Polymer and graphene blended electroactive composite coating material and method for preparing the same

An anti-corrosion coating, graphene technology, applied in anti-corrosion coatings, polyamide coatings, coatings, etc., can solve problems such as accelerated corrosion rate, oxidative corrosion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

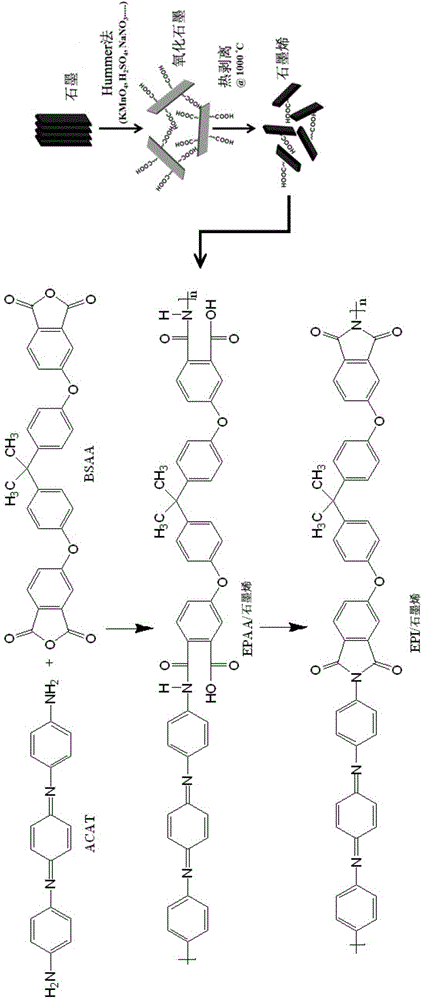

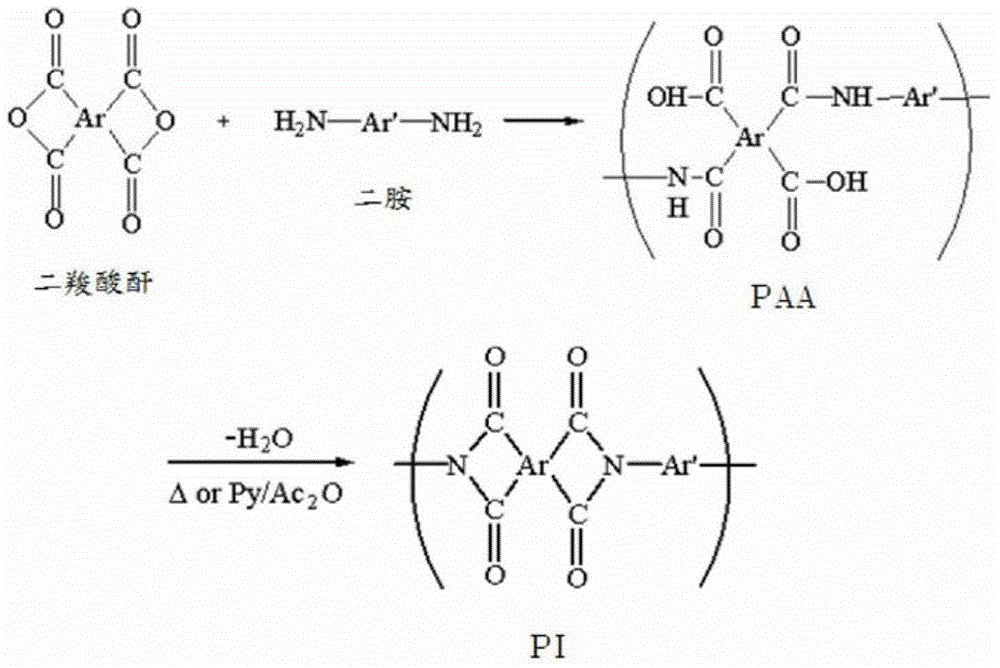

[0070] According to the first embodiment of the present invention, an electroactive composite anticorrosive coating mixed with a polymer and graphene is disclosed, which is a composite material of a specific polymer and graphene, and the specific polymer is made of (A) Aniline oligomers and (B) amine reactive monomers are mixed (C) graphene is modified and then polymerized. It is a polymer selected from the following groups: epoxy compound, polyimide, polyamide , Polyurethane (polyurethane) and polylactic acid, in which (C) modified graphene is uniformly dispersed in the specific polymer structure but does not participate in the polymerization reaction. The polymer is mixed with the electroactive composite of graphene The anti-corrosion coating is electrically active.

[0071] In one embodiment, (A) aniline oligomer is an oligomer composed of 3-8 repeating units in the molecule.

[0072] In one embodiment, (A) the aniline oligomer is an amino-terminated aniline trimer, which has t...

no. 2 approach

[0082] According to the second embodiment of the present invention, a method for preparing an electroactive composite anticorrosive coating mixed with polymer and graphene is disclosed, which includes the following steps in sequence: (1) (A) aniline oligomer and (B) ) Pre-reaction of amine reactive monomers to obtain a polymer precursor (AB); (2) adding (C) modified graphene to the precursor (AB) and mixing uniformly to obtain a mixed solution; and (3) ) Performing the polymerization reaction of the mixed solution to obtain the electroactive composite anticorrosive coating mixed with the polymer and the graphene.

[0083] In one embodiment, when the electroactive composite anticorrosive coating mixed with polymer and graphene is 100% by weight, (C) the modified graphene is 0.1-1.0% by weight.

[0084] In one embodiment, the (B) amine-reactive monomer is a monomer selected from the following group: having the structural formula (B1):

[0085] 4,4'-(4,4'-isopropylidene-diphenoxy)bis(...

Embodiment 1

[0106] Example 1: ACAT+BSAA

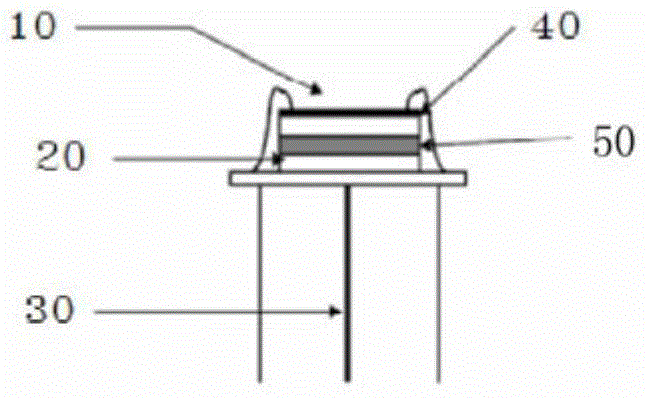

[0107] Dissolve 0.288g (1mmol) of aniline trimer (ACAT) and 0.520g (1mmol) of 4'-(4,4'-Isopropylidene-diphenoxy)bis(phthalic anhydride)(BSAA) in 4g DMAc, and The reaction was stirred at room temperature for 20 minutes to obtain an electroactive polyamic acid solution. Then, 0.5 wt% or 1 wt% of graphene was added to the electroactive polyamic acid solution, and the solution was shaken and stirred at room temperature for 30 minutes to obtain an electroactive polyamic acid / graphene (EPAA / Graphene) composite solution. Coat the electroactive polyamic acid / graphene composite solution onto a 1cm×1cm cold-rolled steel sheet, and use a high-temperature furnace to increase the temperature gradually. The temperature will be raised from room temperature to 80℃ in 30 minutes, and then from 80℃ to 100℃ in 6 hours. , 2 hours to 150°C, 2 hours to 170°C, and finally to room temperature, you can get the electroactive polyamic acid / graphene coating layer, and finally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com