Antistatic and anti-corrosive paint and preparation method thereof

An anti-corrosion coating and anti-static technology, which is applied in the direction of anti-corrosion coatings, conductive coatings, epoxy resin coatings, etc., can solve the problems of general anti-corrosion performance of anti-static coatings and unsatisfactory anti-static performance of anti-corrosion coatings, and achieve excellent barrier performance. Static charge buildup, anti-corrosion performance improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

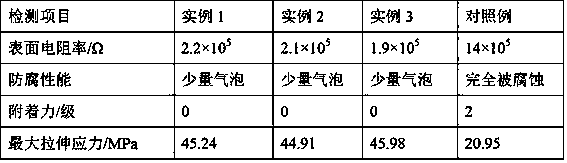

Examples

example 1

[0023] Take 3g of magnesium nitrate, 2.4g of aluminum nitrate, add 80mL of deionized water, stir at 300r / min for 20min, then add 1.2g of sodium carbonate, 0.01g of hydroxymethyl cellulose, 0.4g of monoalkyl ether phosphate sodium salt, 12g The mass fraction is 2% polyvinyl alcohol solution, 12g mass fraction is 10% sodium hydroxide solution, continue to stir at 40°C for 15min, heat to 80°C and keep it for 8h, then add 3g gelatin, 1g silane coupling agent, 300g The mass fraction is 1% chitosan solution, stirred at 300r / min for 3h to obtain a mixed solution, put the mixed solution into a centrifuge and centrifuge to obtain a precipitate, wash the precipitate twice with absolute ethanol, then place the washed precipitate in In a drying oven, dry at 105°C for 3 hours, then transfer to a pulverizer to pulverize, pass through a 320-mesh sieve to obtain a modified filler, take 4g ethylene glycol butyl ether, 20g water-based epoxy resin, 0.5g polysiloxane, 0.5g of leveling agent, 0.05...

example 2

[0025] Take 5g of magnesium nitrate, 3.6g of aluminum nitrate, add 90mL of deionized water, stir at 350r / min for 25min, then add 1.8g of sodium carbonate, 0.01g of hydroxymethyl cellulose, 0.5g of monoalkyl ether phosphate sodium salt, 18g The mass fraction is 2% polyvinyl alcohol solution, 18g mass fraction is 10% sodium hydroxide solution, continue to stir at 45°C for 18min, heat to 85°C and keep it for 9h, then add 4g gelatin, 1g silane coupling agent, 400g The mass fraction is 1% chitosan solution, stirred at 350r / min for 4h to obtain a mixed solution, the mixed solution is put into a centrifuge and centrifuged to obtain a precipitate, the precipitate is washed twice with absolute ethanol, and then the washed precipitate is placed In a drying oven, dry at 108°C for 3 hours, transfer to a pulverizer, and pass through a 320-mesh sieve to obtain a modified filler. Take 6g of ethylene glycol butyl ether, 22g of water-based epoxy resin, and 0.6g of polysiloxane. 0.6g of levelin...

example 3

[0027] Take 6g of magnesium nitrate and 4.8g of aluminum nitrate, add them into 100mL of deionized water, stir at 400r / min for 30min, then add 2.4g of sodium carbonate, 0.02g of hydroxymethyl cellulose, 0.6g of monoalkyl ether phosphate sodium salt, 24g The mass fraction is 2% polyvinyl alcohol solution, 24g mass fraction is 10% sodium hydroxide solution, continue to stir at 50°C for 20min, heat to 90°C and keep it for 10h, then add 5g gelatin, 2g silane coupling agent, 500g The mass fraction is 1% chitosan solution, stirred at 400r / min for 5h to obtain a mixed solution, the mixed solution is put into a centrifuge and centrifuged to obtain a precipitate, washed with absolute ethanol for 3 times, and then the washed precipitate is placed In a drying oven, dry at 110°C for 4 hours, transfer to a pulverizer, and pass through a 320-mesh sieve to obtain a modified filler. Take 8g of ethylene glycol butyl ether, 25g of water-based epoxy resin, and 0.8g of polysiloxane. Put 0.8g of l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com