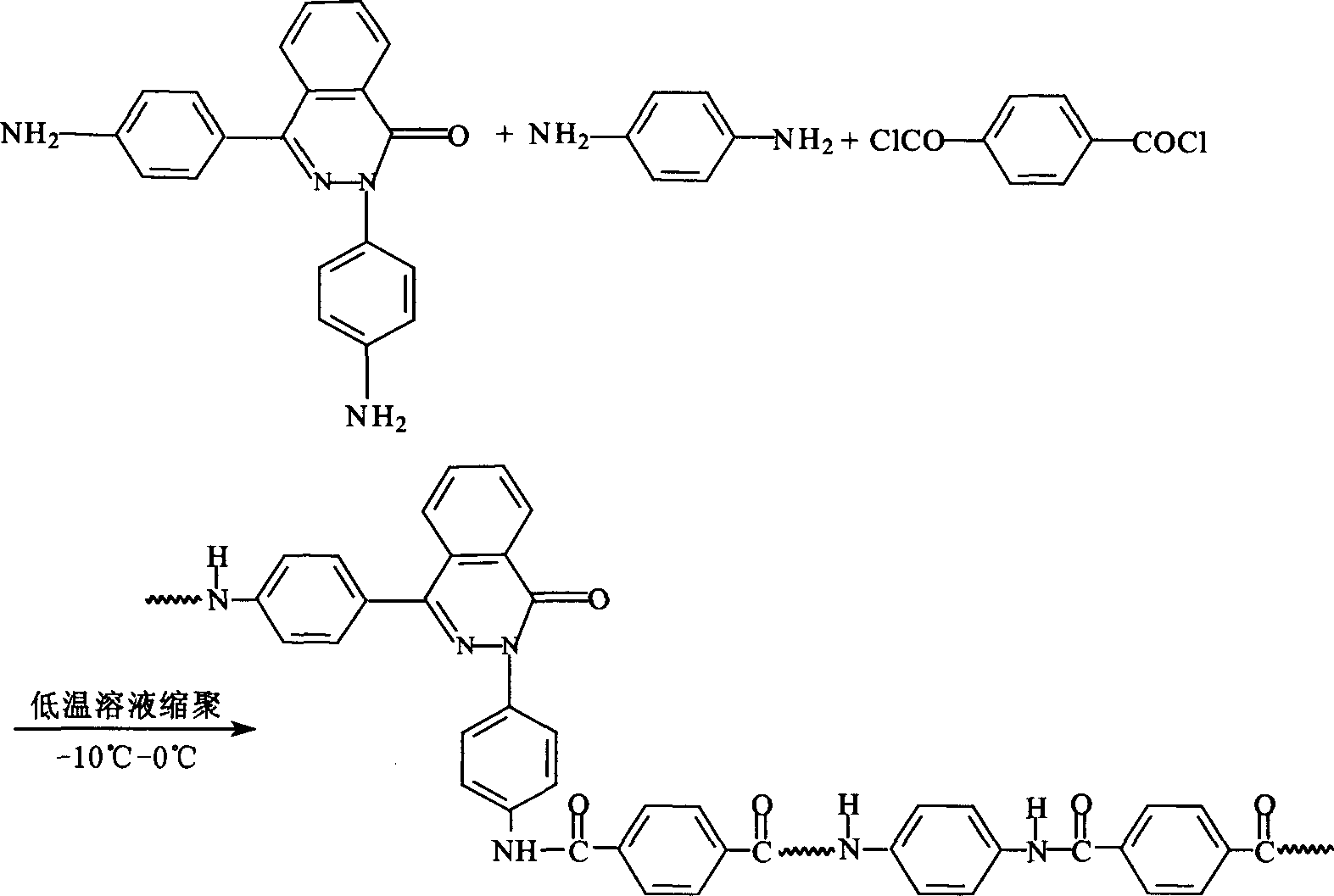

PPTA containing 2,4 di (4-amino phenyl)-2,3-diaza naphthalene-1-one and preparation process thereof

InactiveCN1793199AEase of long-term use requirementsMeet the requirements of long-term useReaction temperatureSolvent

The invention discloses a manufacture method for PPTA that contains 2,4-2(4-amino phenyl)-2, 3dinitrogen phenodiazine-1-detone. It includes the following steps: adding solvent into polymerization reactor, whisking, adding alkali halide, adding 2,4-2(4-amino phenyl)-2, 3dinitrogen phenodiazine-1-detone and p-phenylene diamine; adding paraphthaloyl chloride that has the thickness of 0.3-0.4 mol / l, whisking, keeping reacting at -10-80 degree centigrade for 30-120 minutes; neutralizing by Ca(OH)2 to gain concentrated PPTA solution. The invention has simple technology, low cost, is easy to purity. It could be used in navigation, high capability compounding material, high temperature resistant film and corresponding fabric.

Owner:DONGHUA UNIV

A compound material shell sound reflection board and its making method

InactiveCN101266788AGood sound permeabilitySame acoustic performanceSound producing devicesEpoxyAlkali free

The invention discloses a composite material coat reflection baffle and a method of manufacturing the composite material coat reflection baffle. The baffle comprises rigid polyurethane foam core materials. Outside the core materials is provided with seawater resistance resin matrix composite material coat. The coat is manufactured in a Resin Transfer Molding technics by seawater resistance low viscosity epoxy vinyl ester resin and alkali-free glass fiber mat when a curing agent and an accelerant exist. Compared with existing rubber coat reflection baffle, the composite material coat reflection baffle obviously reduces production energy consumption and other cost, and is provided with a better pressure resistance and seawater resistance performance and a better acoustic performance, and is provided with obvious economic benefit.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

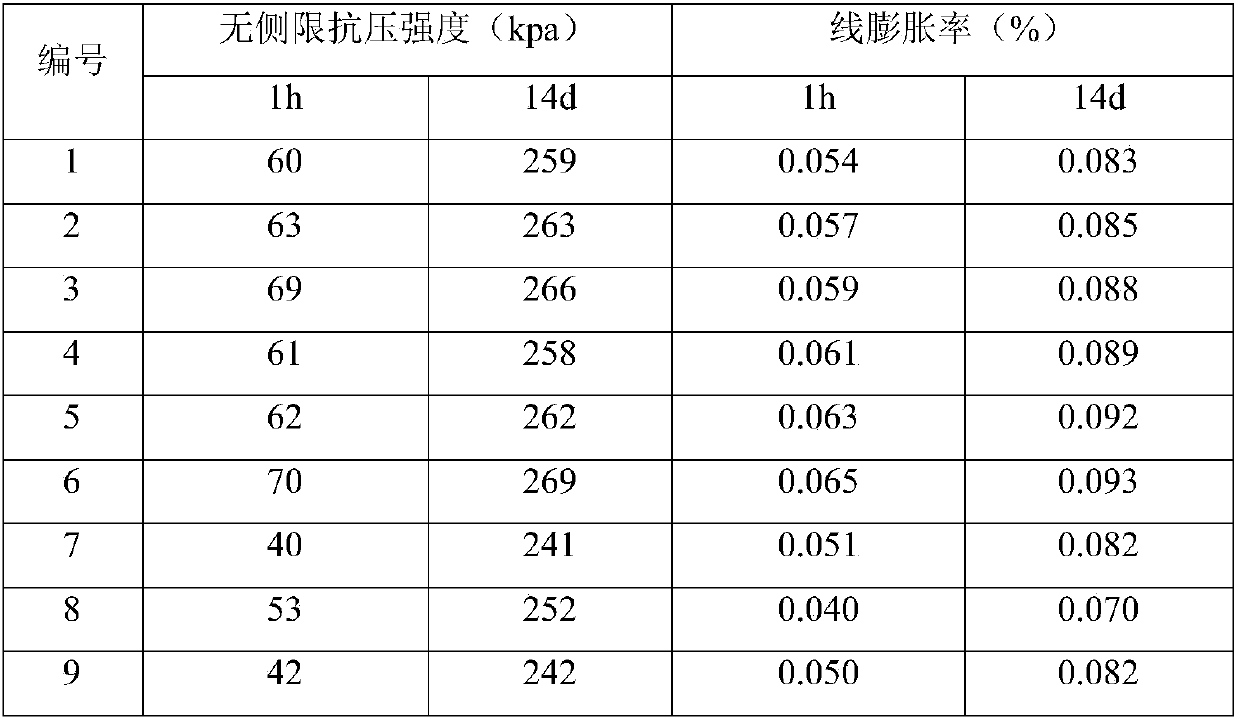

Rapid-hardening microswelling curing agent, cured soil and preparation method therefor

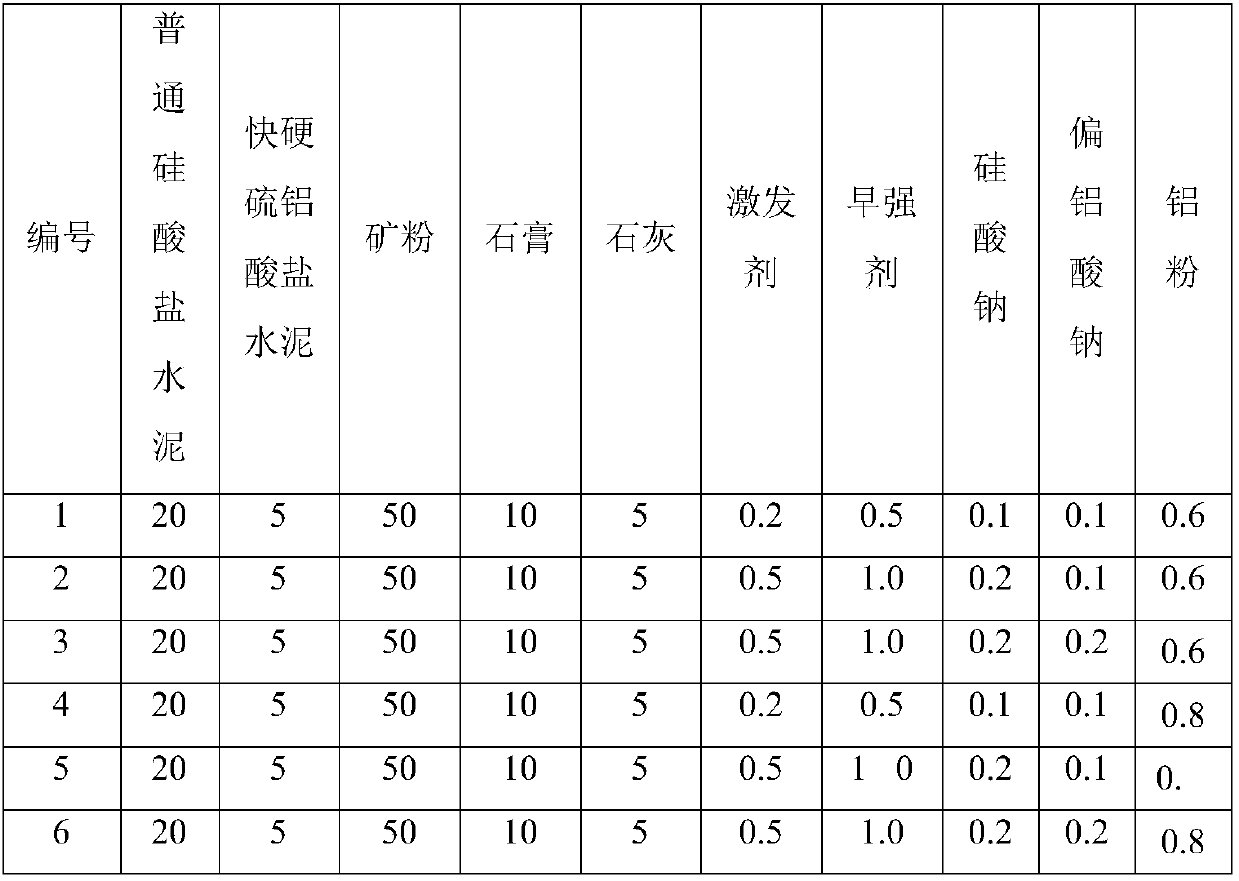

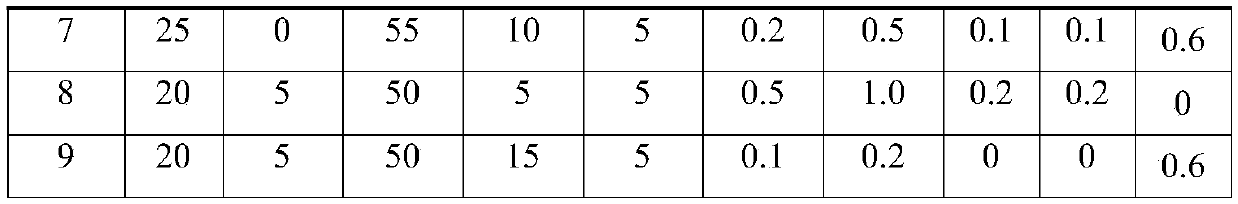

The invention discloses rapid-hardening microswelling cured soil and a preparation method. The cured soil is characterized by being prepared through mixing a curing agent of a special formula with soil, wherein the curing agent is prepared from the ingredients: 20 parts of ordinary Portland cement, 5 parts of rapid hardening sulfo-aluminate cement, 50 parts of mineral powder, 10 parts of gypsum, 5parts of lime, 0.2-0.5 part of excitant, 0.5-1.0 part of early strength agent, 0.1-0.2 part of sodium silicate, 0.1-0.2 part of sodium metaaluminate and 0.6-0.8 part of aluminum powder. The preparation method for the cured soil comprises the steps: 1) borrowing soil in situ according to engineering requirements; 2) uniformly mixing the prepared soil curing agent with the soil; and 3) filling a part to be subjected to leakage blockage with the mixture. Results show that the cured soil prepared by using the curing agent is high in early strength, good in leakage blockage effect and excellent inplasticity and adhesive property and has a microswelling property. The consumption of cement is reduced, and aggregates are not used, so that the cost is low, and the environment-friendly performanceis good.

Owner:JIANGSU NATURE WAY TECH

Fire-resistant pouring material used for bottom of lead smelting furnace

The invention relates to a fire-resistant pouring material used for the bottom of a lead smelting furnace. The fire-resistant pouring material comprises the following components: 10-5mm special-grade alumina clinker, 5-3mm special-grade alumina clinker, special-grade alumina clinker with d90 being less than 0.088mm, 3-1mm brown aluminium oxide, 1-0.088mm brown aluminium oxide, alpha-alumina micro powder with d95 being less than 0.020mm, silica powder, and industrial-grade chromium oxide green; in addition, an additive consisting of compound hardening accelerator and aluminium phosphate solution is also used. The magnesium-aluminium-chrome spinel castable disclosed by the invention can be sintered and shows excellent thermal shock resistance, stripping resistance, erosion resistance, slag bonding prevention and the like under a low temperature process condition during copper smelting, thereby meeting the use requirement of long-term use of a fireproof lining of a copper smelting tundish.

Owner:郑州瑞泰耐火科技有限公司

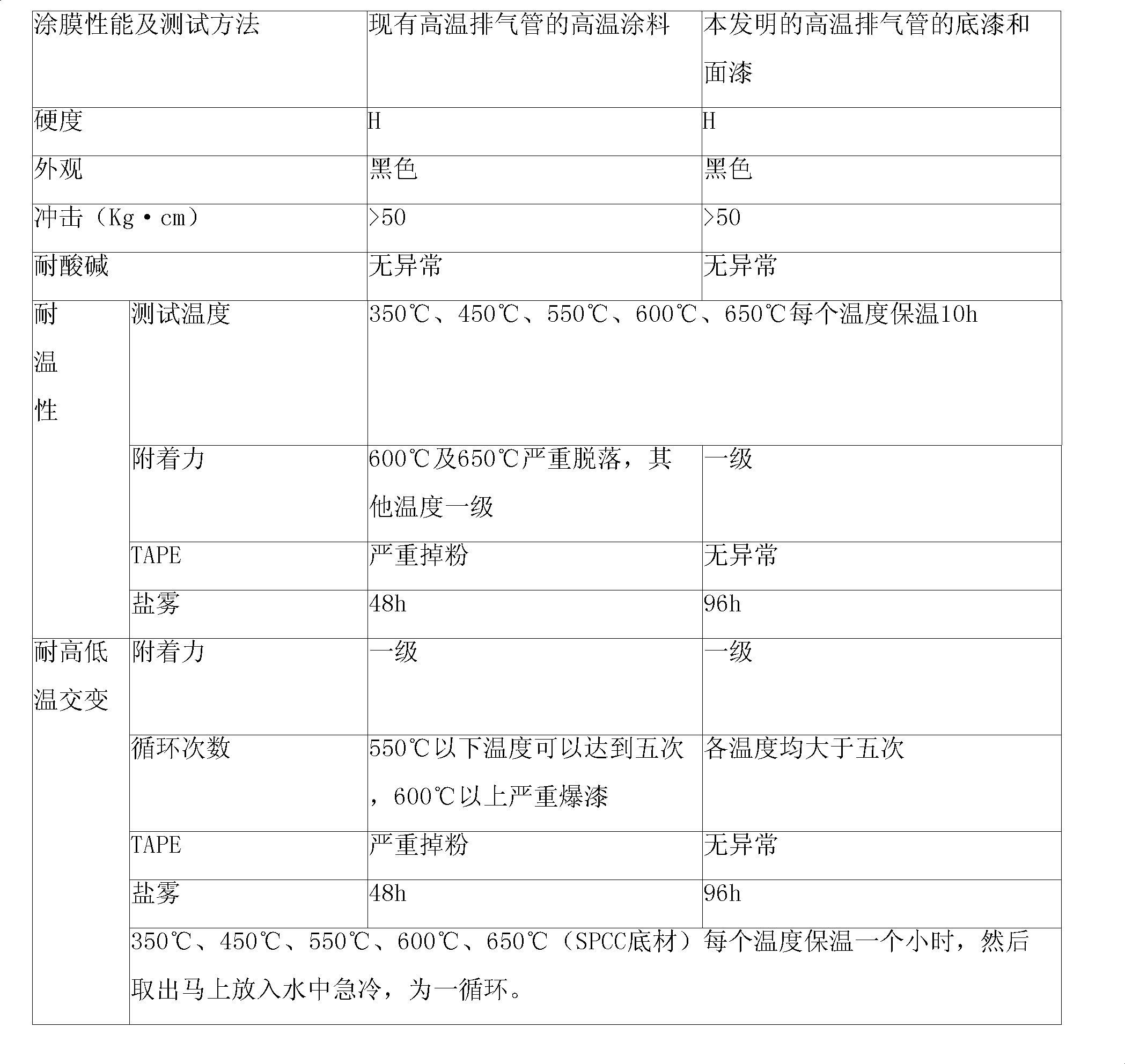

A high-temperature exhaust pipe primer and finish

The invention discloses a high-temperature exhaust pipe primer, including the following components: epoxy-modified silicone resin, epoxy resin, filler, chromium and iron black powder, anti-settling agents and solvents. The invention also discloses a high-temperature exhaust pipe finish, including the following components: methyl phenyl siloxane resin, epoxy resin, filler, chromium and iron black powder, anti-settling agents and solvents. The inventive primer and finish can achieve full temperature range of protection by regulation of primer and finish matching, has a good temperature resistance, coating sintering character and salt spray resistance, and can satisfy the requirement of long-term use in the temperature range of 550-650 DEG C. The coating is not easy to crack, and the phenomenon of powder dropping and rust stripping will not appear after high temperature.

Owner:江苏四方威凯科技有限公司

Abrasion-resistant steel plate with residual stress of 50-100 MPa and preparation method thereof

InactiveCN107723601AImprove mechanical propertiesHigh strengthProcess efficiency improvementCr elementMartensitic microstructure

The invention discloses an abrasion-resistant steel plate with residual stress of 50-100 MPa and a preparation method thereof. the abrasion-resistant steel plate comprises the chemical components of,by weight, 0.10%-0.21% of C, 0.20%-0.60% of Si, 1.0%-1.40% of Mn, 0.15%-0.50% of Cr, 0.015%-0.040% of Ti, 0-0.015% of P, 0-0.003% of S, 0.0010%-0.0025% of B, 0.015%-0.045% of Al, 0-0.00015% of H, 0-0.0035% of N, and the balance Fe and unavoidable inclusions, and the Cr element meets the requirement of 0.491C+0.31Mn+0.101B>=Cr>=0.213C+0.109Mn+0.0032B. The 8-40 mm martensitic structure form tempering-free abrasion-resistant steel plate is obtained, the residual stress of the steel plate is within 100 MPa, and the preparation method is simple, convenient and practical.

Owner:SHANDONG IRON & STEEL CO LTD

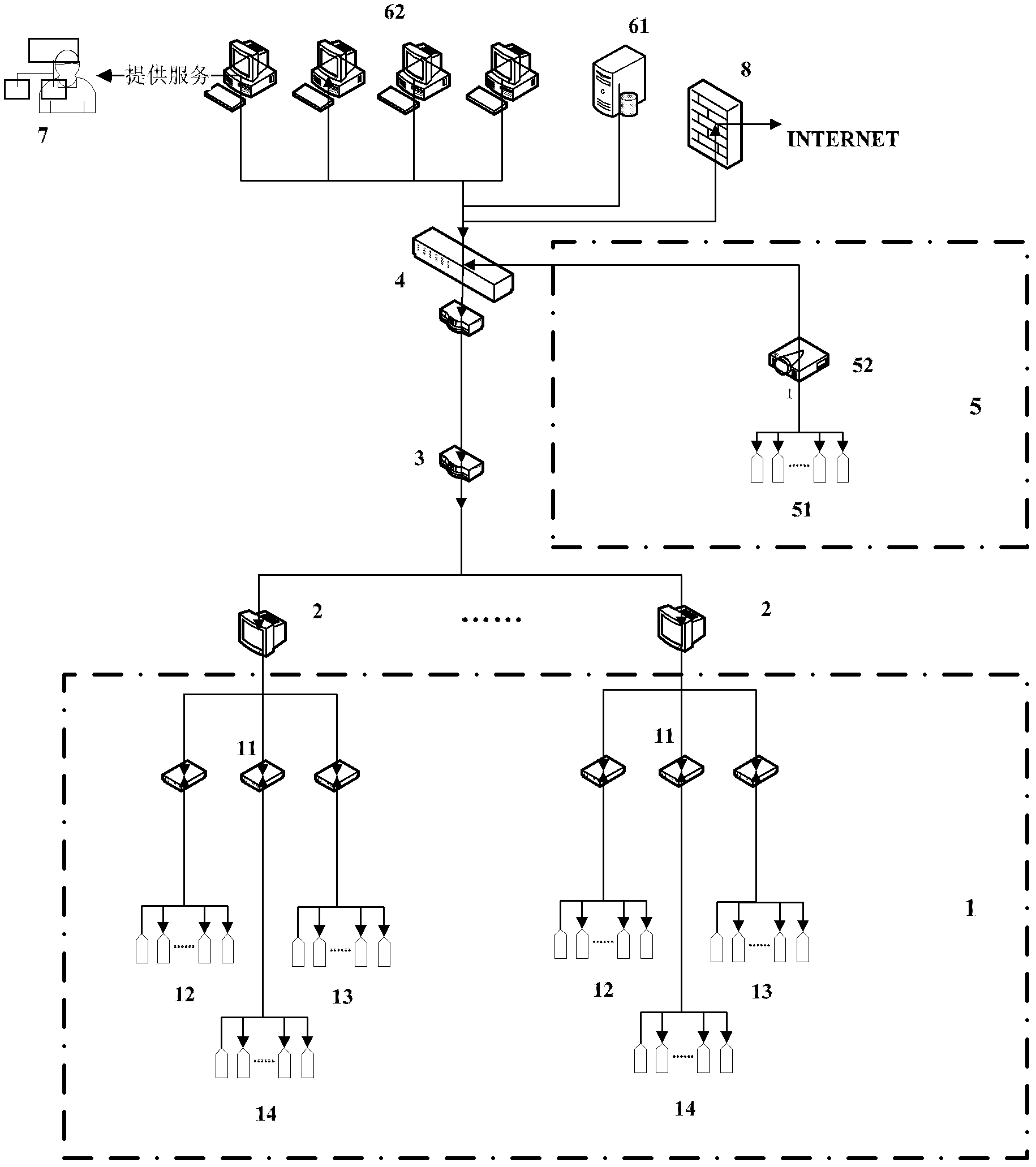

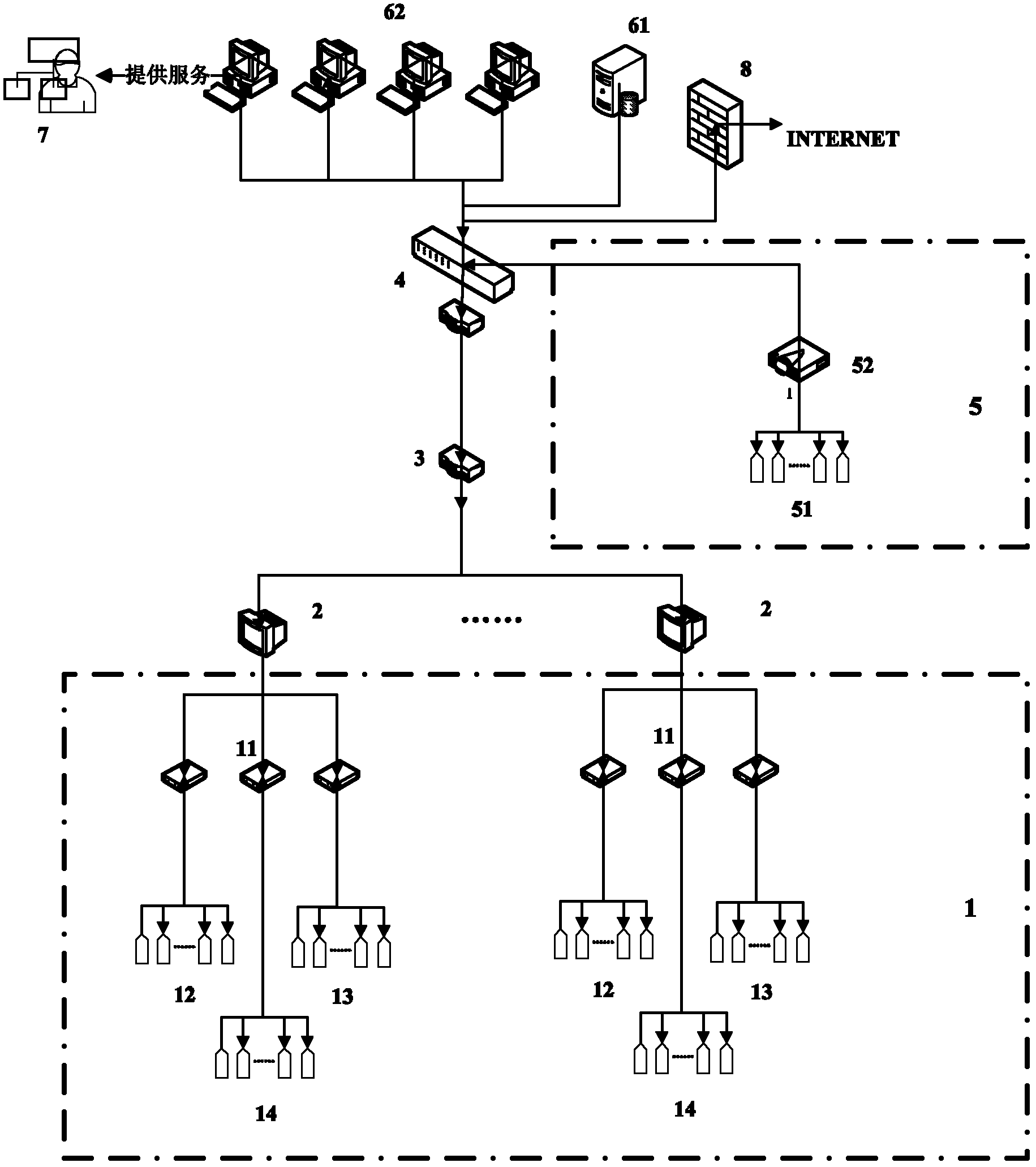

Integrated operation monitoring and maintenance system for power tunnel

InactiveCN102621957AReasonable structureMeet the requirements of long-term useTotal factory controlProgramme total factory controlTransceiverElectric power

The invention relates to an integrated operation monitoring and maintenance system for a power tunnel. The system comprises a real-time data acquisition module, a periodic data acquisition module, acquisition industrial personal computers, a signal transceiver, a switch, a server cluster and a management terminal, wherein the real-time data acquisition module is connected with the switch sequentially through the acquisition industrial personal computers and the signal transceiver; the switch is connected with the periodic data acquisition module and the server cluster respectively; and the server cluster is connected with the management terminal. Compared with the prior art, the system has the advantages of rational system architecture, high reliability, high compatibility, high anti-interference performance and the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO +2

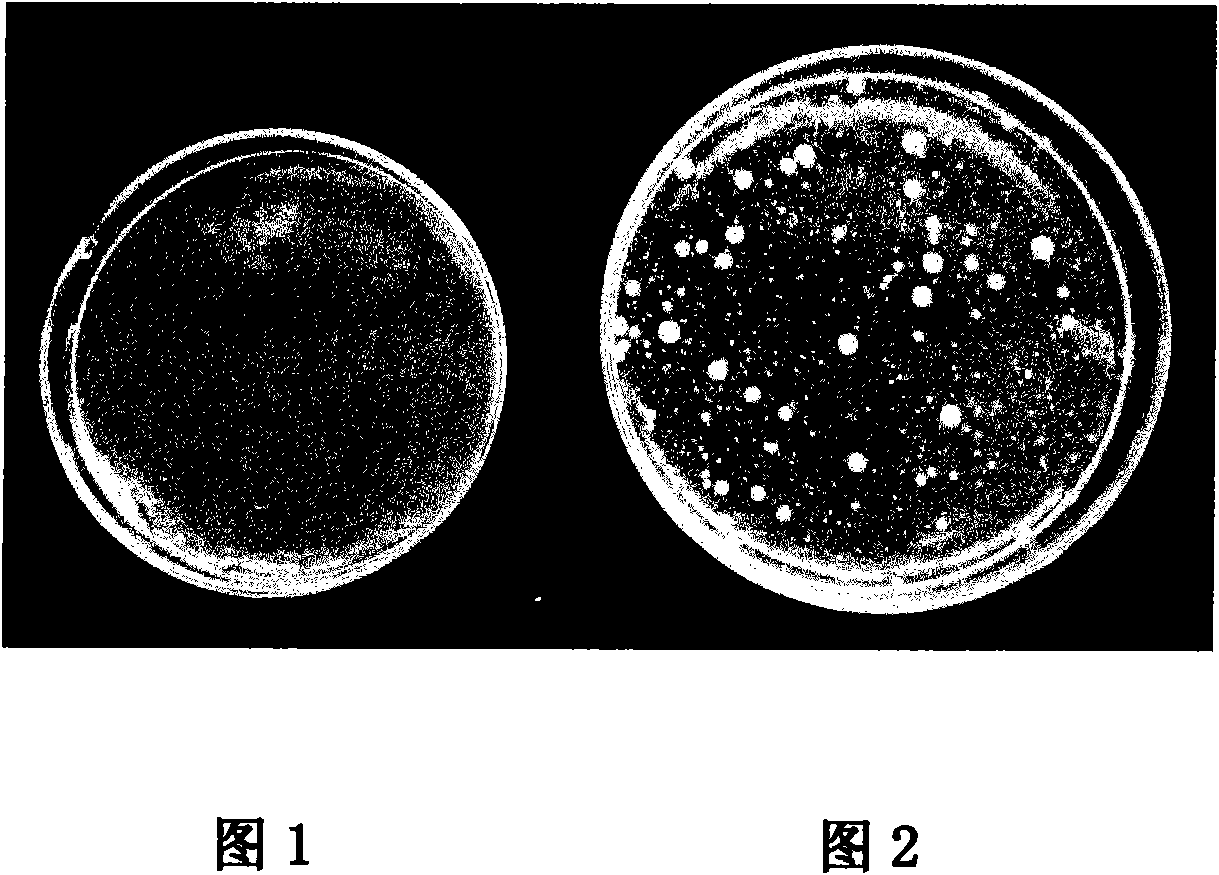

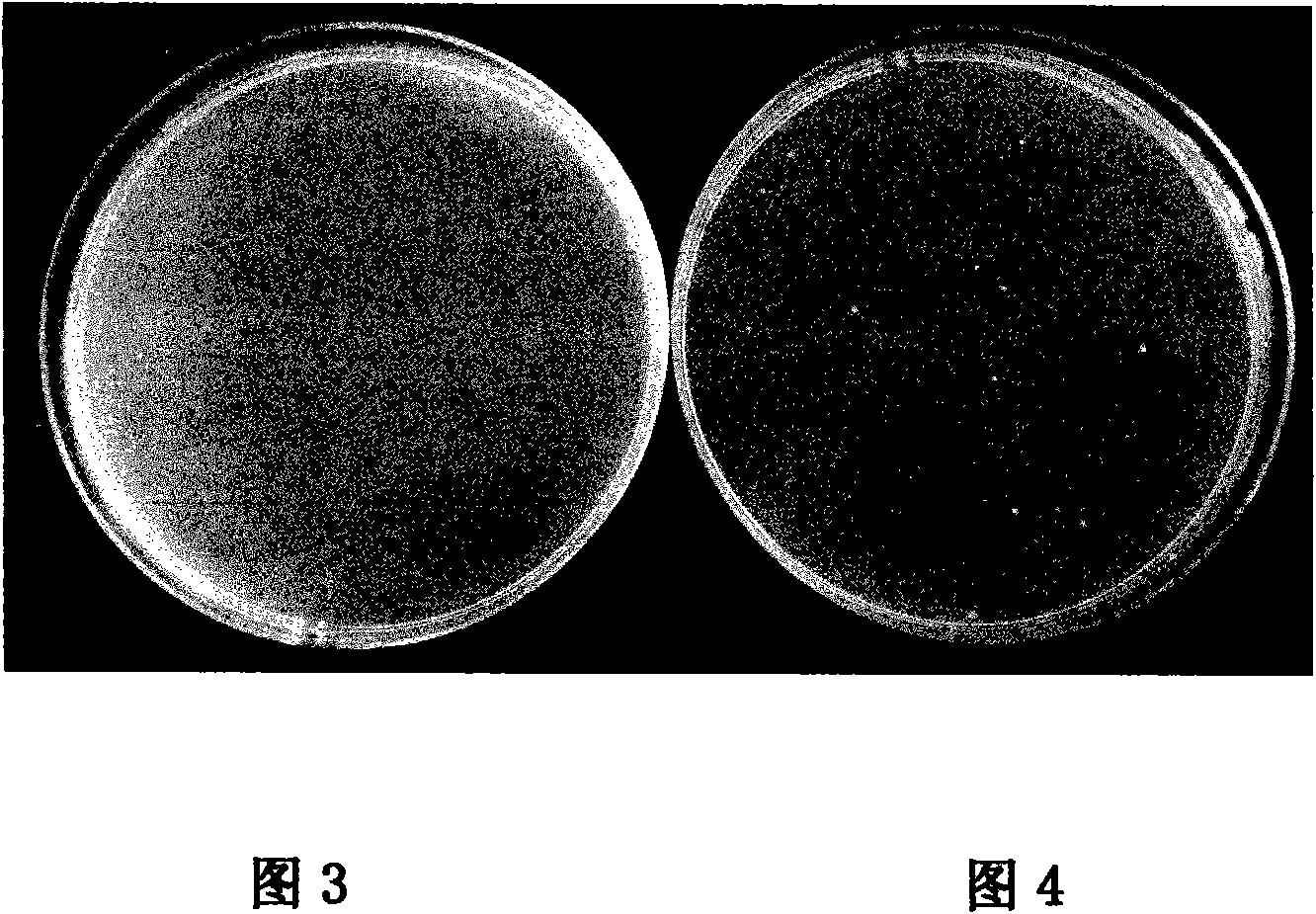

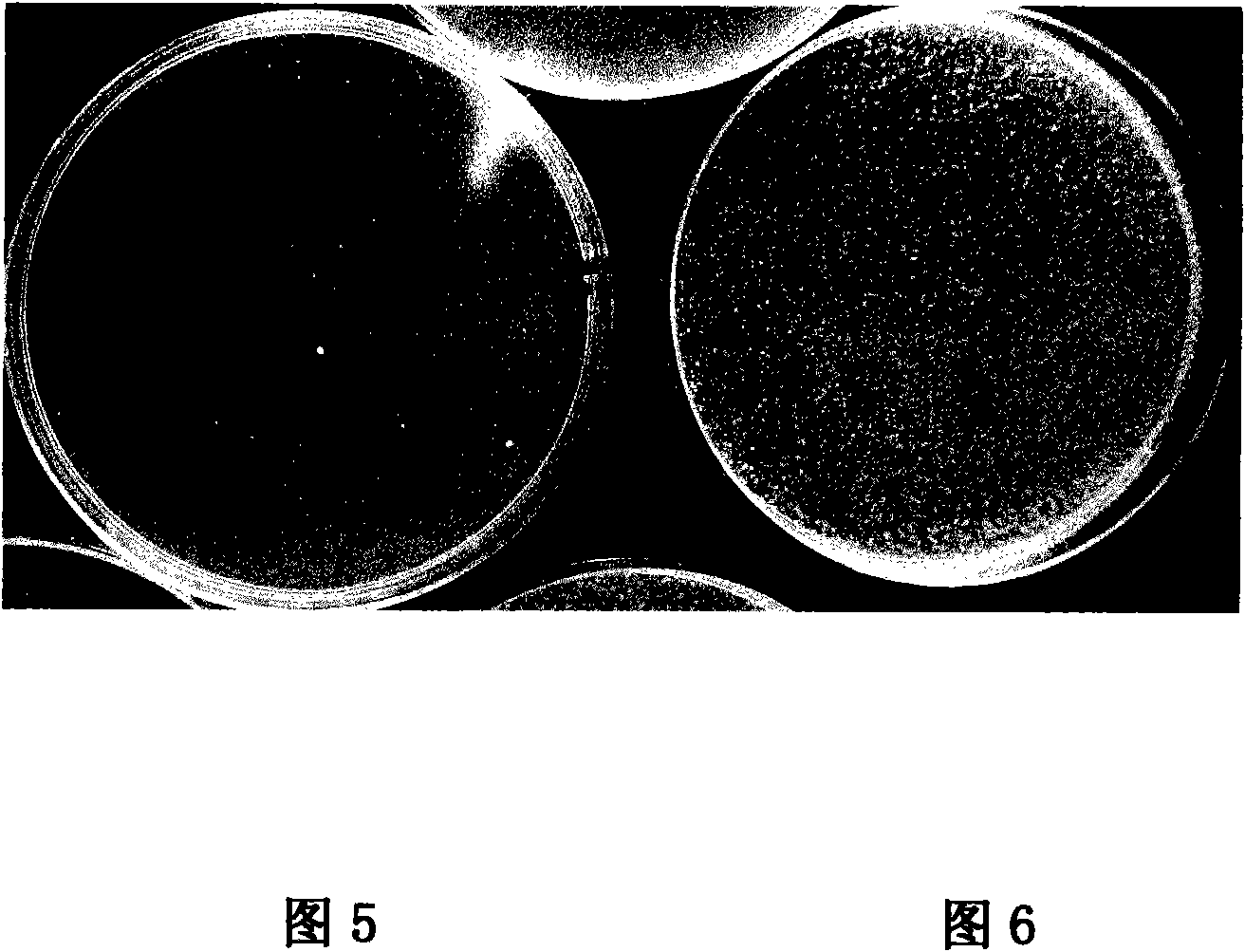

Antibacterium paint and preparation method thereof

InactiveCN101585980AGood antibacterial effectGood product stabilityAntifouling/underwater paintsPaints with biocidesElectrically conductiveNanometre

The invention relates to antibacterium paint and a preparation method thereof. 0.1-20 percent of conductive macromolecule polyaniline nanometer powder doped with inorganic acid or organic sulfoacid is added into a paint base body according to the weight percent. The preparation method of the antibacterium paint comprises the following steps: adopting the conductive macromolecule polyaniline nanometer powder doped with inorganic acid or organic sulfoacid as raw materials, grinding the conductive macromolecule polyaniline nanometer powder doped with inorganic acid or organic sulfoacid, sieving by a 100-500 mesh standard sieve, continuously grinding the raw materials which are not sieved, repeating the sieving step, mixing the sieved raw materials with the paint base body, and ball-milling mixture for 6-8h by a ball mill. The invention has remarkable antibacterium effect, good product stability, simple preparation process and wide application range without toxic and side effect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

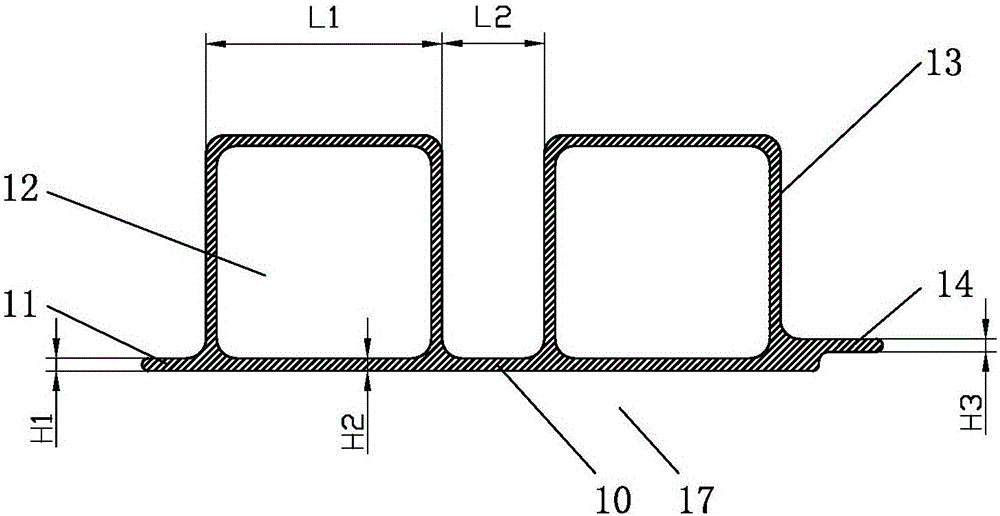

Frame-shaped spiral winding plastic pipe as well as production equipment and production process thereof

InactiveCN106287009AImprove performanceLow costRigid pipesTubular articlesConductor CoilMechanical engineering

The invention belongs to the technical field of municipal drainage and sewage discharging pipelines, and relates to a frame-shaped spiral winding plastic pipe as well as production equipment and a production process thereof. More than one hollow rectangular pipe or hollow arched pipe is transversely formed on an external surface of a plastic tape of the frame-shaped spiral winding plastic pipe at intervals, wherein the top surface of the arched pipe is in smooth transition, a connecting edge is arranged at one side of the frame-shaped spiral winding plastic pipe, and an upper surface of an edge at the other side extends outwards to form a fastening edge, so as to form strip profiles, and the frame-shaped spiral winding plastic pipe is formed by adhering and connecting the strip profiles through a hot melt adhesive after spiral winding. The production equipment comprises an extruding machine, a profile mould, a shaping mould, a cooling and shaping platform, a traction machine, a winding mechanism, a carrying platform and a pipe cutting saw. The production process comprises the following steps: shaping the strip profiles, winding the strip profiles in a spiral manner, and adhering and connecting the strip profiles through the hot melt adhesive to form a pipe. The frame-shaped spiral winding plastic pipe as well as the production equipment and the production process thereof disclosed by the invention have the following advantages: material cost and equipment manufacturing cost are lowered while performance of the pipe is improved, the product is safe and reliable, and the frame-shaped spiral winding plastic pipe can meet the requirement on long-term use, and is applicable to producing large-diameter municipal drainage and sewage discharging pipelines.

Owner:何周富 +1

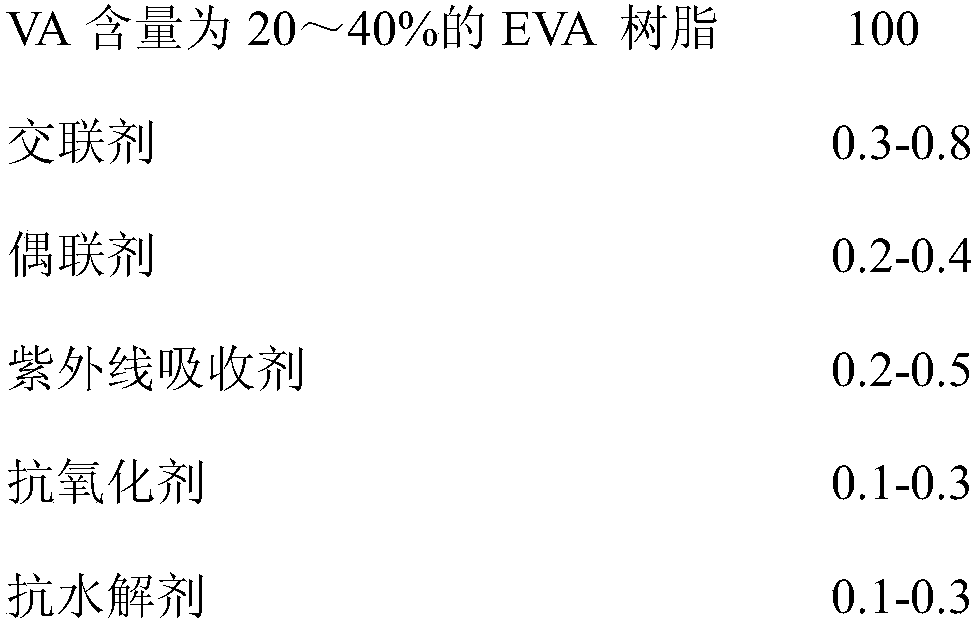

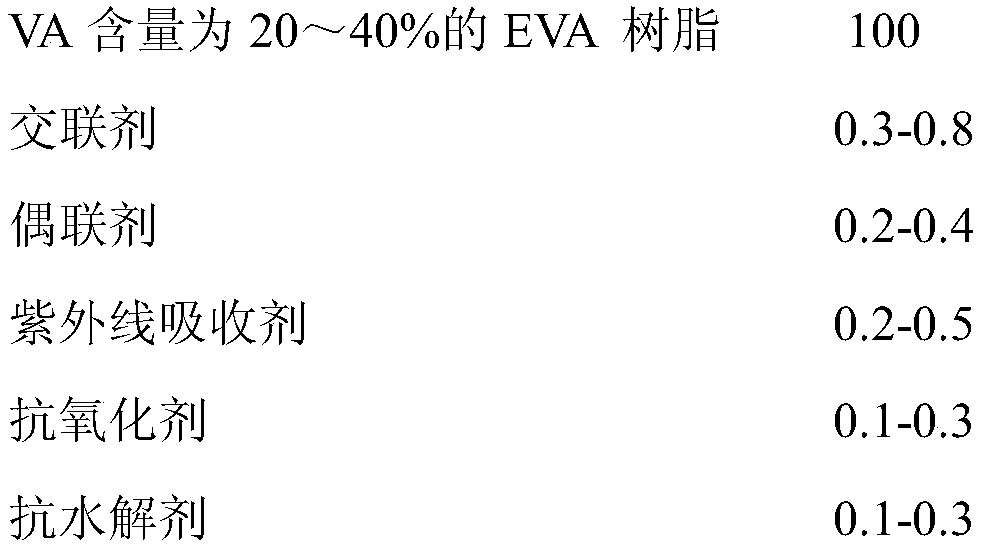

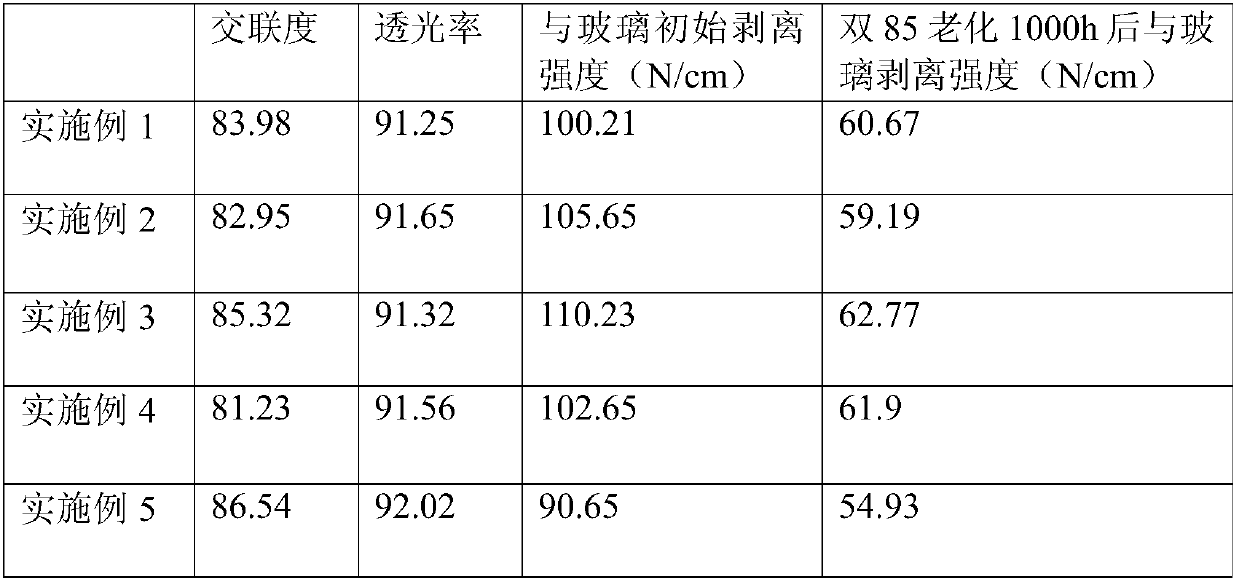

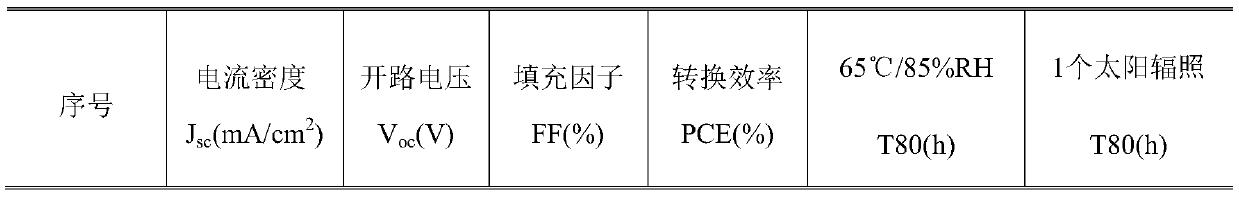

Bonding attenuation resistant EVA (Ethylene-Vinyl Acetate) packaging film for solar packaging material

InactiveCN107686708AMeet the requirements of long-term useIncrease the degree of cross-linkingNon-macromolecular adhesive additivesMacromolecular adhesive additivesCross-linkUltrasound attenuation

The invention relates to a solar cell packaging film and aims to provide a bonding attenuation resistant EVA (Ethylene-Vinyl Acetate) packaging film for a solar packaging material and a preparation method of the EVA packaging film. The EVA packaging film has high anti-pressure ability, resistance to thermal expansion and cold contraction, water resistance and heat resistance and has the characteristic of being long in service life. The preparation method has the characteristics of being simple in process flow and high in production efficiency. According to the technical scheme, the bonding attenuation resistant EVA packaging film for the solar packaging material comprises the following corresponding components in parts by mass: 100 parts of EVA resin with VA content of 20-40%, 0.3-0.8 partof a cross-linking agent, 0.2-0.4 part of a coupling agent, 0.2-0.5 part of an ultraviolet light absorber, 0.1-0.3 part of an antioxidant and 0.1-0.3 part of a hydrolysis resistant agent.

Owner:ZHEJIANG DILONG PHOTOELECTRICITY MATERIAL

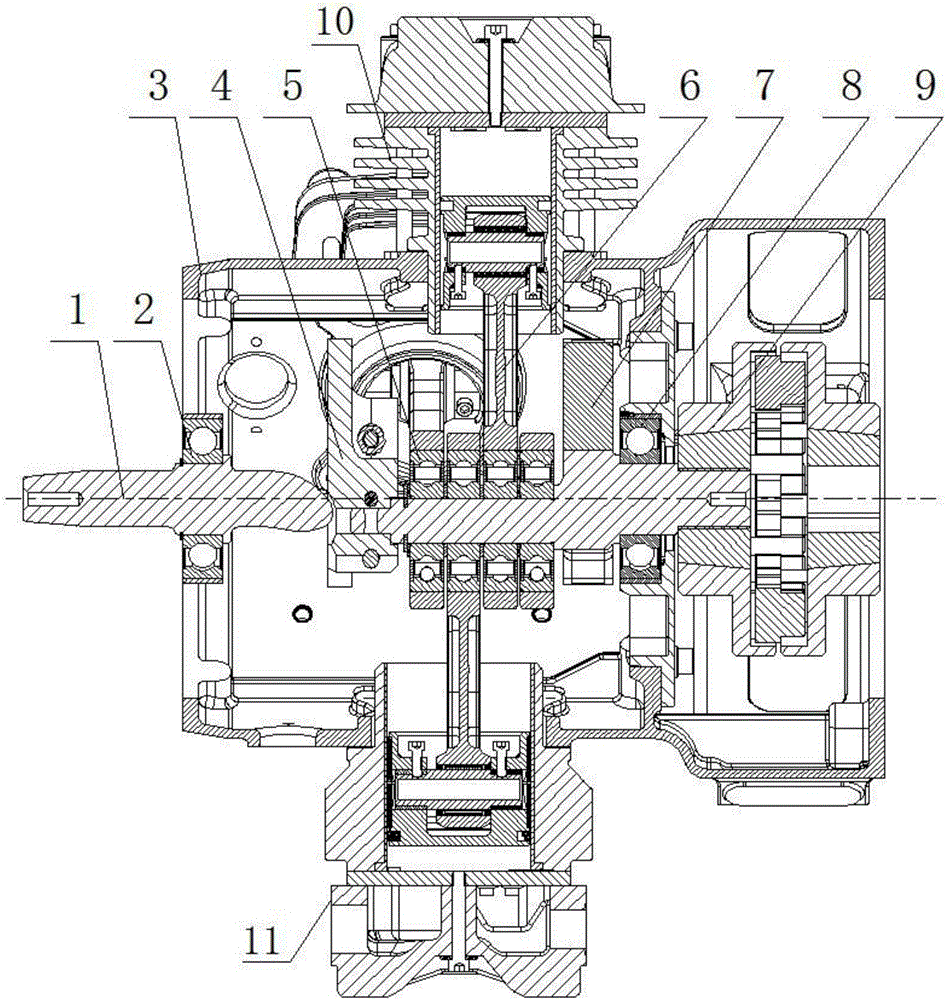

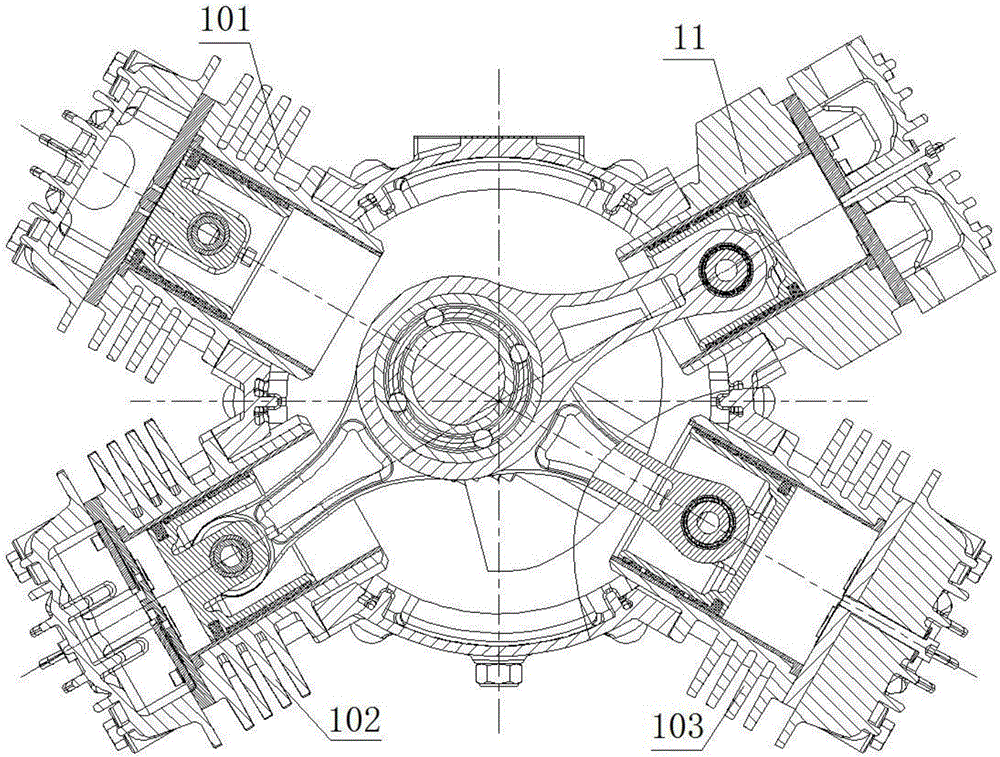

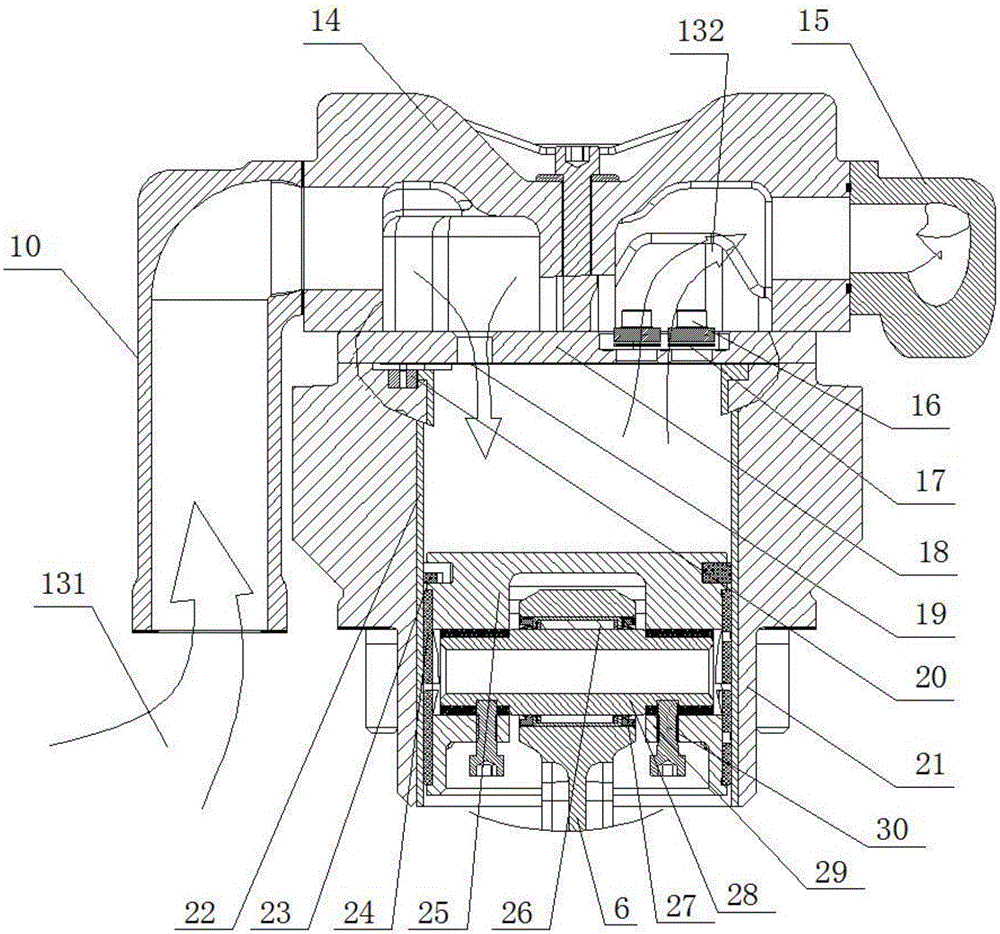

Air compression device of electrical oil-free main air compressor

ActiveCN106194643AAdjustable sizeMeet the requirements of long-term usePositive displacement pump componentsPump parameterOil and greaseEngineering

The invention discloses an air compression device of an electrical oil-free main air compressor, and belongs to the technical field of air compressors. The air compression device comprises a main housing, a crankshaft, a fan end bearing, a large counterweight block, a swinging rod bearing, a swinging rod, a small counterweight block, a motor end bearing, a coupler and a compression cylinder component; the compression cylinder component consists of a low-pressure cylinder cover, an output connector, a valve plate screw, an exhaust reed, a valve plate, an air inlet reed, a low-pressure cylinder body, a cushion block, a low-pressure cylinder sleeve, a piston ring, a supporting ring, a low-pressure piston, a connecting rod small end bearing, an oil seal, a piston pin, a heat insulation ring and a compression screw; the compression cylinder component consists of at least one high-pressure cylinder component and at least two low-pressure cylinder components; the piston ring and the supporting ring are made of teflon; the oil seal avoids leakage of bearing grease; the heat insulation ring insulates heat of the low-pressure piston. Oil leakage and blow-by hidden dangers of the air compressors are eliminated through air cooling, and a reasonable air flow trend is formed. With the adoption of the piston ring and the supporting ring that are made of teflon, no oil cooling is required, and the maintenance cost is reduced.

Owner:RUILI GROUP RUIAN AUTO PARTS CO LTD

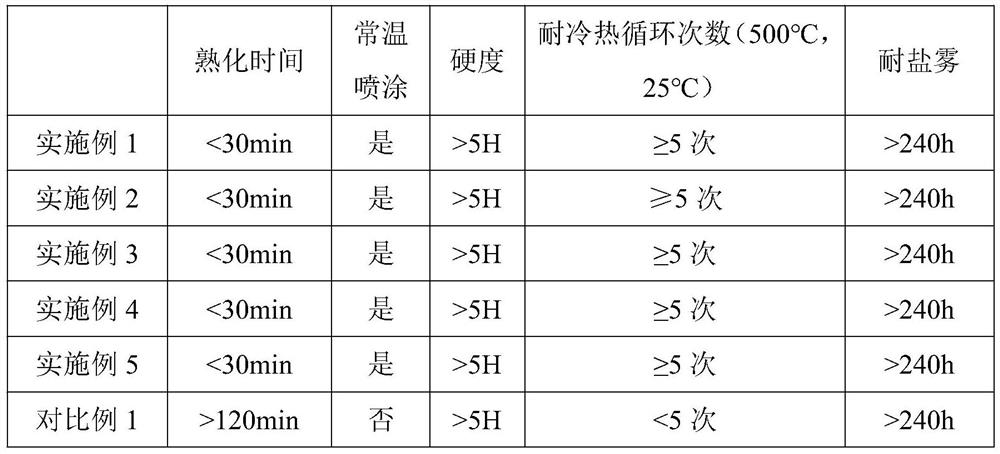

Water-based polysiloxane ceramic simulating coating

InactiveCN111909616AShort maturation timeSimple curing processAnti-corrosive paintsPtru catalystMetallic substrate

The invention relates to the technical field of coatings, in particular to a water-based polysiloxane ceramic simulating coating. The water-based polysiloxane ceramic simulating coating is composed ofa component A, a component B and a component C, wherein the component A is composed of water-based nano sol, filler, pigment, an anti-sagging agent, a leveling agent and a dispersing agent, the component B is a catalyst, the component C is a silane coupling agent, and the mass ratio of the component A to the component B to the component C is 10: (1-10): (0.1-5). The water-based polysiloxane ceramic simulating coating has the advantages of being good in stability before curing, simple in curing process, short in curing time, capable of being sprayed at normal temperature, long in shelf life after curing, resistant to hot and cold circulation, high in hardness, resistant to corrosion and the like, and can meet the requirement for long-term use of various metal base materials in complex andchangeable environments.

Owner:无锡米克新材料有限公司

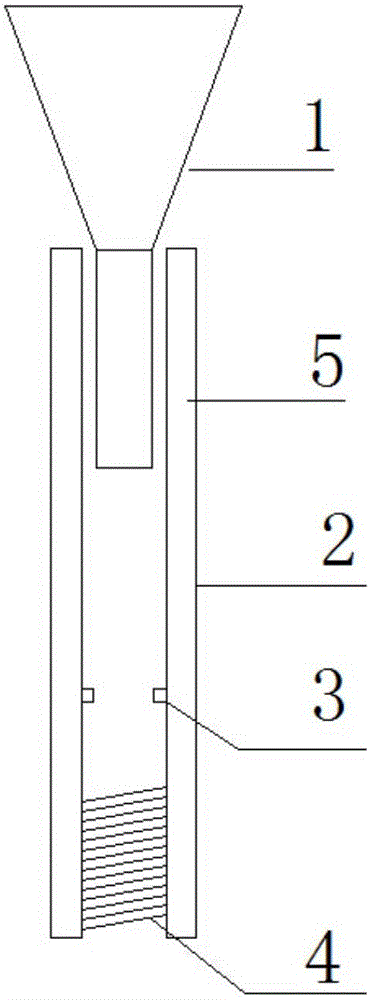

Gravity type self-anchorage connecting device and assembly method

ActiveCN105863069AFirmly connectedSimple technologyBuilding constructionsArchitectural engineeringRebar

The invention relates to a gravity type self-anchorage connecting device and an assembly method and belongs to the field of relevant technical equipment of constructional engineering. The gravity type self-anchorage connecting device mainly comprises a sleeve, and the two ends of the sleeve are open. The lower end of the sleeve is provided with a sleeve thread used for being connected with a protruding bar of a building component. The upper end of the sleeve serves as an expansion part. An expansion head is inserted in the upper end of the sleeve. The expansion head comprises a rod part and a head part which are formed integrally. The diameter of the largest portion of the head part is larger than the outer diameter of the sleeve. According to the gravity type self-anchorage connecting device and the assembly method, two prefabricated building components can be connected rapidly and conveniently through the design of a brand-new connecting component structure.

Owner:SHANDONG TONGYUAN DESIGN GRP

Multi-element solid solution strengthening heat-resistant titanium alloy

InactiveCN105950911ADoes not significantly reduce room temperature plasticityEffective use of strengthening effectsRoom temperatureSolid solution strengthening

The invention provides a multi-element solid solution strengthening heat-resistant titanium alloy. The multi-element solid solution strengthening heat-resistant titanium alloy consists of the following components in percentage by mass: 5.5%-6.5% of Al,, 2.5%-3.5% of Sn, 3.0%-5.0% of Zr, 0.3%-0.7% of Nb, 0.3%-0.7% of Mo, 1.0%-2.0% of W, 1.0%-2.0% of Ta, 0.25%-0.45% of Si, 0.03%-0.07% of C and the balance being Ti and other inevitable impurities. The titanium alloy belongs to the multi-element solid solution strengthening heat-resistant titanium alloy, and the room-temperature strength of the alloy subjected to solid solution and ageing treatment meets the following relationship: Rm greater than or equal to 1100MPa, Rp 0.2 greater than or equal to 910 MPa, A5 greater than or equal to 8%; and the strength under a 650-DEGC high-temperature condition meets the following relationship: Rm greater than or equal to 680 MPa, Rp0.2 greater than or equal to 580 MPa and A5 greater than or equal to 20%.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH +1

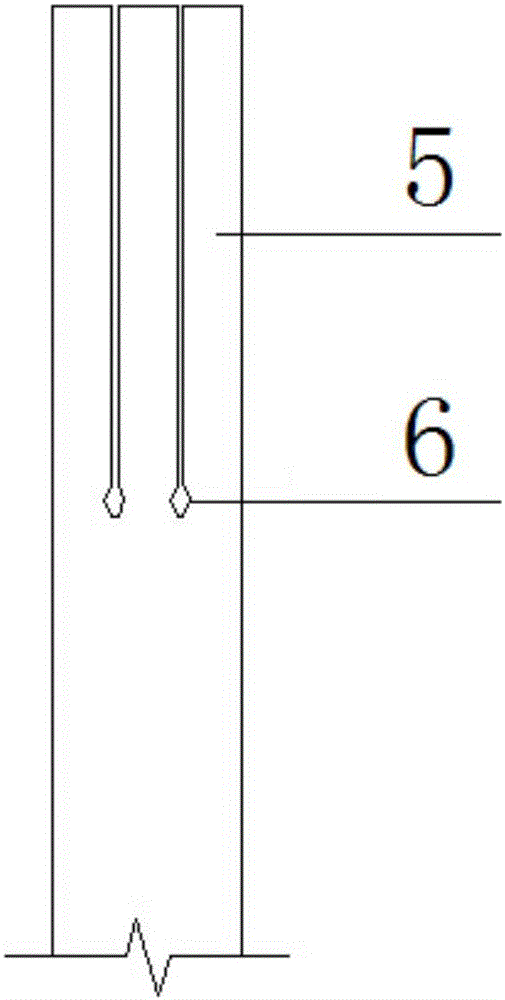

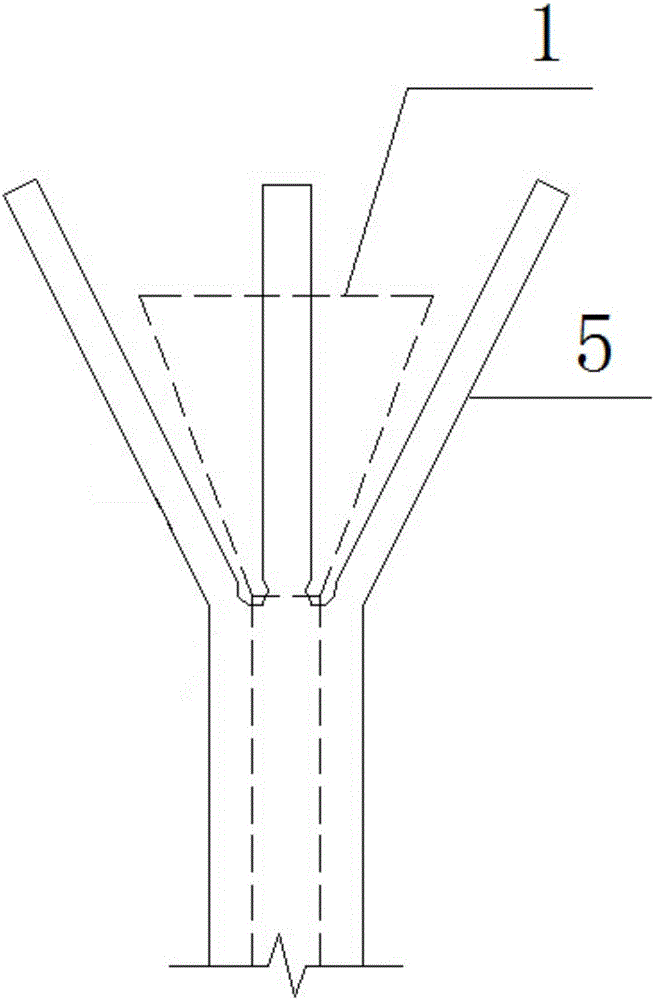

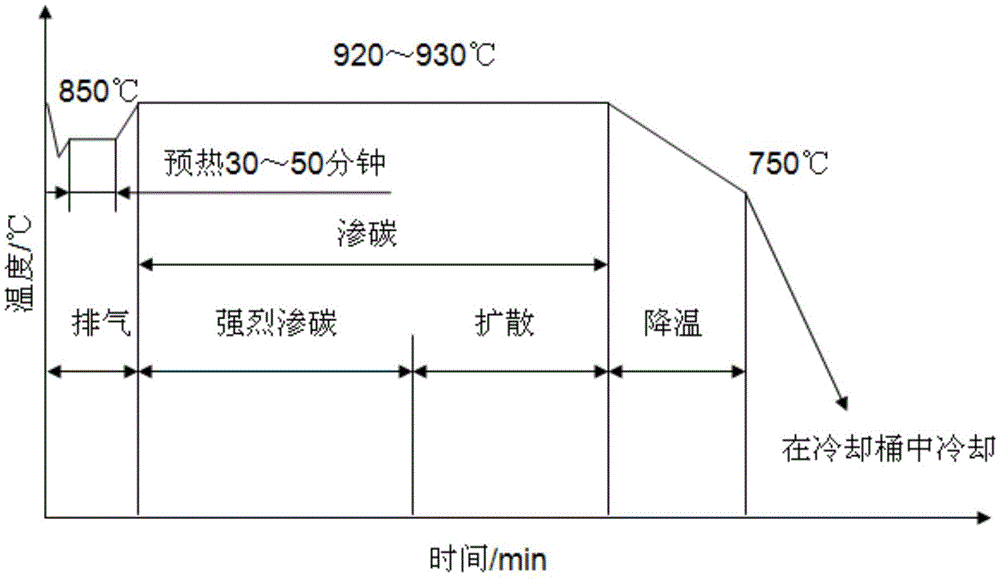

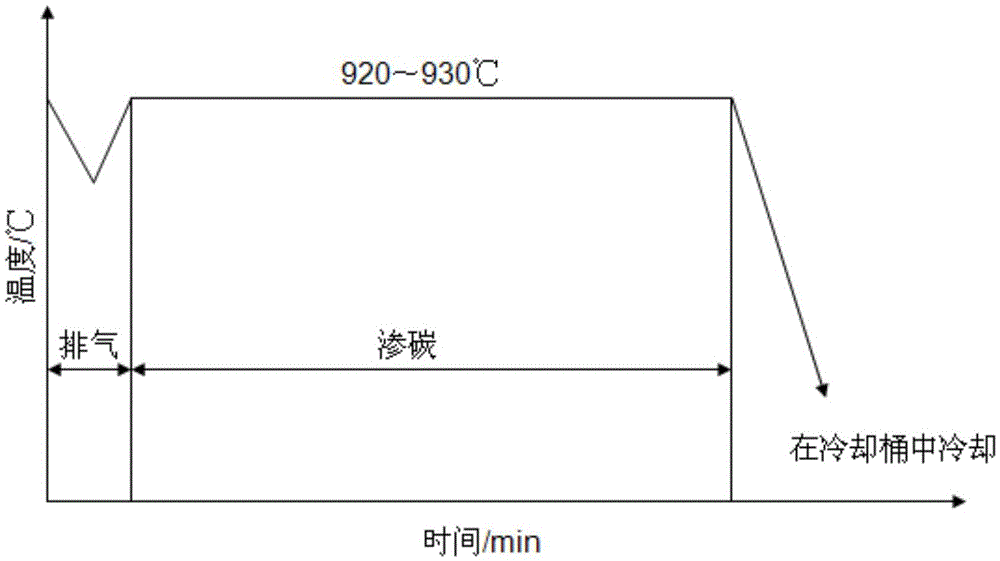

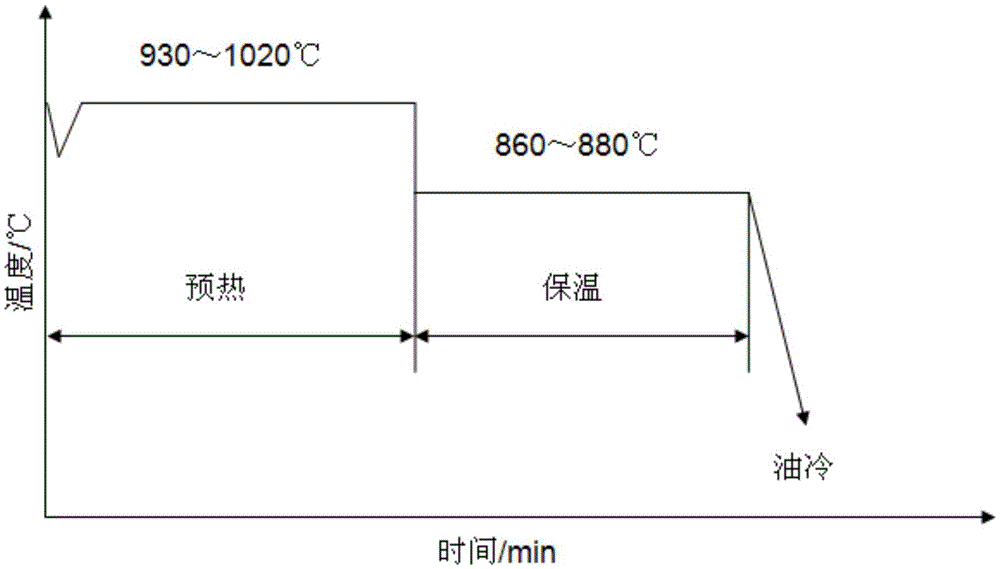

Heat treatment method for 2Cr3WMoV material gear forging

ActiveCN106756750AHigh hardnessImprove wear resistanceSolid state diffusion coatingHigh resistanceChemical treatment

The present invention belongs to the chemical heat treatment in the heat treatment technology category, and relates to a heat treatment method for a 2Cr3WMoV material gear forging. A purpose of the present invention is to make a 2Cr3WMoV material gear achieve excellent performances of high hardness and high wear resistance by using a scientific and reasonable carburizing and quenching process so as to meet the long-term use requirement. According to the present invention, after a 2Cr3WMoV material is subjected to carburizing, the excellent performances of deep infiltration layer, high hardness, high wear resistance, good heat resistance and the like are provided while the defects that the surface layer carbide is easy to accumulate, the carbide level is high, the crack and the block shedding are easily generated, and the like exist, and after 12CrNi3A and other ordinary low-carbon alloy steel are subjected to carburizing, the defects do not exist while the hardness, the wear resistance, the heat resistance and the like are low so as not to meet the use needs of the advanced combat aircraft; and by using the scientific and reasonable carburizing and quenching process, the 2Cr3WMoV material gear has excellent performances of high hardness, high wear resistance, good heat resistance and the like so as to meet the long-term use requirement.

Owner:XIAN AERO ENGINE CONTROLS

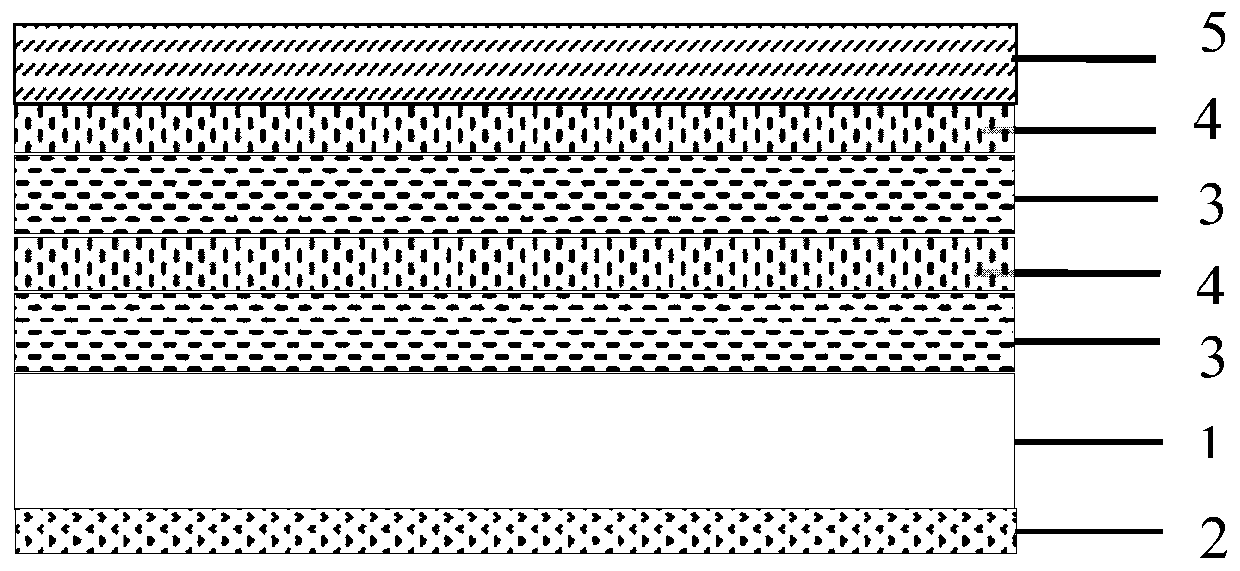

Flexible composite substrate for perovskite thin-film solar cell and preparation method thereof

PendingCN110931657AAvoid erosionGood weather resistanceMaterial nanotechnologySolid-state devicesComposite substrateMaterials science

The invention provides a flexible composite substrate for a perovskite thin-film solar cell and a preparation method thereof. The flexible composite substrate has the characteristics and functions ofultra-thinness, weather resistance, water and oxygen barrier, transparent conductive films and the like, and solves the problem that existing PET, PEN and other base materials are poor in weather resistance. Besides, the water-oxygen blocking layer can prevent water vapor and oxygen in the environment from corroding the perovskite cell, and the requirement for long-term use of the cell in the outdoor humid and hot environment is met. The flexible composite substrate for a perovskite thin-film solar cell and a preparation method thereof can break through the preparation technology of the ultrathin high-barrier layer, integrate the barrier layer, the ultrathin base material and the transparent electrode into one body, reduce the use of a layer of packaging film, reduce the surface density ofthe battery, simplify the traditional sandwich type battery packaging process, only need a one-side pressing process, can reduce the side leakage risk of the device, and can improve the long-term stability of the device.

Owner:CHINA LUCKY FILM CORP

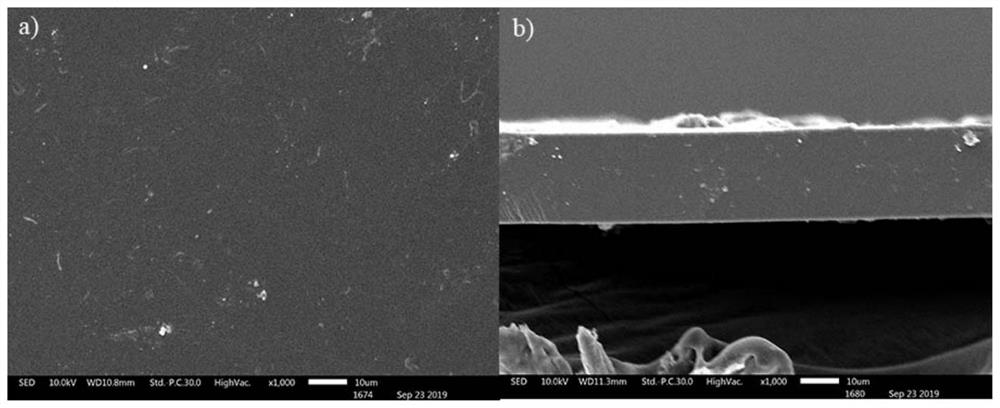

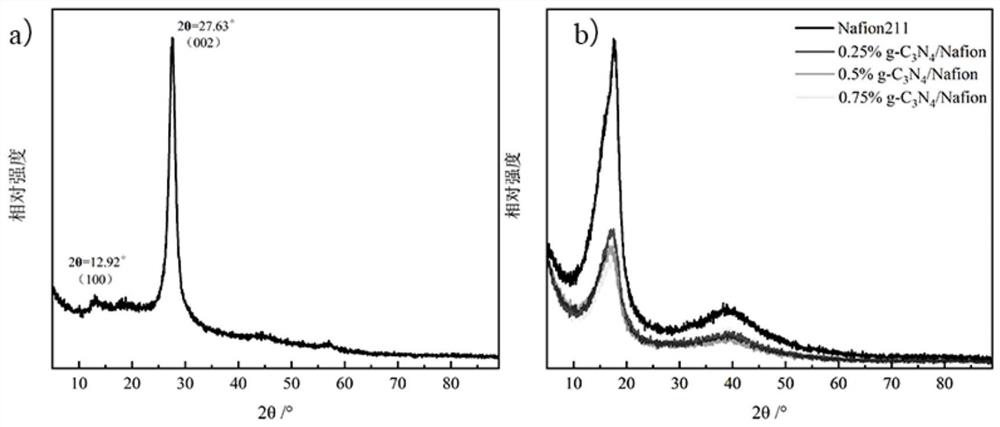

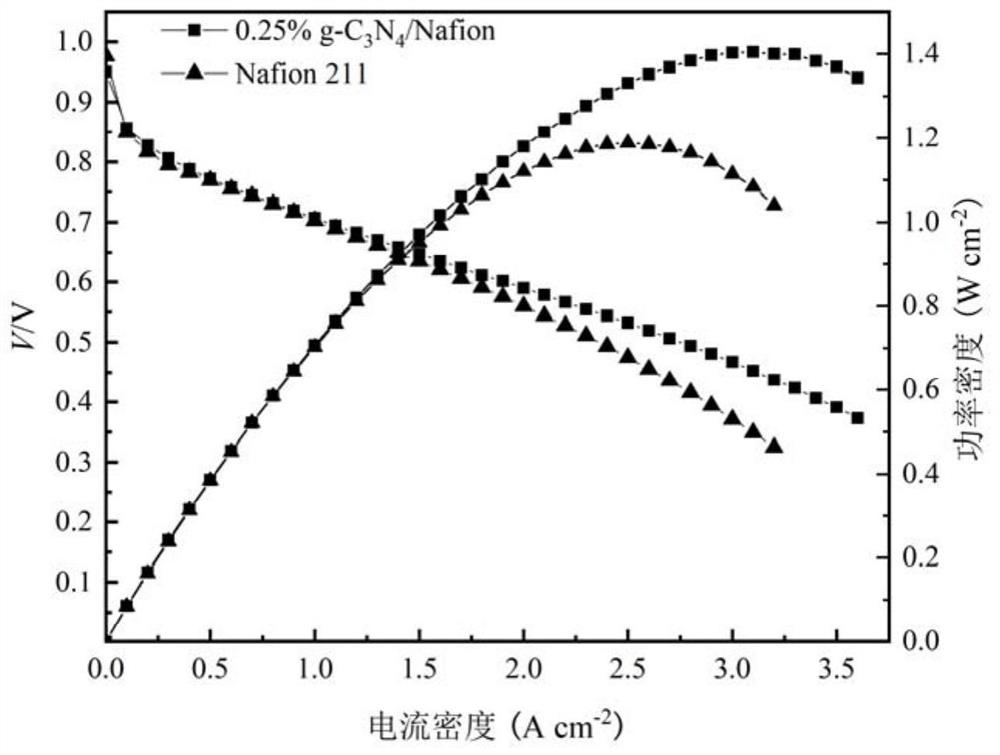

Nafion/g-C3N4 composite film as well as preparation method and application thereof

ActiveCN112820921AEasy to operateThe synthesis method is simpleFuel cellsCarbon nitrideProton exchange membrane fuel cell

The invention provides a Nafion / g-C3N4 composite membrane as well as a preparation method and application thereof, particularly relates to a composite membrane prepared by compounding protonated carbon nitride and Nafion resin, and belongs to the technical field of proton exchange membrane fuel cells. The preparation method comprises the following steps: firstly dissolving Nafion resin in a high-boiling-point solvent, then adding a dispersed g-C3N4 suspension into the Nafion solution, stirring, performing uniform ultrasonic treatment, pouring into a mold, and drying at a certain temperature to form a film, thereby obtaining the composite film. The conductivity of the composite film doped with g-C3N4 is obviously improved, and the polarization performance of a single cell is superior to that of a commercial Nafion 211 film.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Manufacturing method of uranium dioxide-gadolinium oxide pellet standard substance

InactiveCN103162998AGuarantee product qualityImprove reliabilityMaterial analysis using wave/particle radiationPreparing sample for investigationUranium borideAmount of substance

Belonging to a manufacturing method of a standard substance, the invention particularly relates to a manufacturing method of a uranium dioxide-gadolinium oxide pellet standard substance. The method comprises the steps of: (1) determining the content of gadolinium oxide; (2) conducting uncertainty evaluation; (3) synthesizing standard uncertainty; and (4) expanding uncertainty. The invention has the advantages that wavelength dispersive X ray fluorescence spectroscopy is employed in the present invention to establish the testing method for gadolinium oxide in gadolinium-containing pellets, and at the same time, the law of propagation of uncertainty is adopted to evaluate the uncertainty of a measurement result so as to ensure an accurate and reliable standard substance certified value. With the standard substance, an analysis method is evaluated and the analytical instrument is calibrated, the reliability of quality control in analytical measurement is improved, and the long-term use requirement in the future is satisfied.

Owner:CNNC JIANZHONG NUCLEAR FUEL

Cracking furnace tube for inhibiting catalytic coking of hydrocarbon cracking furnace tube, and manufacturing method thereof

ActiveCN102807887BLow costFast growth rateThermal non-catalytic crackingSolid state diffusion coatingCarbon numberSurface layer

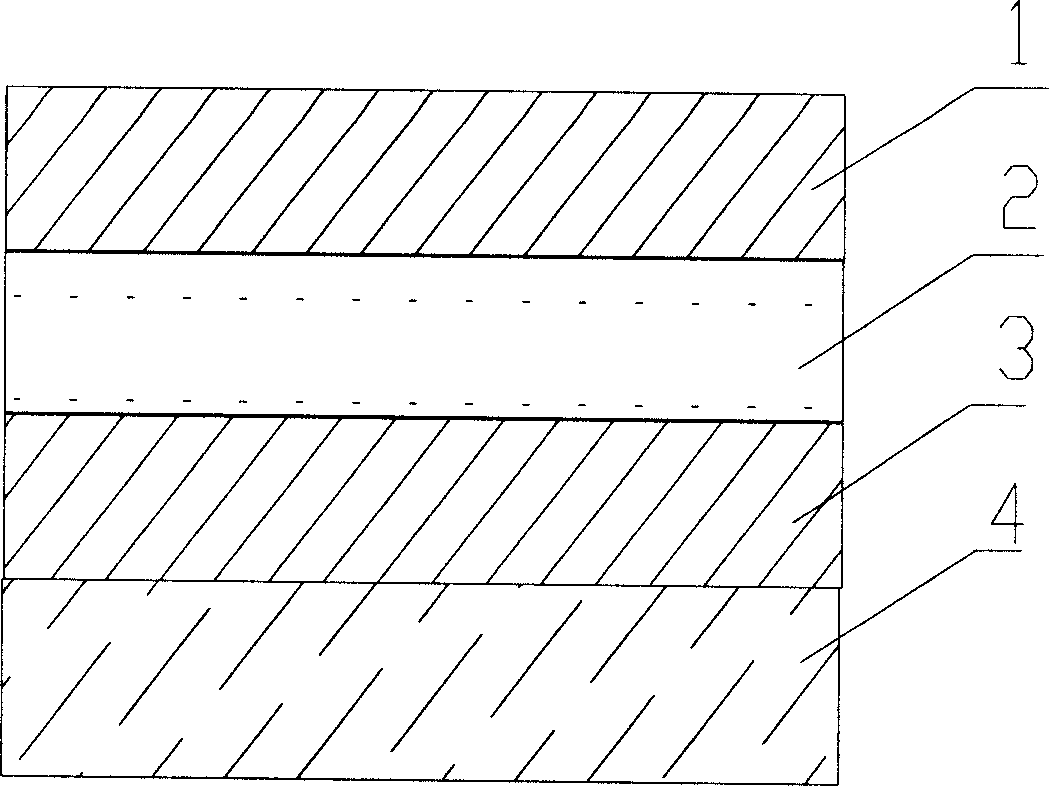

The invention relates to a cracking furnace tube for inhibiting catalytic coking of a hydrocarbon cracking furnace tube, and a manufacturing method thereof. The furnace tube comprises a substrate and an oxide film combined with the substrate, wherein the oxide film is an oxide film obtained by compounding three layers of oxides, the inner layer oxide near the substrate contains at least one selected from SiO2, CeO2 and Y2O3, the middle layer oxide comprises at least one selected from Cr2O3, FeO, Fe2O3 and NiO, the surface layer oxide comprises at least one selected from MnO and MnxCr3-xO4, and x is 0.5-1.5. The cracking furnace tube is manufactured by the following steps: carrying out a step-by-step heating treatment on a nickel-chrome alloy furnace tube material in low oxygen partial pressure gas, and generating an oxide film obtained by compounding three layers of oxides on the inner surface. According to the present invention, Fe content and Ni content in the oxide film of the cracking furnace tube are low, such that catalytic coking of the radiation-section furnace tube of the cracking furnace can be significantly inhibited when the cracking furnace tube is used for production of low carbon number olefin by the hydrocarbon cracking furnace tube.

Owner:CHINA PETROLEUM & CHEM CORP +1

Induction device and electronic equipment

ActiveCN105512634AHigh sensitivitySufficient scratch and abrasion protectionCharacter and pattern recognitionWear resistantEngineering

The invention discloses an induction device comprising an induction component; a packaging layer which is arranged on the induction component; and a nanometer thin-film layer which is arranged on the upper surface of the packaging layer, wherein the lower surface of the nanometer thin-film layer is directly contacted with the upper surface of the packaging layer. The nanometer thin-film layer is directly formed on the upper surface of the packaging layer through a spraying technology. The nanometer thin-film layer has relatively high sensitivity and can realize sufficient scratch-resistant and wear-resistant protection and can be directly contacted with the packaging layer to present as the appearance, and the nanometer thin-film layer has higher connection strength with the packaging layer so that the device structure is enabled to be more stable. The invention also discloses electronic equipment comprising a shell which comprises a first window; and an induction module group which is the induction module group provided by the aforementioned embodiment, wherein the upper surface of the nanometer thin-film layer of the module group is exposed through the first window of the shell, and the lower surface is directly contacted with the upper surface of the packaging layer of the module group. The electronic equipment adopts the induction device so as to meet the requirement of long-term use.

Owner:LENOVO (BEIJING) CO LTD

Fire-resistant pouring material used for bottom of lead smelting furnace

The invention relates to a fire-resistant pouring material used for the bottom of a lead smelting furnace. The fire-resistant pouring material comprises the following components: 10-5mm special-grade alumina clinker, 5-3mm special-grade alumina clinker, special-grade alumina clinker with d90 being less than 0.088mm, 3-1mm brown aluminium oxide, 1-0.088mm brown aluminium oxide, alpha-alumina micro powder with d95 being less than 0.020mm, silica powder, and industrial-grade chromium oxide green; in addition, an additive consisting of compound hardening accelerator and aluminium phosphate solution is also used. The magnesium-aluminium-chrome spinel castable disclosed by the invention can be sintered and shows excellent thermal shock resistance, stripping resistance, erosion resistance, slag bonding prevention and the like under a low temperature process condition during copper smelting, thereby meeting the use requirement of long-term use of a fireproof lining of a copper smelting tundish.

Owner:郑州瑞泰耐火科技有限公司

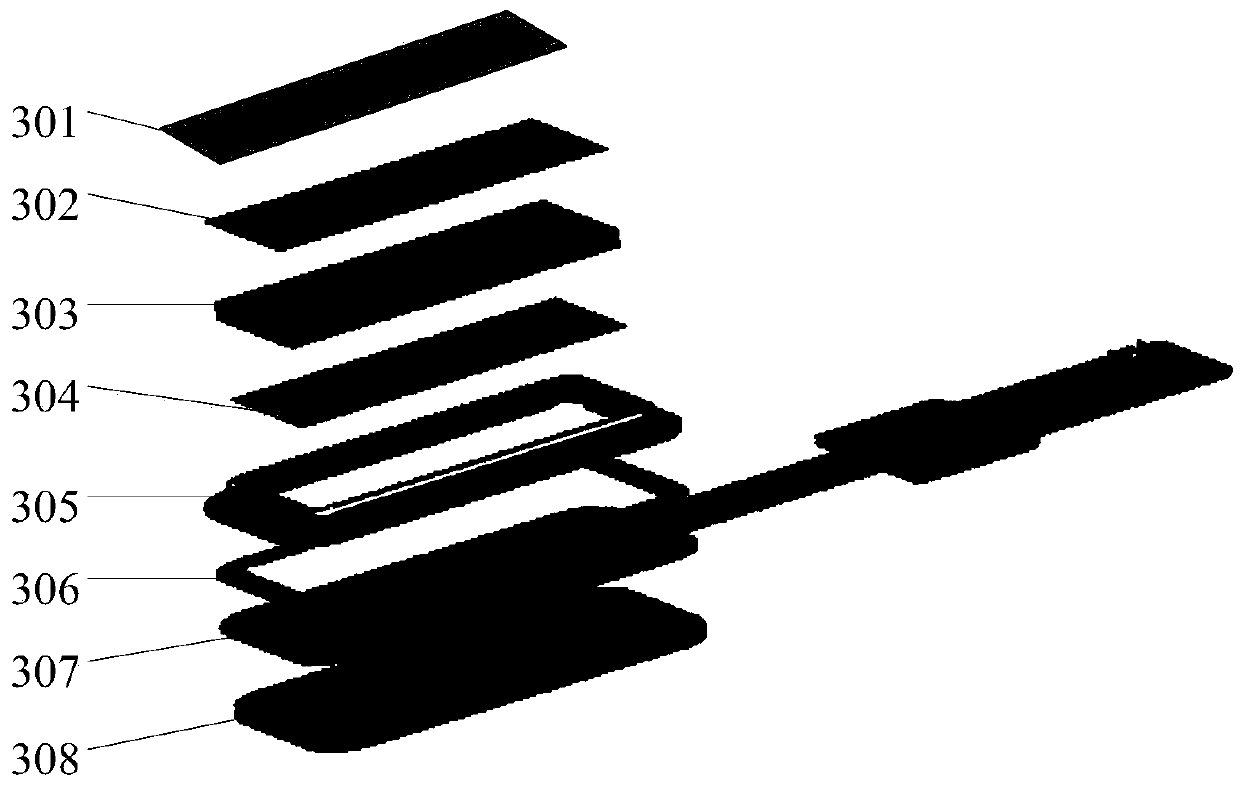

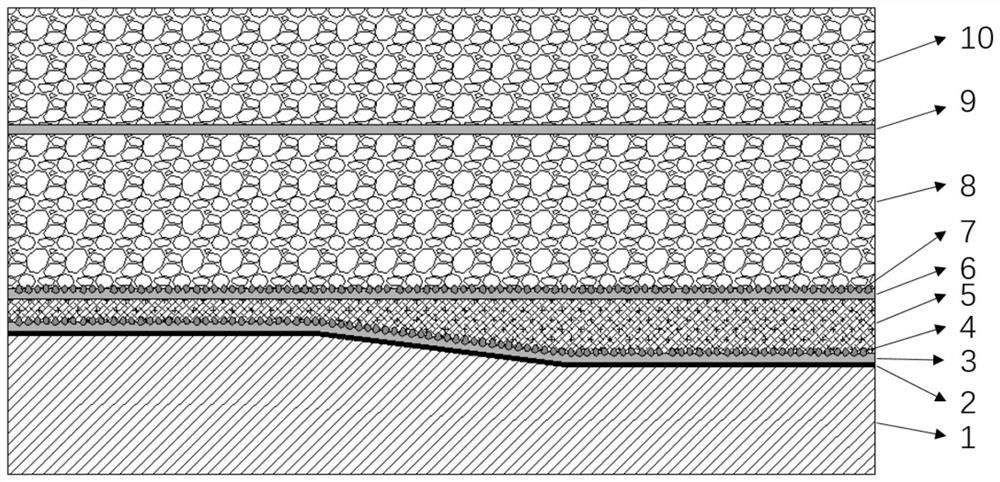

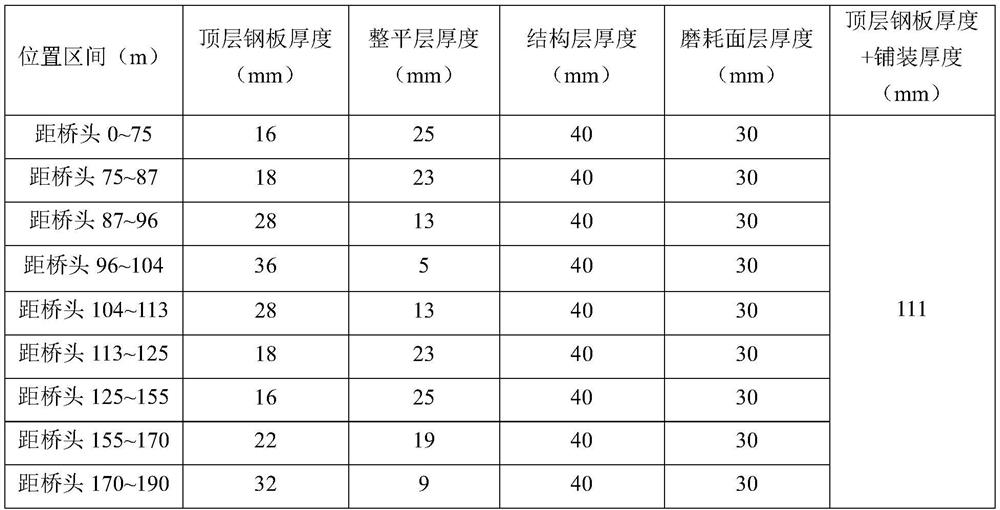

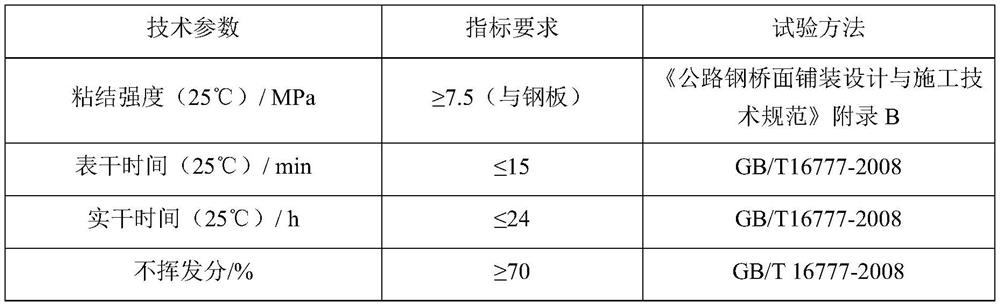

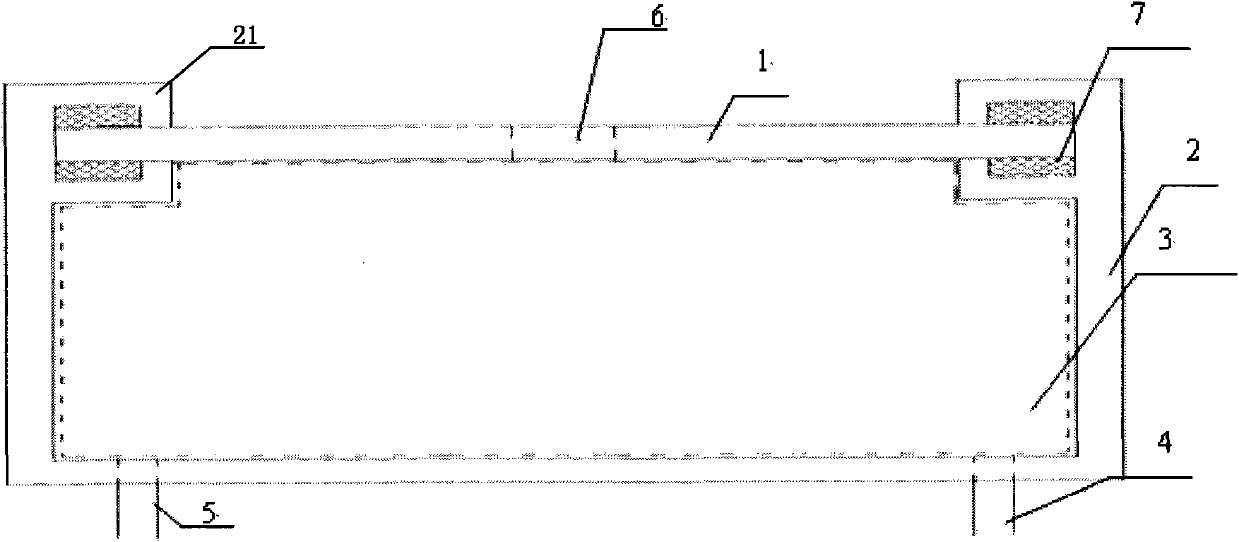

Construction method of high-durability unequal-thickness steel bridge deck pavement structure

ActiveCN114214946AHigh bonding strengthImprove skid resistanceBridge structural detailsBridge erection/assemblySand blastingArchitectural engineering

The invention relates to a construction method of a high-durability unequal-thickness steel bridge deck pavement structure. The construction method comprises the following steps that firstly, cleaning and sand blasting derusting are conducted on an unequal-thickness steel bridge deck slab (1); step 2, arranging an anti-rust layer (2); step 3, spraying a waterproof adhesive layer (3); step 4, laying a bottom gravel layer (4); 5, laying a leveling layer (5); step 6, spraying a lower bonding layer (6); seventhly, a lower gravel layer (7) is arranged; step 8, paving a structural layer (8); step 9, spraying an upper bonding layer (9); and step 10, paving the wearing surface layer (10). The construction method is high in mechanization degree and low in operation difficulty, the pavement structure can be put into service through short-term maintenance after pavement construction is finished, the disease development of the pavement structure is slow and limited under the long-term action of vehicle load, only the abrasion surface layer needs to be overhauled regularly, the overall maintenance cost is low, the maintenance difficulty is low, and the maintenance cost is low. And the steel bridge deck slab has excellent matching performance with the steel bridge deck slabs with different thicknesses.

Owner:中铁五局集团华南工程有限责任公司 +2

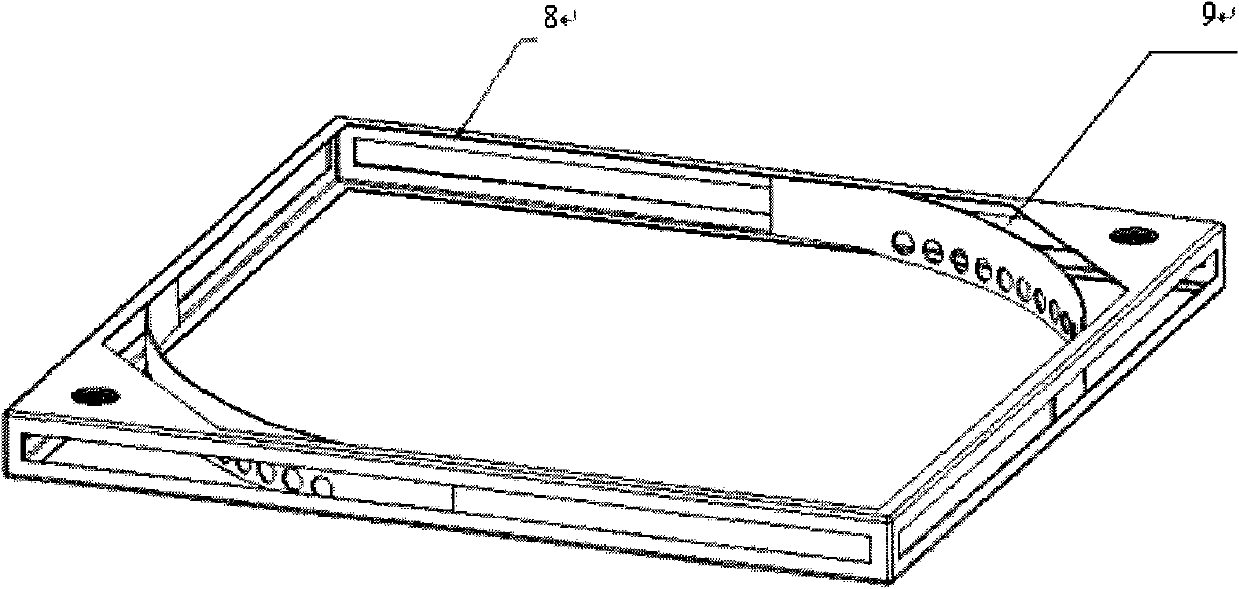

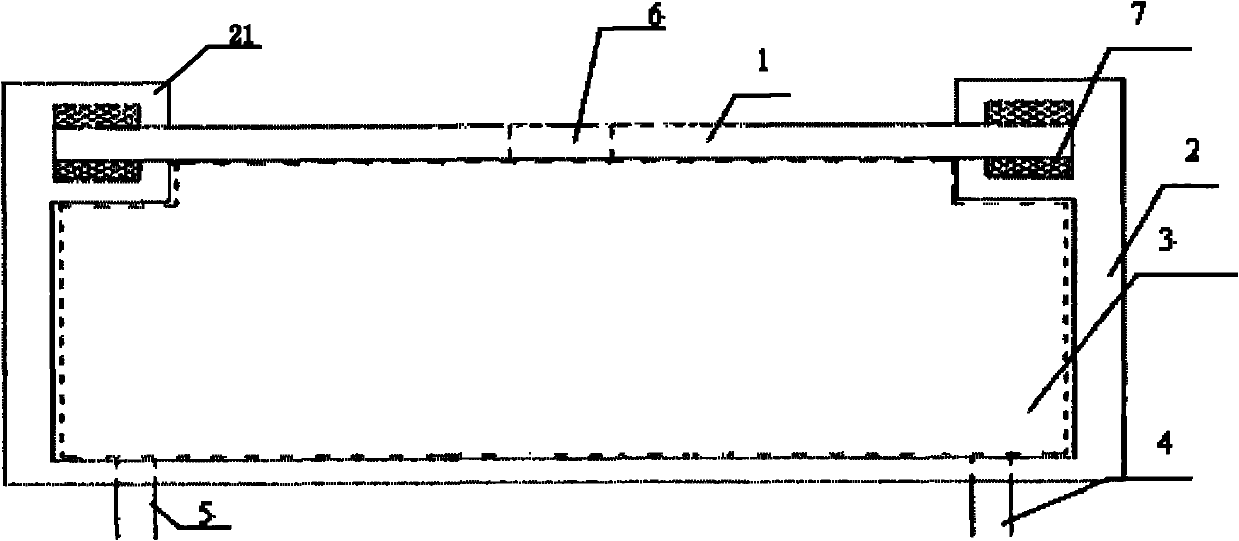

Flexible cooling device of photovoltaic cell

InactiveCN101950767AImprove cooling effectImprove sealingPhotovoltaicsPhotovoltaic energy generationCells panelCurrent divider

The invention relates to a cooling device of a photovoltaic cell, which is particularly suitable for a low-power light condensing photovoltaic cell and belongs to the field of solar energy utilization. An installable and detachable flexible profiled cooling device is installed in a photovoltaic cell frame (2); the flexible profiled cooling device comprises a flexible profiled body (3) which is manufactured in an edge sealing way, a water inlet (4) which is positioned at the bottom of the flexible profiled body (3), a water outlet (5) and a top cover safe hole (6) which is positioned at the top of the flexible profiled body (3); the periphery of a solar cell panel (1) is positioned in a sealing edge (21) on the frame (2); a filler (7) is arranged between the periphery of the solar cell panel (1) and the sealing edge (21); an inner support (8) is positioned in the flexible profiled body (3); and a current divider (9) is arranged in the inner support (8). The device not only meets the heat radiating requirement of the cell panel but also meets the seal requirement of the cell panel, is easy for replacement and is suitable for large-scale industrialized use.

Owner:SOUTHEAST UNIV

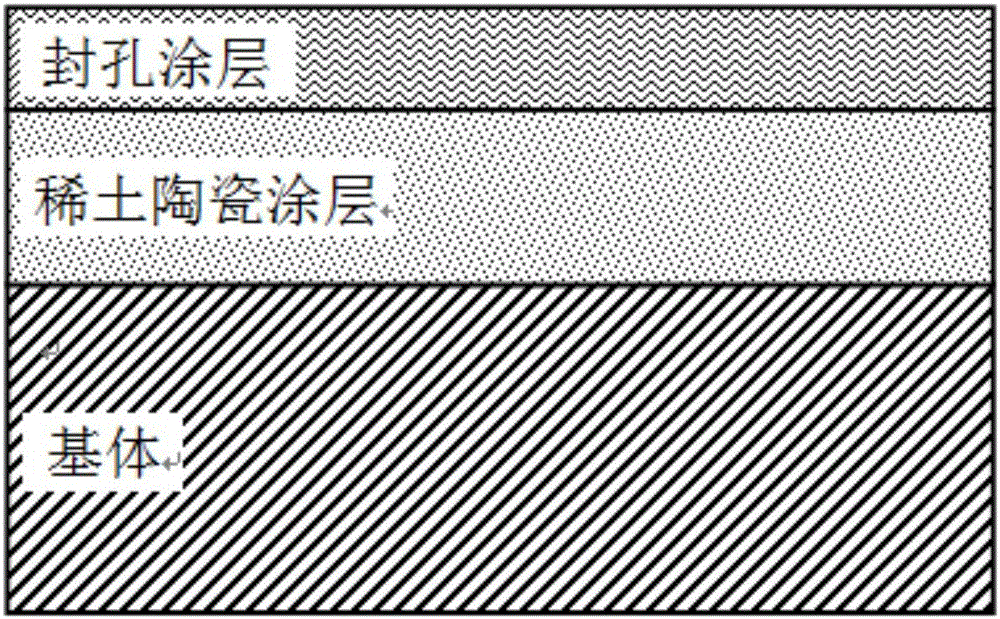

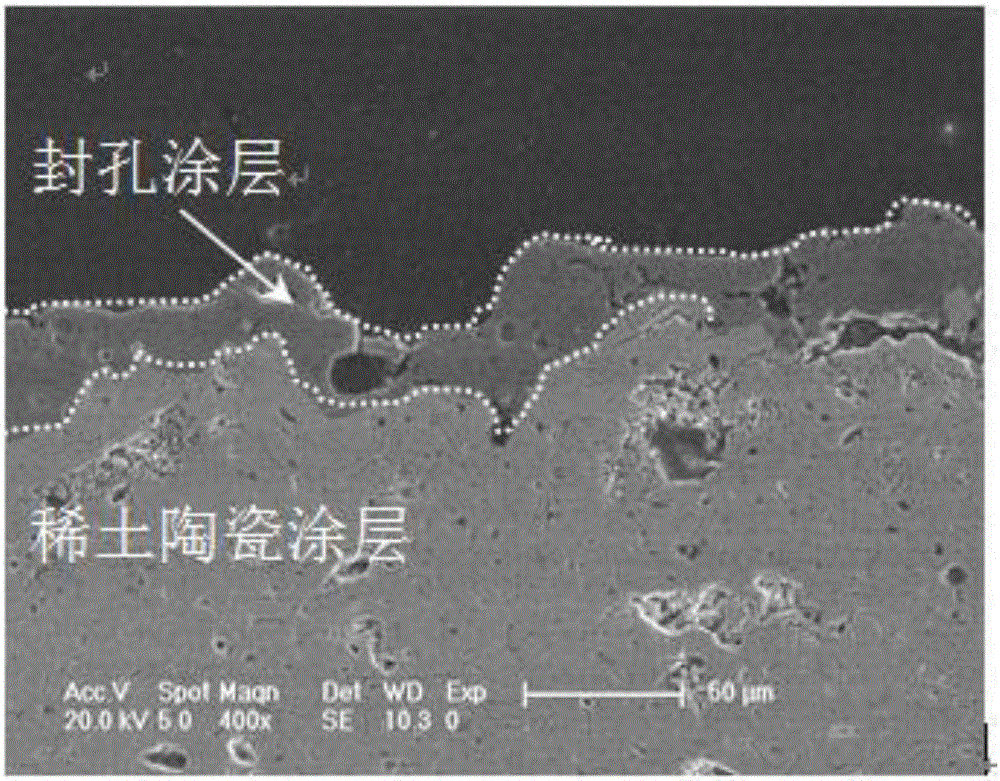

Ship metal component coated with rare earth ceramic electric insulation coating and preparation method of ship metal component

ActiveCN106835002AHigh bonding strengthImprove impact resistanceMolten spray coatingPolyureaFluorocarbon

The invention discloses a ship metal component coated with a rare earth ceramic electric insulation coating. The ship metal component comprises a metal matrix and the rare earth ceramic electric insulation coating coating all outer surfaces of the metal matrix, wherein the rare earth ceramic electric insulation coating comprises a rare earth ceramic coating and a hole sealing coating, the rare earth ceramic coating is a YSZ layer or an LZ layer, the YSZ layer comprises Y2O3 and ZrO2, the LZ layer comprises La2O3 and ZrO2, and the hole sealing coating specifically is polyurea or fluorocarbon. The coating thickness of the rare earth ceramic coating ranges from 0.03 mm to 0.5 mm, and the coating thickness of the hole sealing coating ranges from 0.03 mm to 0.1 mm. By means of the breaking tenacity and the electric insulating performance of rare earth ceramic and the weather fastness and leakproofness of the hole sealing coating, the surface of the rare earth ceramic coating is coated with the polyurea or fluorocarbon, the electric insulation coating with large binding strength, impact resistance and the excellent electrical insulation performance is formed, and the requirement for long-term using of sea pipeline metal components of seaborne ships and submarines is met.

Owner:WUCHANG SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com