Light-cured composite resin based on laminar filler and preparation method of light-cured composite resin

A flake filler and composite resin technology, applied in the field of stomatology materials, can solve the problems of unsatisfactory mechanical properties of composite resin repair materials, insufficient strength and wear resistance, easy formation of secondary caries, etc., so as to reduce the failure of dental caries repair. Fracture, reduce cracking, prolong the effect of penetration path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Accurately weigh 5.0g BisGMA and 5.0g TEGDMA in a small beaker, add 0.1g photoinitiator CQ and EDMAB (3:7) to obtain a mixture solution.

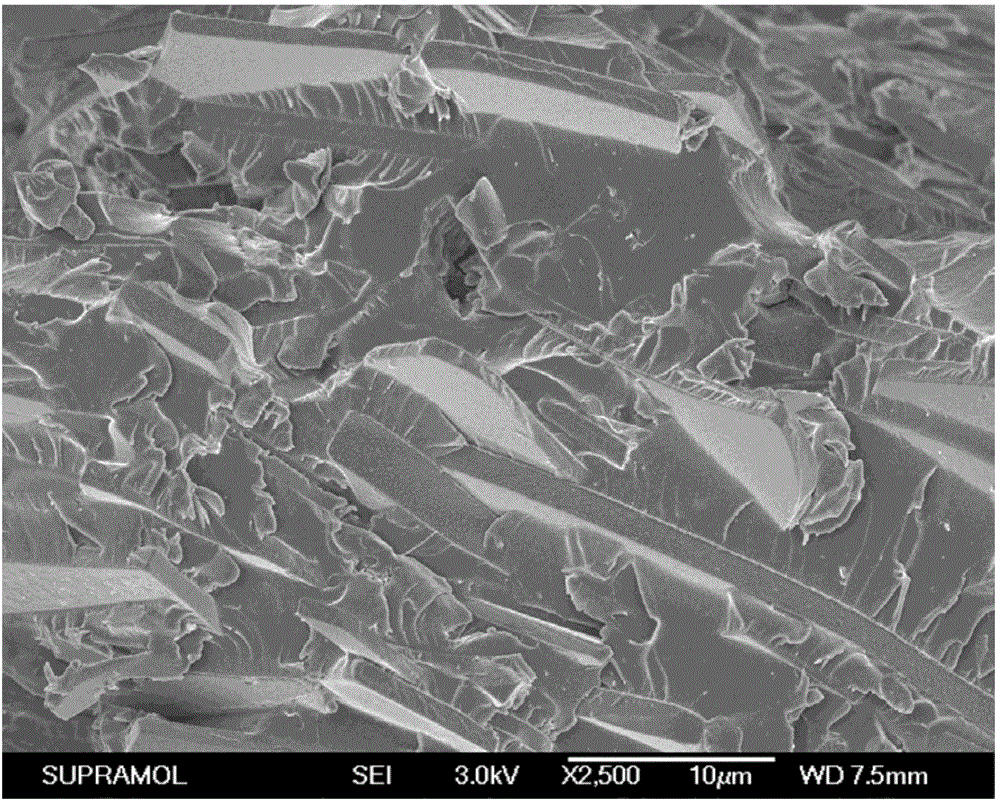

[0017] Weigh 50 g of flaky silicon dioxide, stir in an aqueous solution of 1 microliter / ml hydrofluoric acid for 12 hours, centrifuge, and after drying, reflux for 12 hours in a toluene solution of KH570 with a volume concentration of 30%, and suction filter. After drying, weigh 10g of the treated flaky silica and add it to the above mixture solution, stir and grind to make it evenly mixed, and then evacuate and exhaust to obtain a 50% flaky silica filler. Cured composite resin.

[0018] Prepare the resin as a sample conforming to the YY1042-2009 standard, cure it under a 1000-watt blue light for 40 seconds, then test its hardness and water absorption, and test its curing shrinkage with the pycnometer method. The results are as follows:

[0019] Vickers hardness: 90

[0020] Curing shrinkage: 2.1%

[0021] Water absorption rate: 3...

Embodiment 2

[0023] Accurately weigh 4.0g UDMA and 4.0g TEGDMA in a small beaker, add 0.1g photoinitiator CQ and EDMAB (3:7).

[0024] Weigh 50 g of flake aluminum oxide, stir in 7 microliters / ml of hydrochloric acid solution for 12 hours, centrifuge, after drying, reflux for 12 hours in the toluene solution of KH570 with a volume concentration of 30%, suction filtration, and after drying, Weigh 12g of treated flaky alumina and add it to the mixed solution, stir and grind to make it evenly mixed, and then evacuate and exhaust to obtain a photocurable composite resin with 60% flaky alumina filler doping.

[0025] Take a sample of the resin prepared to meet the YY1042-2009 standard, cure it under a 1000-watt blue light for 40 seconds, then test its hardness and water absorption, and test its curing shrinkage by the pycnometer method. The result is as follows:

[0026] Vickers hardness: 110

[0027] Curing shrinkage: 1.8%

[0028] Water absorption: 30 days water absorption 1.23% (wt.%) The...

Embodiment 3

[0030] Accurately weigh 2.0g UDMA and 2.0g TCDMA in a small beaker, add 0.08g photoinitiator CQ and EDMAB (3:7) and mix well.

[0031] Weigh 50g of flaky alumina, stir in 3 microliters / ml of hydrochloric acid solution for 12 hours, centrifuge, after drying, reflux for 12 hours in the toluene solution of KH570 with a volume concentration of 30%, filter with suction, and weigh after drying. Take 16g of treated flaky alumina and add it to the mixed solution, stir and grind to make it evenly mixed, and then evacuate and exhaust to obtain a photocurable composite resin with 80% flaky alumina filler doping.

[0032] Take a sample of the resin prepared to meet the YY1042-2009 standard, cure it under a 1000-watt blue light for 40 seconds, then test its hardness and water absorption, and test its curing shrinkage by the pycnometer method. The result is as follows:

[0033] Vickers hardness: 93

[0034] Curing shrinkage: 1.8%

[0035] Water absorption rate: 30 days water absorption r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com