Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101results about How to "Extended permeation path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

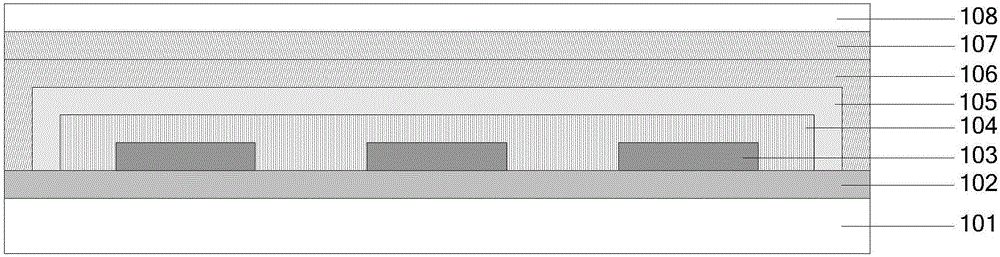

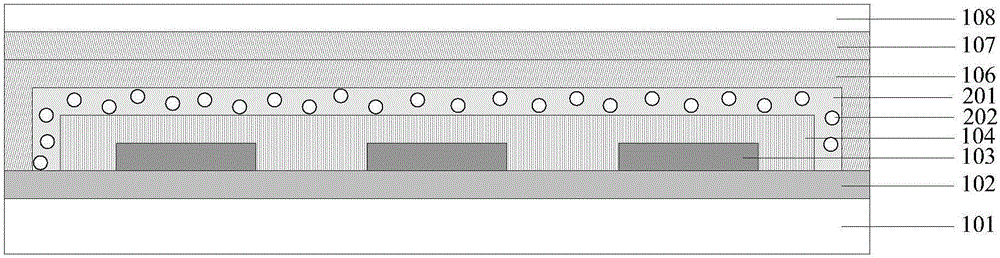

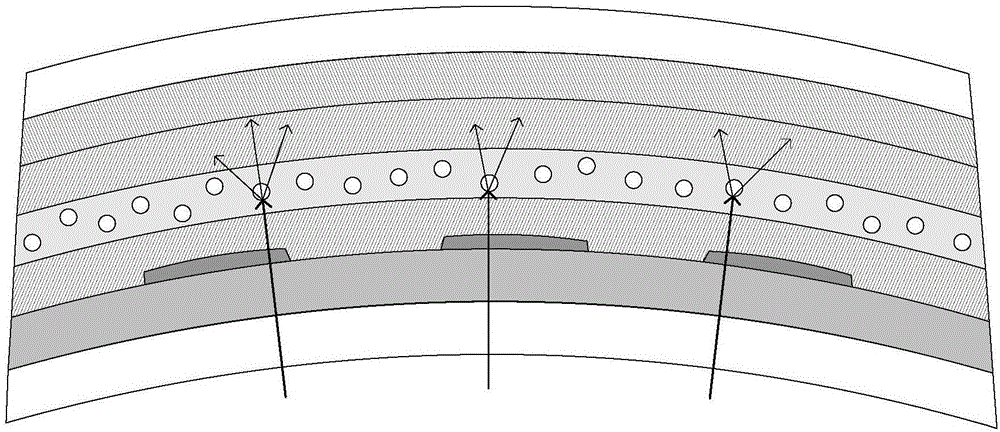

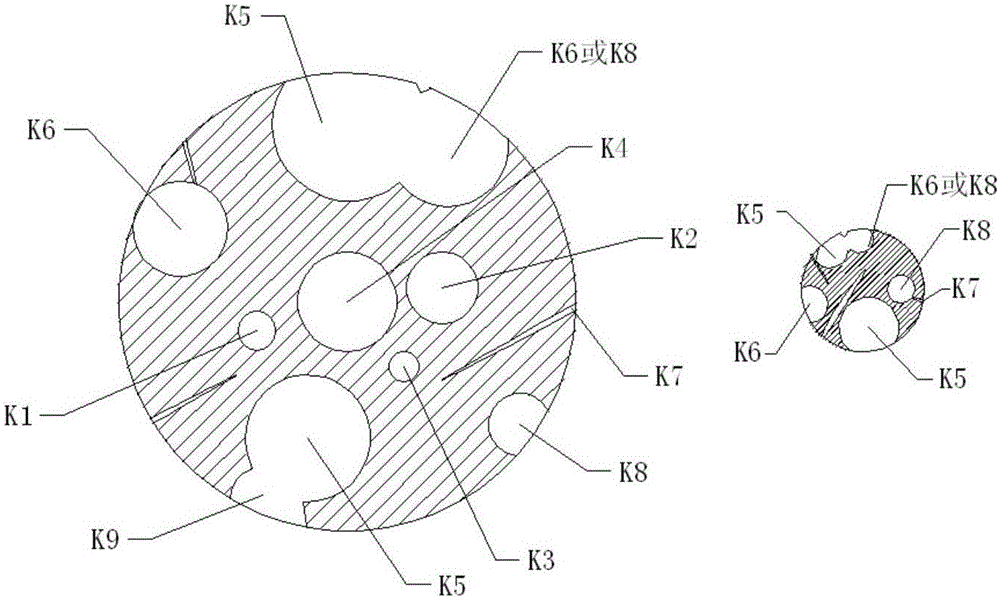

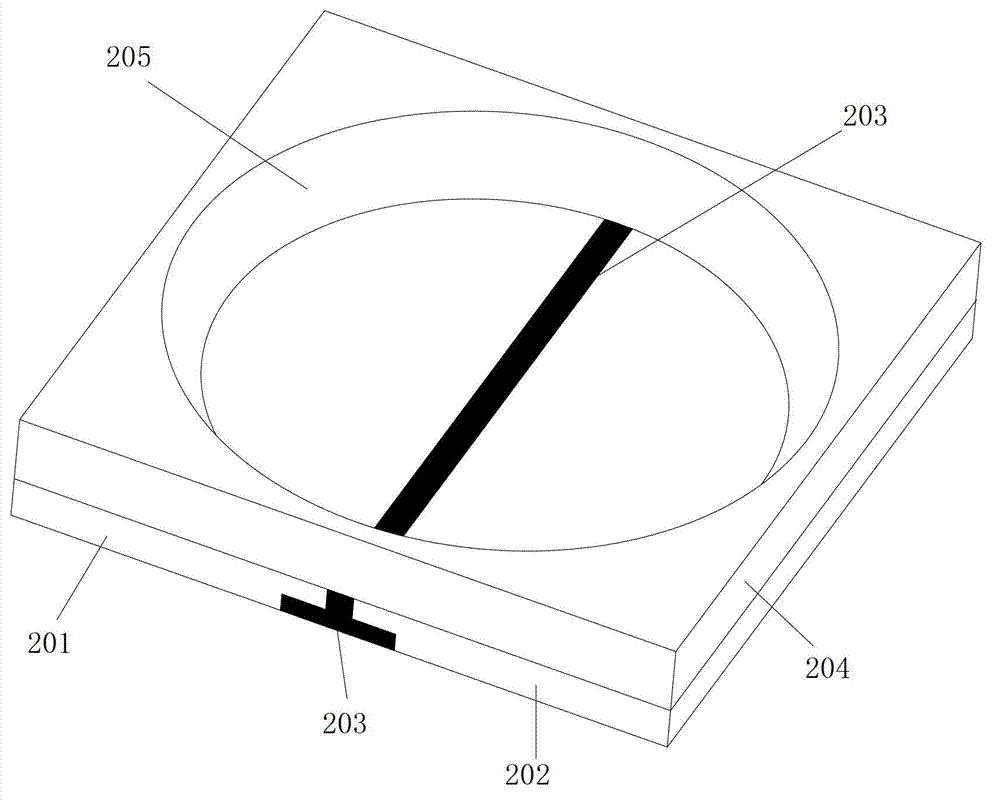

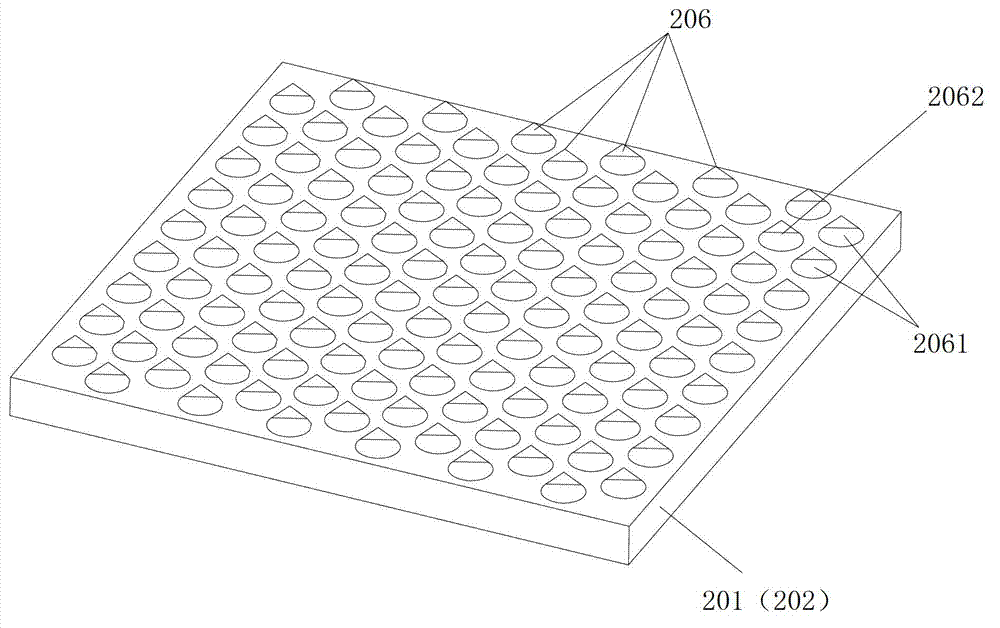

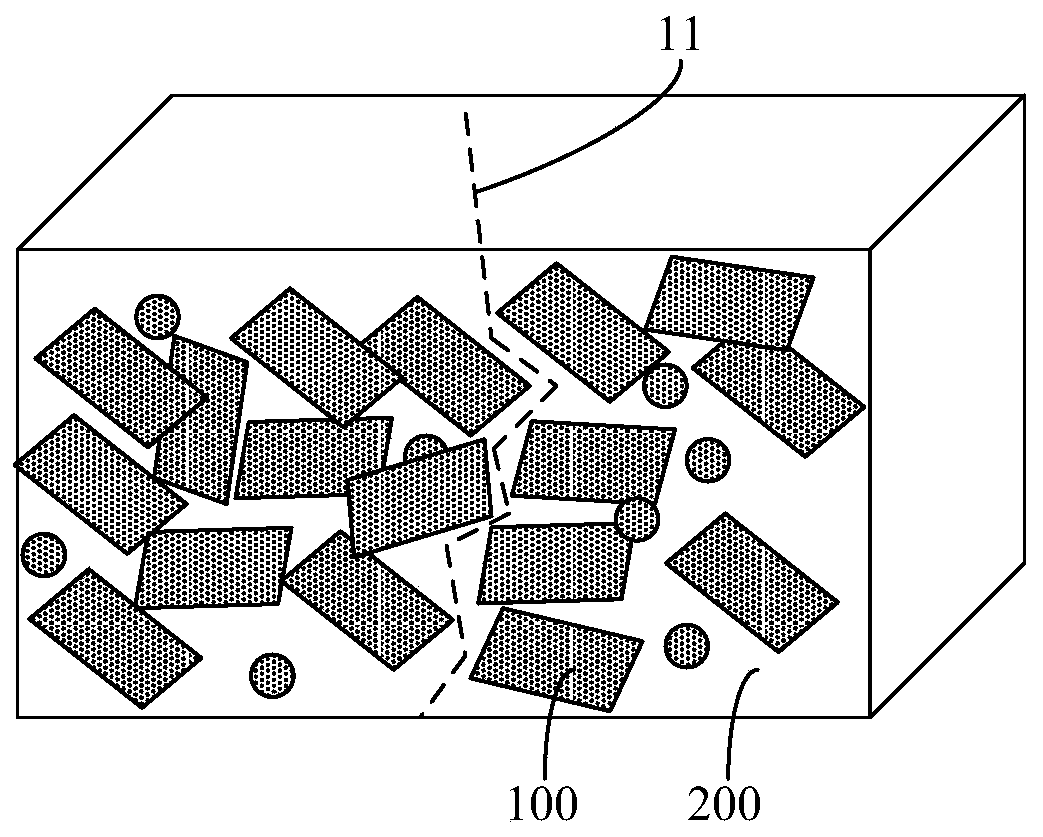

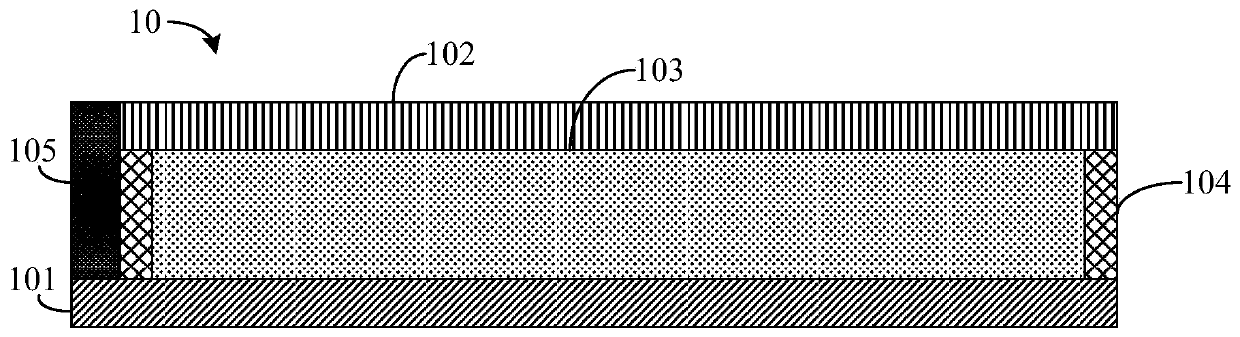

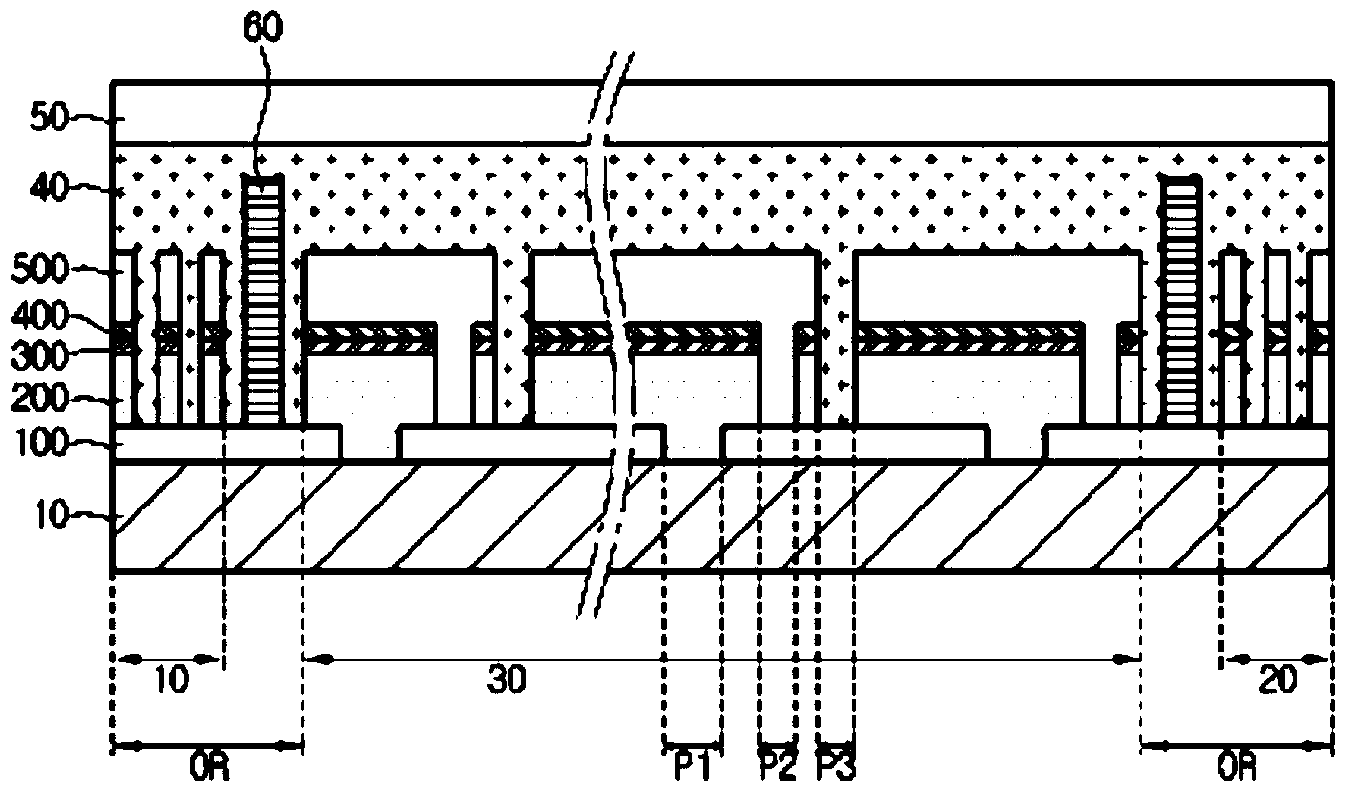

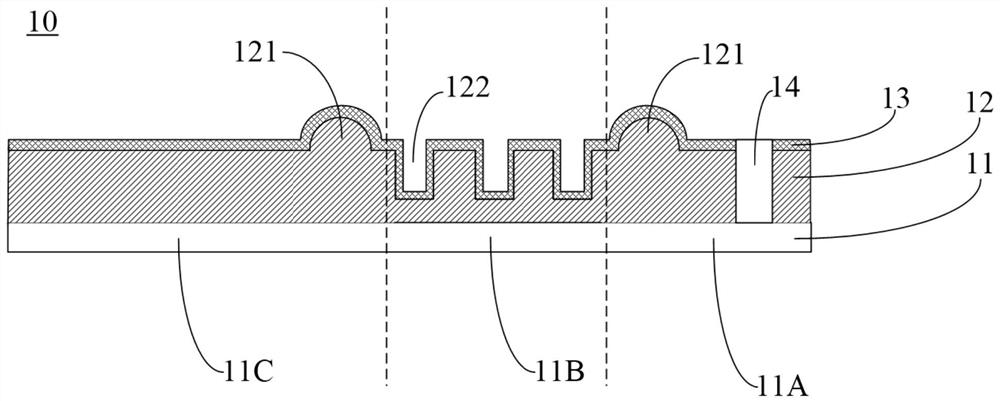

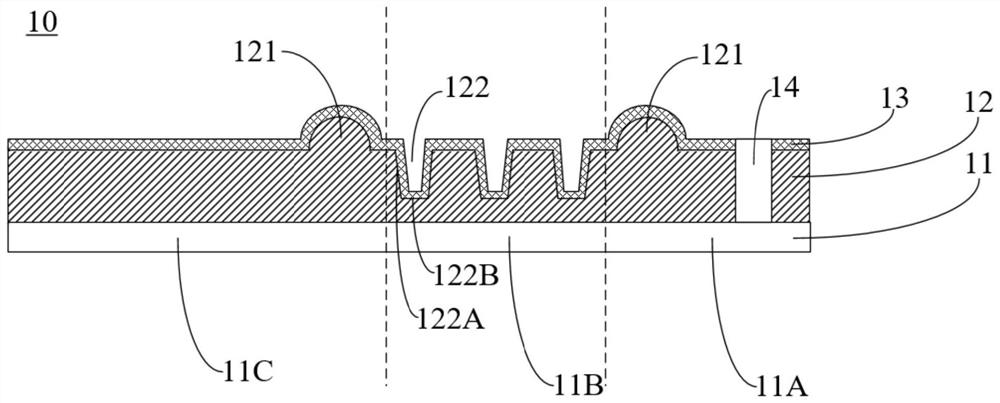

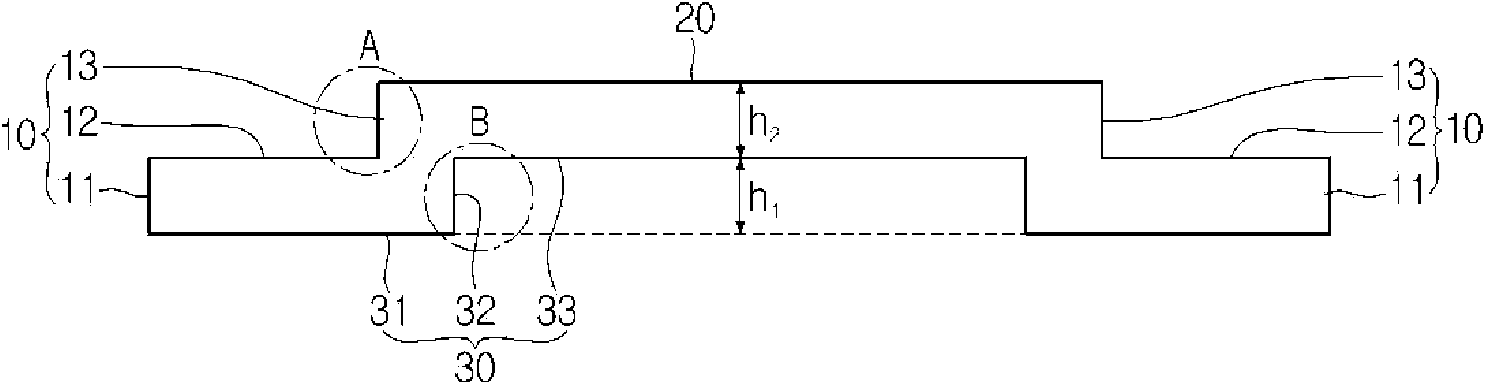

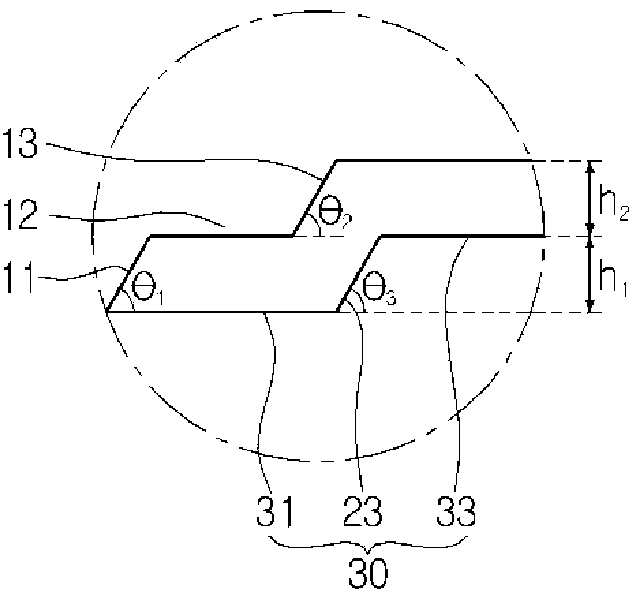

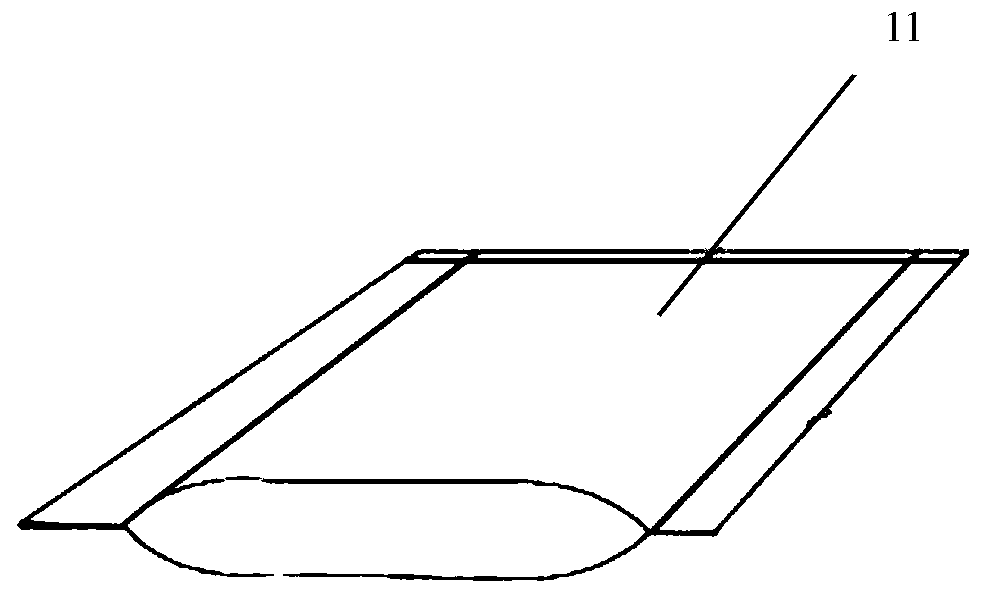

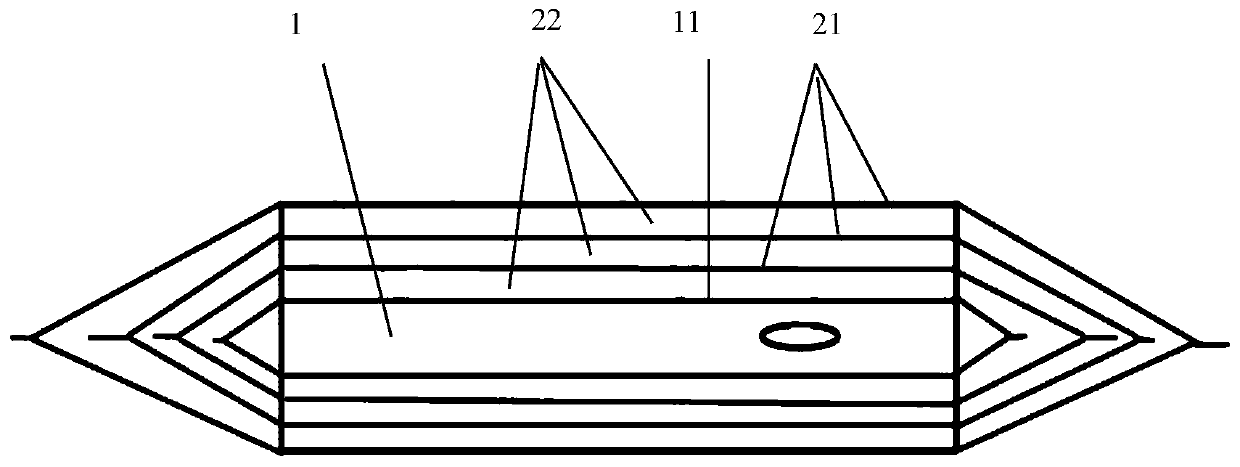

Display panel and preparation method

ActiveCN106206994AImprove stress concentrationExtended permeation pathFinal product manufactureSolid-state devicesMicrostructureCorrosion

The invention provides a display panel and a preparation method. The stress of stress faces of water resisting layers in the buckling process is dispersed through a microdroplet microstructure in an organic buffer layer, and the problems that the stress of the stress faces of the water resisting layers is centralized and the problem that due to water resisting layer fracture caused by the toughness difference of the water resisting layers, new water molecule corrosion channels are formed at fracture positions are changed. The microdroplet microstructure in the organic buffer layer lengthen the path of water molecule permeation, the time for water molecules to reach a light emitting layer in the display panel is prolonged, and the service life of devices of the light emitting layer is prolonged. The display panel comprises the first inorganic water resisting layer, the second inorganic water resisting layer and the organic buffer layer located between the first inorganic water resisting layer and the second water resisting layer. The organic buffer layer comprises the microdroplet microstructure used for dispersing stress of the organic buffer layers.

Owner:BOE TECH GRP CO LTD

Epoxy polyurethane anticorrosive coating capable of resisting light aging and preparation method

InactiveCN101597455AImproves photoaging performanceEffectively adjust viscosityAnti-corrosive paintsEpoxy resin coatingsEpoxyPhosphate

The invention discloses an epoxy polyurethane anticorrosive coating capable of resisting light aging and a preparation method; A component is prepared by mixing, stirring and grinding epoxy resin with medium molecular weight, hydroxyl-containing polyester resin, dimethylbenzene, butyl acetate, titanium pigment, ultraviolet absorber, talcum powder, mica powder, organosiloxane, isopropyl tri (dioctylpyrophosphato) titanate, poly-organic phosphate and the like; B component is prepared by mixing and stirring diphenylmethane diisocyanate and biuret. A component and B component are uniformly mixed according to weight ratio of 4:1 to be used. The epoxy polyurethane anticorrosive coating is capable of resisting light aging and has excellent corrosion resistance against acid, alkali and salt and salt fog resistance. The invention is external anticorrosive preferential coating for steel structures under severe environment such as chemical factories, refineries and the like.

Owner:CNPC RES INST OF ENG TECH

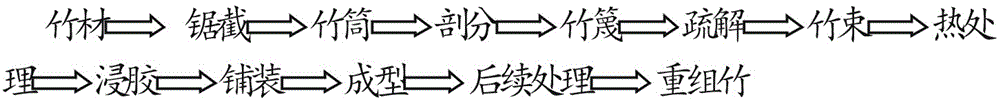

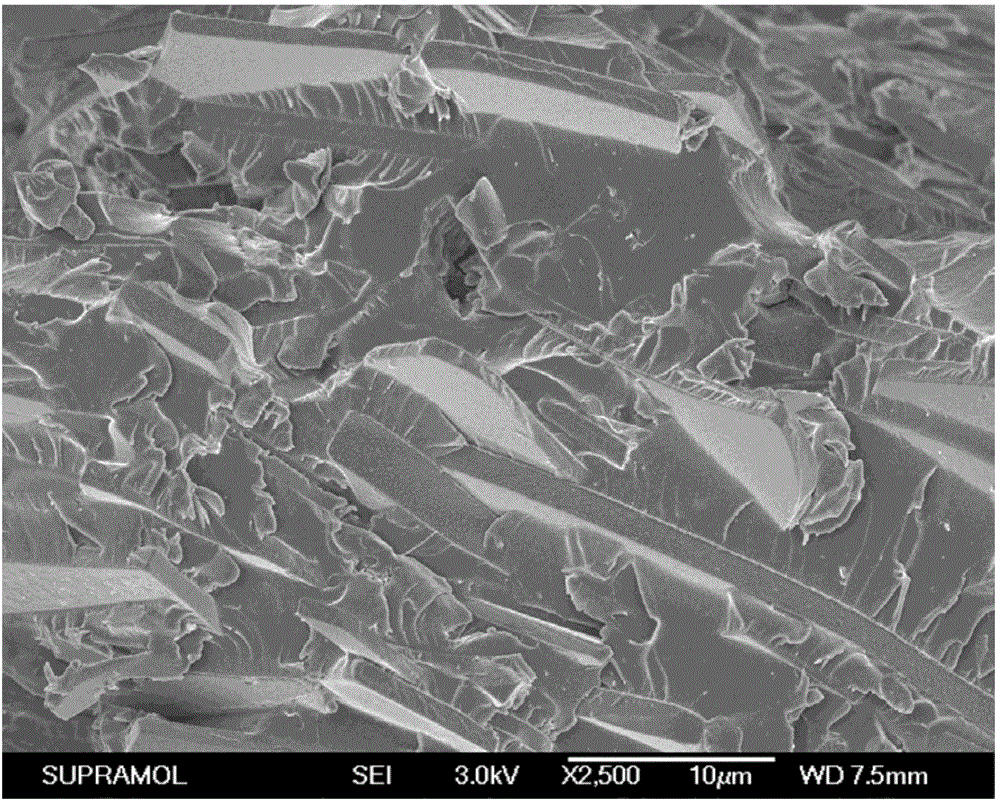

Preparing method of high-weather-resistance reconsolidated bamboo

ActiveCN105619570AControl thicknessReduce widthWood treatment detailsReed/straw treatmentWeather resistanceFiber bundle

Disclosed is a preparing method of high-weather-resistance reconsolidated bamboo. A pressure tank is adopted to treat bamboo ties, and is placed in hot oil, so that sealing performance in the heat treatment process is ensured; the temperature of heat treatment can be up to 250 DEG C, and nutrient substances such as protein, starch and low carbon sugar in the bamboo can be fully degraded; through improvement of a subdivision and defibering process, the thickness of bamboo strips is controlled, the width of bamboo fiber bundles is controlled, and a seepage path of water steam and adhesive of the bamboo in a heat treatment process and a gum dipping process is improved; through the control over the gum dipping process and the molecular weight of adhesive, the gum dipping amount and gum dipping uniformity are ensured; and through the control over a paving technology and a forming technology, density of a product and uniformity of the density are ensured, and the reconsolidated bamboo is prepared. The properties of size stability, corrosion prevention, mould prevention and the like of the product are improved, and the use requirement of the outdoor reconsolidated bamboo for weather resistance is met.

Owner:NANJING FORESTRY UNIV

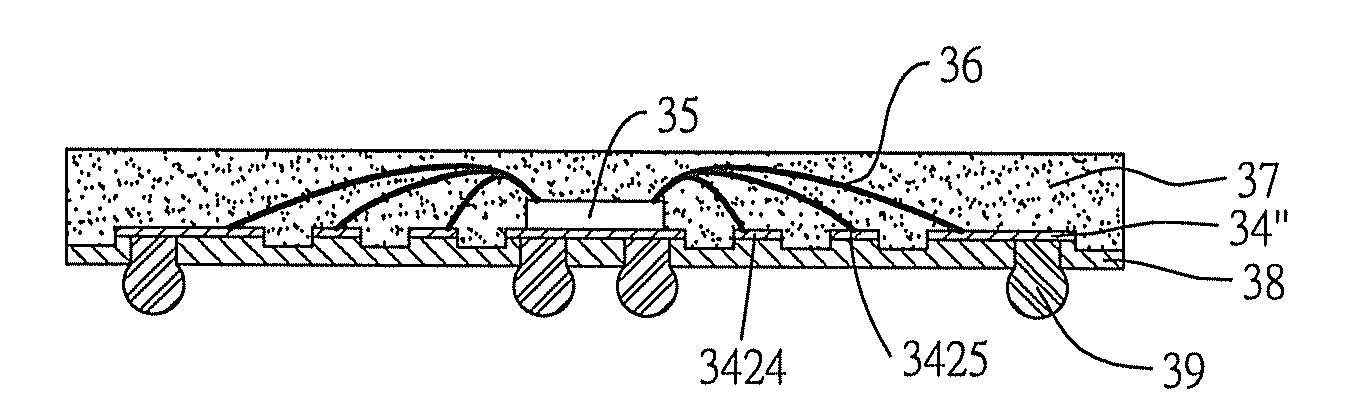

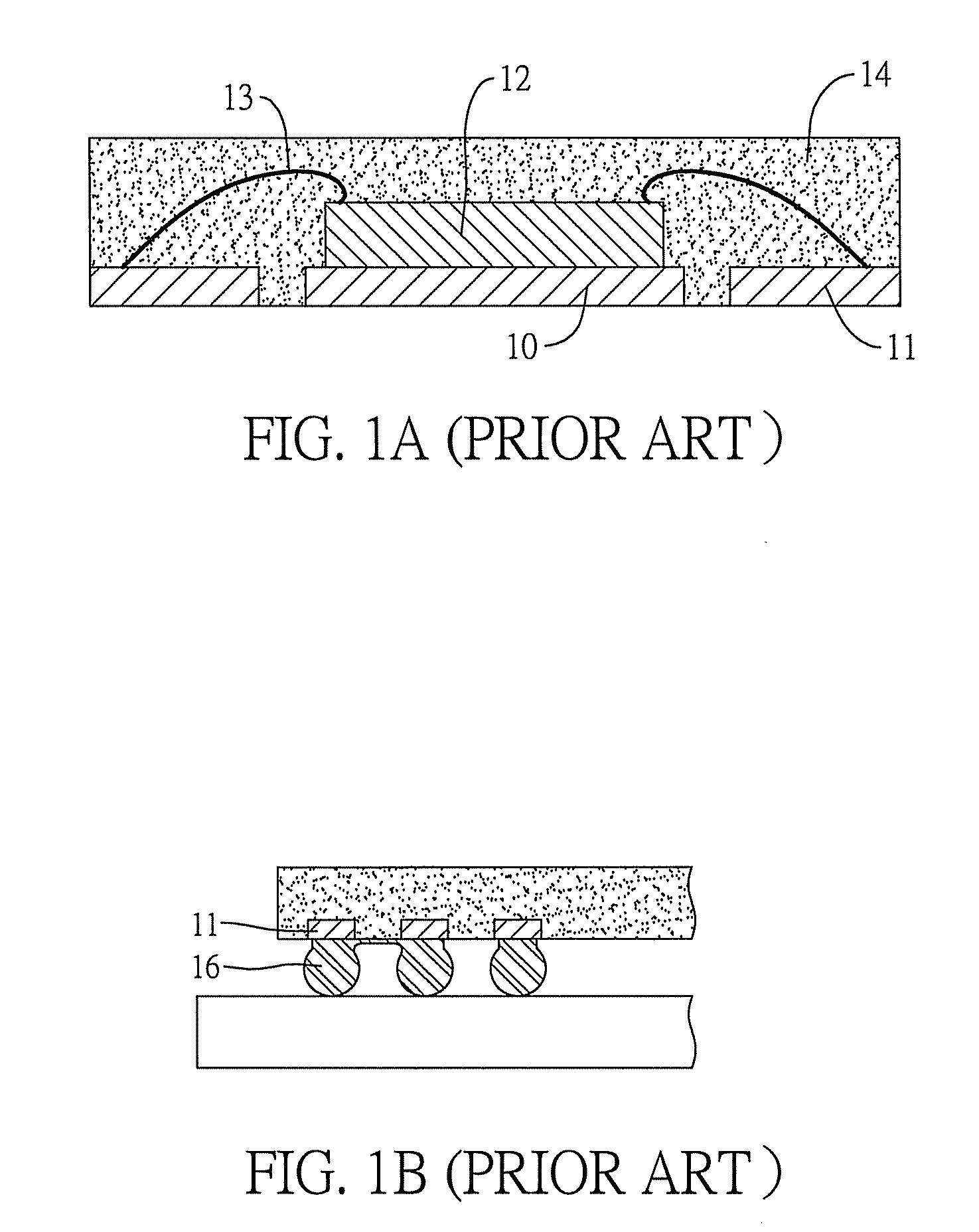

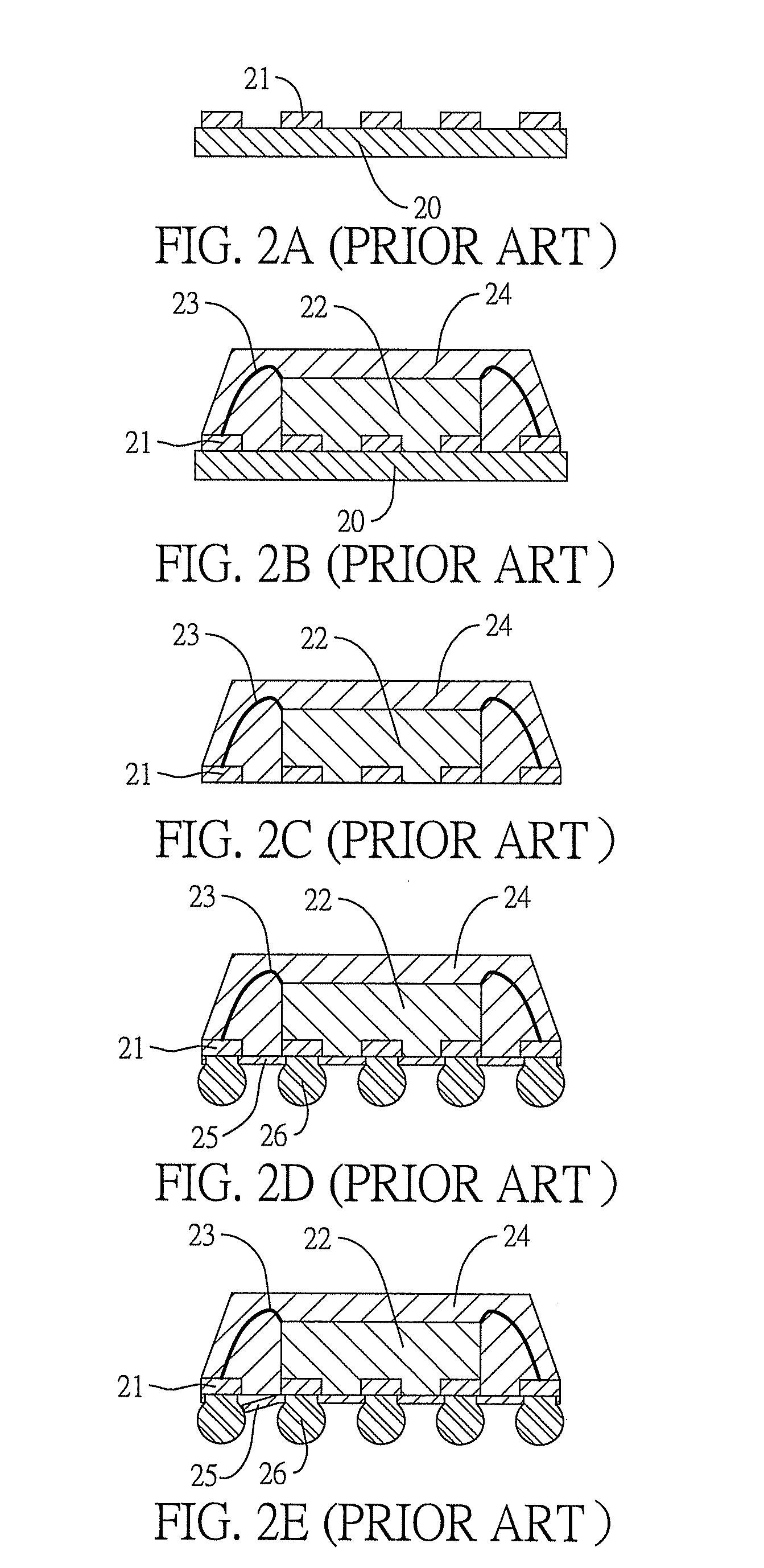

Semiconductor package having electrical connecting structures and fabrication method thereof

ActiveUS20110156252A1Shorten the lengthReduce packaging costsSemiconductor/solid-state device detailsSolid-state devicesSolder maskSolder ball

A semiconductor package having electrical connecting structures includes: a conductive layer having a die pad and traces surrounding the die pad; a chip; bonding wires; an encapsulant with a plurality of cavities having a depth greater than the thickness of the die pad and traces for embedding the die pad and the traces therein, and the cavities exposing the die pad and the traces; a solder mask layer formed in the cavities and having a plurality of openings for exposing the trace ends and a portion of the die pad; and solder balls formed in the openings and electrically connected to the trace ends. Engaging the solder mask layer with the encapsulant enhances adhesion strength of the solder mask layer so as to prolong the moisture permeation path and enhance package reliability.

Owner:SILICONWARE PRECISION IND CO LTD

Precious wood imitating dyeing method

InactiveCN106078990AImprove reliabilityExtended permeation pathPressure wood treatmentWood treatment detailsPositive pressureSodium sulfate

The invention discloses a precious wood imitating dyeing method. The precious wood imitating dyeing method comprises the following technology steps that firstly, dye liquor is prepared, the dye liquor is prepared through three kinds of dyestuff including reactive red, reactive yellow and reactive blue according to the mass ratio of (2-3):(4-7):1, sodium chloride or sodium sulfate with the concentration of 5 g / L-40 g / L is added to serve as a dyeing accelerant, and sodium carbonate or ammonium chloride or propylene glycol with the concentration of 20 g / L-60 g / L is added to serve as a dye fixing agent; and secondly, impregnation dyeing is conducted, dyed wood is immersed in the dye liquor with the concentration of 0.5%-5% and the bath ratio of 1:(10-40) in a vacuum impregnation tank, dyeing is conducted in a negative pressure and positive pressure alternating manner, the dye liquor sufficiently seeps into the wood, and the surface, the inner portion and the outer portion of the dyed wood are uniform. The method has the beneficial effects that the wood treated through the provided precious wood imitating dyeing formula and the provided dyeing method is clear in texture, the total color difference between the wood color and the target wood color is smaller than or equal to 1.5 NBS, and permeability and color uniformity of the dyeing liquor are good.

Owner:梅州市汇胜木制品有限公司 +1

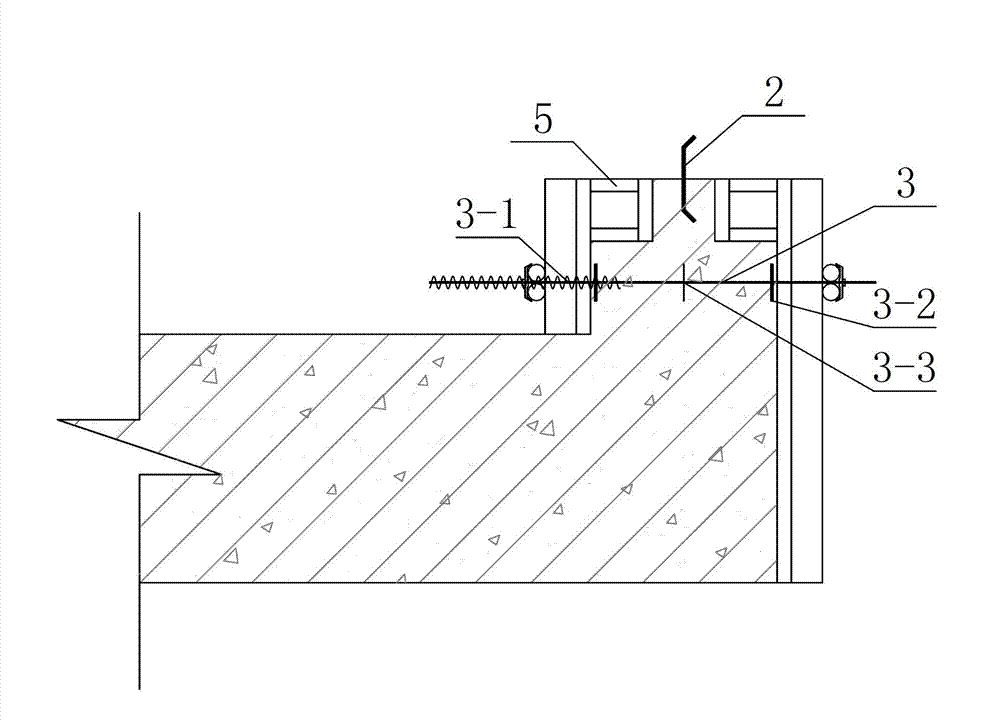

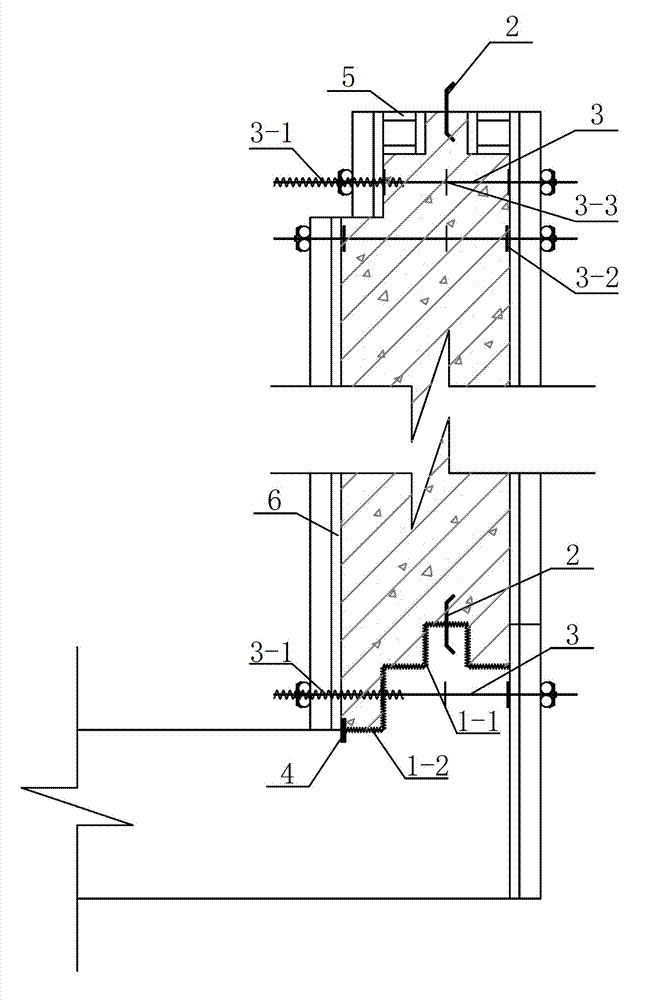

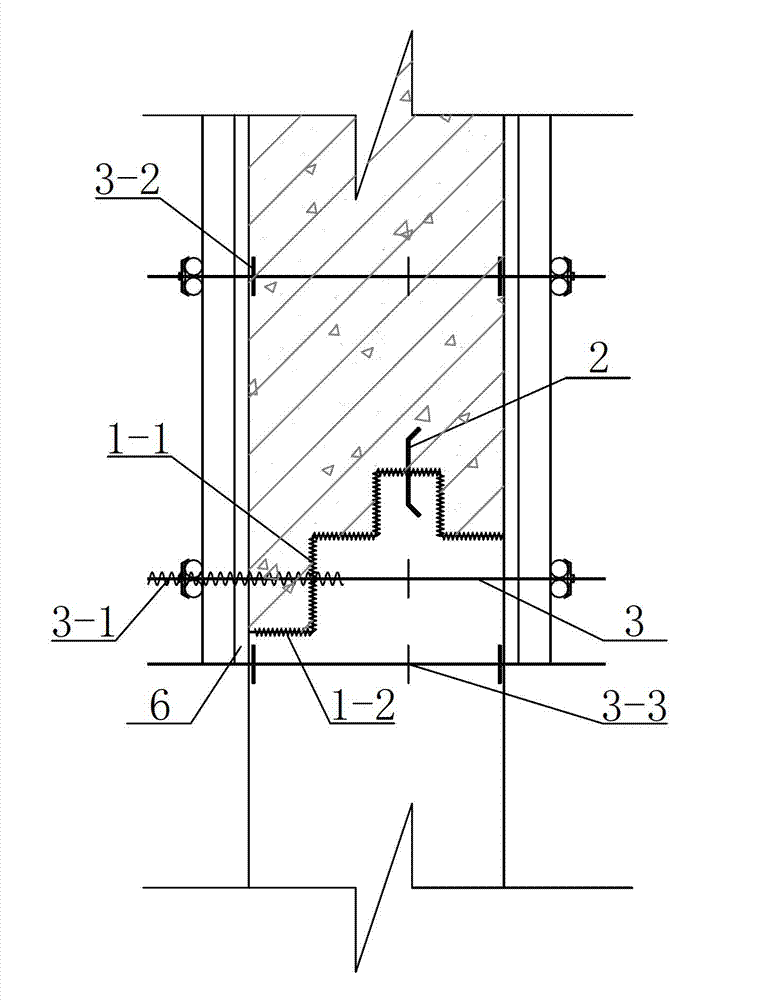

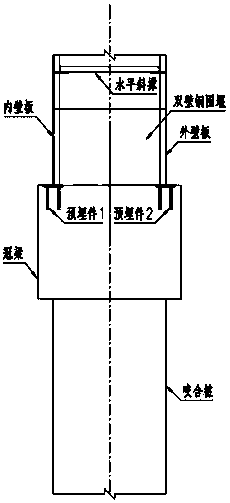

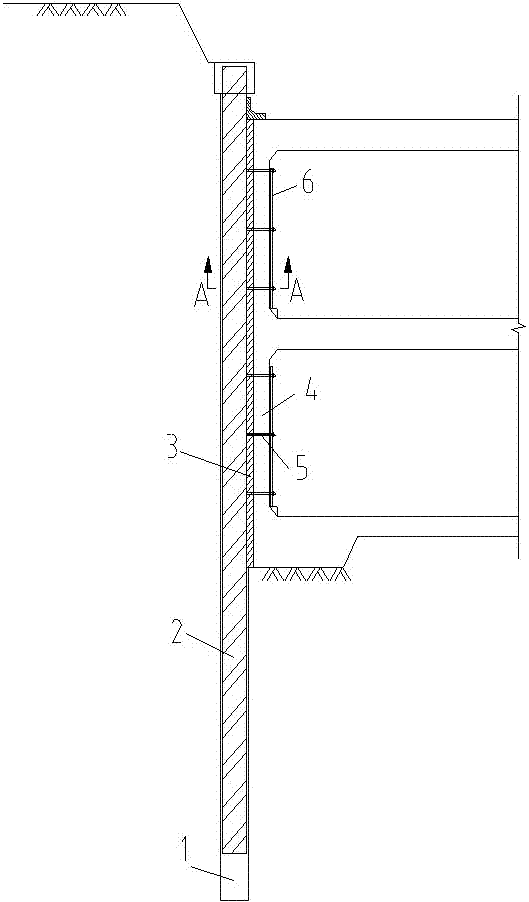

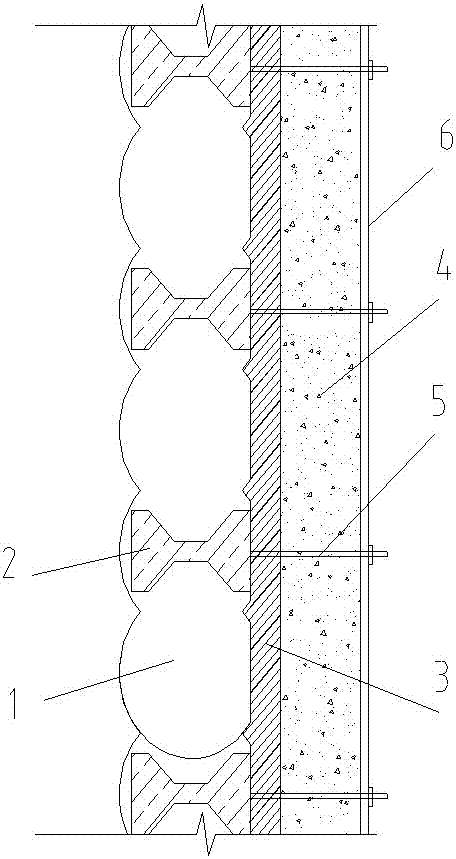

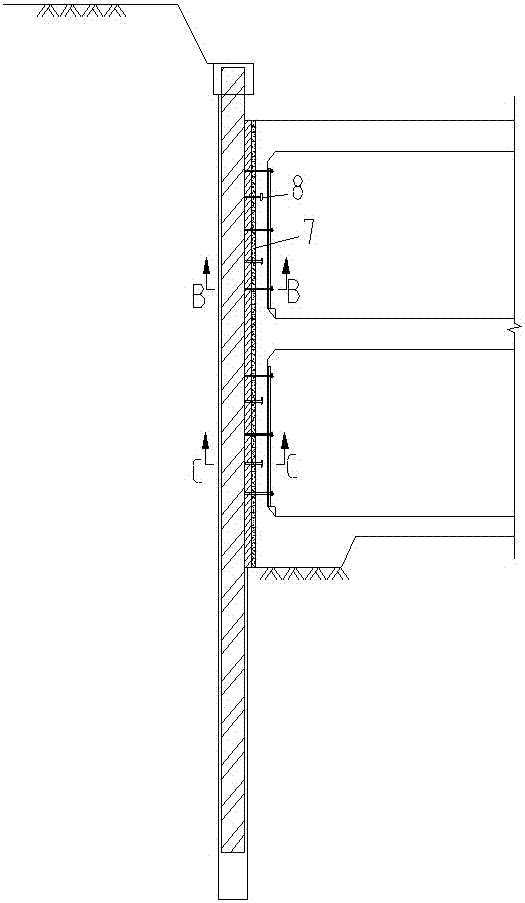

Construction gap of underground waterproof concrete structure and wall template installation method thereof

ActiveCN102900103AExtended permeation pathImprove impermeabilityArtificial islandsUnderwater structuresArchitectural engineeringSurface construction

The invention discloses a construction gap of an underground waterproof concrete structure and a wall template installation method thereof. Aiming at the technical problem that a wall template of a ladder-shaped construction gap is difficult to install and easy to deform, on the basis of a novel ladder-shaped construction gap, short wood beams are used for controlling forming of the construction gap, the template is fixed by a split boltwith reserved threads secondarily, numerous specific construction measures of a reinforced steel bar blocking foot fixed on a base plate, a transom arranged on the split bolt and the like reduce wall surface construction gaps, improve impression quality of concrete surface, improve anti-permeability capacity of the waterproof concrete structure, reduce leakage of buildings, guarantee that the structure is more stable, controlsectional dimension of a wall body, prevent the wall body from deforming, guarantee construction quality, is simple and easy inconstruction operation, improve working efficiency, and reduce construction cost.

Owner:TIANJIN 20 CONSTR

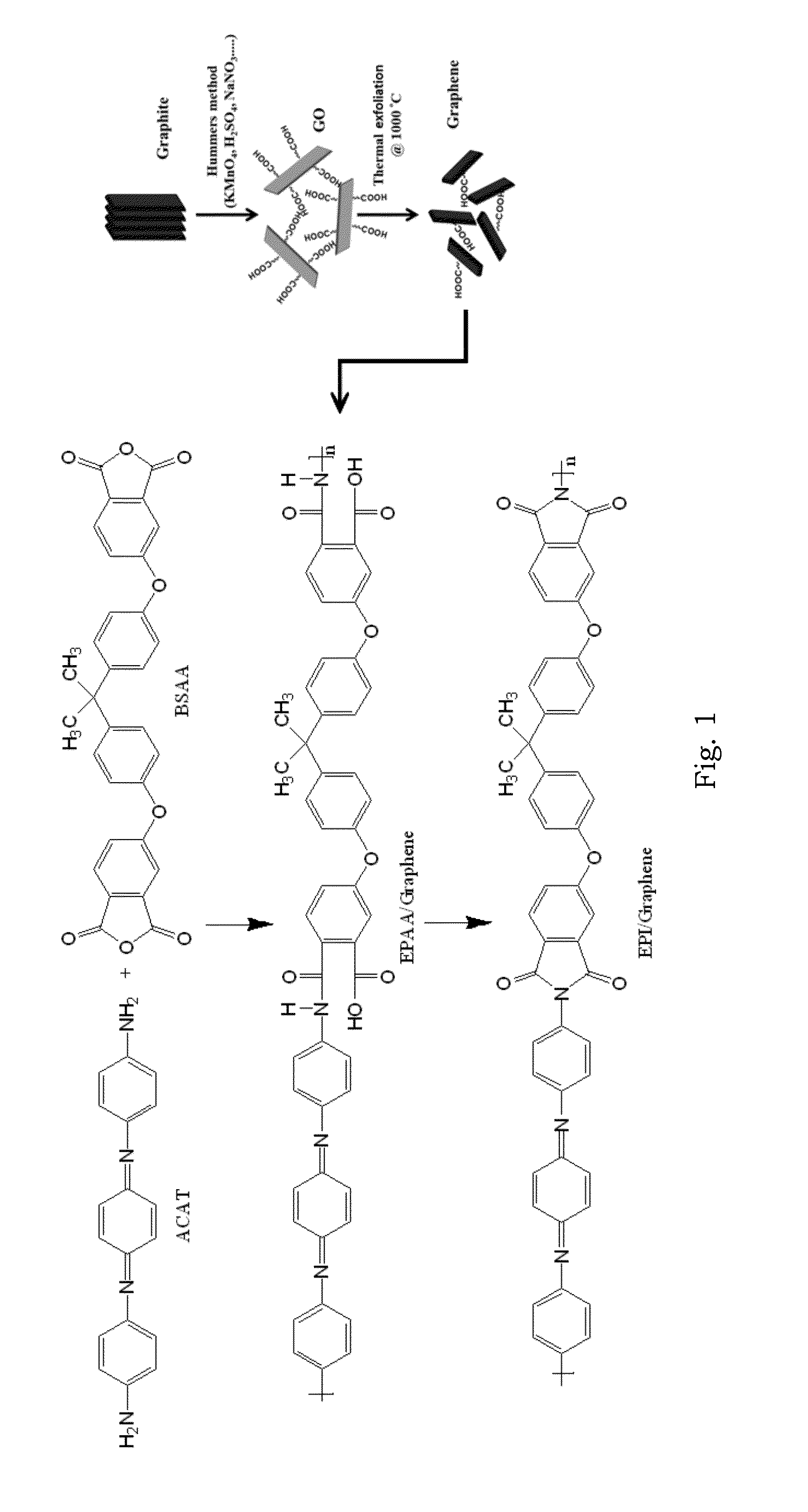

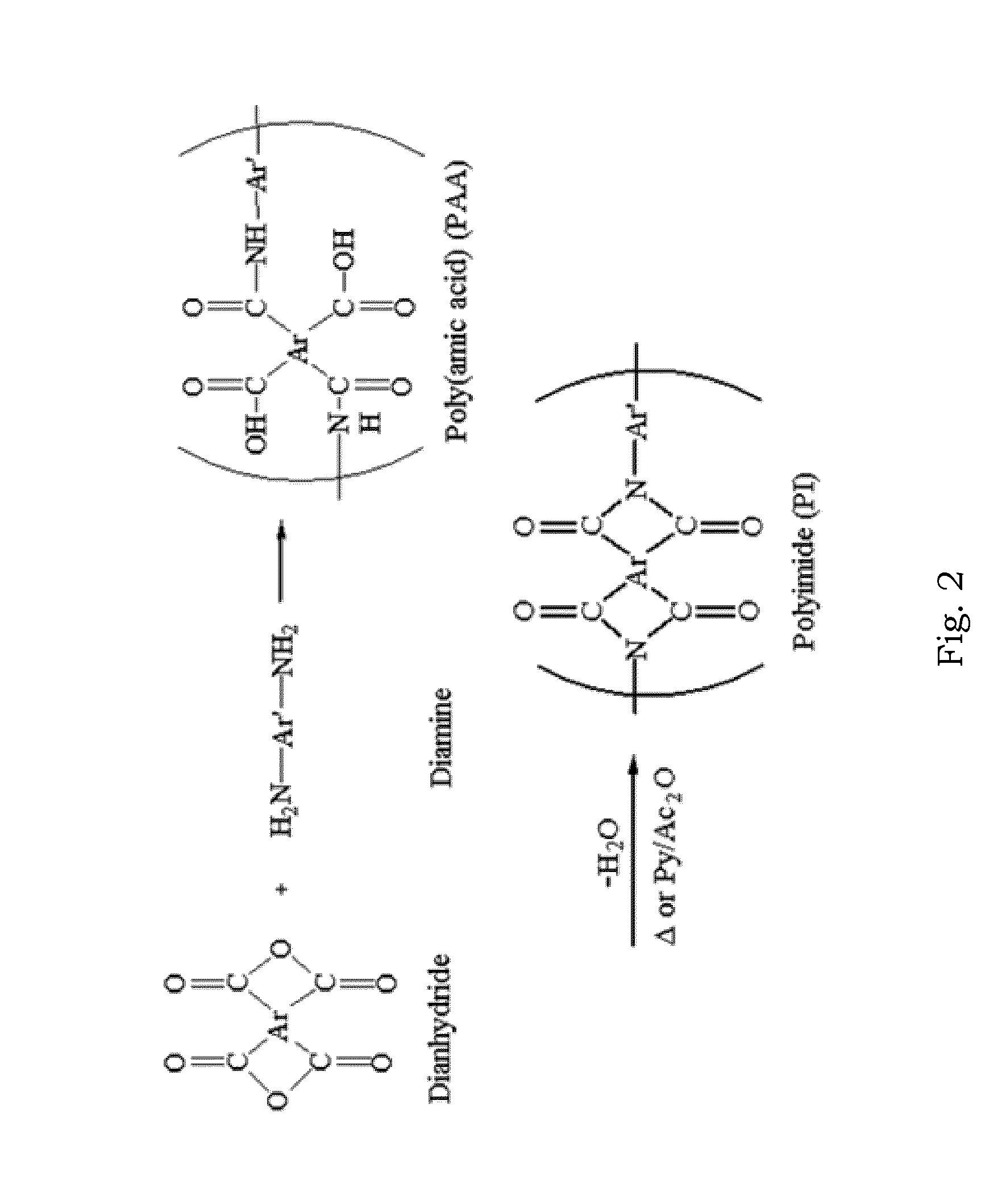

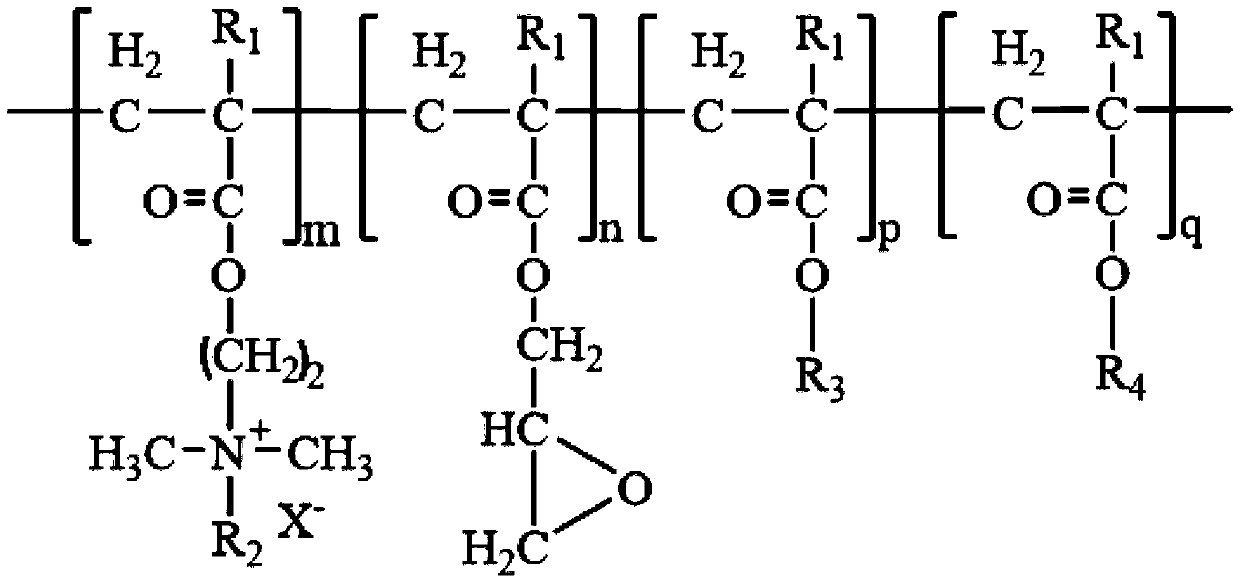

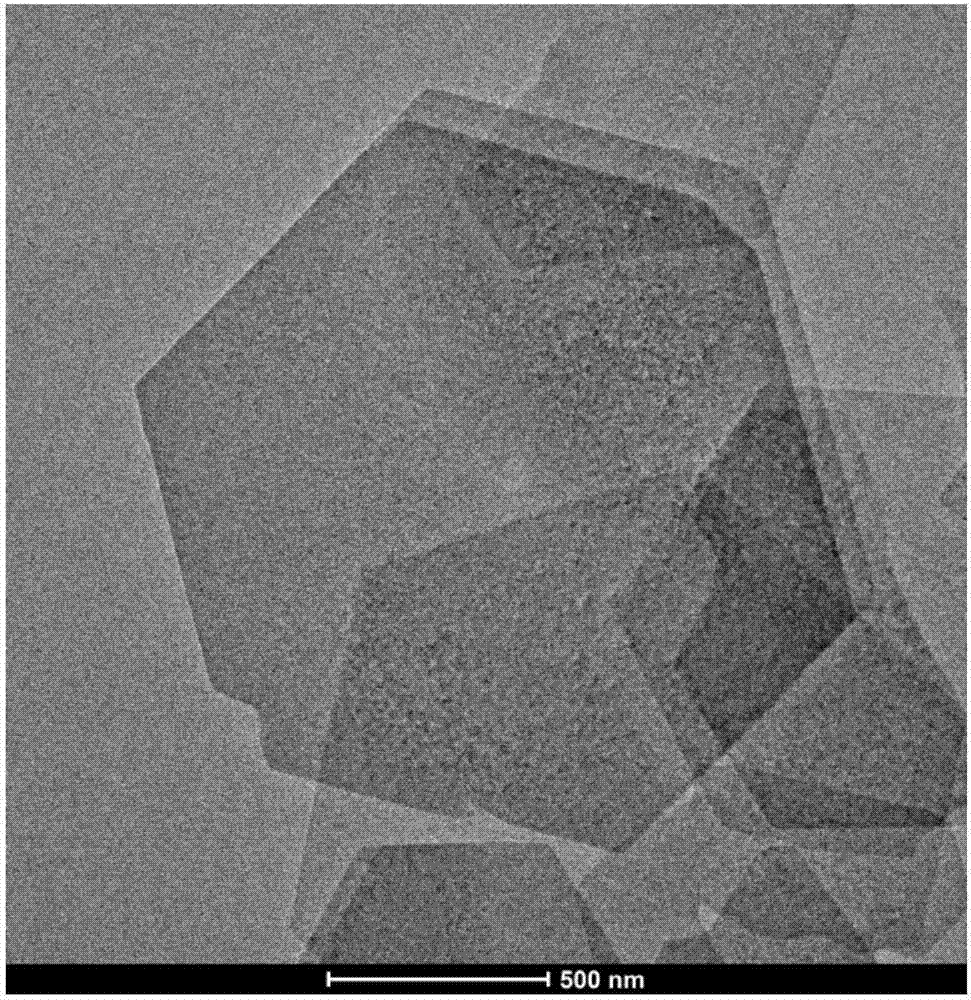

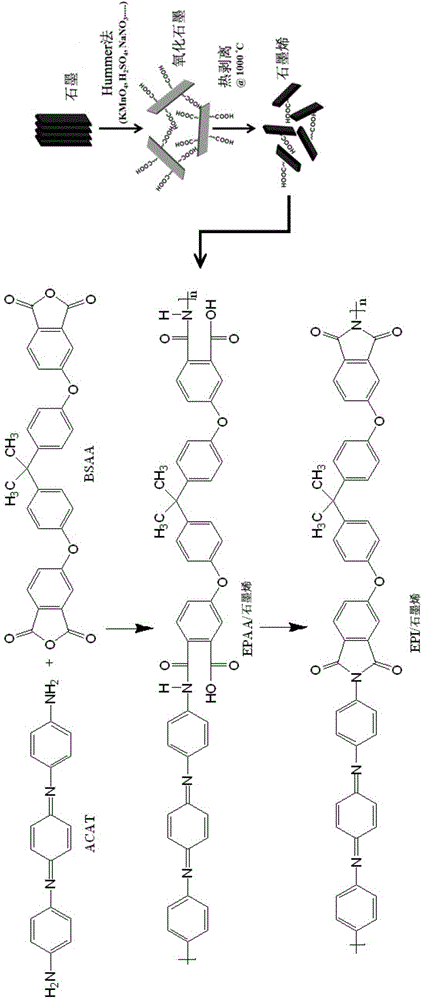

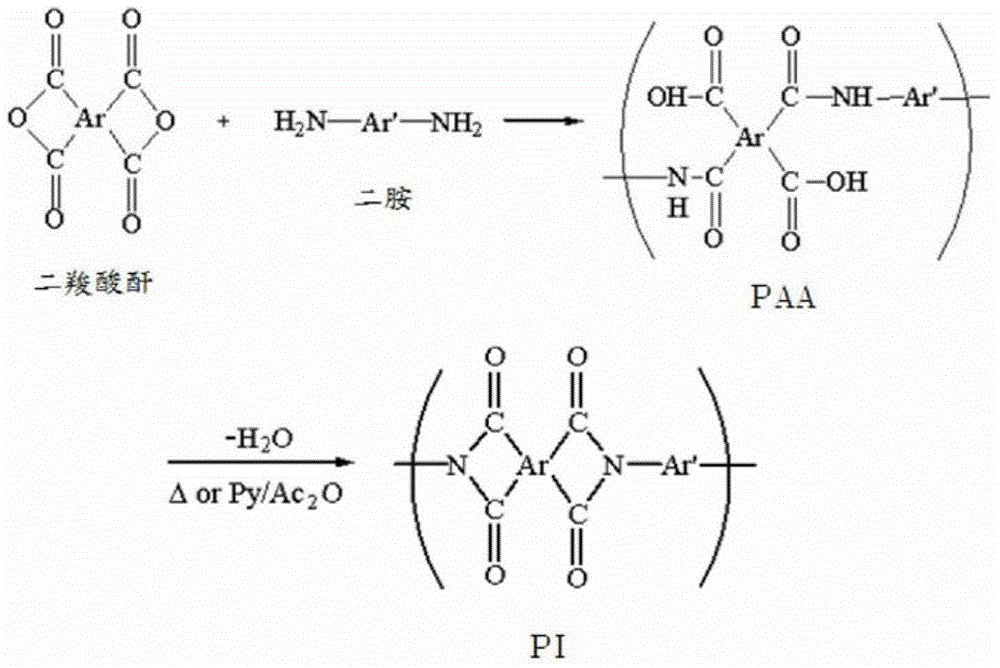

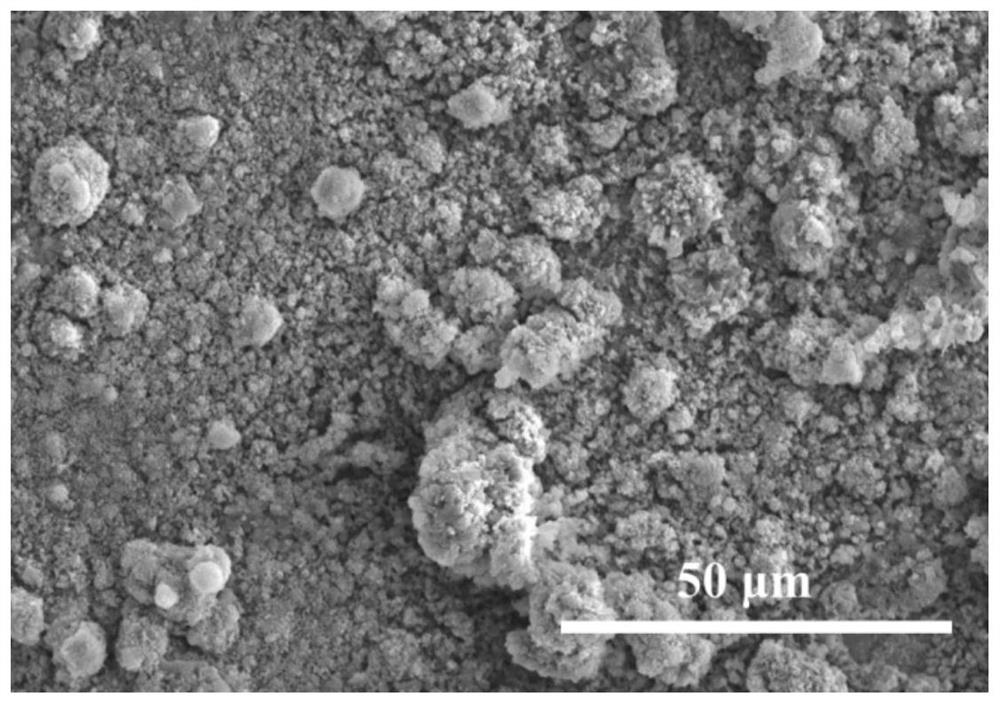

Polymer And Graphene Blended Electroactive Composite Coating Material And Method For Preparing The Same

InactiveUS20150315387A1Improve corrosion resistanceLow corrosion rateAnti-corrosive paintsPolyamide coatingsEpoxyPolymer science

The present invention provides a polymer and graphene blended electroactive composite coating material and method for preparing the same. The composite coating material is a composite material formed by blending a specific polymer and graphene; where the specific polymer is formed by polymerization of (A) aniline oligomer and (B) amino reactive monomer together with (C) modified graphene and is a kind of polymer selected by the group consisting of the following: epoxy resin, polyimide, polyamide, polyurethane, polylactic acid; (C) modified graphene is uniformly dispersed in the matrix of the specific polymer but not involved in polymerization; and the composite coating material is electroactive.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Wear-resistant nonskid polyurethane deck paint, and manufacture method thereof

InactiveCN102190954AGood chemical stabilityImprove acid and alkali corrosion resistancePolyurea/polyurethane coatingsGas phaseWear resistant

The invention relates to a wear-resistant nonskid polyurethane deck paint, and a manufacture method thereof. The manufacture method comprises the following steps of: adding a hydroxyl acrylic resin, polyether polyol, hydroxyl-containing fluorocarbon acrylic resin, a polyacrylate copolymer solution, poly(methyl alkyl siloxane) solution and [b-[3-(2-H-benzotriazol-2-yl)-5-(1,1-dimethylethyl)-4-hydroxyphenyl]-1-oxopropyl]-hydroxypoly(oxo-1,2-ethanediyl) to a mixed solvent of xylene, n-butyl acetate, methyl isobutyl ketone and butanone for high-speed stirring; adding rutile titanium white powder, talcum powder, aluminum oxide ceramic powder, sericite powder, silicon micropowder, carbon black and gas-phased silicon dioxide; milling with a sand mill while controlling fineness of a mixture not higher than 60 mu m to obtain a liquid A; and forming a liquid B by a mixed solution of 1,6-hexamethylene diisocyanate tripolymer, anhydrous xylene and n-butyl acetate, and mixing 1 weight part of the liquid A with 0.2-1.0 weight part of the liquid B for use. The obtained wear-resistant nonskid polyurethane deck paint can be used for the corrosion protection of the steel surfaces of deck and ocean facilities.

Owner:TIANJIN BO XING ENG SCI & TECH LIMITED COMPANY OF CNPC +2

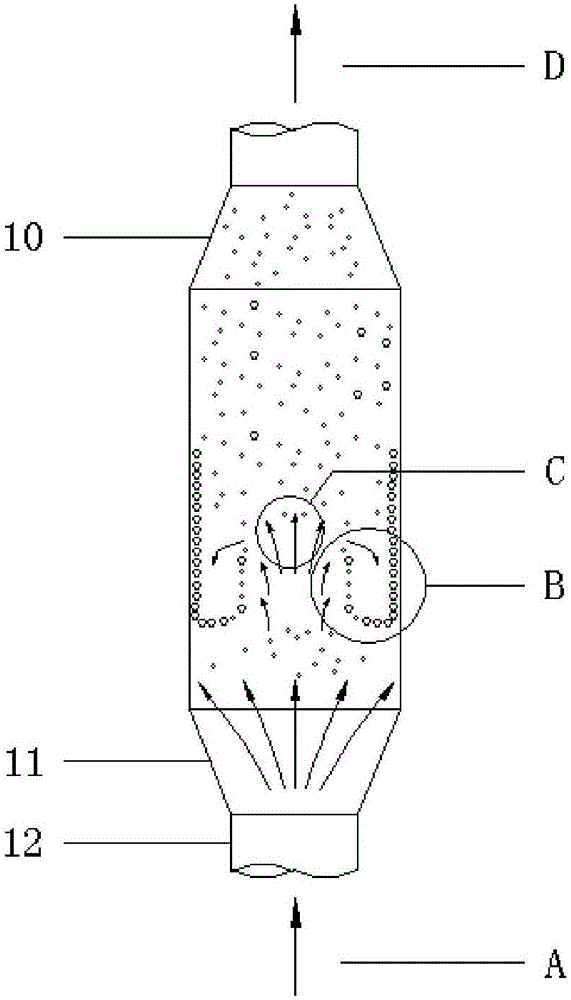

Roasting-ammonia leaching processing method for brown iron type laterite nickel ore

A roasting-ammonia leaching processing method for brown iron type laterite nickel ore includes the steps that firstly, suspension fluidized roasting is performed on ore powder of the brown iron type laterite nickel ore and reduction gas, nickel oxide and cobalt oxide in the ore powder are fast and dynamically reduced into metal nickel and metal cobalt within 20-120 s, brown iron is reduced into magnetic iron, roasted ore is obtained, and according to the technological condition of roasting, temperature is 600-900 DEG C, and the volume percentage of CO in reducing gas is 2-7%; secondly, magnetic separation is performed on the roasted ore, and magnetite concentrate containing metal nickel and metal cobalt is obtained through separation; and thirdly, ammonia leaching is performed on the magnetite concentrate, and nickel and cobalt leaching agents and magnetic iron leaching slag are obtained. The method achieves the purpose of extracting and purifying nickel and cobalt and comprehensively recovering iron.

Owner:湖南长拓高科冶金有限公司

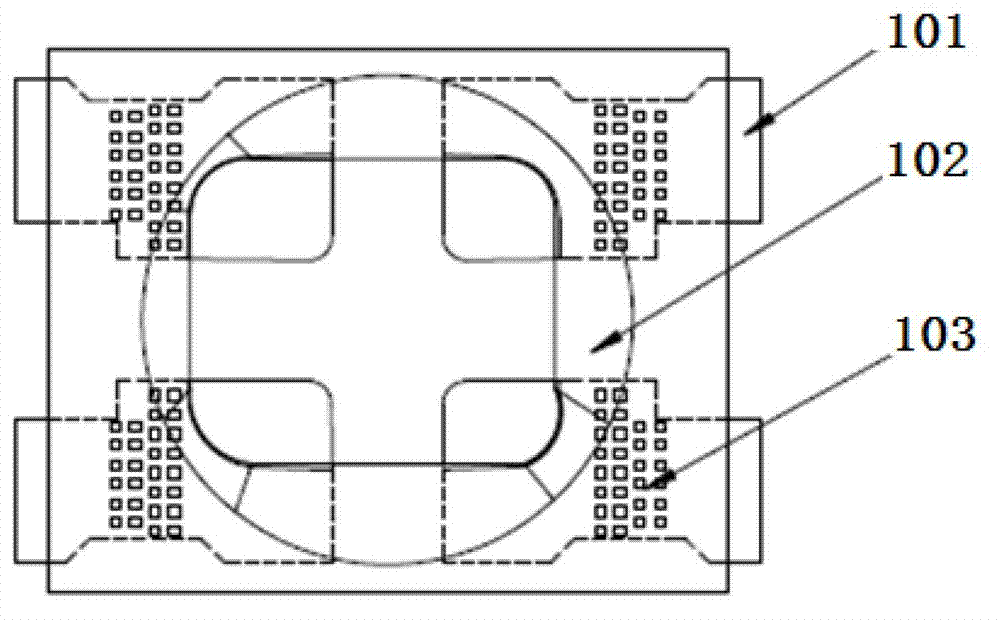

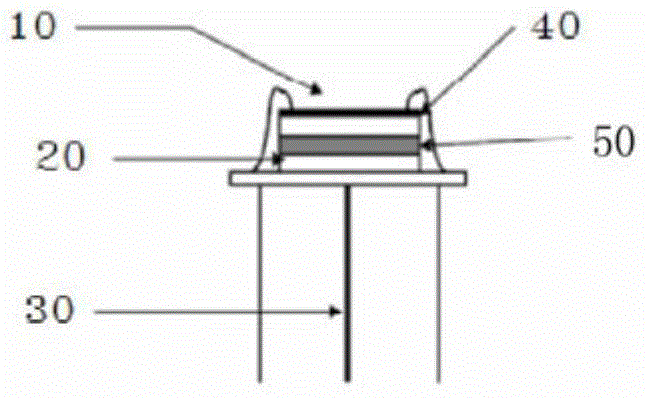

High-reliability LED (light emitting diode) bracket and LED device thereof

ActiveCN103400927AImprove stabilityIncrease contact areaSemiconductor devicesConvex structureAdhesive

The invention discloses a high-reliability LED (light emitting diode) bracket and an LED device thereof. The bracket comprises a first welding disc and a second welding disc, wherein the first welding disc and the second welding disc are used as conductive pins, the first welding disc and the second welding disc are connected together through an insulation connecting adhesive, the upper surfaces of the first welding disc and the second welding disc are provided with an insulation seat which is integrally formed with the connecting adhesive, the interior of the insulation seat is provided with a reflective cup for mounting an LED chip and reflecting the LED light rays, the upper surfaces of the first welding disc and the second welding disc, in contract with the insulation seat, are provided with a plurality of unit convex structures which are longitudinally and transversely staggered, and each unit convex structure of the back row is arranged relatively behind the gap between the two adjacent unit convex structures of the front row. The bracket and the LED device have the advantages that the firmness is further improved, the airtightness and the heat radiating performance are also improved, and the reliability is further improved.

Owner:APT ELECTRONICS

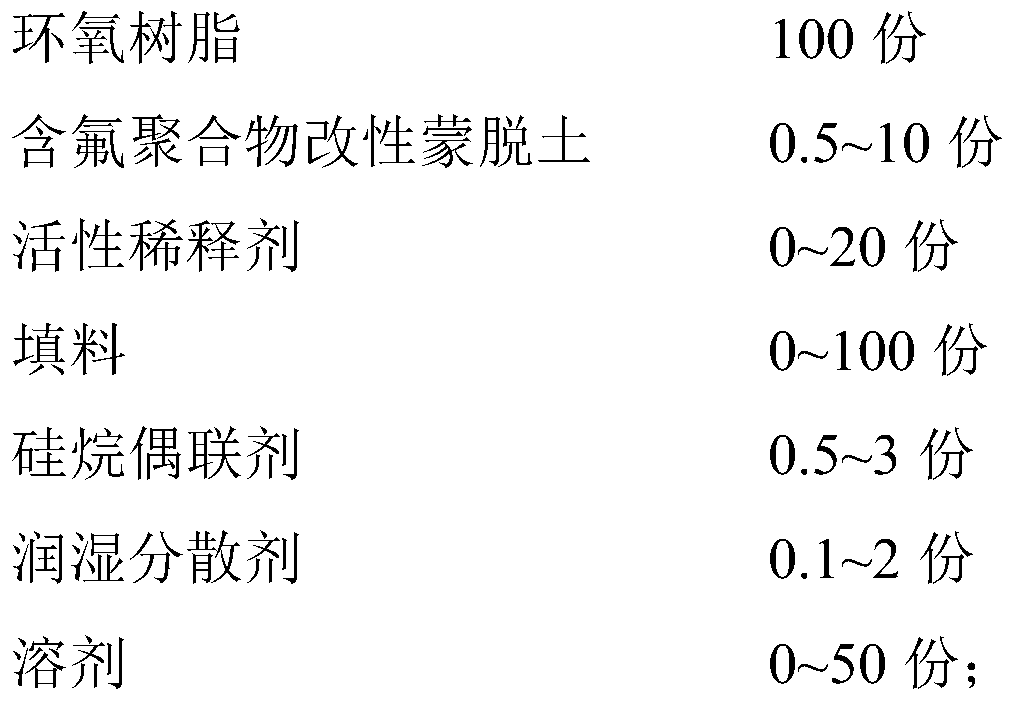

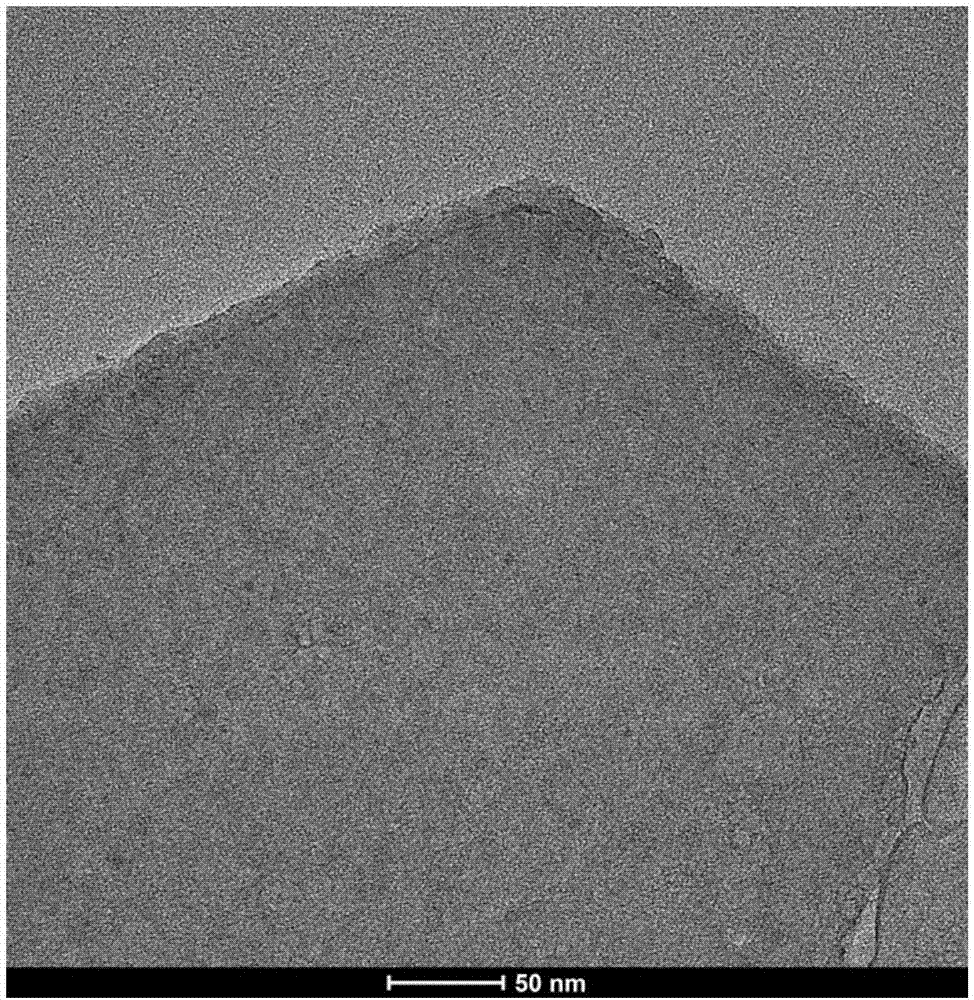

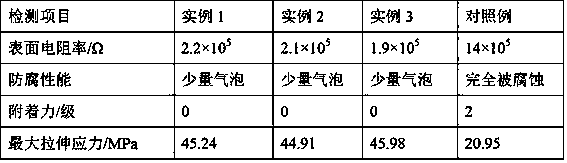

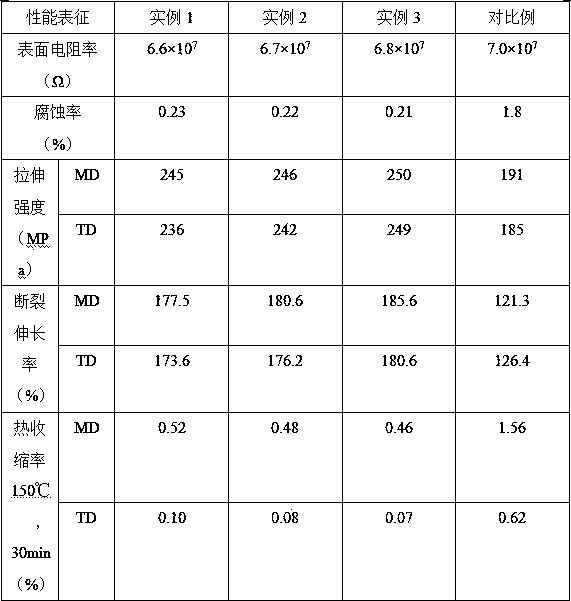

Epoxy resin anticorrosive coating with fluoropolymer modified montmorillonite as well as preparation method and application of coating

InactiveCN110240850AImprove abrasion resistance and hydrophobicityExtended permeation pathAnti-corrosive paintsEpoxy resin coatingsSolventDefoaming Agents

The invention discloses a wear-resistant hydrophobic epoxy resin anticorrosive coating with fluoropolymer modified montmorillonite as well as a preparation method and application of the coating. The coating comprises an A component and a B component; the A component specifically comprises the following materials, in parts by mass: 100 parts of epoxy resin, 0.5-10 parts of the fluoropolymer modified montmorillonite, 0-20 parts of a reactive diluent, 0-100 parts of a filler, 0.5-3 parts of a silane coupling agent, 0.1-2 parts of a wetting dispersing agent, and 0-50 parts of a solvent; the B component comprises the following materials, in parts by mass: 100 parts of a curing agent, 0.05-0.5 part of a defoaming agent, 0.05-0.5 part of a levelling agent, and 0-20 parts of a solvent; and a mass ratio of the A component to the B component is 100:(20-100). An anticorrosive coating layer prepared from the wear-resistant hydrophobic epoxy resin anticorrosive coating with the fluoropolymer modified montmorillonite provided by the invention has good hydrophobicity and corrosion protection performance, and the coating layer can maintain good hydrophobic protection capability for a long time under the conditions such as friction and wear.

Owner:中科广化(重庆)新材料研究院有限公司 +2

Chlorinated rubber coating used for marine environment and production method

InactiveCN105315796AHigh glossEliminate Bubble ProblemsRubber derivative coatingsAnti-corrosive paintsEpoxyPolymer science

The invention relates to a chlorinated rubber coating used for a marine environment and a production method. The production method includes the steps of adding modified chlorinated rubber resin, modified hydrogenated bisphenol F-type epoxy resin and epoxidized soybean oil to a mixed solvent composed of dimethylbenzene and solvent oil, adding modified titanium dioxide, feldspar powder, talcum powder, silicon micro-powder, mica powder, phthalocyanine green, chrome yellow, polyamide wax, chlorinated paraffin, a hydroxyl triazine derivative and epoxy chloropropane and the like to the mixed solution, mixing, stirring and grinding the mixed solution to obtain the high-glossiness weather-resistant chlorinated rubber coating used for the marine environment. The marine environment can be uniformly stirred and directly used for coating surfaces. The coating allows construction at -20 DEG C, is excellent in storage stability, anti-ultraviolet light aging property, adhesive force, corrosion resistance of acids, alkalis and salts and sea water scouring resistance, and can be used for corrosion resistance of offshore structures such as ships, ocean platforms, docks and the like.

Owner:CNPC RES INST OF ENG TECH +2

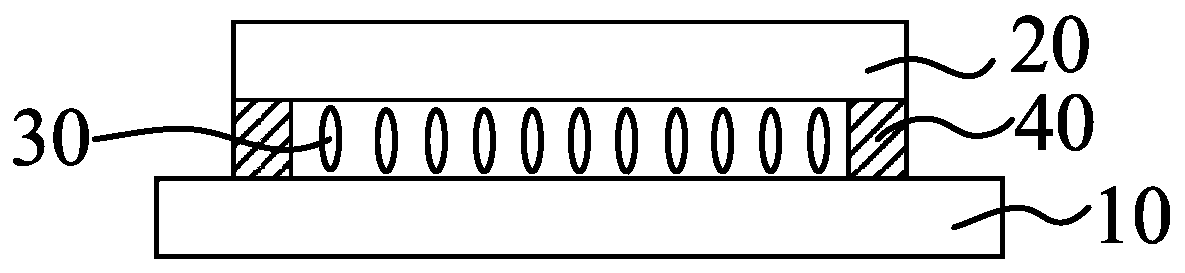

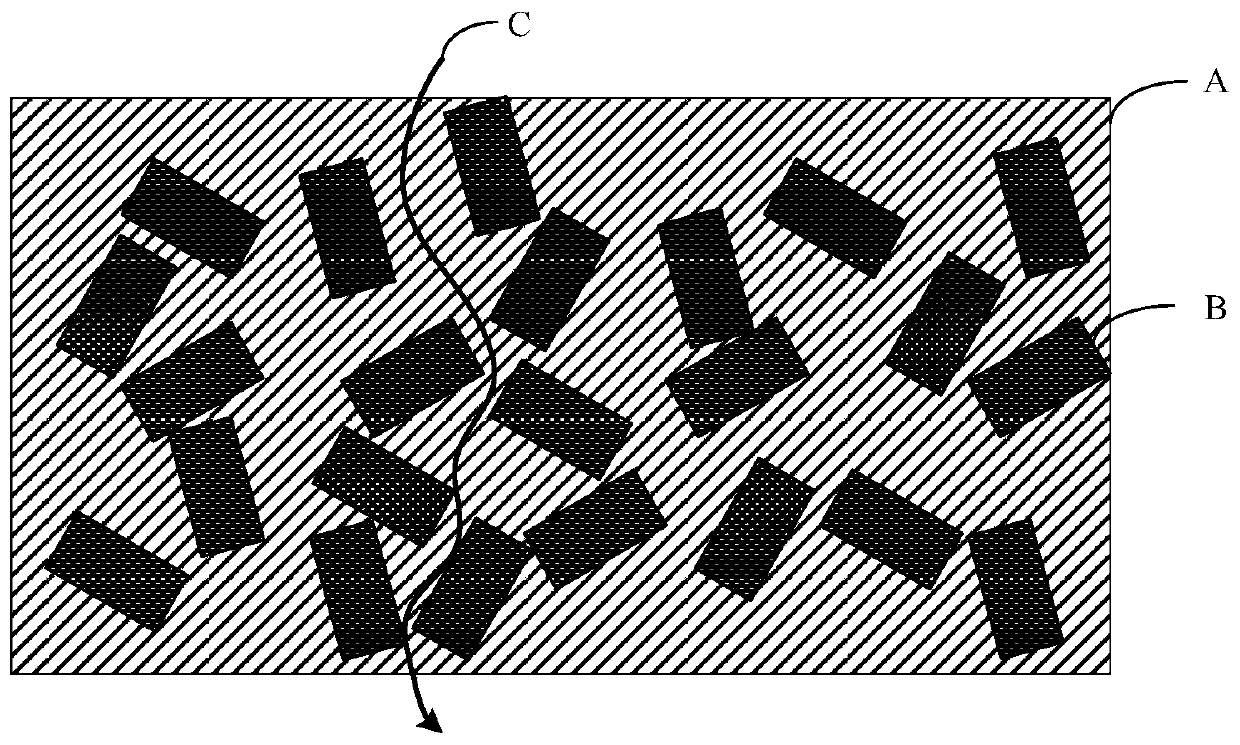

Frame sealing adhesive material and liquid crystal display panel

PendingCN110903793AExtended permeation pathImprove barrier propertiesNon-macromolecular adhesive additivesEster polymer adhesivesEpoxyPolymer science

The invention provides a frame sealing adhesive material and a liquid crystal display panel. The frame sealing adhesive material comprises the following components in percentage by mass: 25%-50% of anepoxy resin prepolymer, 5%-25% of an acrylic resin prepolymer, 0.1%-12% of a curing agent, 0-3% of a curing accelerator, 3%-20% of a filler, 0-3% of a stabilizer, 0-3% of an additive and 1-15% of a nano inorganic substance. The nano inorganic substance is added into the prepolymer and is uniformly dispersed in the prepolymer system, so that a water vapor permeation path can be prolonged after thenano inorganic substance is cured, and the water vapor barrier capacity of the frame sealing adhesive under high-temperature and high-humidity conditions is effectively improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

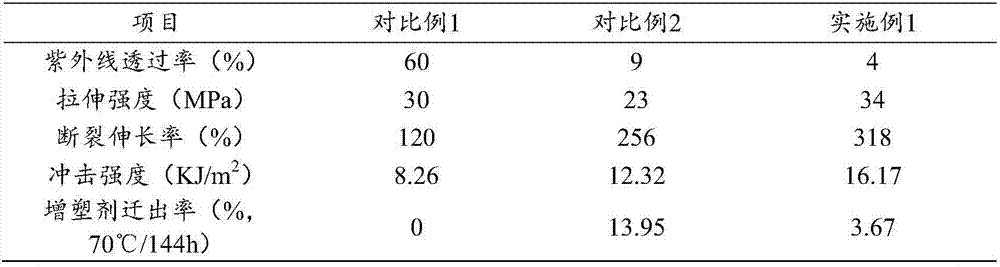

Toughening and plasticizer migration-resisting polyvinyl chloride material as well as preparation method and application thereof

The invention provides a toughening and plasticizer migration-resisting polyvinyl chloride material as well as a preparation method and application thereof and relates to the technical field of macromolecular materials. The preparation method of the toughening and plasticizer migration-resisting polyvinyl chloride material comprises the following steps: preparing laminar di-hydroxyl metal oxide through a high-temperature hydrothermal method; carrying out surface modification on the laminar di-hydroxyl metal oxide by utilizing dopamine, dopamine hydrochloride or a dopamine derivative, so as to obtain polydopamine modified laminar di-hydroxyl metal oxide; finally, mixing polyvinyl chloride, a plasticizer, a stabilizer and the polydopamine modified laminar di-hydroxyl metal oxide to obtain modified polyvinyl chloride. The prepared material has the advantages of relatively remarkable toughening and plasticizer migration-resisting properties and the like, and the compatibility of inorganic nanoparticles and the polyvinyl chloride is improved; furthermore, polydopamine can be used for preventing a polymer matrix from being degraded in an UV (Ultraviolet) illumination process, the performance stability of the polyvinyl chloride material is improved and the service life of the polyvinyl chloride material is prolonged.

Owner:XIAMEN UNIV OF TECH

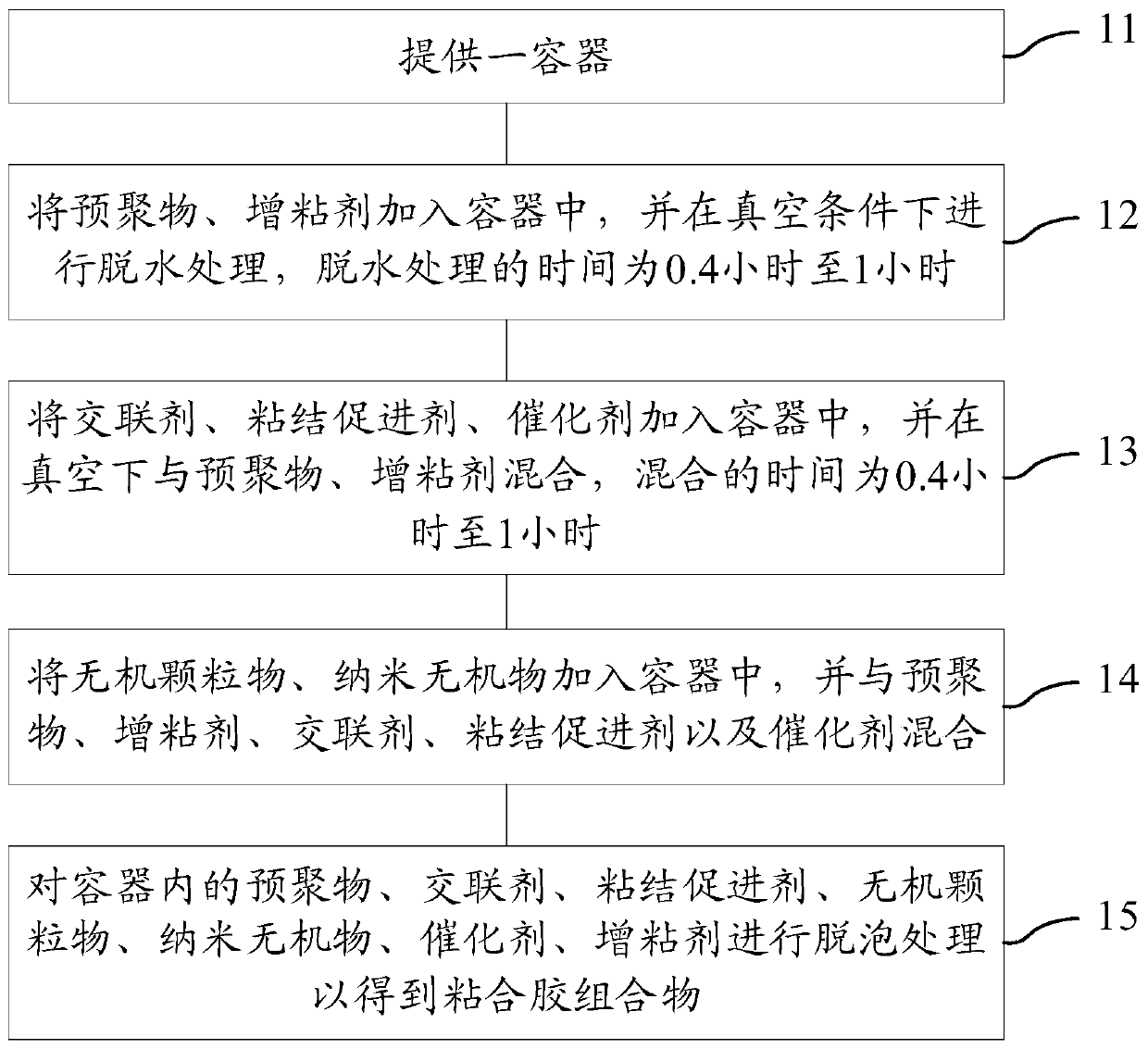

Adhesive composition, adhesive composition manufacturing method, and packaging structure

PendingCN111171782AImprove thermal conductivityExtended permeation pathNon-macromolecular adhesive additivesNon-linear opticsPolymer sciencePtru catalyst

The embodiment of the invention provides an adhesive composition. The adhesive composition comprises a prepolymer, a cross-linking agent, an adhesion promoter, inorganic particles, a nano inorganic matter, a catalyst and a tackifier, wherein the mass percent of the prepolymer is 70%-75%, the mass percent of the cross-linking agent is 5%-8%, the mass percent of the adhesion promoter is 1%-5%, the mass percent of the inorganic particulate matter is 0.5%-1%, the mass percent of the nano inorganic matter is 3%-5%, the mass percent of the catalyst is 3%-5%, and the mass percent of the tackifier is10%-15%. The nano inorganic matter is added into the adhesive composition, wherein the nano inorganic matter is uniformly dispersed in a mixed system of the prepolymer, the cross-linking agent, the adhesion promoter and the tackifier, and then the nano inorganic matter is cured, so that the water vapor permeation path is prolonged, and the water vapor blocking capacity of the adhesive material isimproved. In addition, the selected nano inorganic matter is good in thermal conductivity, and electrostatic damage caused by heat accumulation can be prevented.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

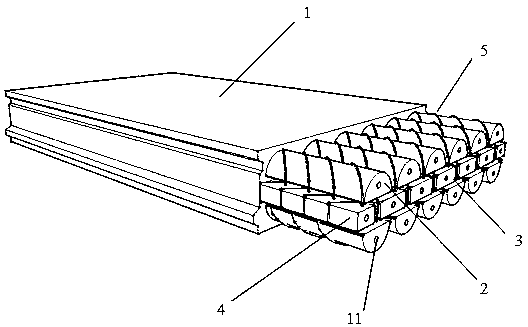

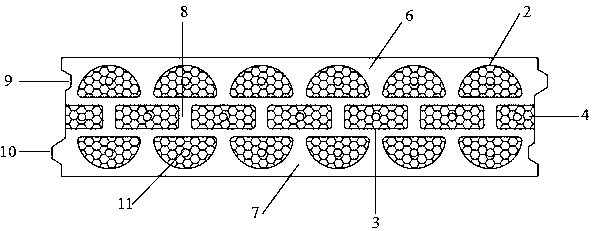

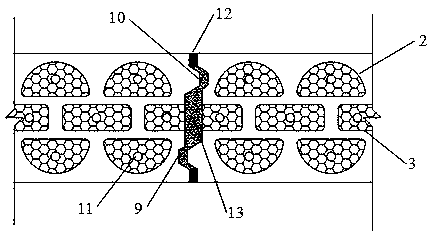

Self-heat-preservation outer wall board and outer wall for fabricated building

ActiveCN107605098ANot prone to crackingNot easy to crack and other quality problemsClimate change adaptationBuilding componentsEarthquake resistanceEngineering

The invention discloses a self-heat-preservation outer wall board and outer wall for a fabricated building. The self-heat-preservation outer wall board comprises a wall board base body and a prefabricated heat-preservation piece embedded in the wall board base body; the wall board base body is composed of an upper transverse rib board, a lower transverse rib board and an intermediate rib board; arow of semicircular hole channels is formed in each of the upper transverse rib board and the lower transverse rib board at intervals, and a row of rectangular hole channels is formed in the intermediate rib board at intervals; a female mortise and a male mortise are formed in the transverse splicing face of the wall board base body; and during mounting, the two ends of a wall board splicing seamare filled with elastic waterproof sealant, and the middle of the wall board splicing seam is filled with heat-preservation anti-crack bonding mortar. The self-heat-preservation outer wall board has the advantages of good integrity, stable force bearing, lightness, earthquake resistance, heat preservation, sound insulation and the like.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS +1

Antistatic and anti-corrosive paint and preparation method thereof

InactiveCN108441078AFunction increaseTo achieve the purpose of sustained releaseAnti-corrosive paintsEpoxy resin coatingsCross-linkPhosphate

The invention relates to antistatic and anti-corrosive paint and a preparation method of the paint, and belongs to the technical field of paint. A lamellar structure is prepared; hydrotalcite with specific surface area, lamellar exchange density and chemical inertness absorbs monoalkyl ether phosphate into interlayers; gelatin and chitosan are cross-linked for enclosing to achieve the purpose of slow release; monoalkyl ether phosphate and inorganic filling are combined for use to combine an antistatic effect and an anti-corrosive effect; a function of a coating is effectively improved; when phosphate molecules are contacted with the surface of a material, hydrophobic chains in the molecules are absorbed on the surface of the material to form a continuous absorption layer; a hydrophilic group of phosphate faces towards air; since the molecules of phosphate contains -OH, phosphate can form a hydrogen bond with water molecules; an absorbed water layer can form a conductive film; the surface conductivity of the material is improved, so that static charge accumulation on the surface of the material is reduced; a seepage path of oxygen molecules to reaching the surface of a matrix is prolonged; the paint has an excellent barrier property; and an anti-corrosive property is improved.

Owner:俞小峰

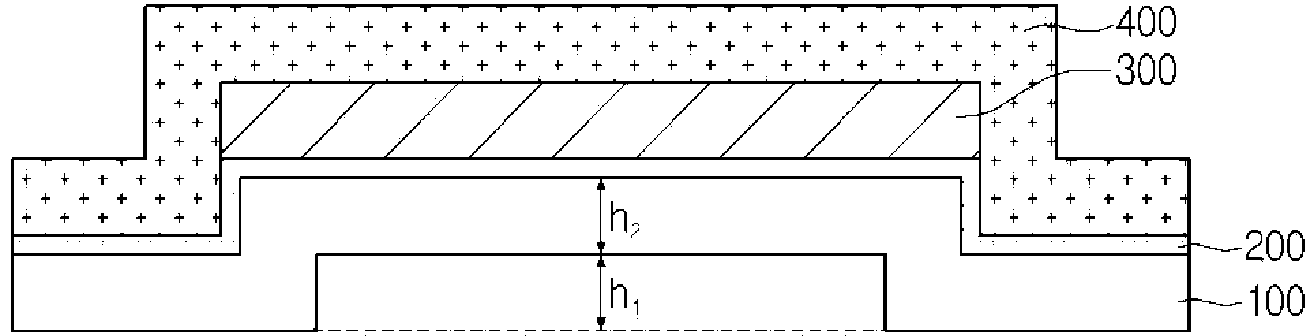

SOLAR CELL APPARATUS AND METHOD OF FABRICATING THE SAMe

InactiveCN103988315AExtended permeation pathIncrease contact areaFinal product manufactureEnergy conversion devicesThumb oppositionEngineering

Disclosed are a solar cell apparatus and a method of fabricating the same. The solar cell apparatus includes: barrier parts disposed in an outer region of a support substrate and arranged to be in opposition to each other; a plurality of solar cells between the barrier parts; and a protective layer on the barrier parts and the solar cells.

Owner:LG INNOTEK CO LTD

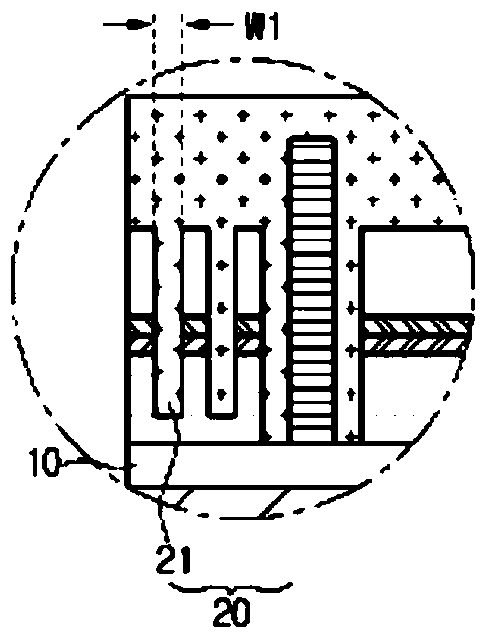

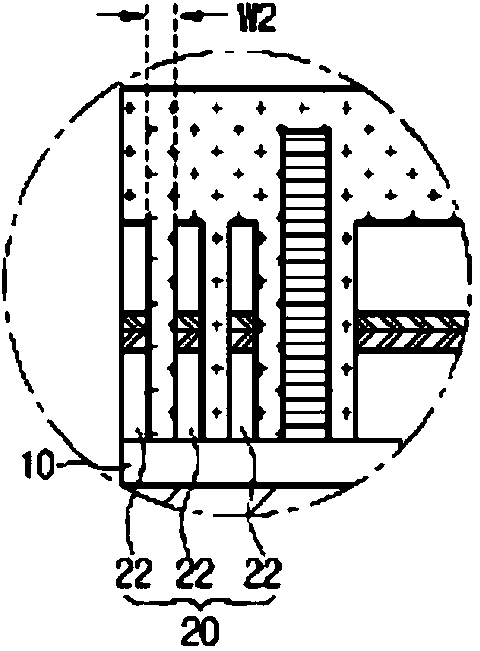

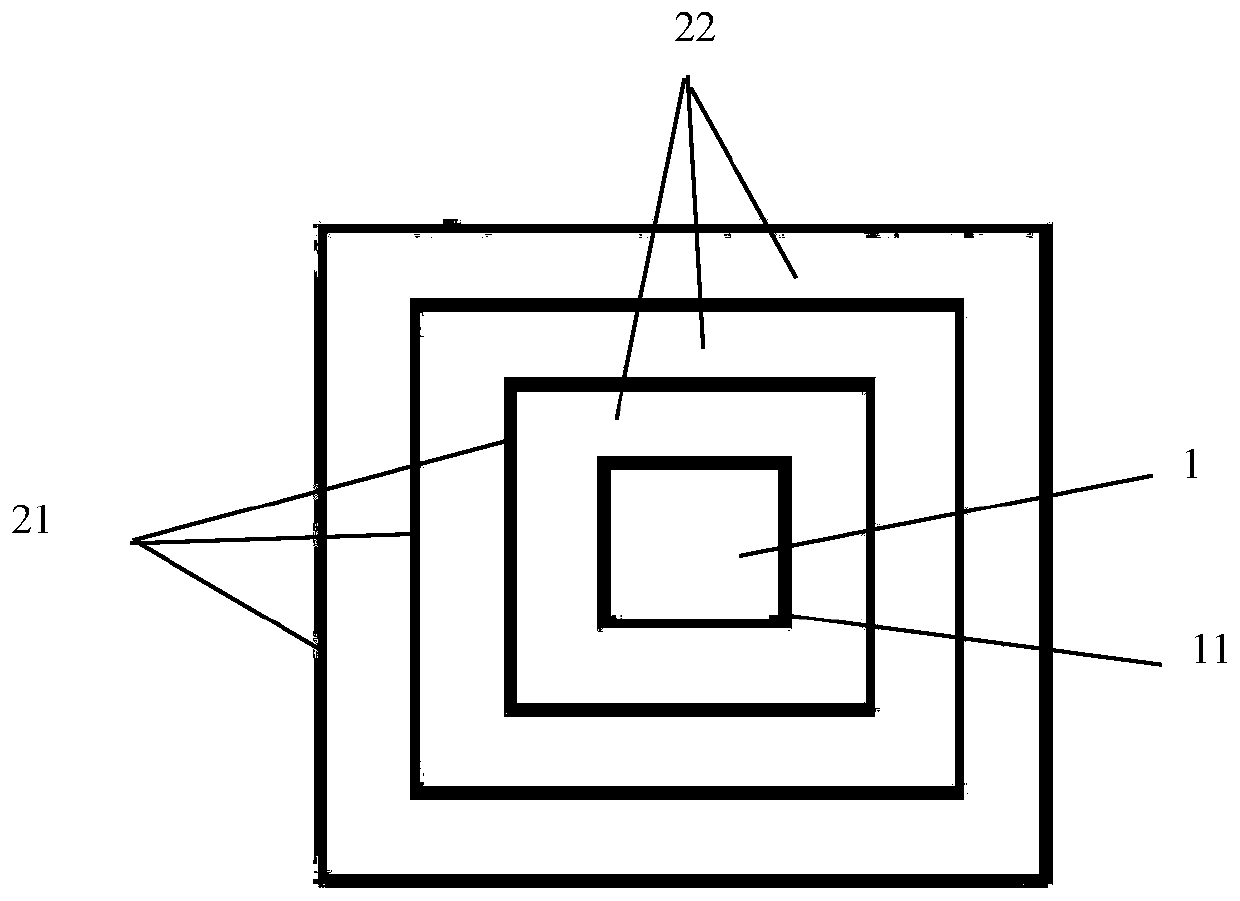

Display panel and display device

ActiveCN112018262AImprove production yieldExtended service lifeSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceEngineering

The invention relates to a display panel and a display device. The display panel comprises a substrate, a light-emitting structure layer and a packaging structure layer, wherein the substrate comprises an opening area, a spacing area and a display area, the opening area and the display area are spaced apart by the spacing area, and the opening area isused for mounting a camera; the light-emittingstructure layer is arranged on the substrate; the side, deviating from the substrate, of the light-emitting structure layer protrudes to form at least two circles of dams arranged at intervals, the atleast one circle of dam is located on the display area and surrounds the edge of the interval area, the at least one circle of dam is located on the opening area and surrounds the edge of the openingarea, the side, away from the substrate, of the light-emitting structure layer is sunken to form at least one groove, and the groove is located on the interval area and surrounds the opening area; and the packaging structure layer is arranged on the light-emitting structure layer. Thus, the water-oxygen blocking capability at the edge of the opening area can be enhanced, the path of water-oxygenpermeating from the opening area to the display area is prolonged, the production yield of the display panel is further improved, and the service life is prolonged.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Solar cell module and method of fabricating the same

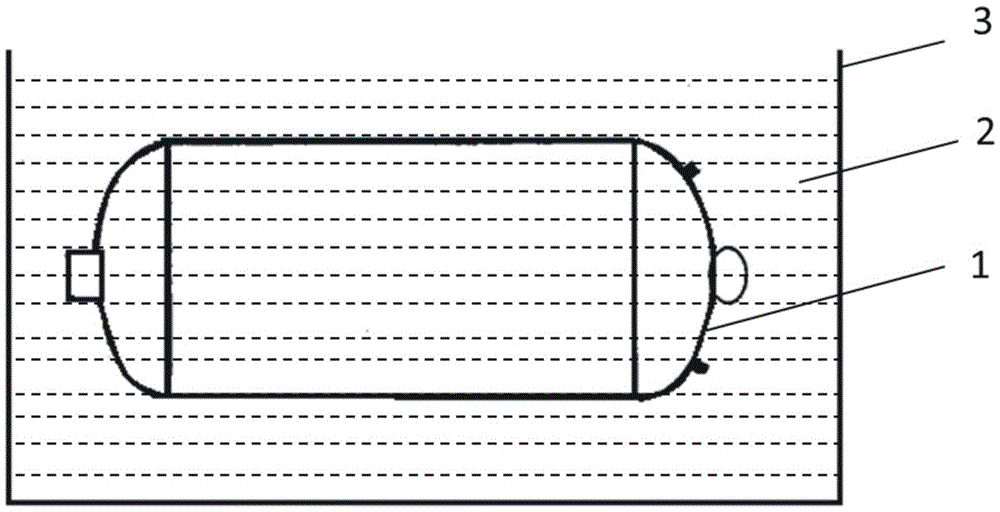

InactiveCN103988319AExtended permeation pathGuaranteed stabilityPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

Disclosed are a solar cell module and a method of fabricating the same. The solar cell module includes a support substrate including a lateral side, at which a 1st bending portion is formed, and a rear side at which a 2nd bending portion is formed, a solar cell on the support substrate, and a protective layer on the support substrate and the solar cell.

Owner:LG INNOTEK CO LTD

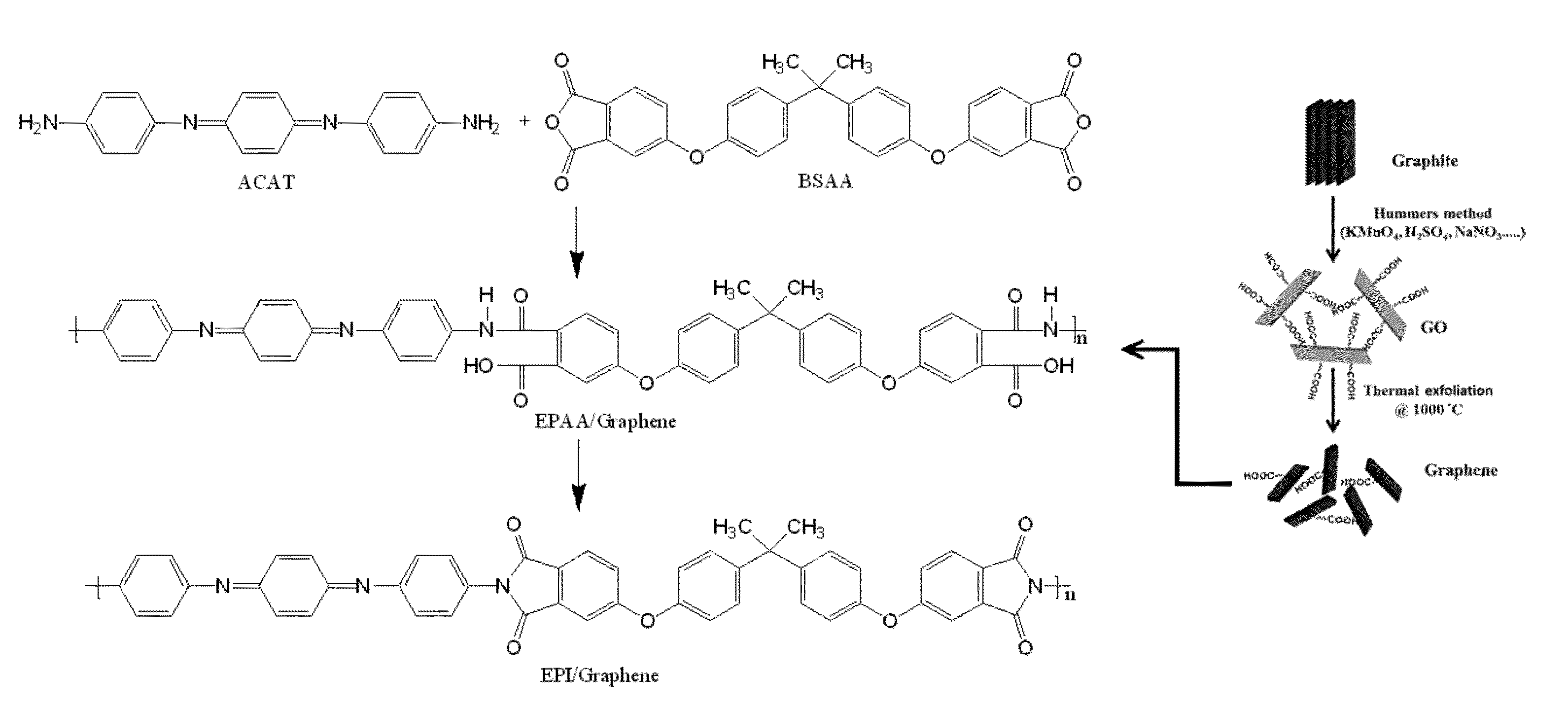

Polymer and graphene blended electroactive composite coating material and method for preparing the same

ActiveCN105017956AImprove anti-corrosion performanceExtended permeation pathAnti-corrosive paintsPolyamide coatingsEpoxyPolymer science

The present invention provides a polymer and graphene blended electroactive composite coating material and method for preparing the same. The composite coating material is a composite material formed by blending a specific polymer and graphene; where the specific polymer is formed by polymerization of (A) aniline oligomer and (B) amino reactive monomer together with (C) modified graphene and is a kind of polymer selected by the group consisting of the following: epoxy resin, polyimide, polyamide, polyurethane, polylactic acid; (C) modified graphene is uniformly dispersed in the matrix of the specific polymer but not involved in polymerization; and the composite coating material is electroactive.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

Light-cured composite resin based on laminar filler and preparation method of light-cured composite resin

InactiveCN104434541AHigh hardnessExtended permeation pathImpression capsDentistry preparationsChemical treatmentCementum caries

The invention discloses light-cured composite resin based on a laminar filler for oral cavities and a preparation method of the light-cured composite resin, belonging to the field of oral medical materials. According to the light-cured composite resin disclosed by the invention, a common filler in the conventional light-cured composite resin is replaced by the laminar filler subjected to chemical treatment. The orientation and own characteristics of the laminar filler ensure that during light curing of a light-cured resin matrix, the curing shrinkage ratio of the light-cured resin matrix is greatly reduced and the strength and hardness of the light-cured resin matrix are increased. By using the laminar filler, a seepage path of water molecules is greatly increased, the water absorption rate of the composite resin is greatly reduced, the dehiscence between repair resin and a tooth matrix can be significantly reduced, and clinically most common ruptures and secondary caries causing repair failure can be effectively reduced. The light-cured composite resin is of great significance for reducing pains of patients and promoting the development of oral cavity repair materials.

Owner:JILIN UNIV

Multifunctional composite vacuum insulation board and manufacturing and packaging method thereof

ActiveCN111578045AImprove insulation effectLow thermal conductivityThermal insulationPipe protection by thermal insulationPolyesterAdhesive cement

The invention discloses a multifunctional composite vacuum insulation board, and relates to the technical field of vacuum insulation boards. The multifunctional composite vacuum insulation board comprises a single-layer vacuum insulation board body, a heat insulation and preservation composite layer and a protective layer, wherein the single-layer vacuum insulation board body comprises a core material and a first polyester base film; the heat insulation and preservation composite layer wraps the single-layer vacuum insulation board body, and the heat insulation and preservation composite layercomprises three polyester-based films and three glass fiber layers; and the protective layer wraps the outer side of the heat insulation and preservation composite layer and comprises a core materialframework, a pore filler and a phenolic resin adhesive. The invention further discloses a manufacturing and packaging method of the multifunctional composite vacuum insulation board. According to themultifunctional composite vacuum insulation board, the heat insulation and preservation composite layer prolongs the permeation path of external gas passing through heat seals and the polyester-basedfilms, the heat insulation and preservation performance and the service life are guaranteed; from the manufacturing perspective of the vacuum insulation board, the six surfaces of the single-layer vacuum insulation board body are covered with the glass fiber layers; and from the packaging perspective, after one glass fiber layer is covered, vacuumizing packaging is carried out once so that heat bridges can be reduced, and the protective layer is high in strength and not prone to deform.

Owner:山东信泰节能科技股份有限公司

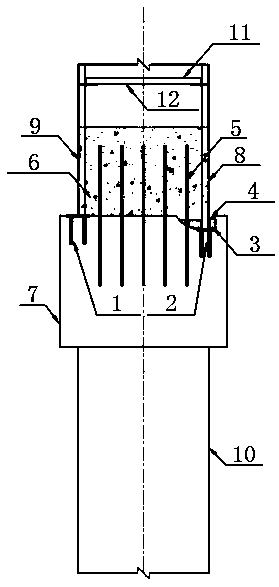

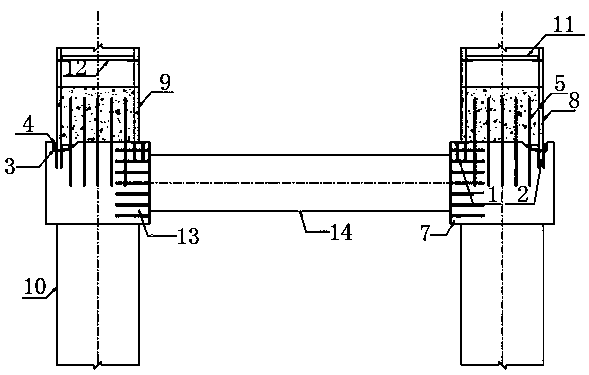

Engaged pile-double wall steel combined cofferdam connecting structure and construction operation technology

The invention discloses an engaged pile-double wall steel combined cofferdam connecting structure and a construction operation technology. The engaged pile-double wall steel combined cofferdam connecting structure and the construction operation technology are characterized in that the novel engaged pile-double wall steel combined cofferdam connecting structure is provided with an embedded part A,an embedded part B, a ring-shaped groove formed in the contact position of the top of a crown beam and an outer wall plate of a double wall steel cofferdam, a groove interior water stop material, anchor bars stretching in the crown beam and the double wall steel cofferdam and concrete poured in a sandwich cabin of the double wall steel cofferdam. The embedded part A is directly connected with theinner wall plate of the double wall steel cofferdam. The ring-shaped groove is formed in the contact position of the top of the crown beam and the outer wall plate. The embedded part B is arranged atthe bottom of the ring-shaped groove. The outer wall plate is connected with the embedded part B at the bottom of the ring-shaped groove. A certain clearance is reserved between the outer wall plate and the position, close to the outer wall of an engaged pile, of groove wall of the ring-shaped groove, and the clearance is filled with the water stop material. The engaged pile-double wall steel combined cofferdam connecting structure and the construction operation technology are specific to engaged pile-double wall steel combined cofferdams, and safe of the combined cofferdam in the whole building and use period is ensured under the premise that construction convenience is achieved.

Owner:SICHUAN ROAD & BRIDGE GRP

Preparation method for anticorrosion iron-coating film

InactiveCN108997604AImprove conductivityReduce static charge build-upAlkali metal silicate coatingsAnti-corrosive paintsTectorial membraneInositol hexakisphosphate binding

The invention relates to a preparation method for an anticorrosion iron-coating film, belonging to the technical field of metal coating films. According to the invention, a corrosion inhibitor is prepared by reacting ascorbic acid with phytic acid; since the ascorbic acid has the characteristics of low toxicity or non-toxicity and low price, and oxygen atoms in molecules thereof have strong electron donating ability, a firm adsorption protective film can be formed on a metal surface, and can stably exist under alkaline conditions; after bonding of the ascorbic acid with the phytic acid, when phosphate molecules contacts with the surface of a material, hydrophobic chains in the molecules are adsorbed on the surface of the material so as to form a continuous adsorption layer, and hydrophilicgroups thereof face air; since the molecules contain -OH, the molecules can form hydrogen bonds with water molecules, and an adsorbed water layer forms a conductive film, so the surface conductivityof the material is enhanced, static charge accumulation on the surface of the material is reduced, and an infiltration path which oxygen molecules takes to reach the surface of a substrate is extended; and the anticorrosion iron-coating film has excellent barrier properties, improved corrosion resistance, and good application prospects.

Owner:FOSHAN CHANCHENG DISTRICT NUOGAO ENVIRONMENTAL PROTECTION TECH CO LTD

Anti-corrosion composite coating on surface of magnesium alloy and preparation method and application thereof

ActiveCN113106439AStrong fast repair abilityImprove corrosion resistanceSuperimposed coating processPressure inorganic powder coatingCoated surfaceMetallurgy

The invention belongs to the technical field of metal surface treatment, and discloses an anti-corrosion composite coating on the surface of magnesium alloy and a preparation method and application thereof. The structure of the composite coating on the surface of the magnesium alloy is magnesium alloy / MgAl-LDH / Al2O3 / Ni / Zn-G / compact coating Zn5 (OH) 8Cl2-Zn4CO3 (OH) 6. According to the anti-corrosion composite coating on the surface of the magnesium alloy and the preparation method and application thereof, an LDH film is grown on a magnesium alloy matrix in situ in advance, then a Zn-G / Ni / Al2O3 coating is cold-sprayed, a Zn-G / Ni / Al2O3 / MgAl-LDH composite coating is prepared on the surface of the magnesium alloy, the composite coating is soaked in a sodium chloride solution, and a Zn5 (OH) 8Cl2 and Zn4CO3 (OH) 6 compact coating is generated on the surface of the Zn-G / Ni / Al2O3 coating. The MgAl-LDH coating of the composite coating has strong binding force with the magnesium alloy, and the corrosion resistance is excellent.

Owner:GUANGDONG UNIV OF TECH

Underground structure outer wall superposed wall adopting HCMW construction method and construction method thereof

PendingCN107326924AHigh strengthCrystal growthArtificial islandsUnderwater structuresReinforced concreteArchitectural engineering

The invention discloses an underground structure outer wall superposed wall adopting the HCMW construction method. The underground structure outer wall superposed wall adopting the HCMW construction method comprises a cement-soil mixed pile wall, a levelling course and an underground structure outer wall. The cement-soil mixed pile wall comprises multiple cement-soil mixed piles which are continuously and mutually engaged. Reinforced concrete precast piles are inserted in the multiple cement-soil mixed piles at intervals or continuously. The levelling course is arranged on the inner wall of the cement-soil mixed pile wall. The underground structural outer wall is arranged on the inner wall of the levelling course and comprises reinforcing steel bars and concrete mixed with a waterproof compacting agent. The cement-soil mixed pile wall and the underground structural outer wall constitute an integrated force bearing component through a connection structure. The invention further provides a construction method of the underground structure outer wall superposed wall adopting the HCMW construction method. In this way, the underground structure outer wall superposed wall adopting the HCMW construction method is simple and reasonable in structure, a foundation pit is omitted, a series of defects of the foundation pit are avoided, the waterproof performance is improved, a support wall and a underground structure wall are connected into the force bearing integrated body, the strength is improved, the procedure is simplified, construction is convenient and the construction period is shortened.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +2

Dyeing process of wool fabric

The invention relates to a dyeing process of a wool fabric. The dyeing process comprises the steps such as preparing a dye mixed solution, dyeing by immersion bath, washing and drying. According to the dyeing process, an ionic liquid is used to gradually dissolve keratin on the surface of wool fiber under heating conditions to destroy a scale layer, a negative pressure and positive pressure interaction dyeing method improves penetration of the dyeing solution inside the wool fiber, so that the dyeing solution fully penetrates into the wool fiber to make the dyed wool fabric uniform inside andoutside, and the dyeing process can effectively improve the dyeing depth of the wool fabric. The dye mixed solution is heated to 30 to 90 DEG C, so that when the dyeing solution penetrates into the wool fabric, dye agent molecules have high activity so as to achieve a faster penetration speed and improve dyeing effect and efficiency.

Owner:JIANGYIN XINGWU WOOL FABRIC TECH

Deep and shallow pit combined supporting structure with water resistance function and construction method thereof

PendingCN107386298AEnsure safetyEasy to closeProtective foundationExcavationsCivil/structural engineersStructure support

The invention belongs to the field of foundation pit supporting structures, and particularly discloses a deep and shallow pit combined supporting structure with a water resistance function. The deep and shallow pit combined supporting structure with the water resistance function comprises a shallow foundation pit structure and a deep foundation pit structure. The shallow foundation pit structure comprises a shallow foundation pit base and a foundation slab, wherein the shallow foundation pit base is horizontally arranged, and the foundation slab is arranged above the shallow foundation pit base. A water-blocking sunken pool is formed in the side, facing the foundation slab, of the shallow foundation pit base. The upper end of the deep foundation pit structure is connected with one end of the foundation slab and abuts against the side face of the shallow foundation pit base. The deep foundation pit structure comprises a diaphragm wall and a deep foundation pit side wall, wherein the diaphragm wall and the deep foundation pit side wall are vertically arranged. One side of the diaphragm wall is attached to the deep foundation pit side wall, the other side of the diaphragm wall is attached to the side face of the shallow foundation pit base, and a water-resisting blocking groove is formed in the side, attached to the deep foundation pit side wall, of the diaphragm wall. The invention further provides a construction method corresponding to the deep and shallow pit combined supporting structure with the water resistance function. The deep and shallow pit combined supporting structure with the water resistance function and the construction method guarantee the foundation pit safety and the durability of structural engineering, and have the advantages of being convenient and fast to construct, economical, practical, high in water resistance and seepage resistance and the like.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Anticorrosive drainage valve

InactiveCN106833345AImprove heat resistanceImprove adhesionFireproof paintsAnti-corrosive paintsFoaming agentEmulsion

The invention discloses an anticorrosive drainage valve. The outer surface of an drainage valve is coated with an anticorrosive layer; the anticorrosive layer is formed by coating anticorrosive paint; the anticorrosive paint is prepared from a component A and a component B, wherein the component A is prepared from the following components: polyphenylene oxide resin powder, methylphenyl silicone resin, modified waterborne polyurethane emulsion, a coupling agent, a curing agent, a curing agent accelerant DMP-30, pigment and filler and a dispersant; the component B is prepared from the following components: nano SiC powder, styrene-acrylic emulsion, a flatting agent, a thickener, an emulsifier and a de-foaming agent; the anticorrosive drainage valve provided by the invention has the advantages that the valve has a good anticorrosive effect and can be used in environment with relatively poor water quality; the service life is long and the cost is reduced.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com