Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Crystal growth" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

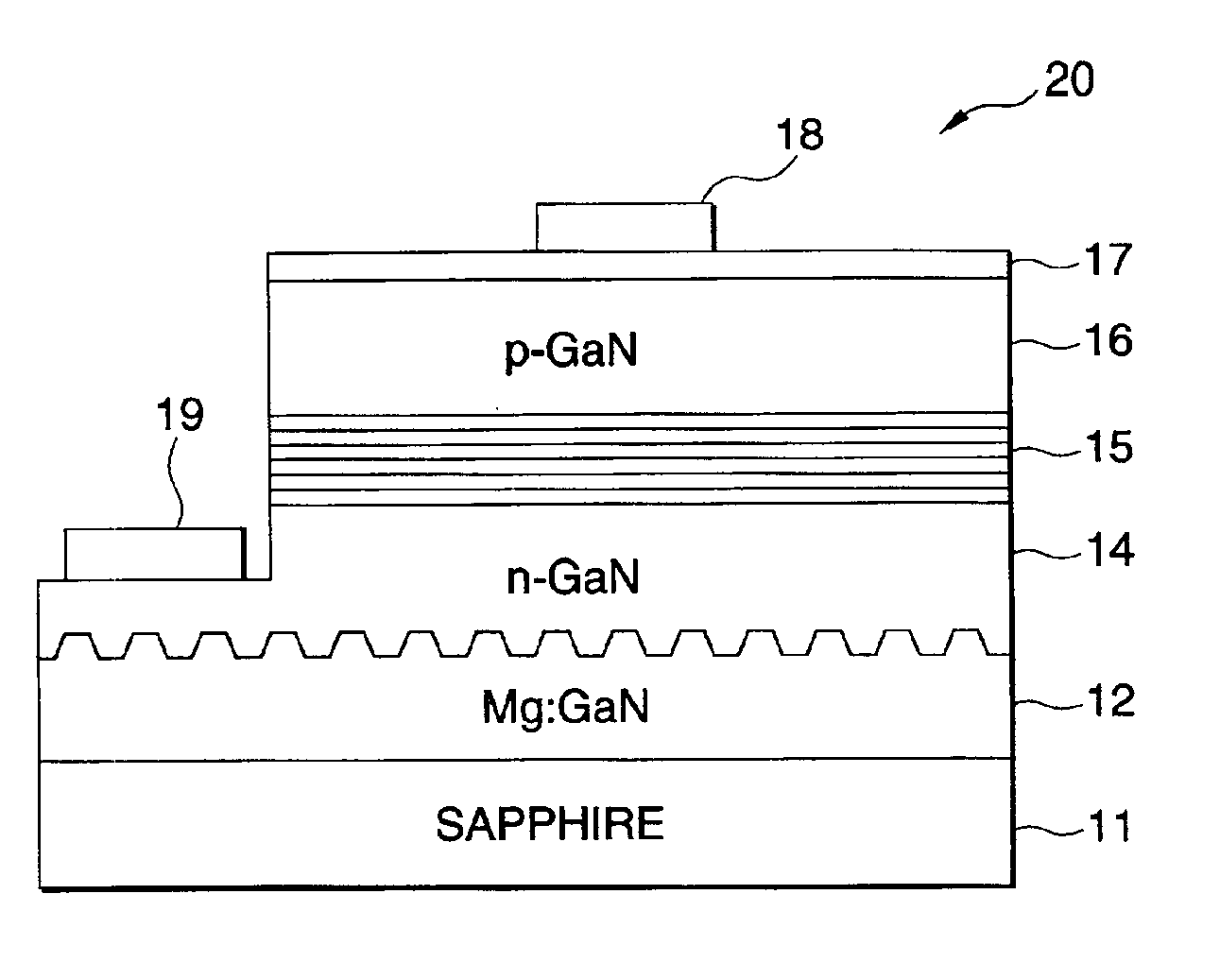

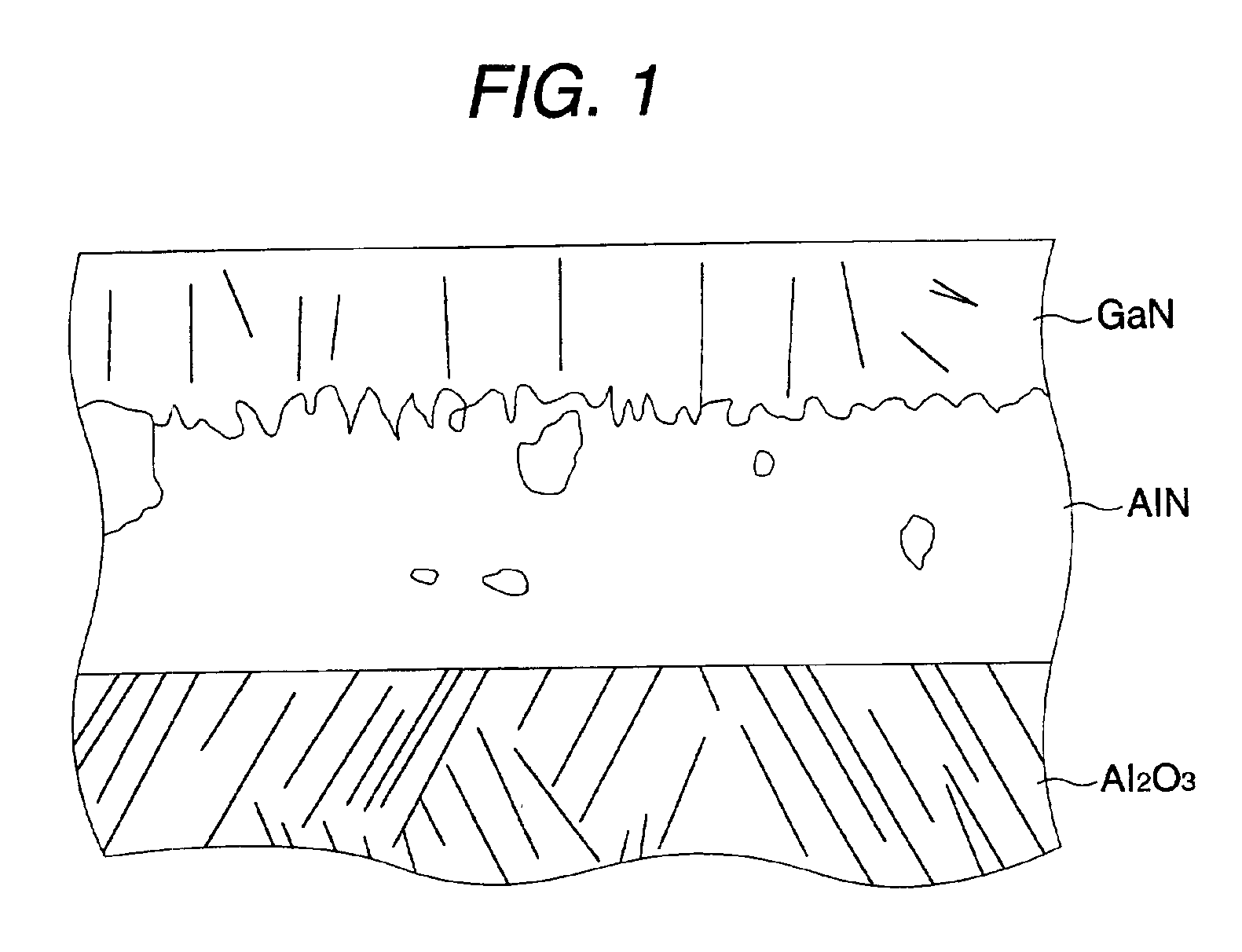

Group III nitride compound semiconductor device and method for producing the same

InactiveUS6841808B2Shorten production timeReduce laborSolid-state devicesSemiconductor/solid-state device manufacturingLateral overgrowthNitride

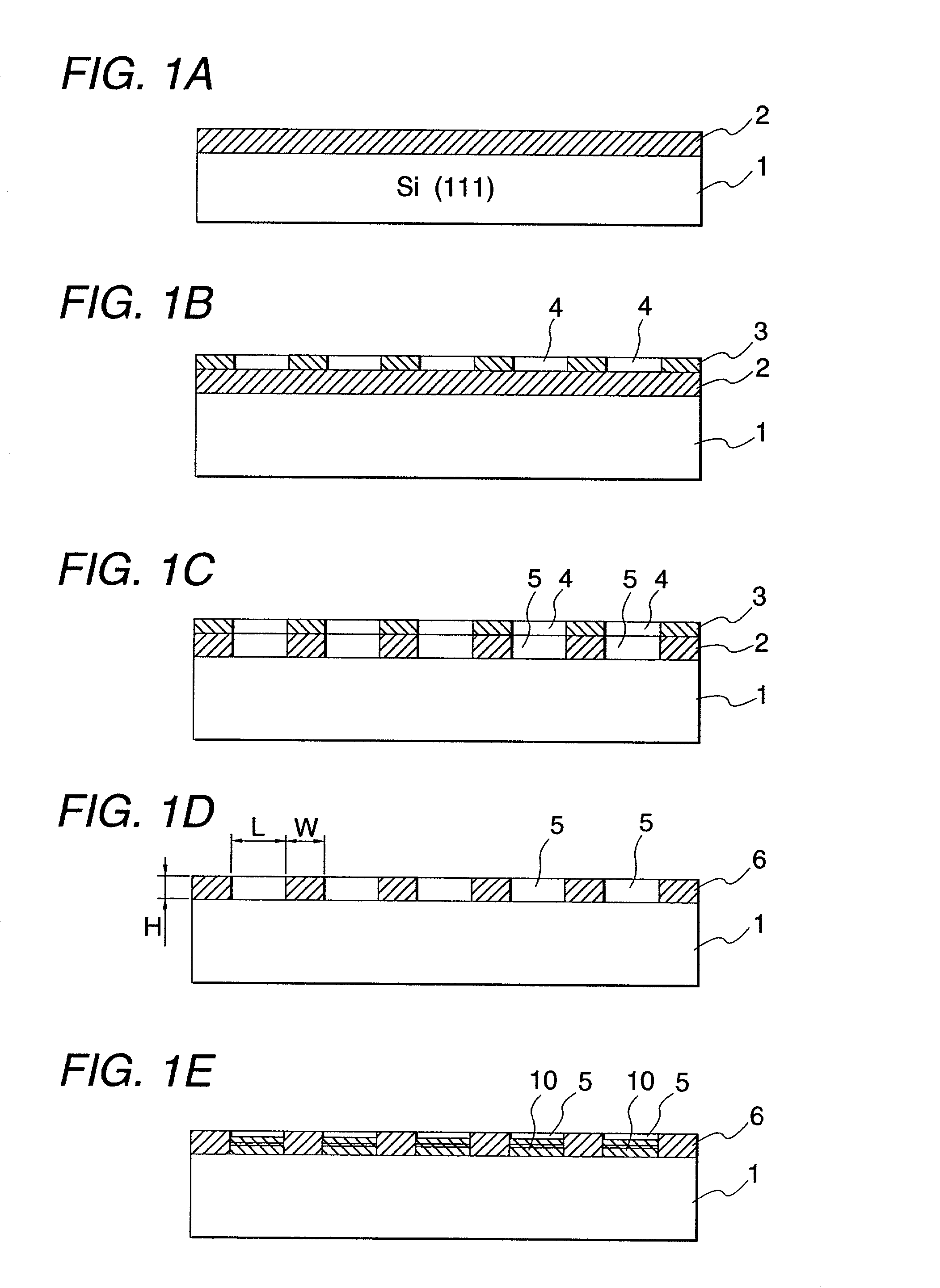

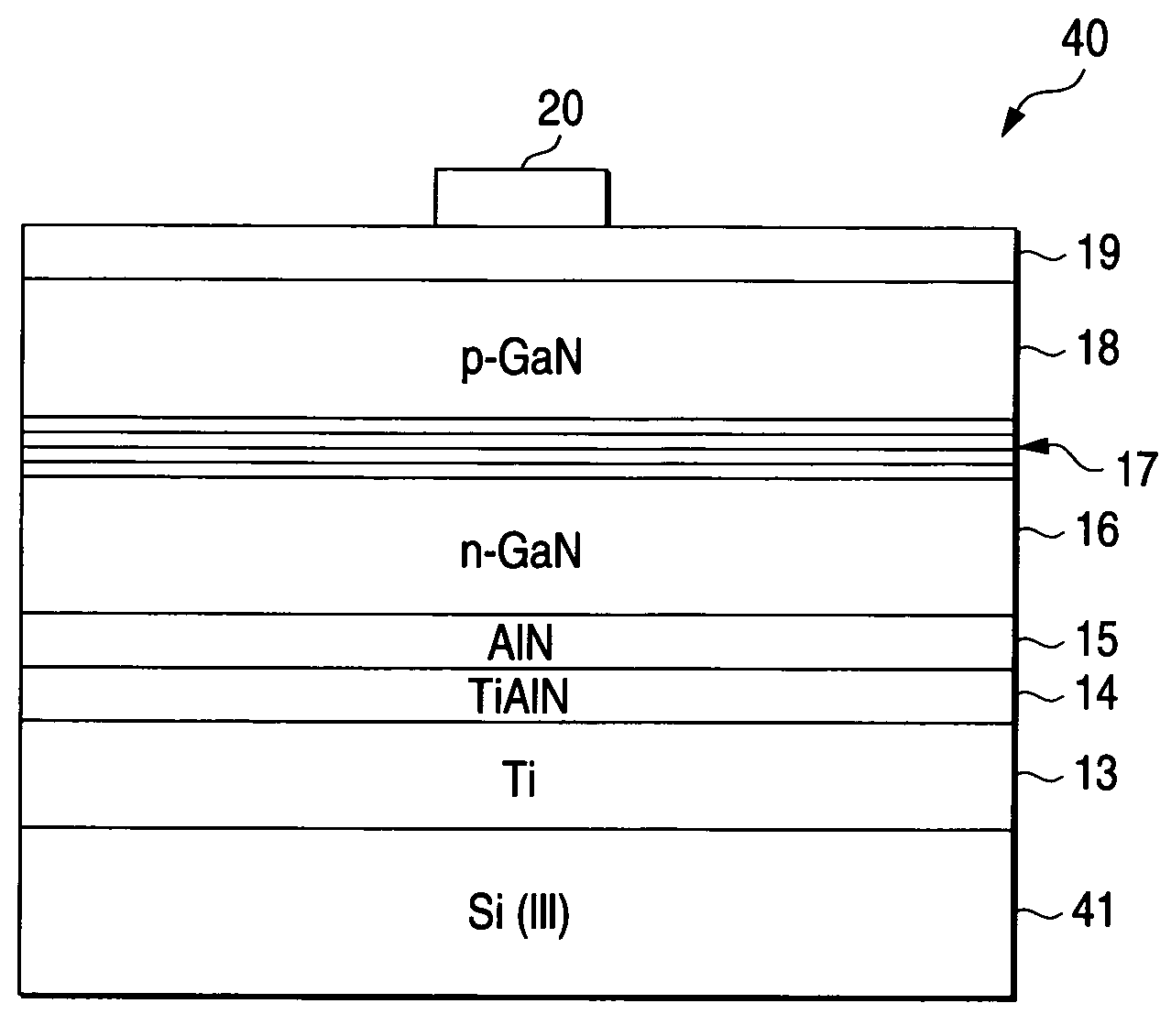

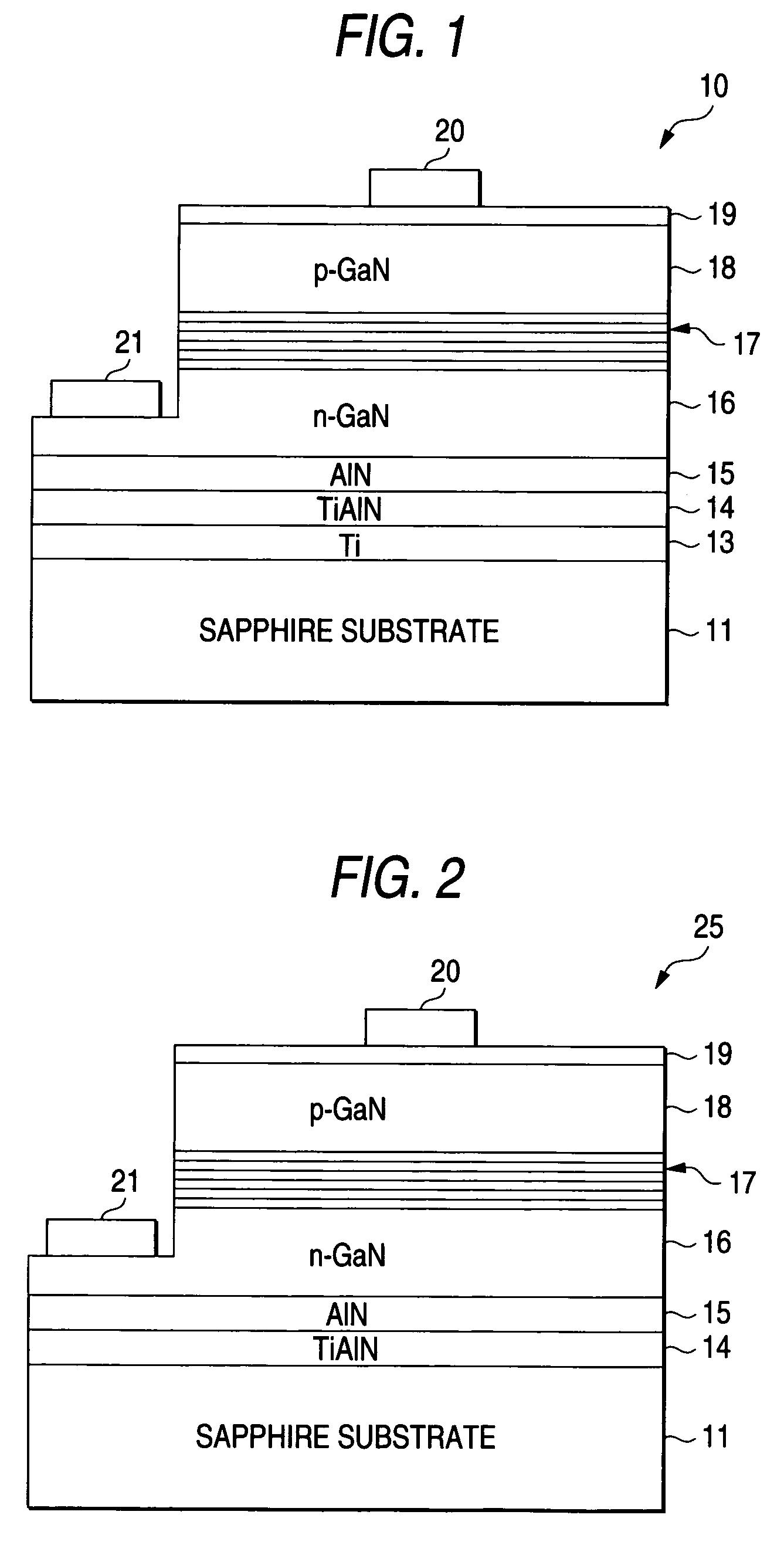

An AlN layer having a surface of a texture structure is formed on a sapphire substrate. Then, a growth suppressing material layer is formed on the AlN layer so that the AlN layer is partially exposed to the outside. Then, group III nitride compound semiconductor layers are grown on the AlN layer and on the growth suppressing material layer by execution of an epitaxial lateral overgrowth method. Thus, a group III nitride compound semiconductor device is produced. An undercoat layer having convex portions each shaped like a truncated hexagonal pyramid is formed on a substrate. Group III nitride compound semiconductor layers having a device function are laminated successively on the undercoat layer.

Owner:TOYODA GOSEI CO LTD

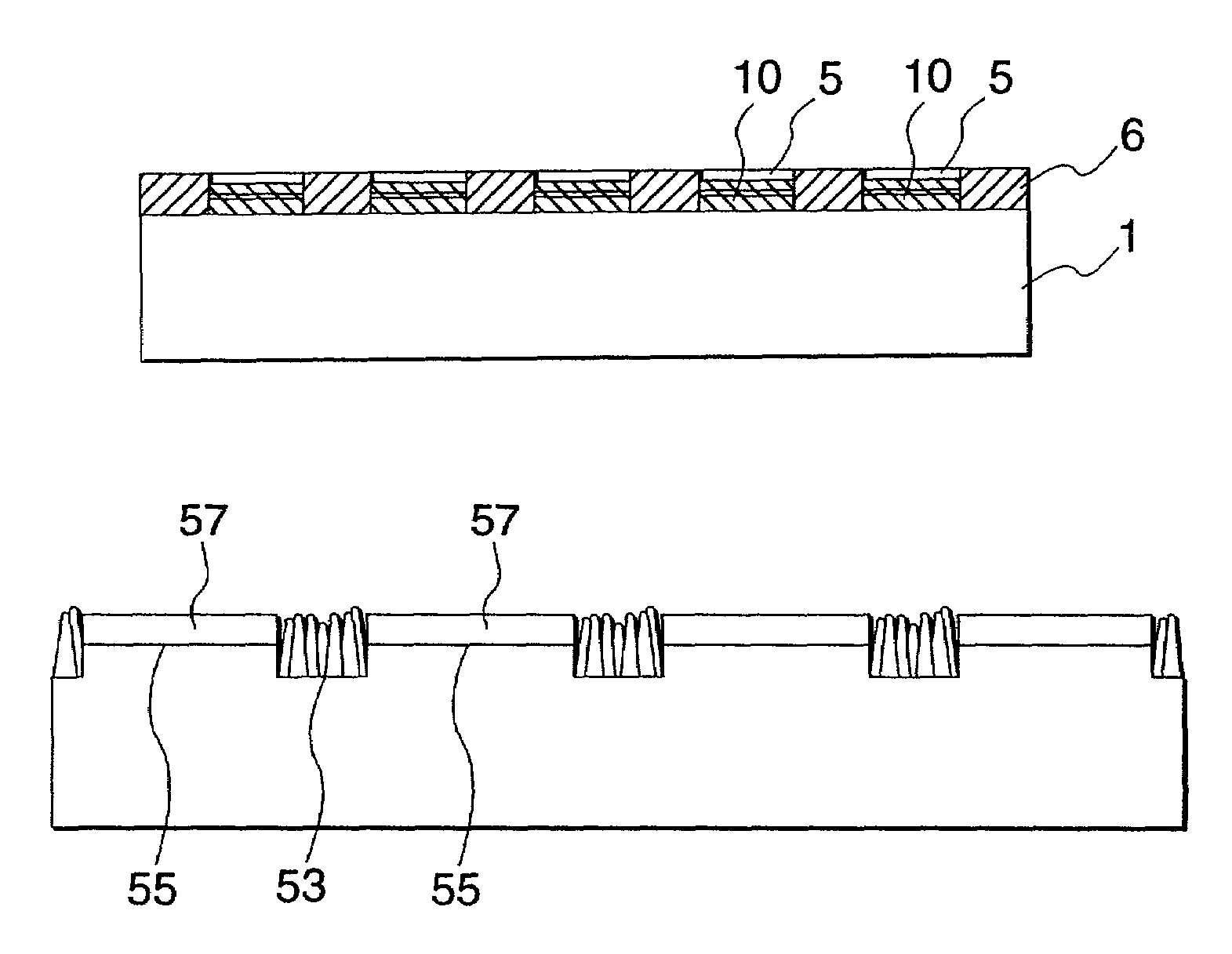

Group III nitride compound semiconductor device and method for producing the same

InactiveUS6982435B2Substrate surface efficientlyEfficiently formedLaser detailsSolid-state devicesNitrideSubstrate surface

A group III nitride compound semiconductor device is produced according to the following manner. A separation layer made of a material which prevents group III nitride compound semiconductors from being grown thereon is formed on a substrate. Group III nitride compound semiconductors is grown on a surface of the substrate uncovered with the separation layer while keeping the uncovered substrate surface separated by the separation layer.

Owner:TOYODA GOSEI CO LTD

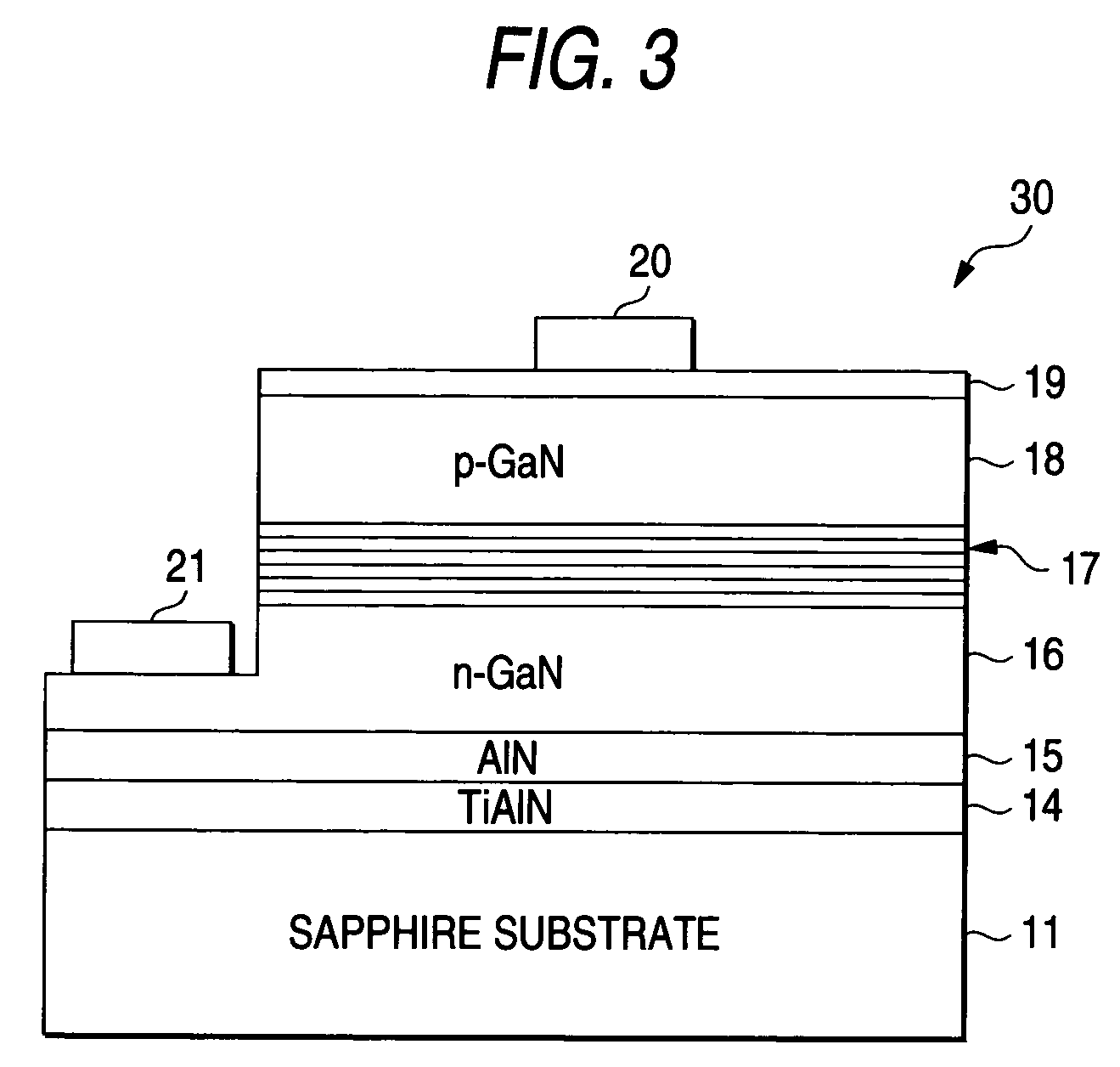

Compound semiconductor element based on Group III element nitride

InactiveUS7312472B2High crystallinityCrystal growthSolid-state devicesSemiconductor/solid-state device manufacturingTitaniumNitride

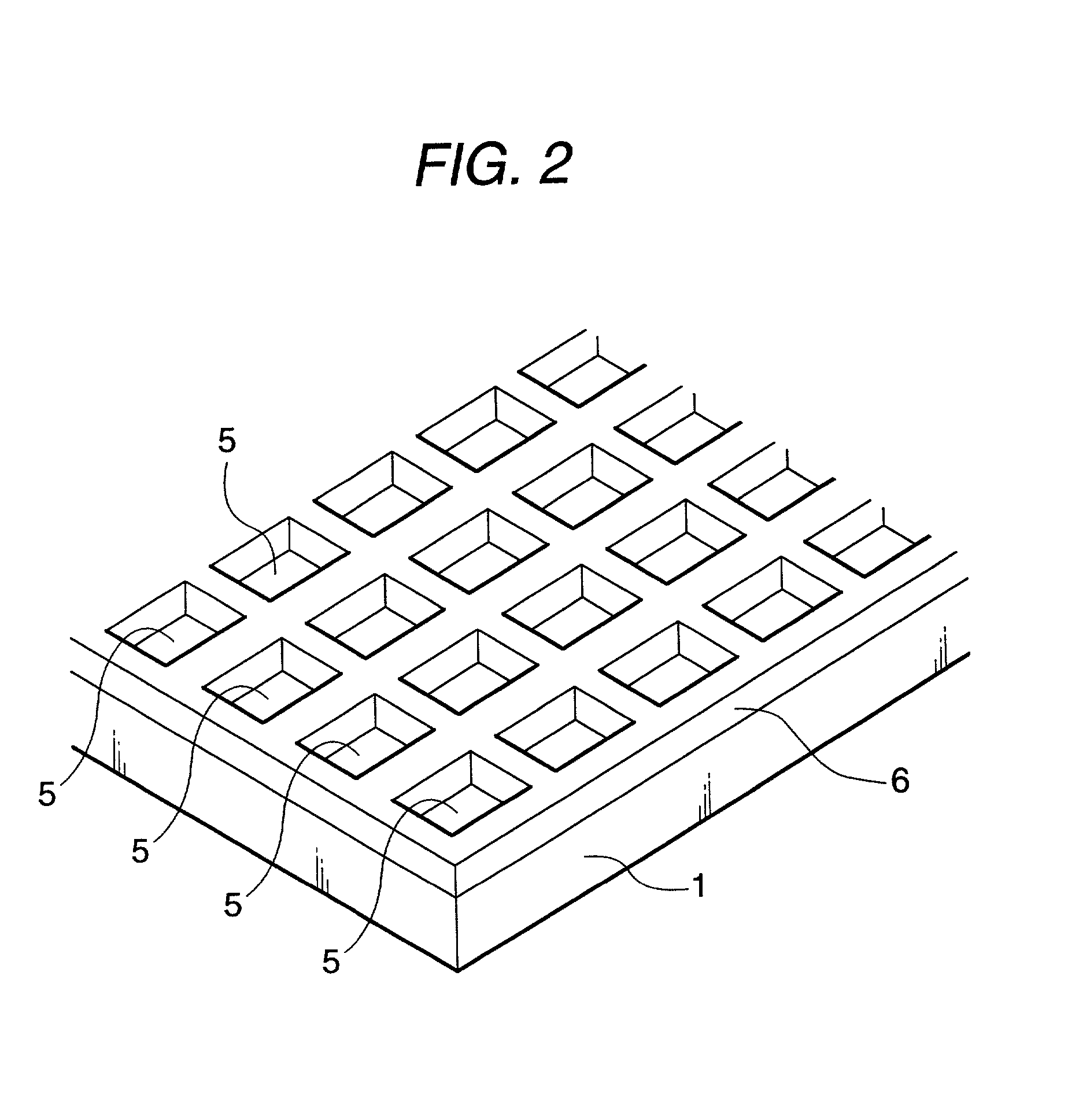

In the present invention, (Ti1−xAx)N [in which A is at least one kind of metal selected from the group consisting of Al, Ga, and In] is used as a metal nitride layer, so that a Group III nitride compound semiconductor layer is formed on the metal nitride layer. When a Ti layer is formed between the metal nitride layer having a sufficient thickness and a substrate and the titanium layer is removed, a Group III nitride compound semiconductor device using metal nitride as a substrate can be obtained.

Owner:TOYODA GOSEI CO LTD

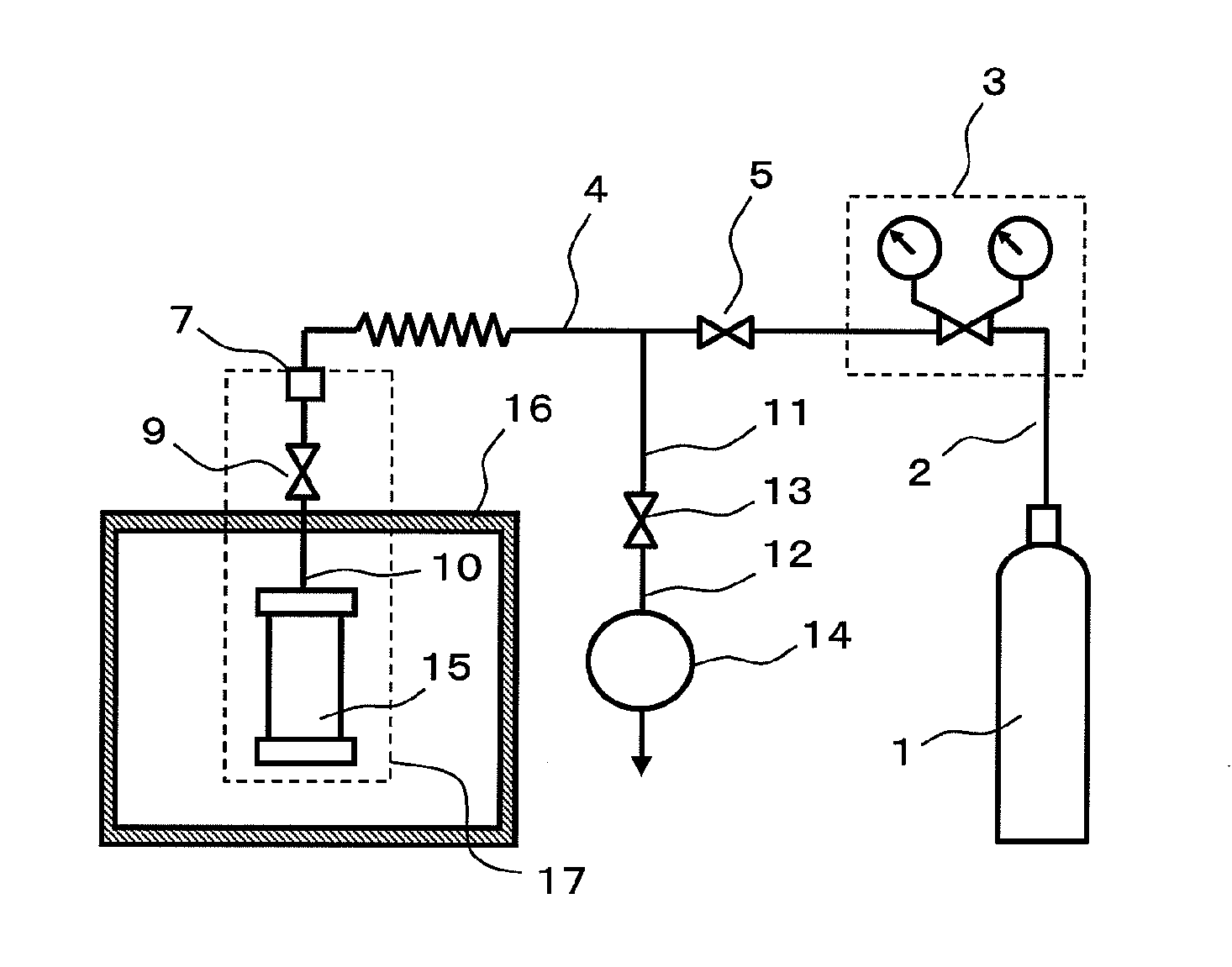

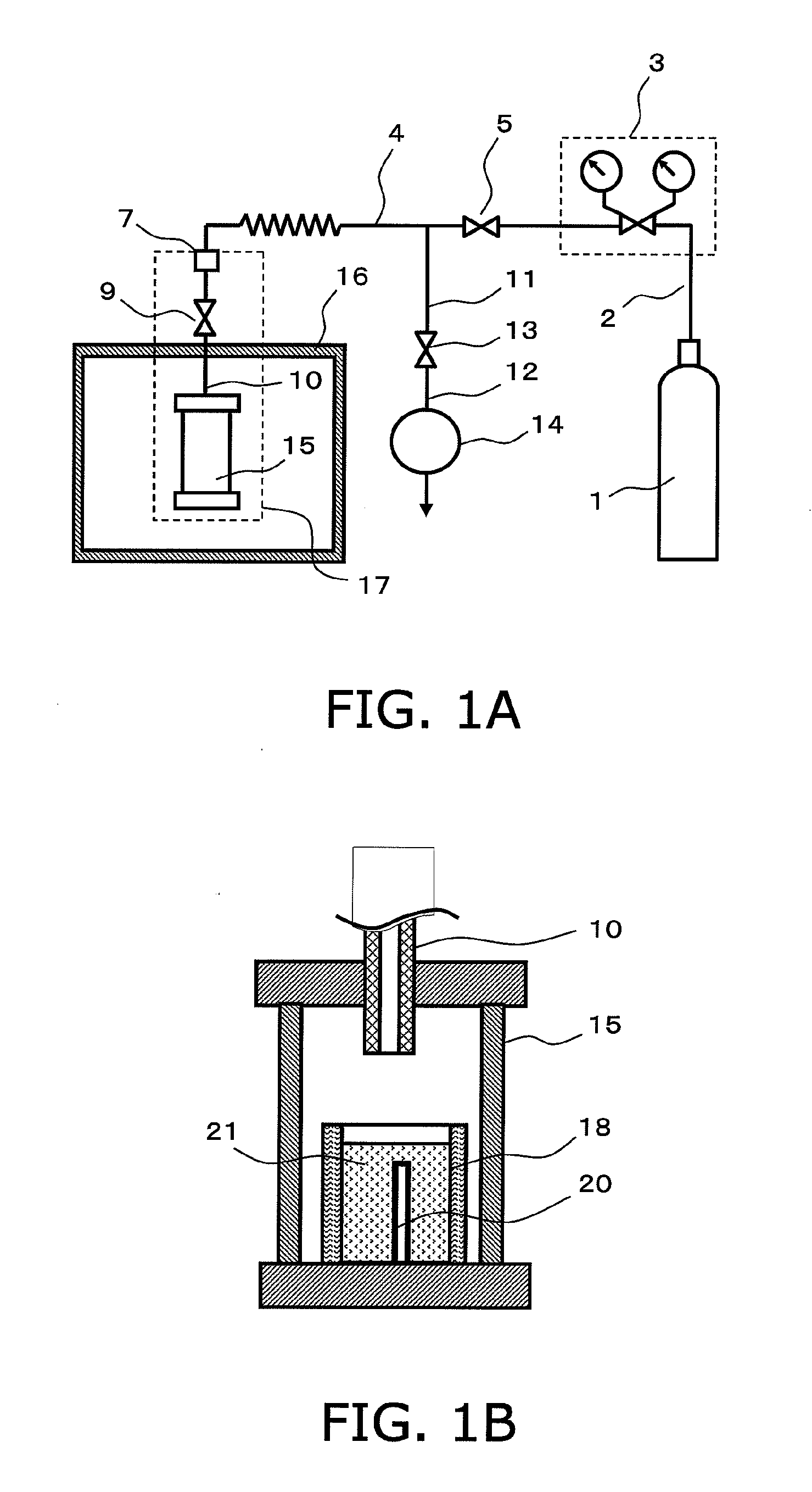

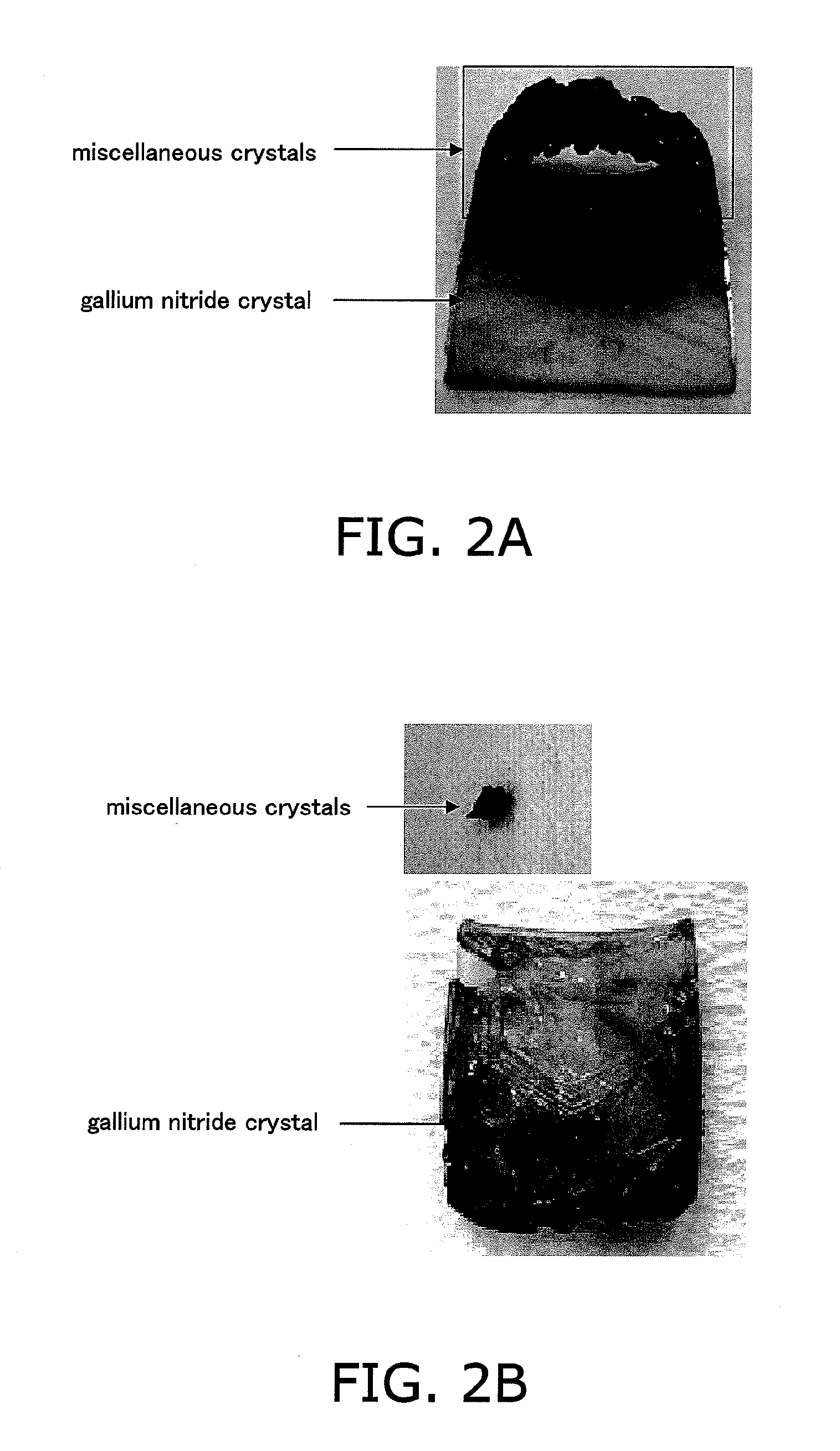

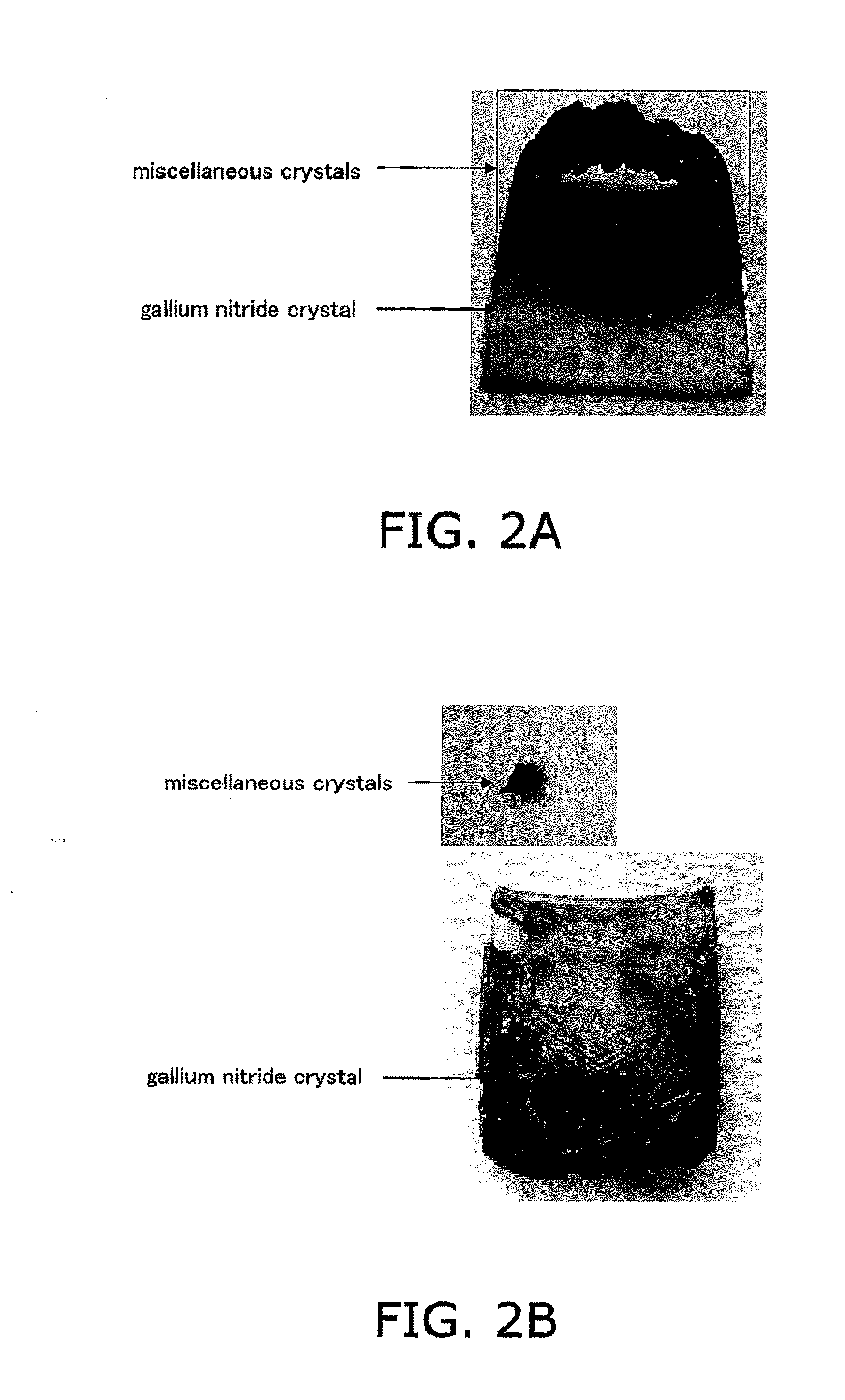

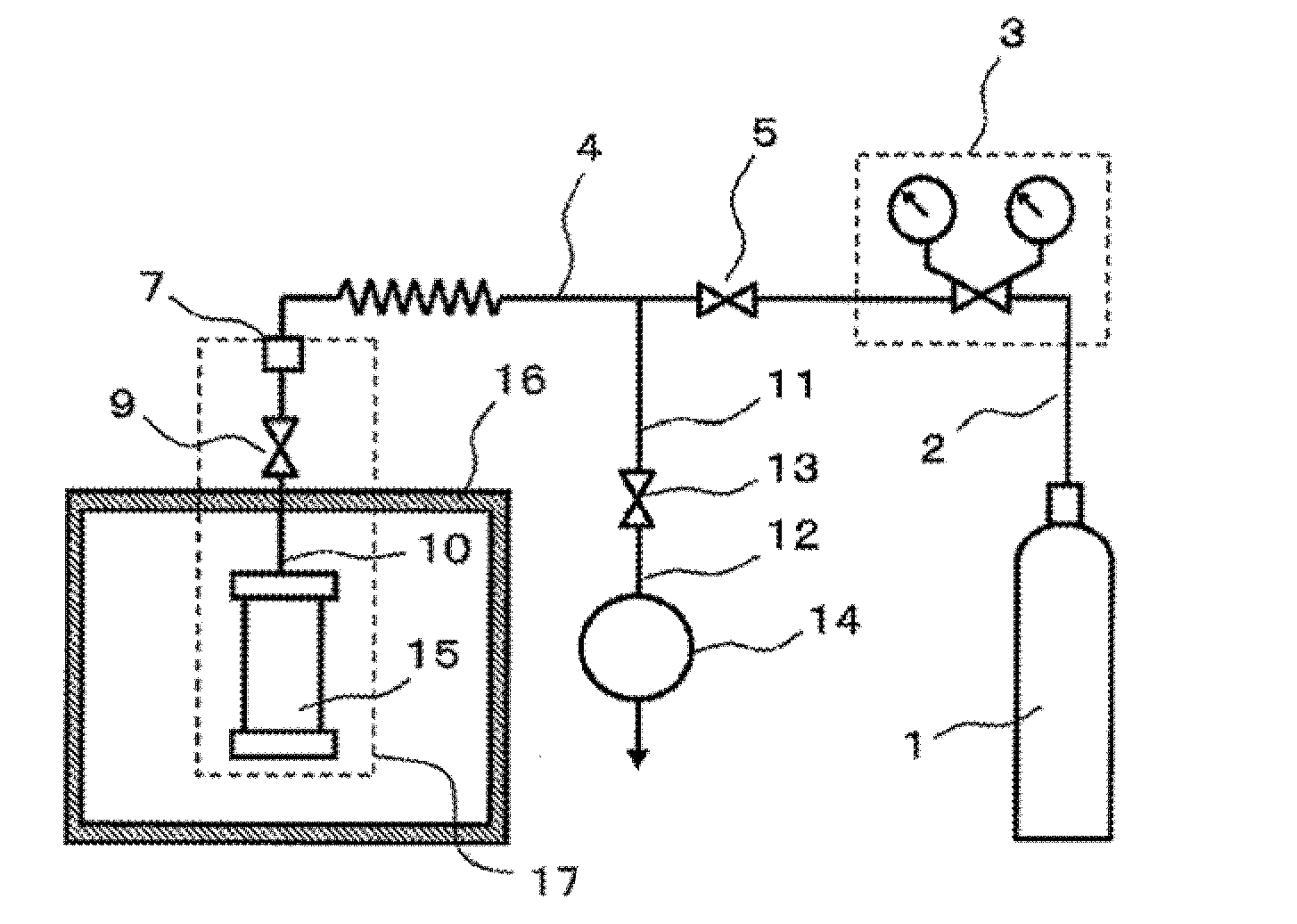

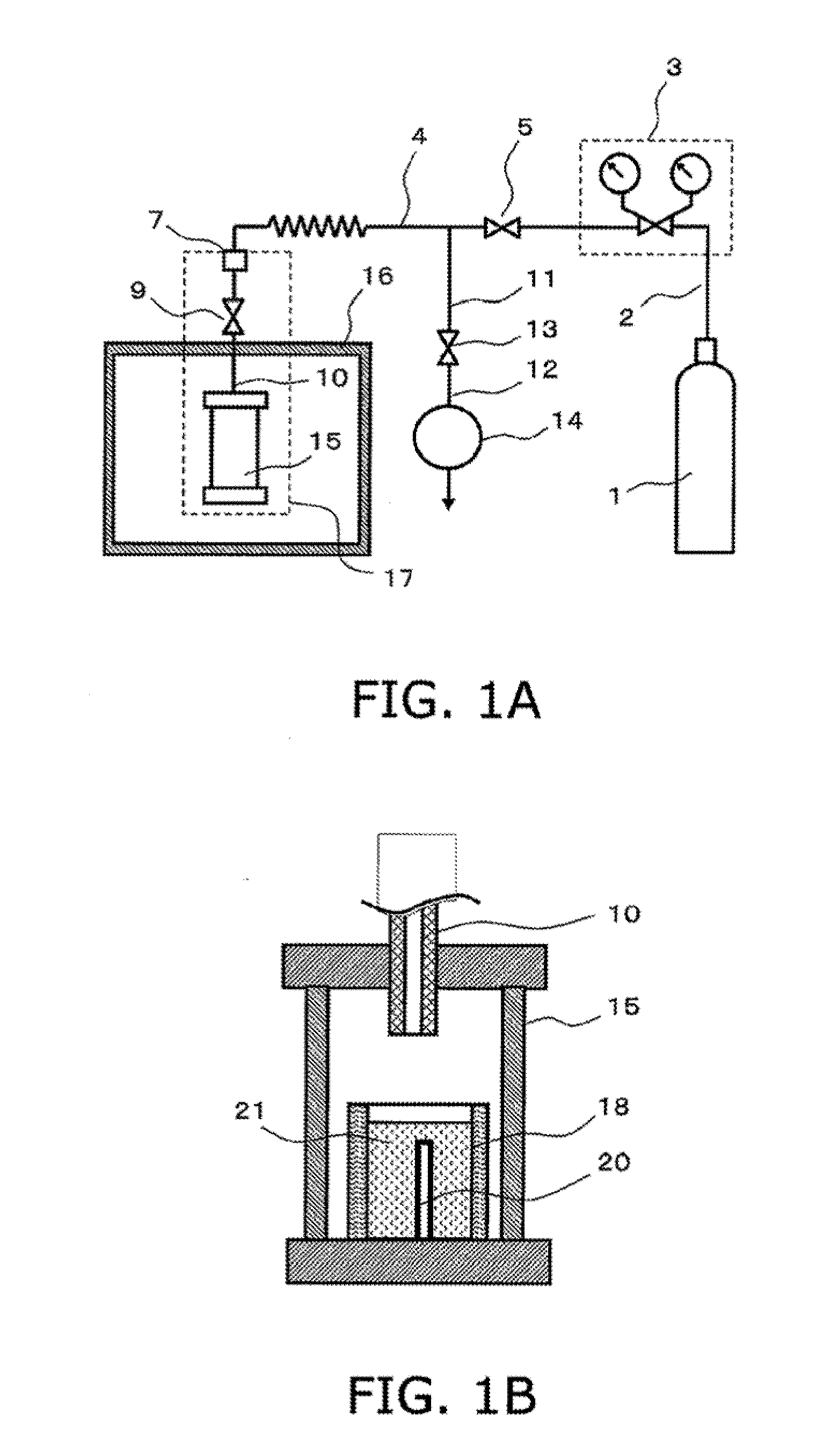

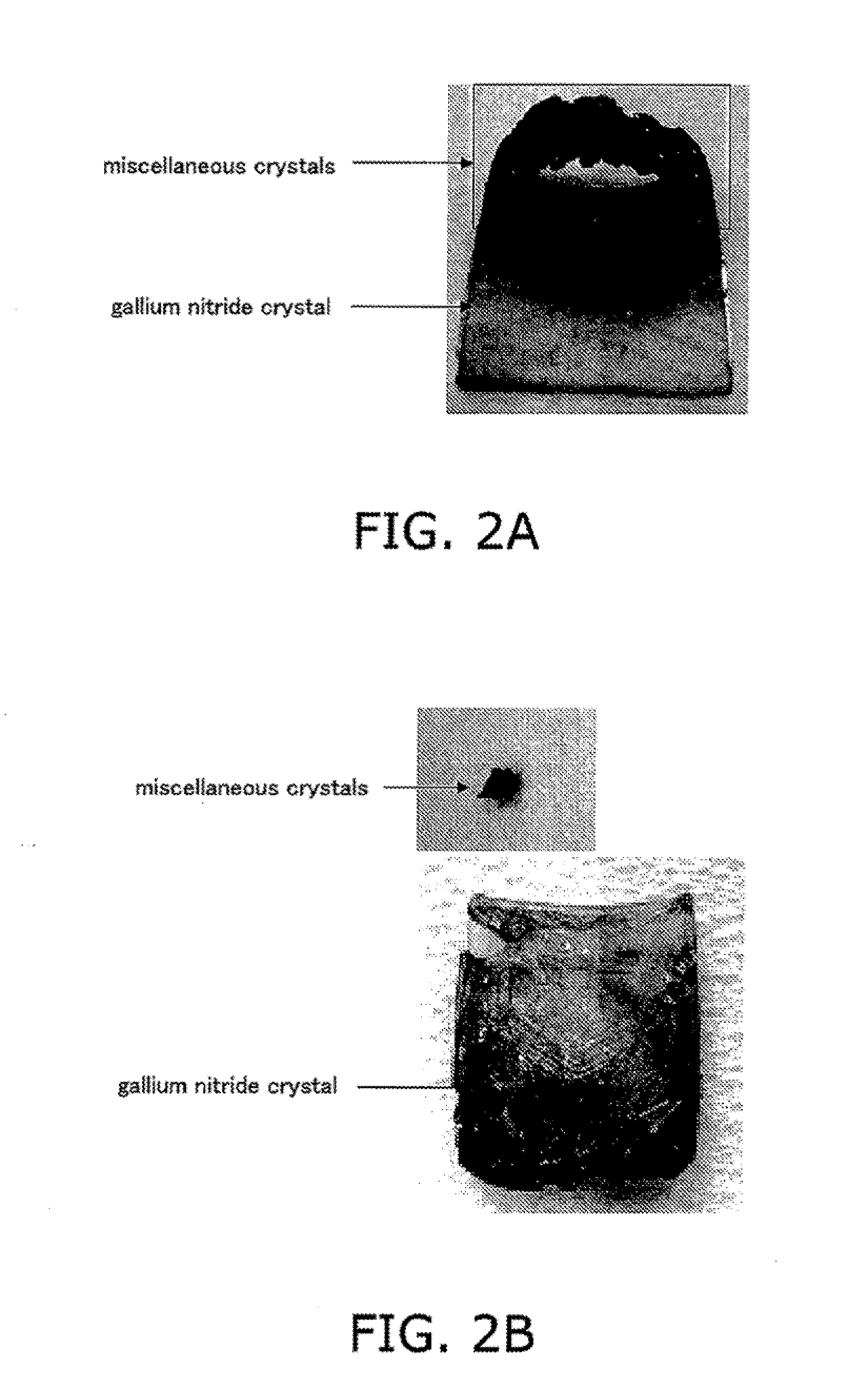

Process for producing group iii element nitride crystal, and group-iii element nitride crystal

InactiveUS20100078606A1Increase volumeEfficiently dissolve nitrogen in the fluxFrom normal temperature solutionsConductive materialBoiling pointNitrogen

A method for producing a high-quality group-III element nitride crystal at a high crystal growth rate, and a group-III element nitride crystal are provided. The method includes the steps of placing a group-III element, an alkali metal, and a seed crystal of group-III element nitride in a crystal growth vessel, pressurizing and heating the crystal growth vessel in an atmosphere of nitrogen-containing gas, and causing the group-III element and nitrogen to react with each other in a melt of the group-III element, the alkali metal and the nitrogen so that a group-III element nitride crystal is grown using the seed crystal as a nucleus. A hydrocarbon having a boiling point higher than the melting point of the alkali metal is added before the pressurization and heating of the crystal growth vessel.

Owner:RICOH KK

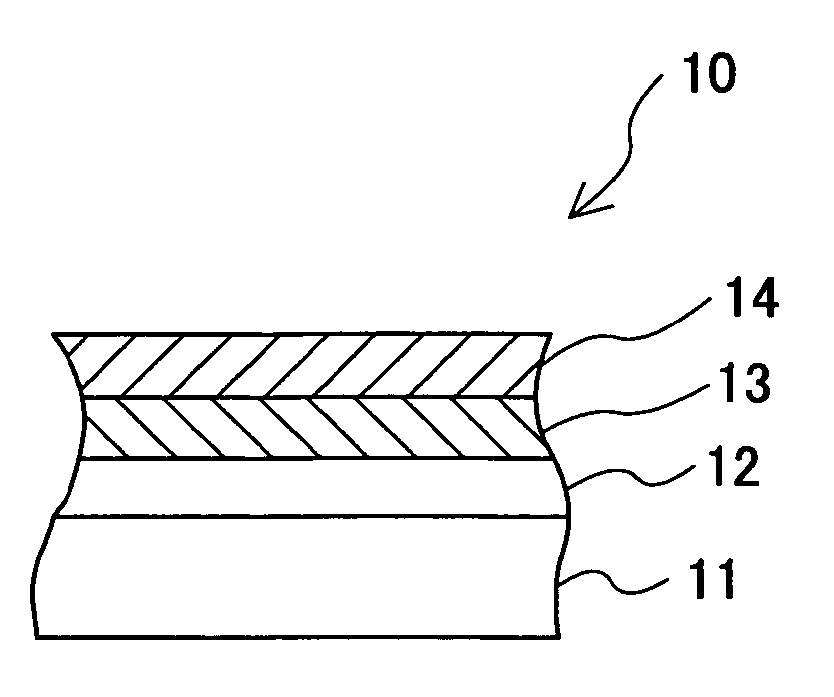

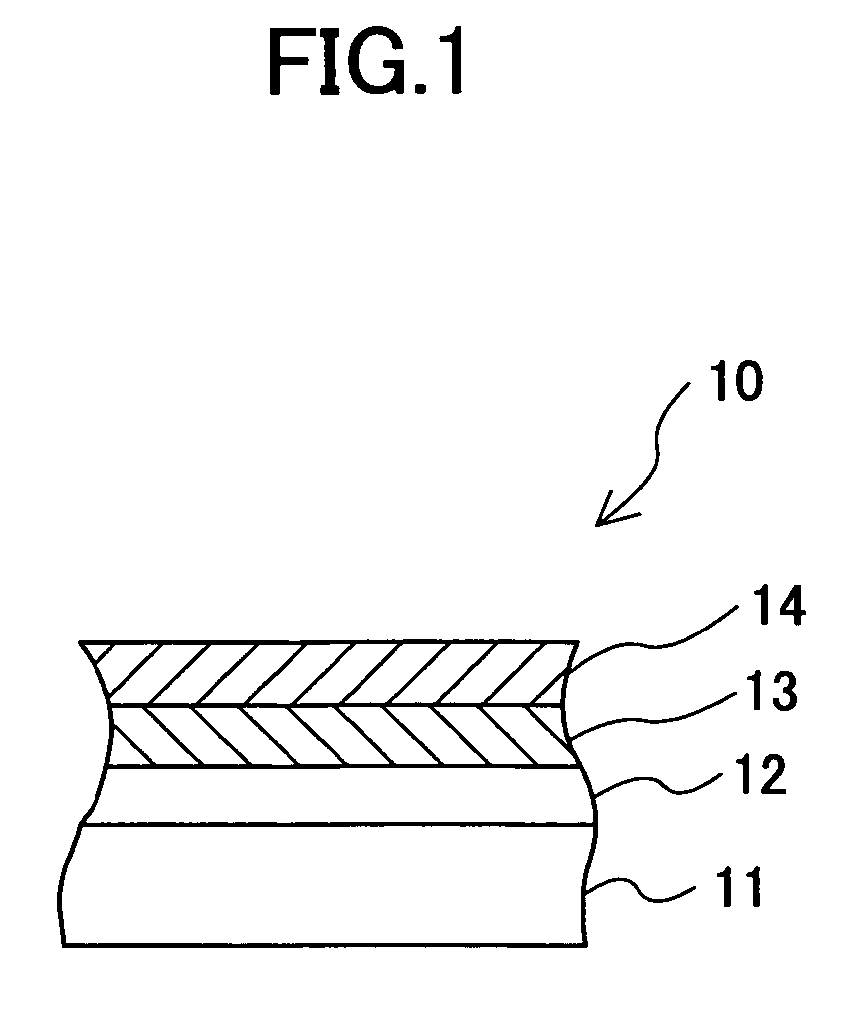

Magnetic recording medium and fabrication method thereof

InactiveUS7132177B2Crystal growthImprove recording densityBase layers for recording layersRecord information storageAlloyNitride

A magnetic recording medium includes an underlayer formed on a substrate and a magnetic layer formed by epitaxial growth on the underlayer. The underlayer is made of Cr based substance, and the magnetic layer is made of Co based magnetic substance. The magnetic layer further includes a plurality of layers, each made of Co based alloy including at least one of oxide and nitride as additional content.

Owner:SHOWA DENKO KK

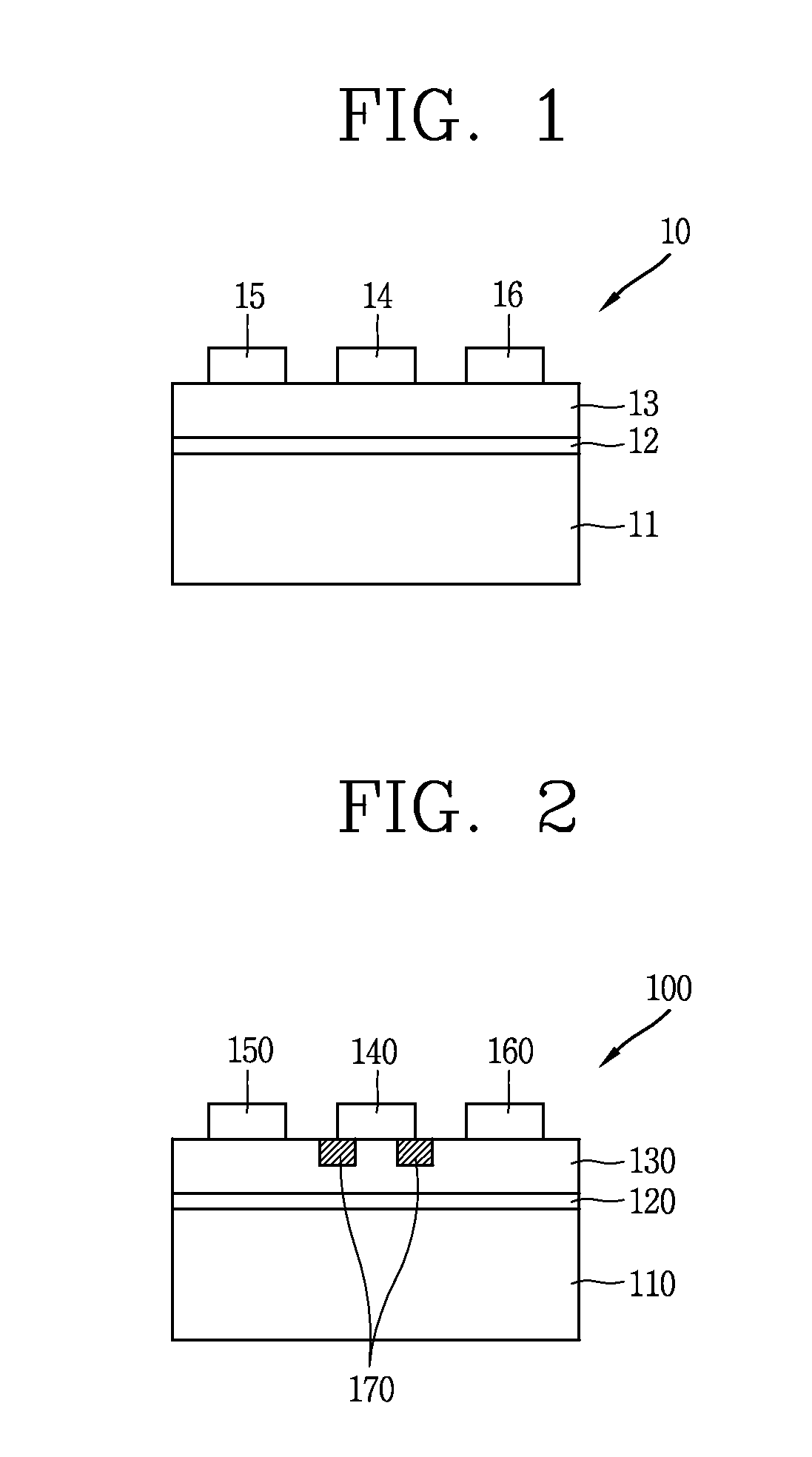

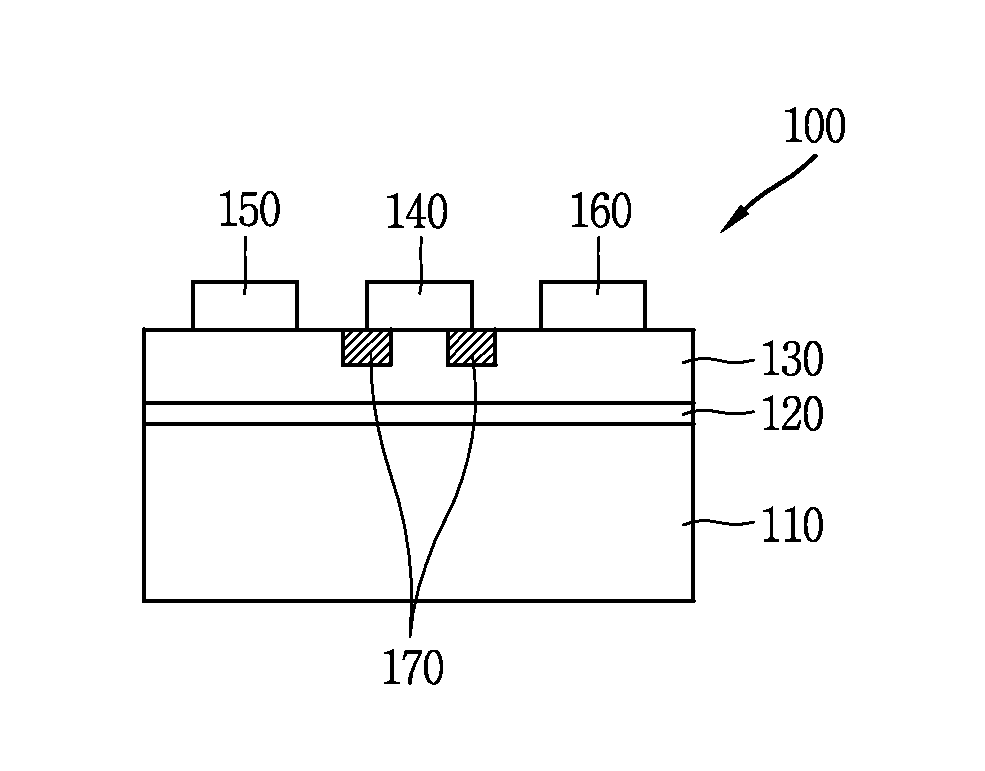

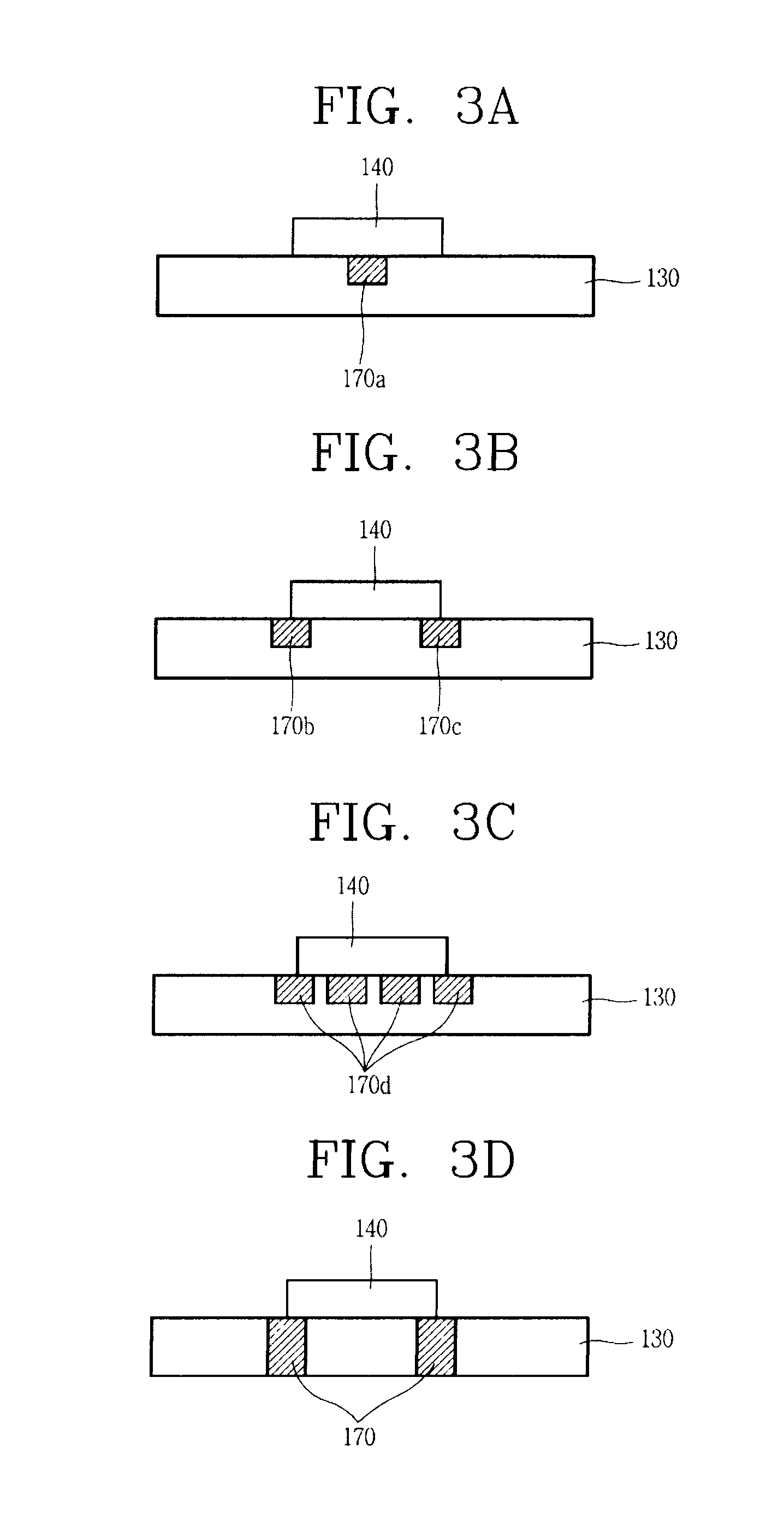

Nitride semiconductor device using selective growth and manufacturing method thereof

ActiveUS20130153921A1Reduce and remove leakage currentImproved breakdown voltage characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

A semiconductor device including a first GaN layer, an AlGaN layer, a second GaN layer, a gate electrode, a source electrode, and a drain electrode sequentially stacked on a substrate, capable of improving a leakage current and a breakdown voltage characteristics generated in the gate electrode by locally forming a p type GaN layer on the AlGaN layer, and a manufacturing method thereof, and a manufacturing method thereof are provided.The semiconductor device includes: a substrate, a first GaN layer formed on the substrate, an AlGaN layer formed on the first GaN layer, a second GaN layer formed on the AlGaN layer and including a p type GaN layer, and a gate electrode formed on the second GaN layer, wherein the p type GaN layer may be in contact with a portion of the gate electrode.

Owner:LG ELECTRONICS INC

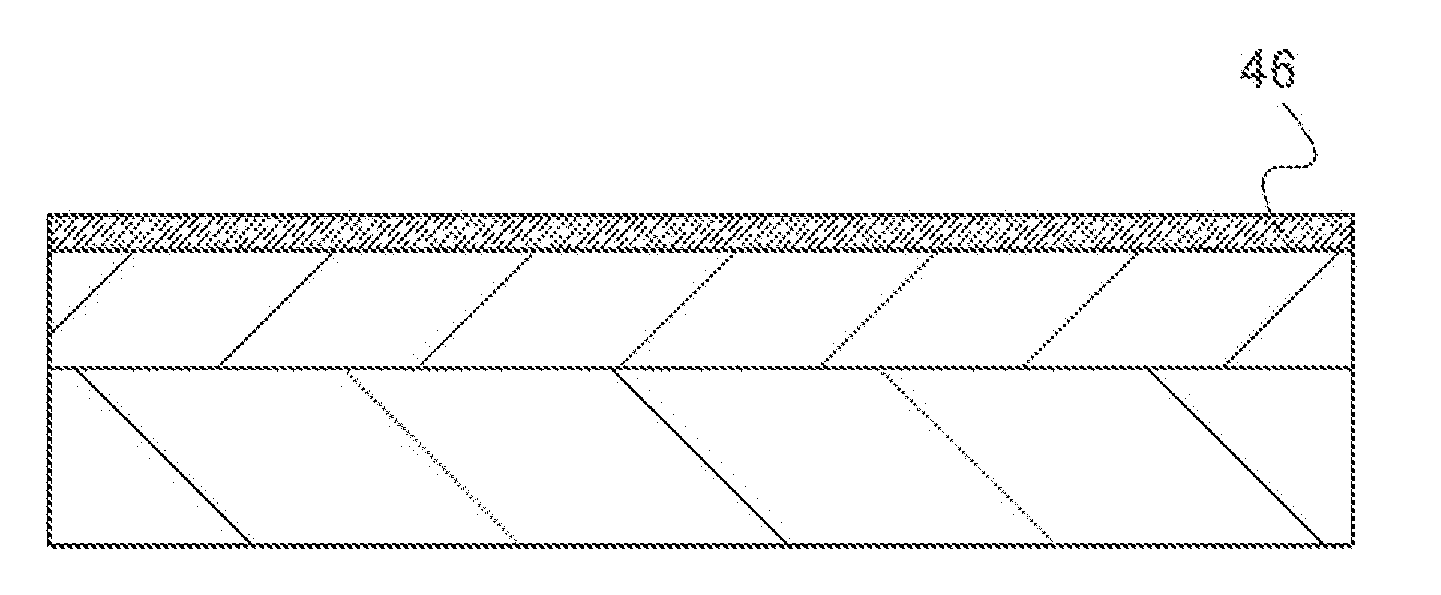

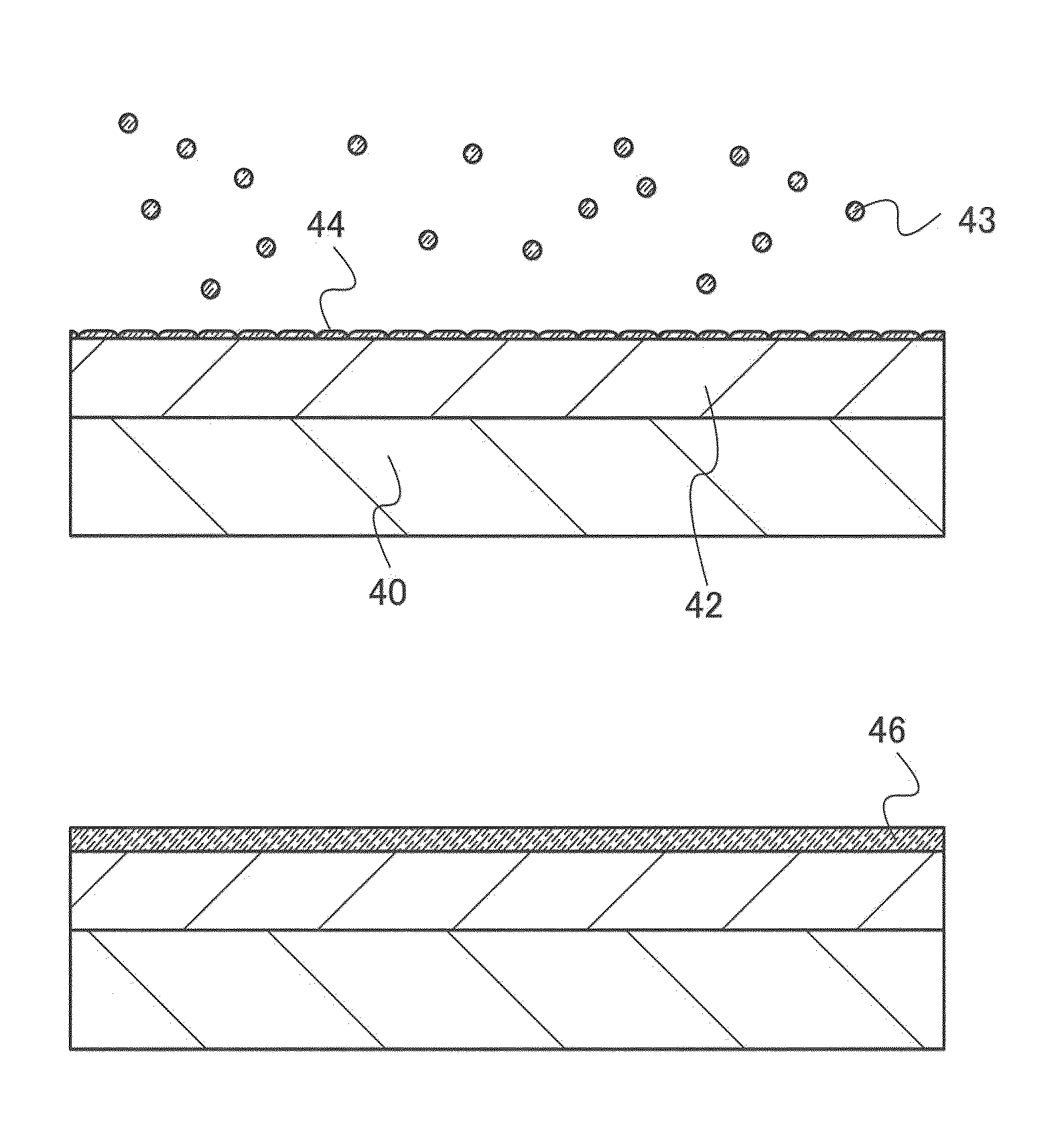

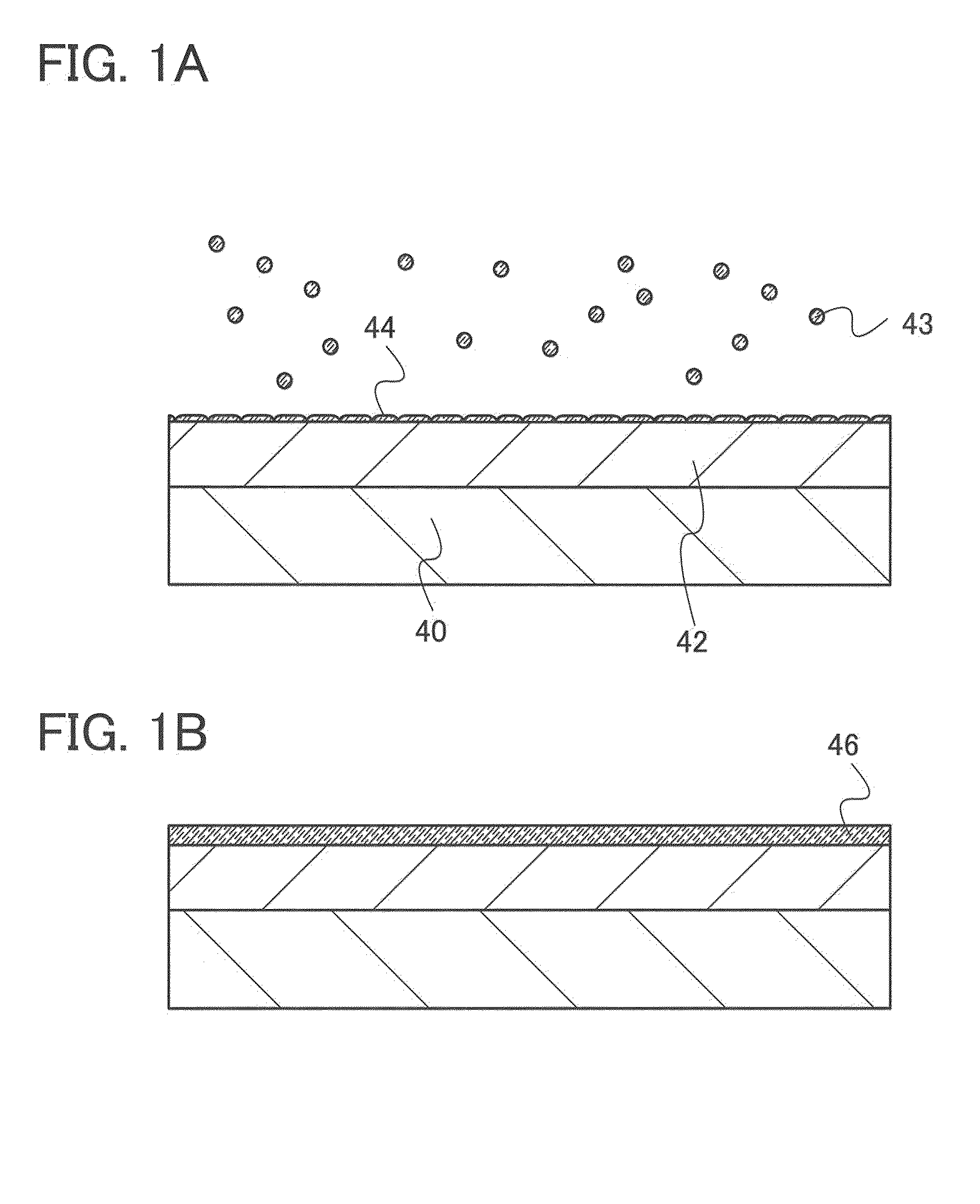

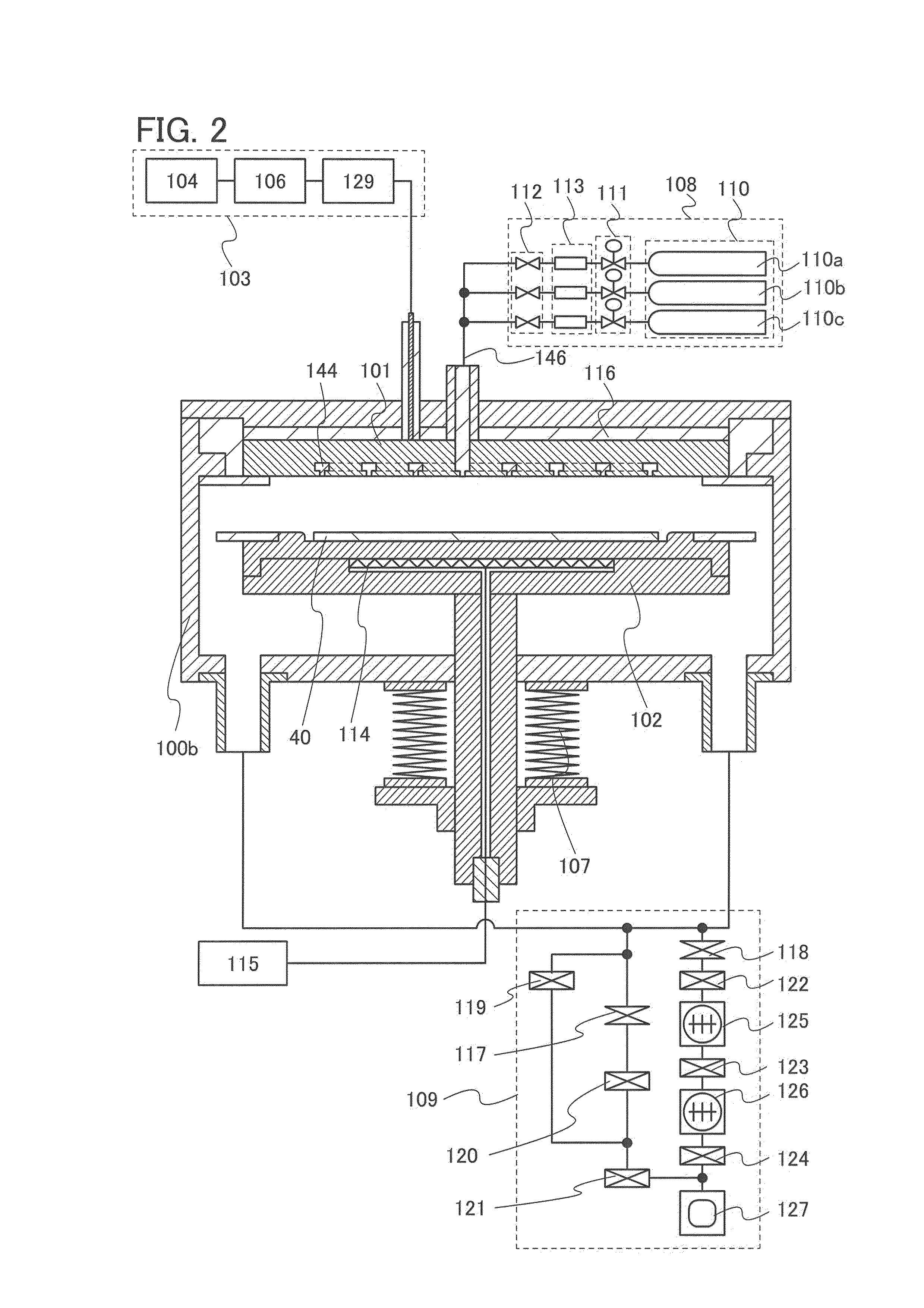

Method of manufacturing photoelectric conversion device

InactiveUS20110053311A1Reduce distanceIncrease probabilityFinal product manufactureSemiconductor/solid-state device manufacturingHigh frequency powerReactive gas

Provided is a technique for manufacturing a photoelectric conversion element using a dense crystalline semiconductor film without a cavity between crystal grains. A method of manufacturing a photoelectric conversion device having a first electrode, a unit cell, and a second electrode over a substrate includes the steps of: forming a plasma region between a first electrode and a second electrode by supplying high-frequency power of 60 MHz or less to the first electrode under a condition where a pressure of a reactive gas in a chamber of a plasma CVD apparatus is set to from 450 Pa to 13332 Pa, and a distance between the first electrode and the second electrode of the plasma CVD apparatus is set to from 1 mm to 20 mm, preferably, 4 mm to 16 mm; forming deposition precursors including a crystalline semiconductor in a gas phase including the plasma region; forming a crystal nucleus having a grain size of from 5 nm to 15 nm by depositing the deposition precursors; and forming a semiconductor film having a first conductivity type, a semiconductor film effective in photoelectric conversion, or a semiconductor film having a first conductivity type in the unit cell, by growing a crystal from the crystal nucleus.

Owner:SEMICON ENERGY LAB CO LTD

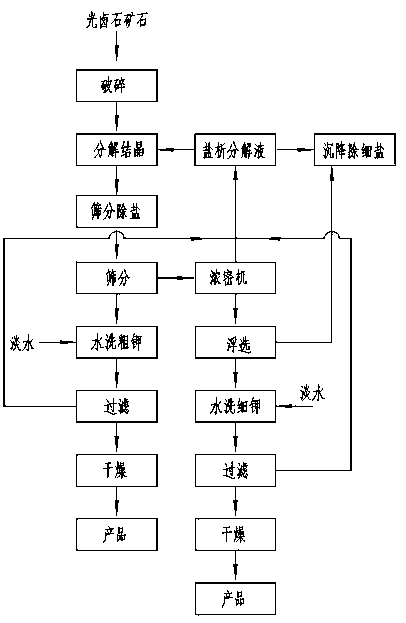

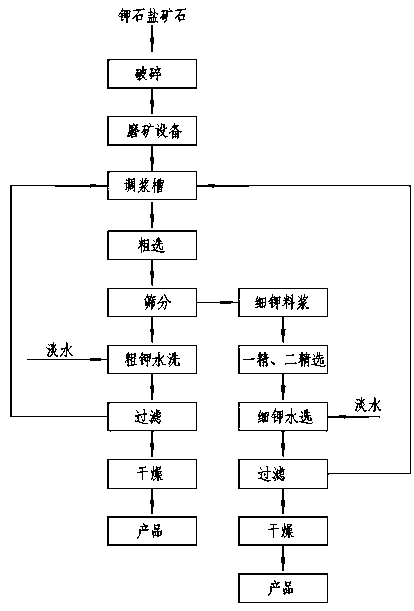

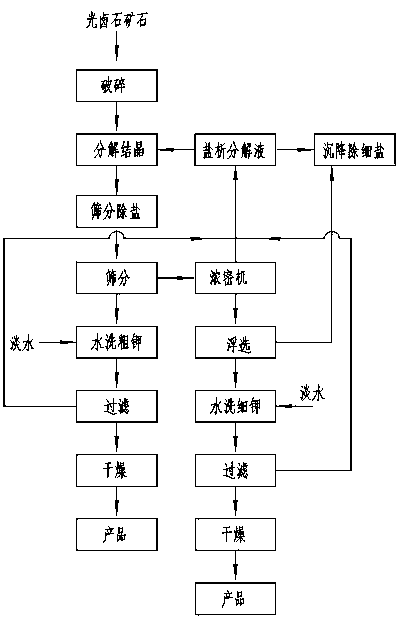

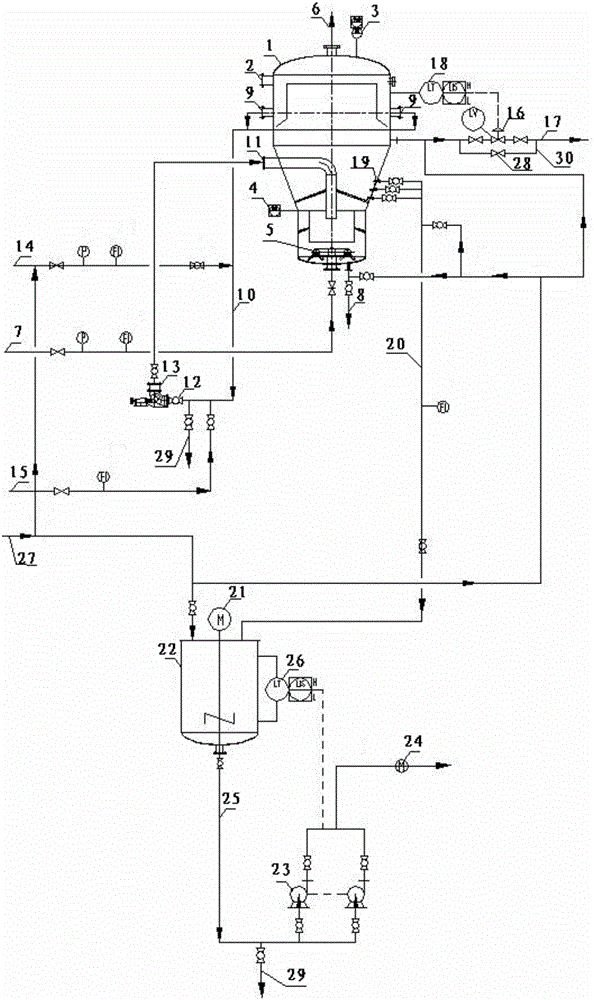

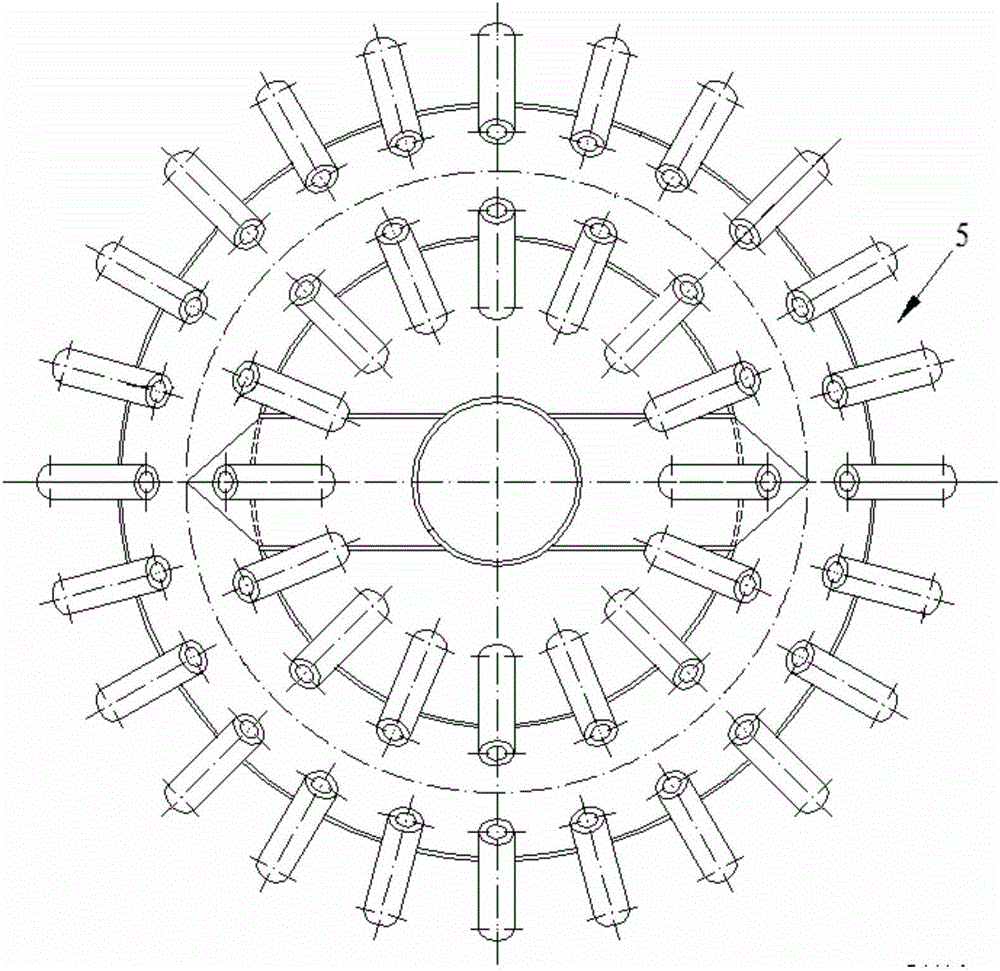

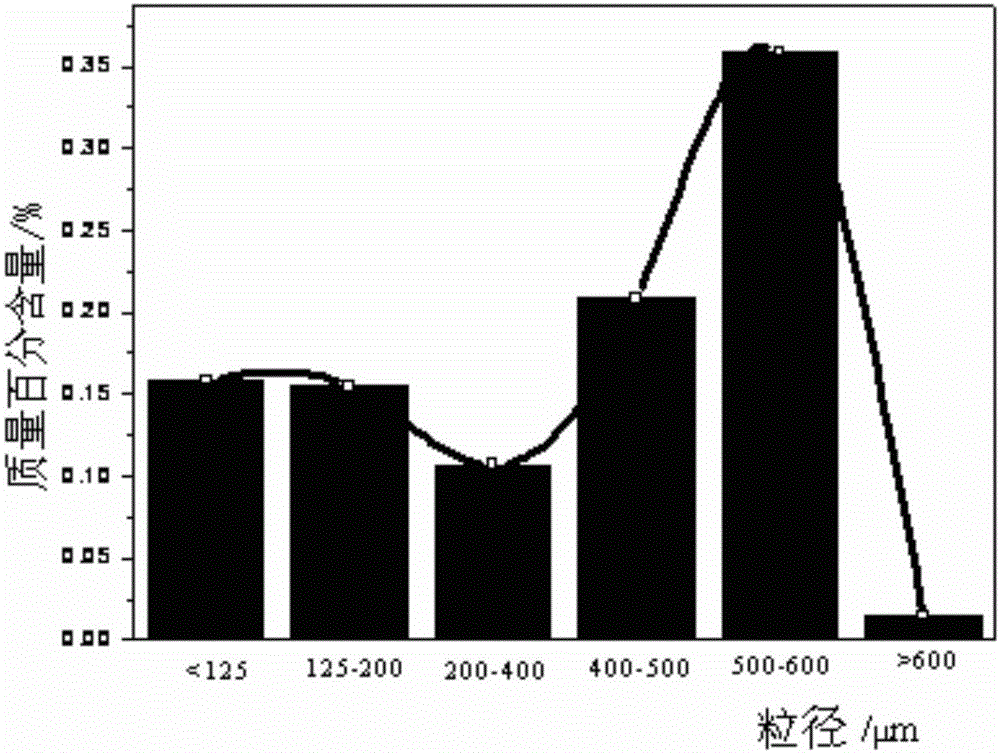

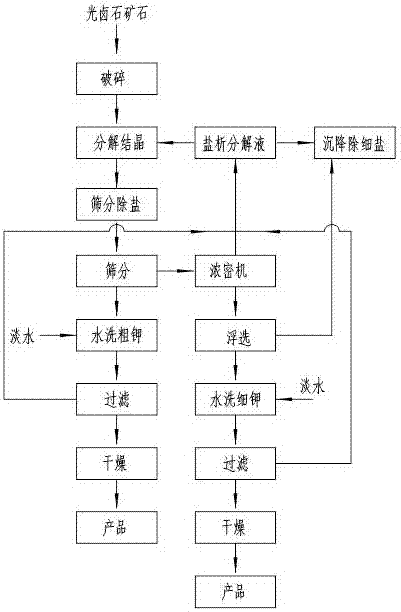

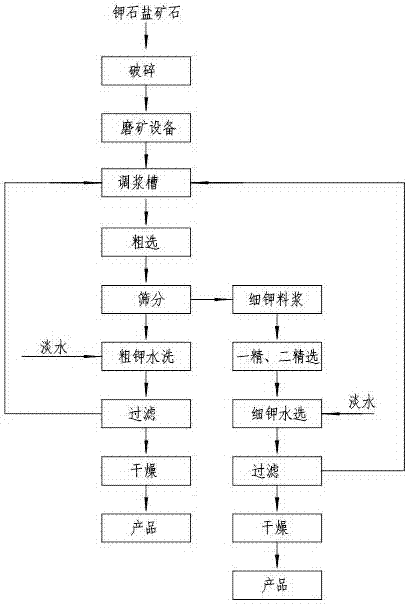

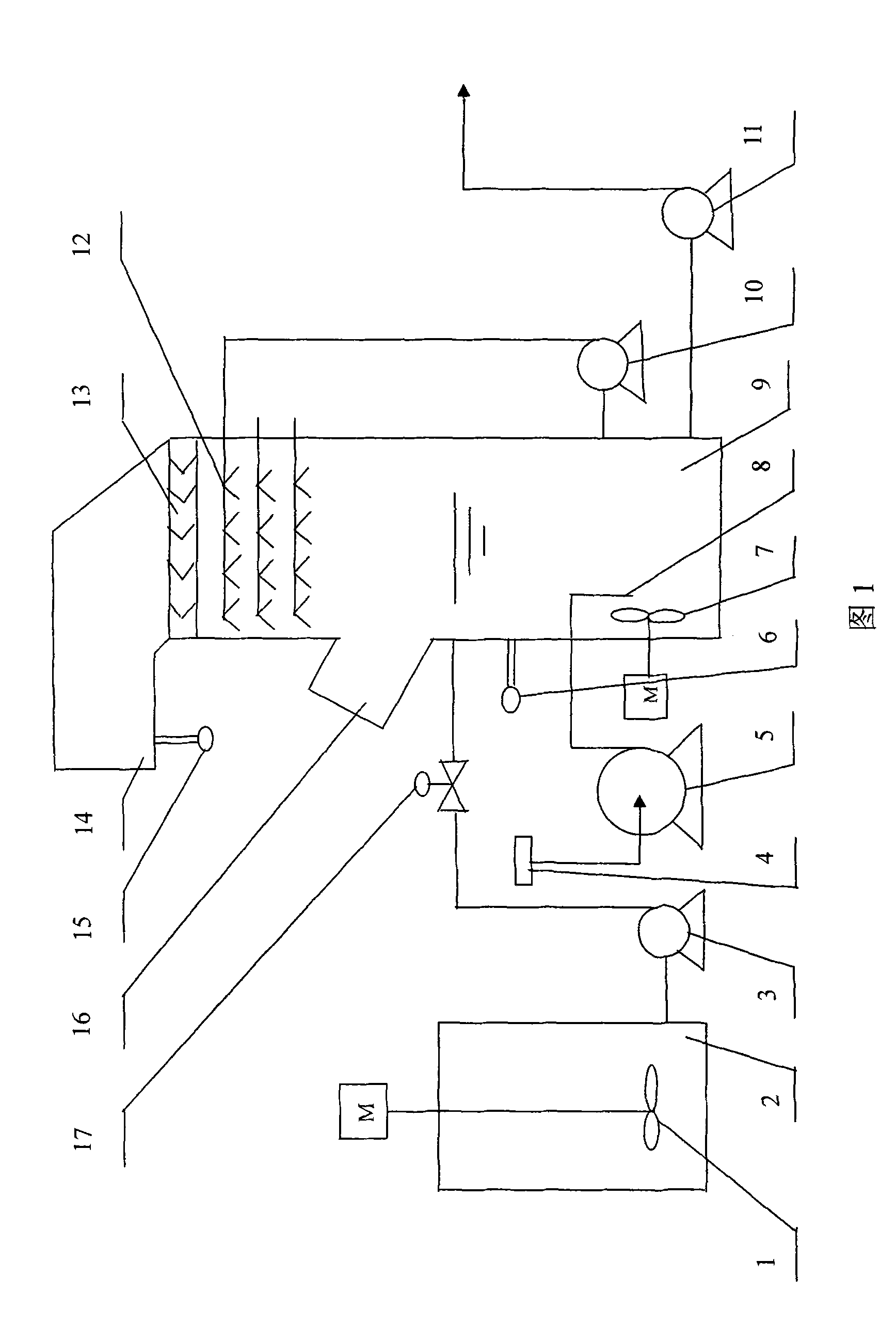

A kind of method for stepwise separation and high-efficiency flotation of potassium salt ore to produce KCl

ActiveCN107188200BQuality improvementEfficient quality productionAlkali metal chloridesGranularityPotassium

The invention discloses a method for efficient flotation production of KCL through sequential separation of sylvite ore, and relates to a method for producing KCl from sylvite ore. According to the technical scheme, the method comprises the steps that after the sylvite ore is manufactured into the certain granularity, pulping, desalting, coarse KCL grain separation, coarse KCl grain washing, fine KCl grain floatation, fine KCl grain washing, dehydration and drying are performed to obtain crude KCl grain products and fine KCl grain products with the purity being 95% or more are obtained; on the basis of advanced separation of some NaCl tail salt and crude KCL grains before KCL floatation or during floatation, the KCL floatation amount is decreased, the floatation strength is lowered, the equipment input is decreased, the building investment is lowered, the floatation reagent consumption is reduced, the environment-friendly pressure is relieved, the mineral separation energy consumption is reduced, the production cost is lowered, the product type is optimized, the product quality is improved, and the KCL recycling rate is increased; the method is mainly used for washing machining of carnallite and sylvine ore of deposit mining.

Owner:山东瑞源钾盐工程技术股份有限公司

Group-iii element nitride crystal producing method and group-iii element nitride crystal

InactiveUS20110012070A2Increase volumeEfficiently dissolve nitrogen in the fluxConductive materialFrom melt solutionsBoiling pointNitrogen

A method for producing a high-quality group-III element nitride crystal at a high crystal growth rate, and a group-III element nitride crystal are provided. The method includes the steps of placing a group-III element, an alkali metal, and a seed crystal of group-III element nitride in a crystal growth vessel, pressurizing and heating the crystal growth vessel in an atmosphere of nitrogen-containing gas, and causing the group-III element and nitrogen to react with each other in a melt of the group-III element, the alkali metal and the nitrogen so that a group-III element nitride crystal is grown using the seed crystal as a nucleus. A hydrocarbon having a boiling point higher than the melting point of the alkali metal is added before the pressurization and heating of the crystal growth vessel.

Owner:RICOH KK

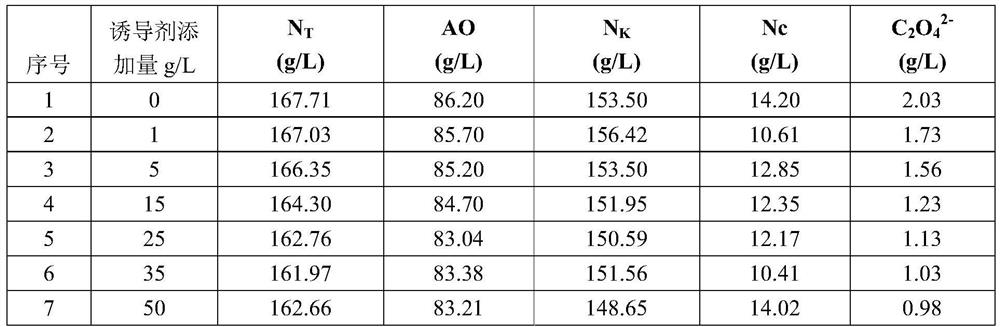

Device and process for removing oxalate in sodium aluminate solution

ActiveCN112299461AExclude implementationShort processAluminates/aluminium-oxide/aluminium-hydroxide purificationProcess efficiency improvementSodium aluminateSlurry

The invention discloses a device and a process for removing oxalate in a sodium aluminate solution. The device comprise three parts, namely an oxalate reaction growth system, a grading system and a solid-liquid separation system. The process comprises the following steps: firstly, adding an oxalate growth agent, the sodium aluminate solution in an aluminum oxide production section and an oxalate inducer into a reaction tank; performing stirring to separate out oxalate in the form of large-particle agglomerates so as to obtain reaction slurry; pumping the reaction slurry into a grader for grading to obtain underflow and overflow; and finally, respectively carrying out solid-liquid separation on the underflow and the overflow to remove oxalate in the sodium aluminate solution. The method isshort in technological process, economical and feasible, and has a good industrial popularization prospect.

Owner:湖南诺兰蒂尔环保科技有限公司

Group-iii element nitride crystal producing method and group-iii element nitride crystal

InactiveUS20120168695A2Increase volumeEfficiently dissolve nitrogen in the fluxConductive materialFrom melt solutionsPhysical chemistryCrystal growth rate

A method for producing a high-quality group-III element nitride crystal at a high crystal growth rate, and a group-III element nitride crystal are provided. The method includes the steps of placing a group-III element, an alkali metal, and a seed crystal of group-III element nitride in a crystal growth vessel, pressurizing and heating the crystal growth vessel in an atmosphere of nitrogen-containing gas, and causing the group-III element and nitrogen to react with each other in a melt of the group-III element, the alkali metal and the nitrogen so that a group-III element nitride crystal is grown using the seed crystal as a nucleus. A hydrocarbon having a boiling point higher than the melting point of the alkali metal is added before the pressurization and heating of the crystal growth vessel.

Owner:RICOH KK

Method for producing baking soda large in particle size

ActiveCN105819471AExtend reaction residence timeCrystal growthBicarbonate preparationSlurrySeed crystal

The invention discloses a method for producing baking soda large in particle size .The method comprises the following steps that seed crystals are put into a reaction crystallizer; mother liquor is introduced into the reaction crystallizer till the liquor level reaches an alkali liquor circulating outlet, and the solid-to-liquor ratio in the reaction crystallizer is controlled to be (0.05-0.15):1; alkali liquor and carbon dioxide containing mixed gas are introduced into the reaction crystallizer for reacting, meanwhile, the mixed liquor in the reaction crystallizer is circulated to an alkali liquor circulating inlet from the alkali liquor circulating outlet, and an external circulating system is set up; under the action of the external circulating system, baking soda crystals obtained through reacting are suspended in the reaction crystallizer, upper-layer fine grains are discharged to a large production system, lower-layer baking soda crystal slurry is discharged, the discharged lower-layer baking soda crystal slurry is thickened, dried and separated, and the baking soda product large in particle size is obtained .Reacting and crystallizing are integrated, the large-particle baking soda product with the grain size ranging from 20 mesh to 60 mesh can be continuously prepared, cost is low, and technological operation is easy.

Owner:TIANJIN BOHUA YONGLI CHEM IND +1

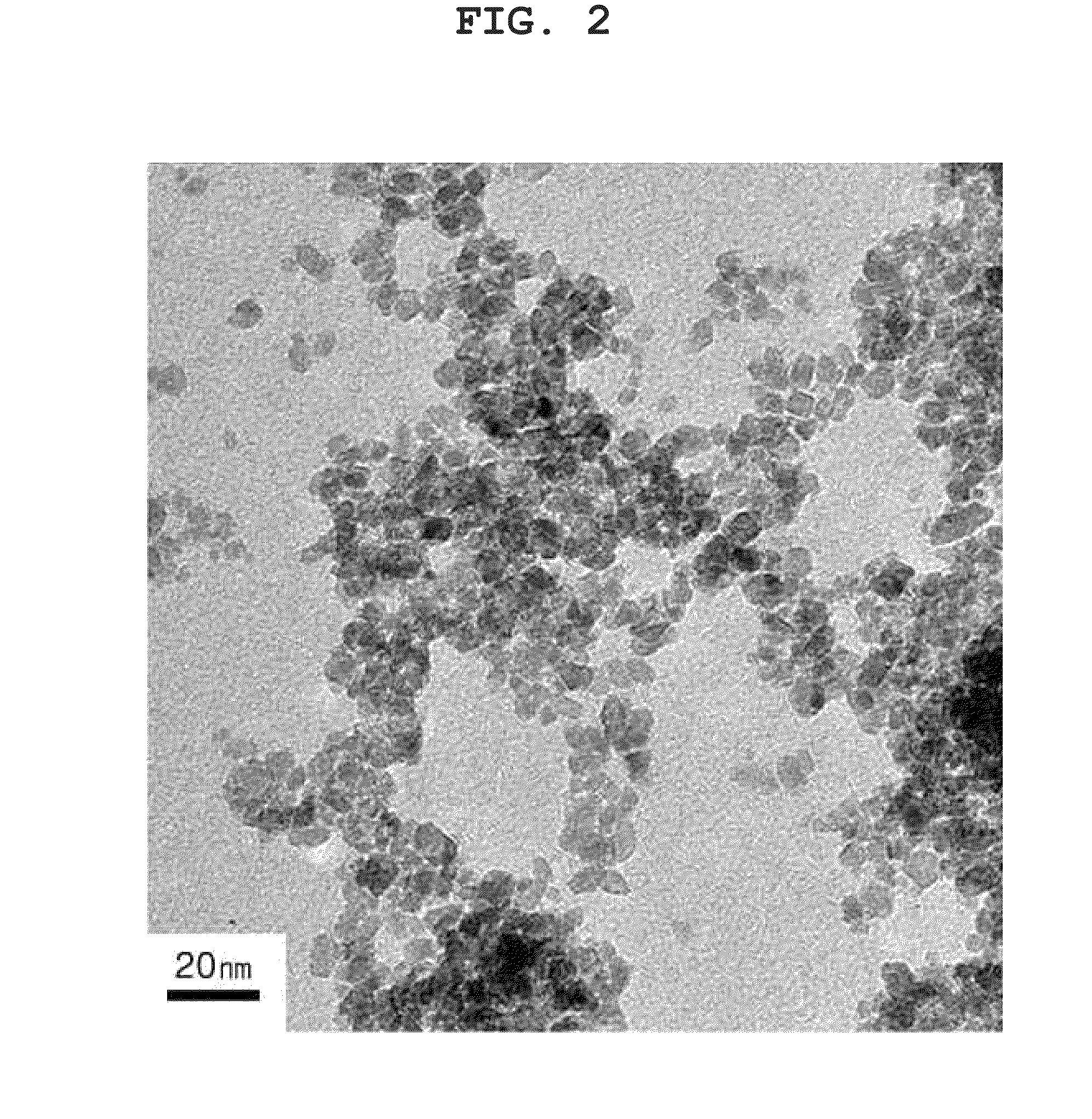

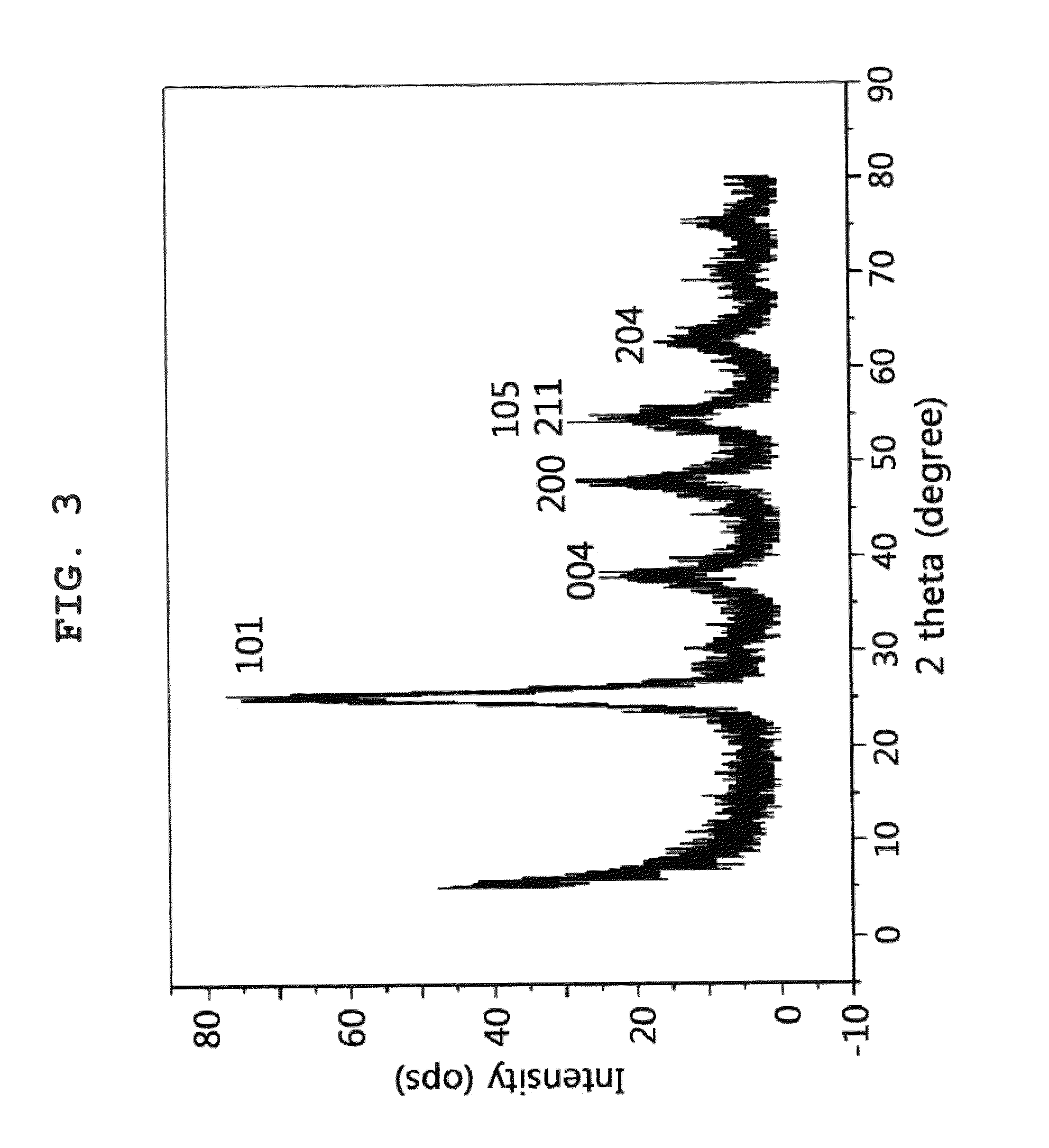

Method for preparing uniform anatase-type titanium dioxide nanoparticles

InactiveUS8357348B2Keep for a long timeIncrease in sizeMaterial nanotechnologyNanostructure manufactureTitaniumCrystallinity

The present invention relates to a method for preparing anatase-type titanium dioxide (TiO2) nanoparticles, the method comprising the steps of: uniformly mixing titanium n-butoxide and cetyltrimethyl ammonium salt (CTAS) in water; subjecting the mixture to hydrothermal treatment at a temperature of 60˜120° C.; and collecting anatase-type titanium dioxide nanoparticles produced by the hydrothermal treatment and drying the collected nanoparticles. According to the present invention, anatase-type titanium dioxide nanoparticles having excellent crystallinity can be easily prepared in large amounts by a simple process without needing heat treatment.

Owner:KOREA BASIC SCI INST

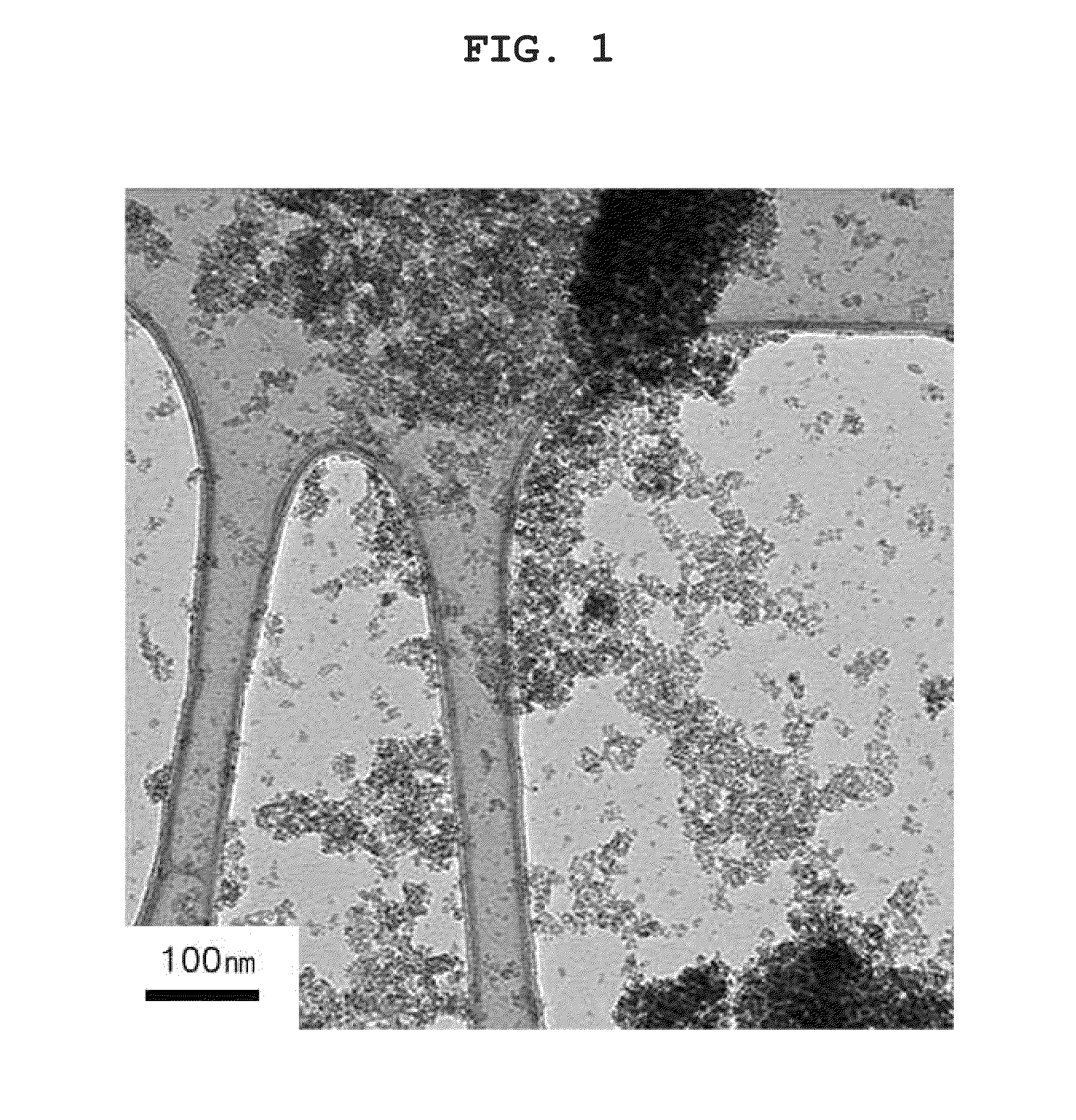

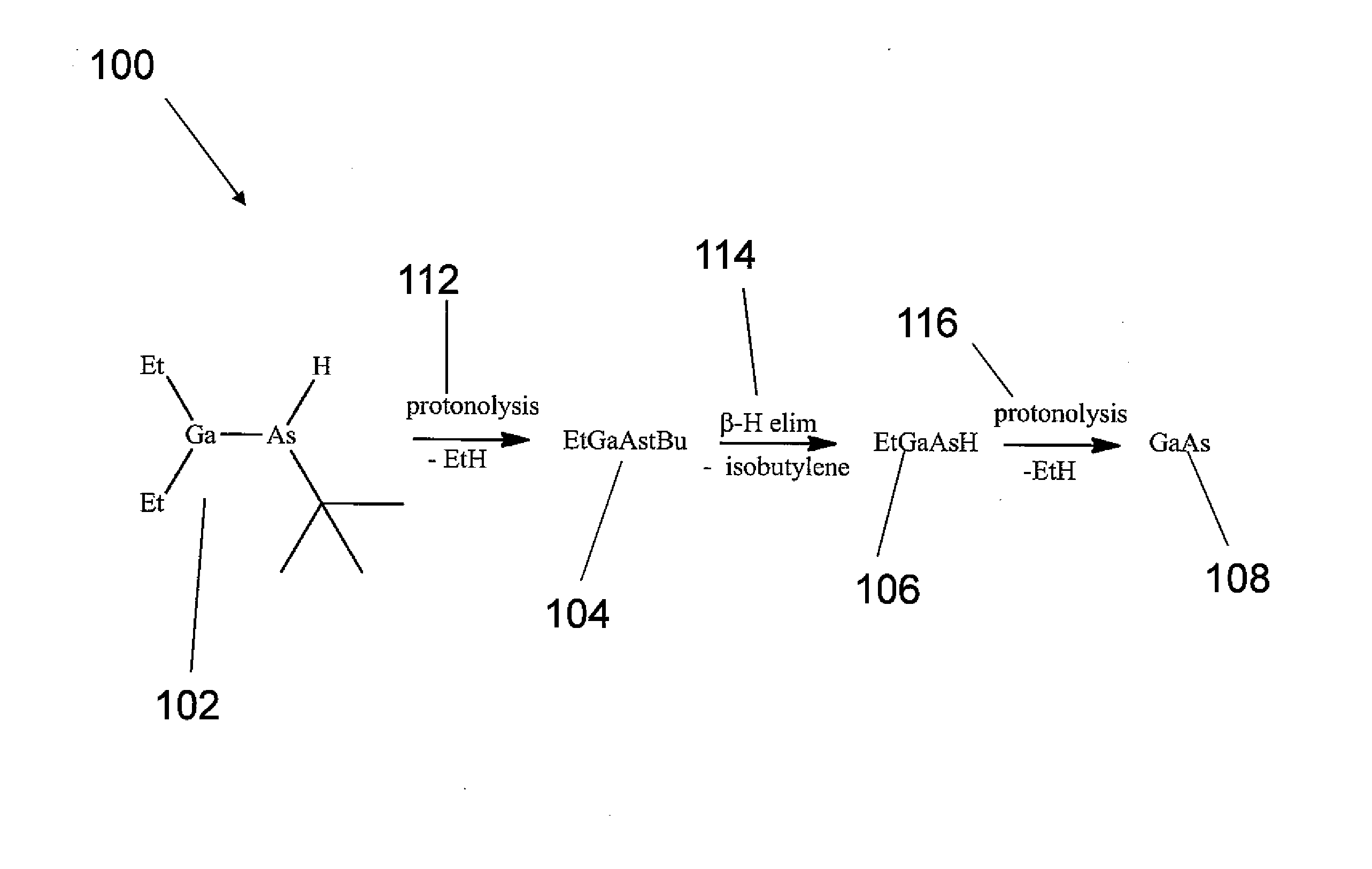

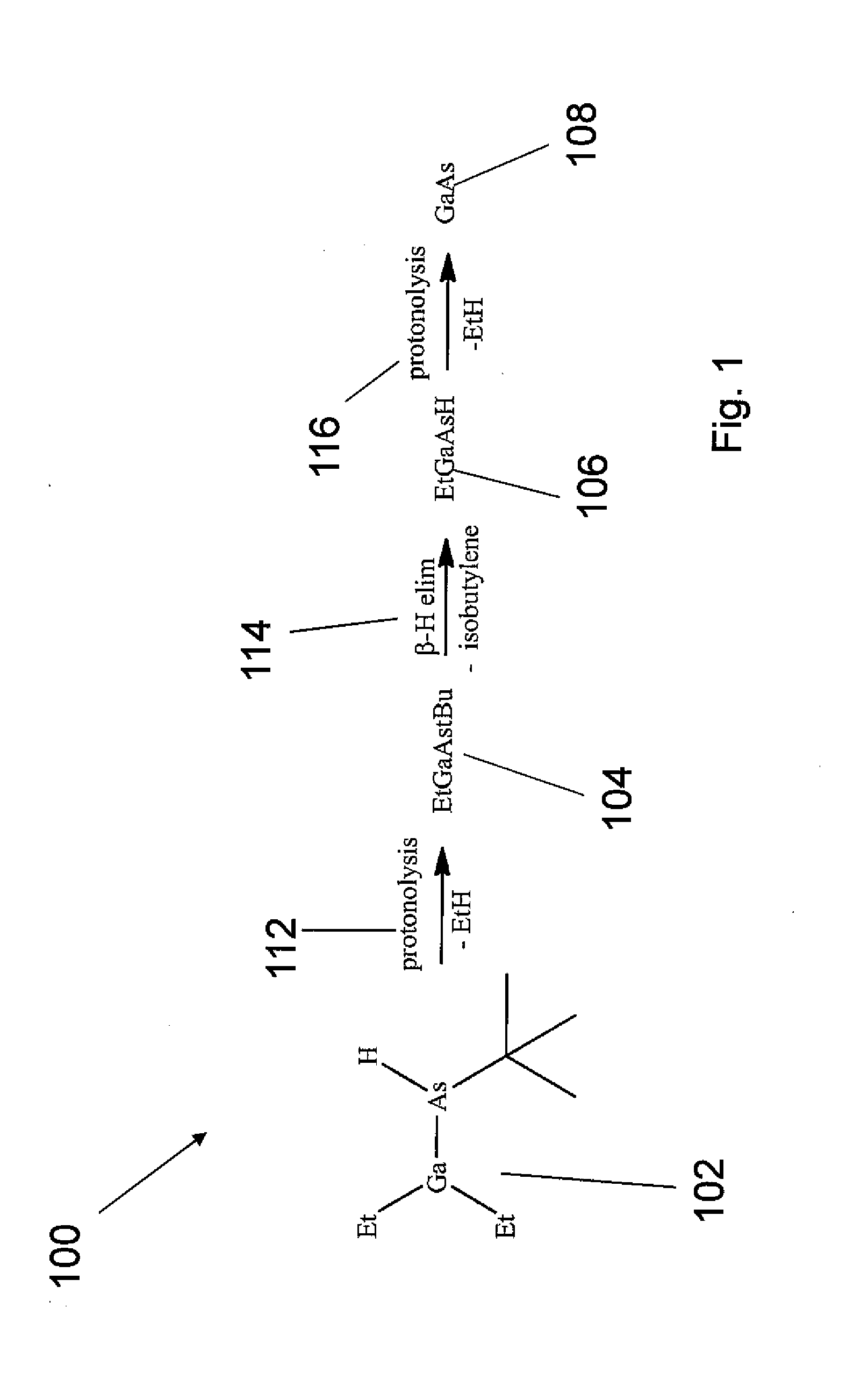

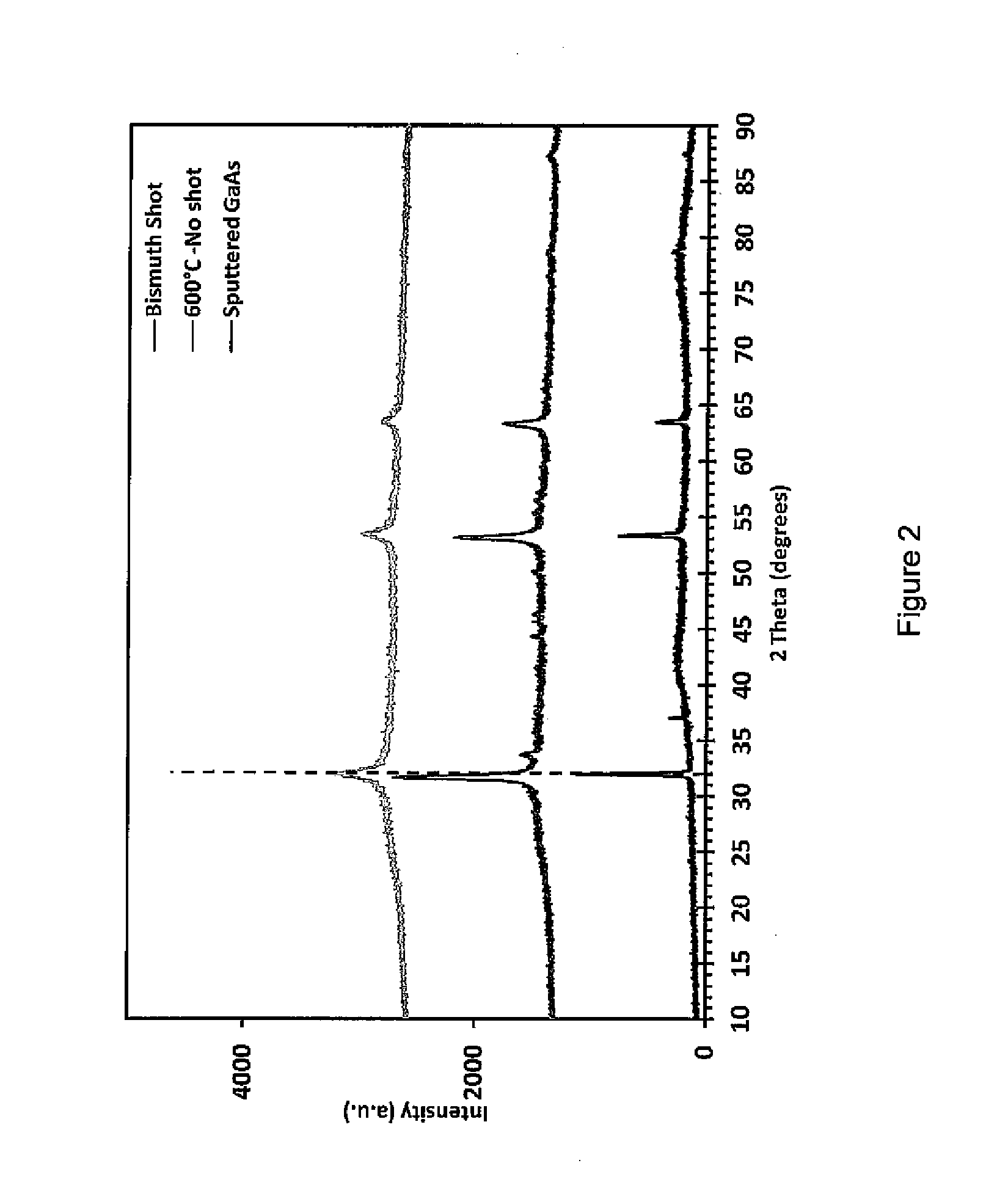

Processes for using flux agents to form polycrystalline group iii-group v compounds from single source organometallic precursors

InactiveUS20160322224A1Refined grain sizeElectronic propertyGroup 5/15 element organic compoundsSemiconductor/solid-state device manufacturingElectronic propertiesTM compound

The present invention provides methods for using single source organometallic precursors in the fabrication of polycrystalline Group III-Group V compounds, preferably semiconductor compounds. The present invention teaches how to select organometallic ligands in single-source precursors in order to control the stoichiometry of the corresponding Group III-Group V compounds derived from these precursors. The present invention further teaches how to anneal precursors in the presence of one or more flux agents in order to increase the crystalline grain size of polycrystalline Group III-Group V compounds derived from organometallic precursors. This helps to provide Group III-Group V semiconductors with better electronic properties. The flux layer also helps to control the stoichiometry of the Group III-Group V compounds.

Owner:DOW GLOBAL TECH LLC

Method for efficient flotation production of KCL through sequential separation of sylvite ore

ActiveCN107188200AQuality improvementEfficient quality productionAlkali metal chloridesGranularityMachining

The invention discloses a method for efficient flotation production of KCL through sequential separation of sylvite ore, and relates to a method for producing KCl from sylvite ore. According to the technical scheme, the method comprises the steps that after the sylvite ore is manufactured into the certain granularity, pulping, desalting, coarse KCL grain separation, coarse KCl grain washing, fine KCl grain floatation, fine KCl grain washing, dehydration and drying are performed to obtain crude KCl grain products and fine KCl grain products with the purity being 95% or more are obtained; on the basis of advanced separation of some NaCl tail salt and crude KCL grains before KCL floatation or during floatation, the KCL floatation amount is decreased, the floatation strength is lowered, the equipment input is decreased, the building investment is lowered, the floatation reagent consumption is reduced, the environment-friendly pressure is relieved, the mineral separation energy consumption is reduced, the production cost is lowered, the product type is optimized, the product quality is improved, and the KCL recycling rate is increased; the method is mainly used for washing machining of carnallite and sylvine ore of deposit mining.

Owner:山东瑞源钾盐工程技术股份有限公司

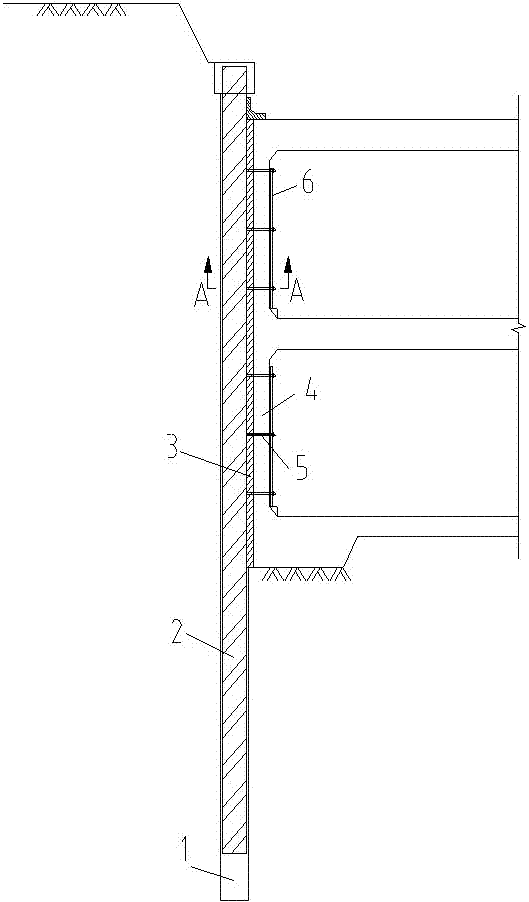

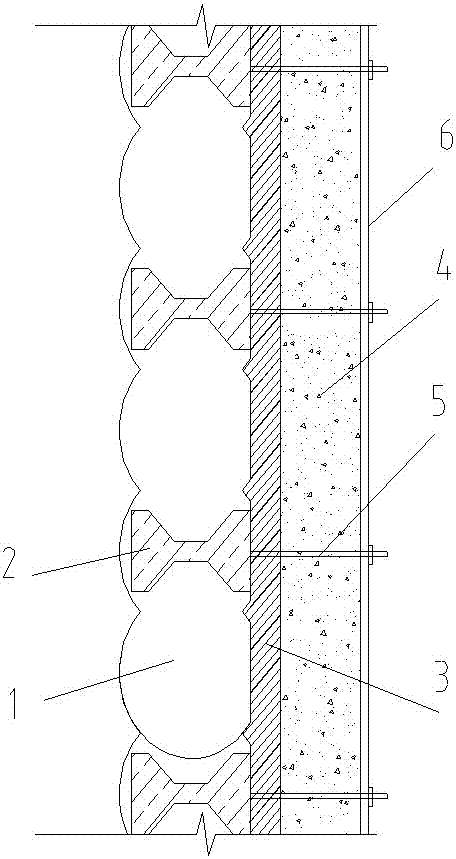

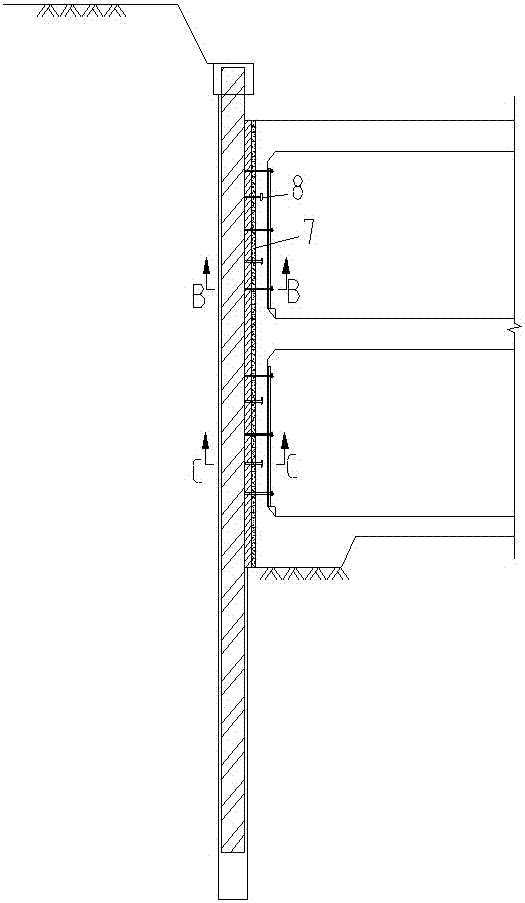

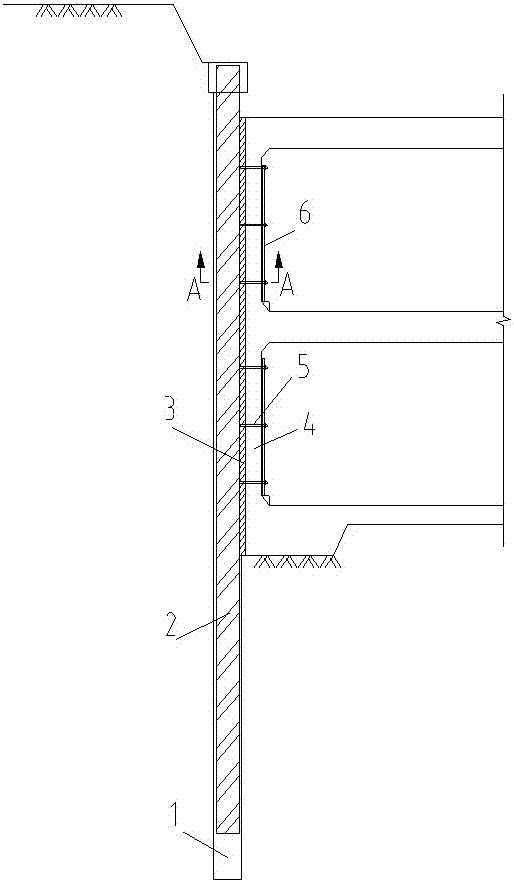

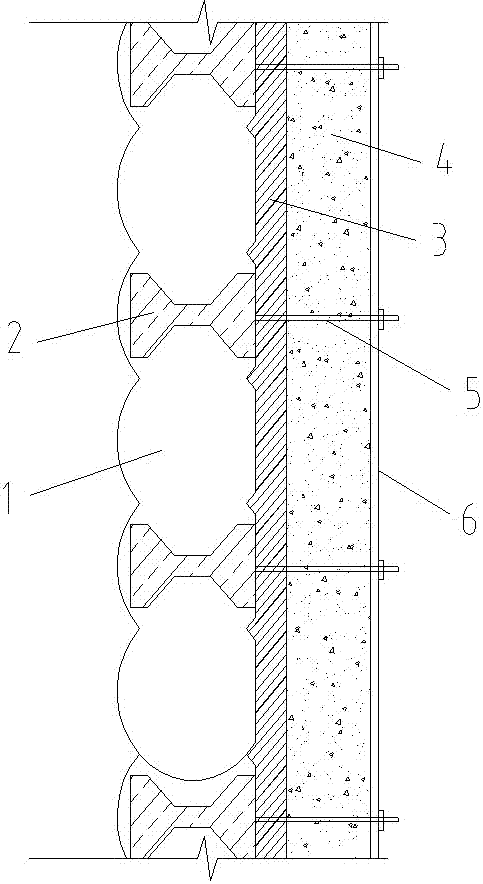

Underground structure outer wall superposed wall adopting HCMW construction method and construction method thereof

PendingCN107326924AHigh strengthCrystal growthArtificial islandsUnderwater structuresReinforced concreteArchitectural engineering

The invention discloses an underground structure outer wall superposed wall adopting the HCMW construction method. The underground structure outer wall superposed wall adopting the HCMW construction method comprises a cement-soil mixed pile wall, a levelling course and an underground structure outer wall. The cement-soil mixed pile wall comprises multiple cement-soil mixed piles which are continuously and mutually engaged. Reinforced concrete precast piles are inserted in the multiple cement-soil mixed piles at intervals or continuously. The levelling course is arranged on the inner wall of the cement-soil mixed pile wall. The underground structural outer wall is arranged on the inner wall of the levelling course and comprises reinforcing steel bars and concrete mixed with a waterproof compacting agent. The cement-soil mixed pile wall and the underground structural outer wall constitute an integrated force bearing component through a connection structure. The invention further provides a construction method of the underground structure outer wall superposed wall adopting the HCMW construction method. In this way, the underground structure outer wall superposed wall adopting the HCMW construction method is simple and reasonable in structure, a foundation pit is omitted, a series of defects of the foundation pit are avoided, the waterproof performance is improved, a support wall and a underground structure wall are connected into the force bearing integrated body, the strength is improved, the procedure is simplified, construction is convenient and the construction period is shortened.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +2

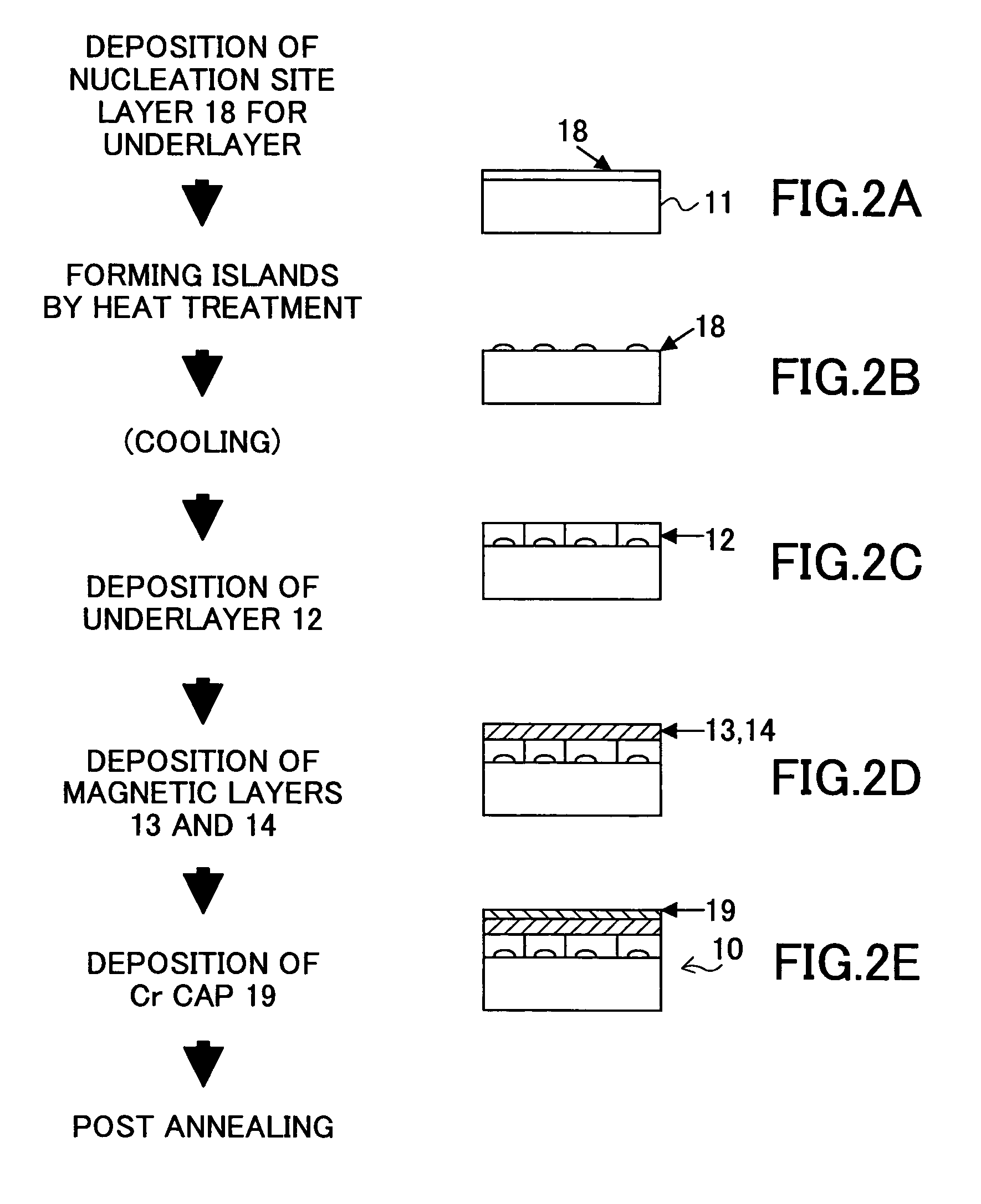

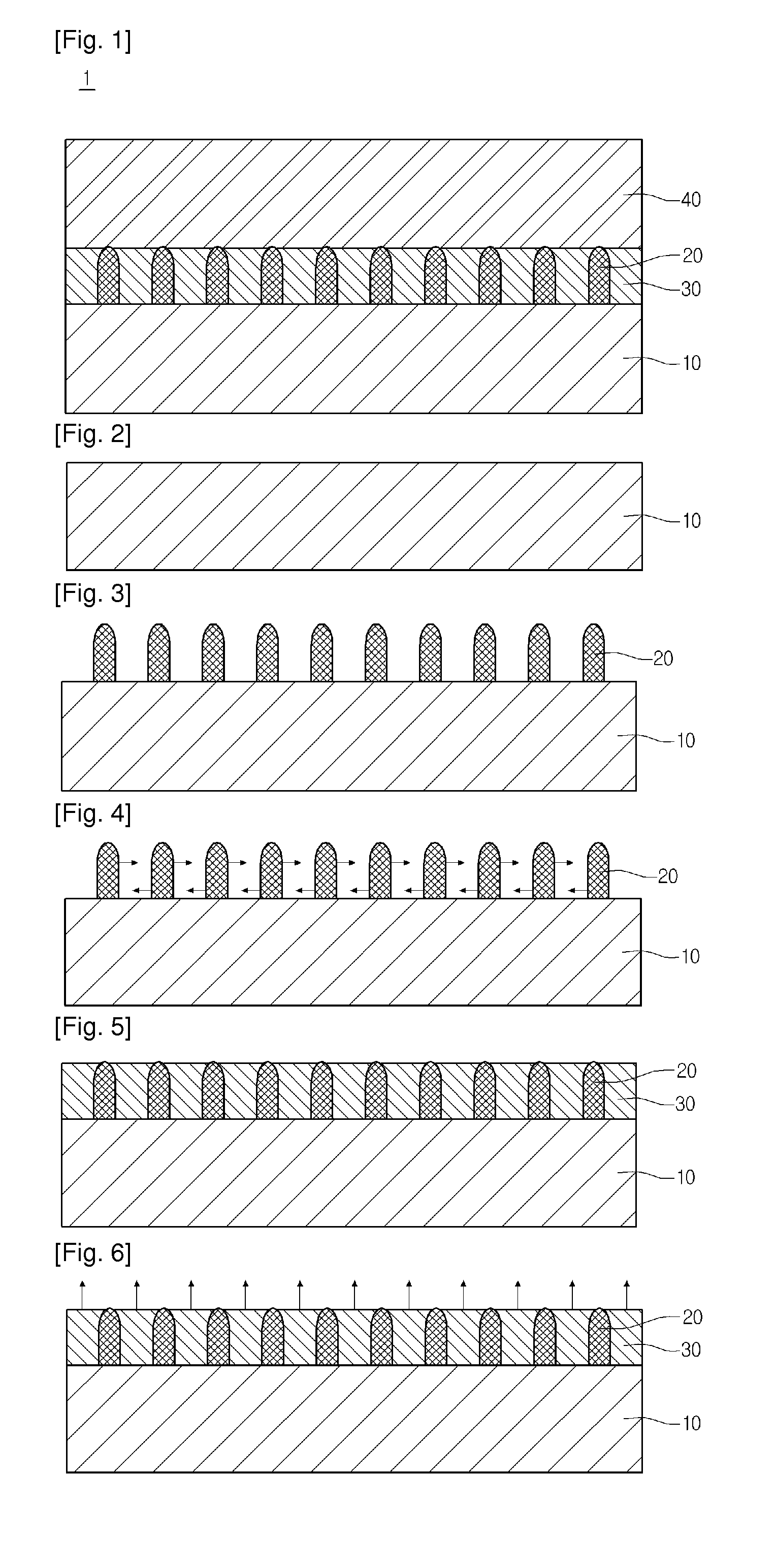

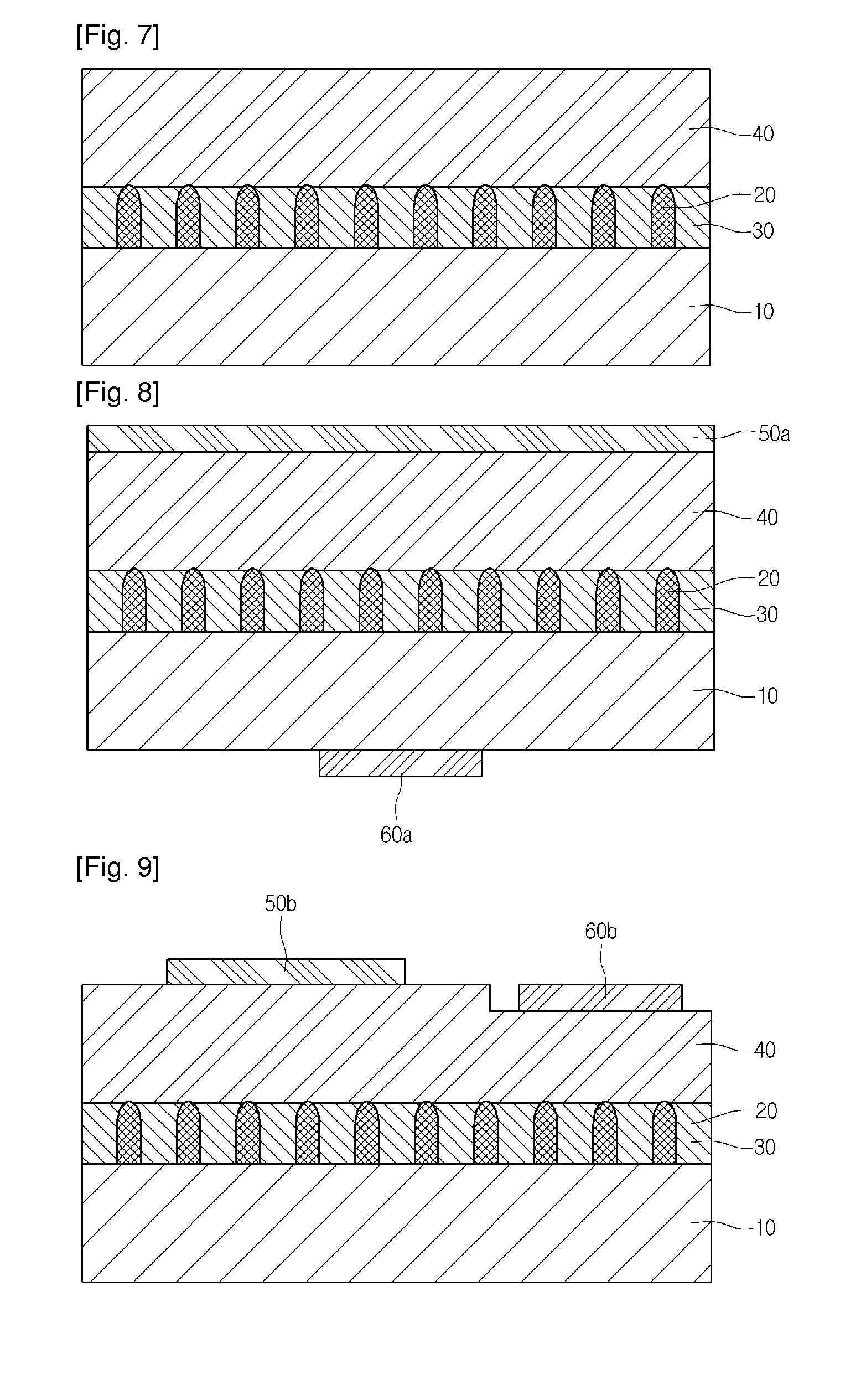

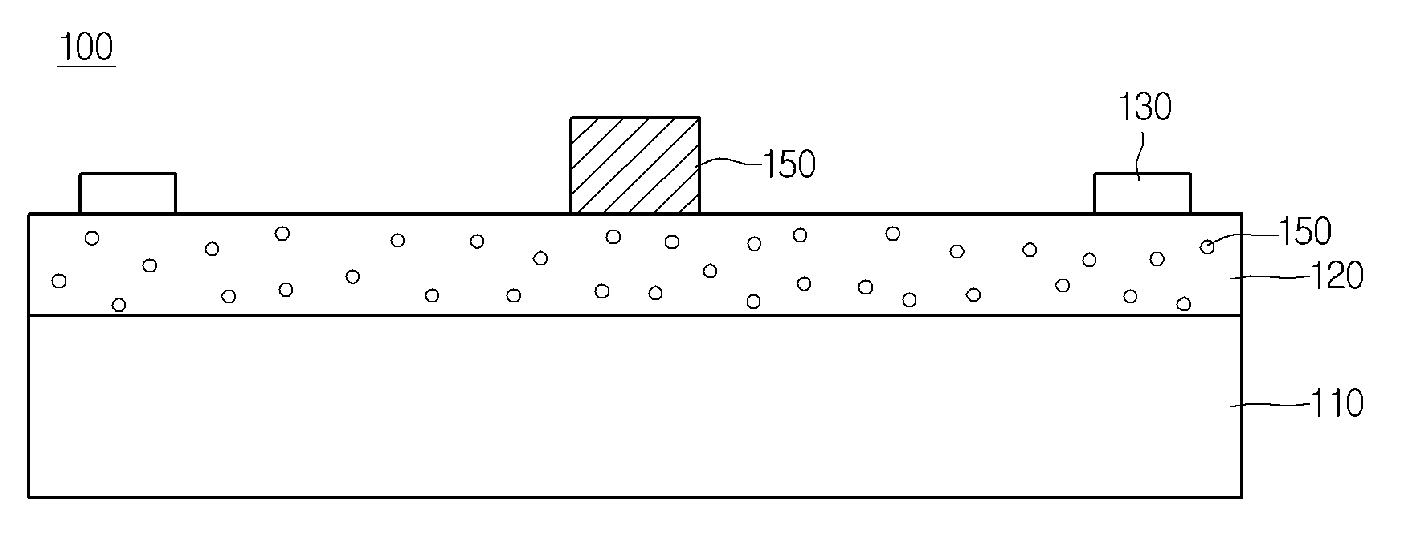

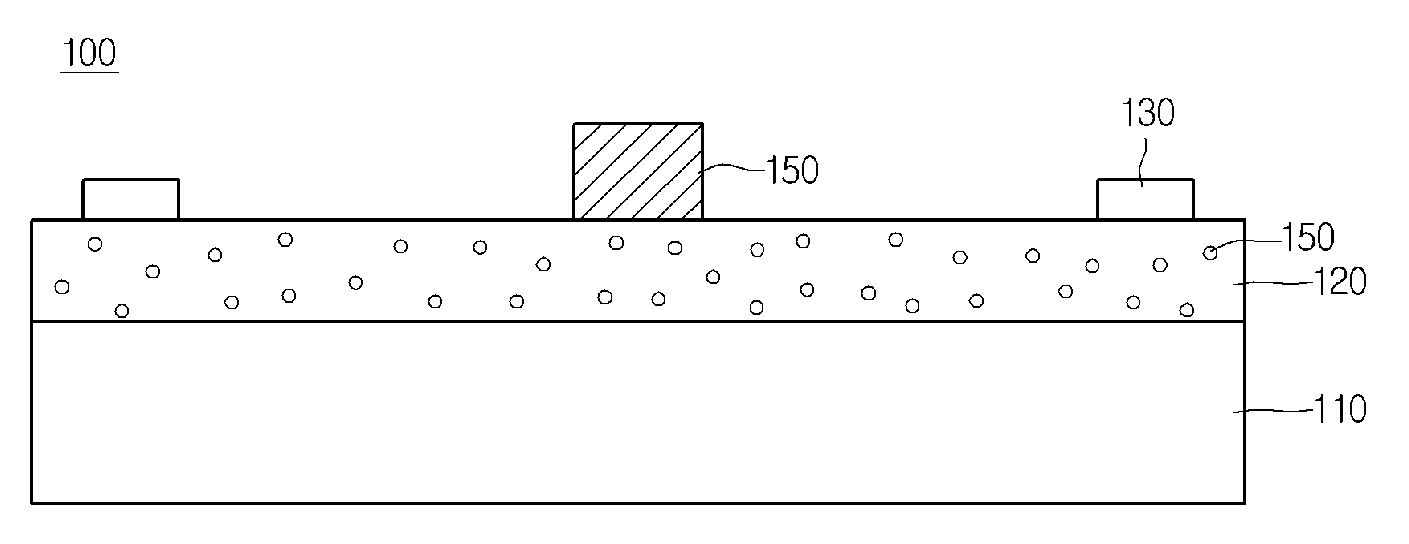

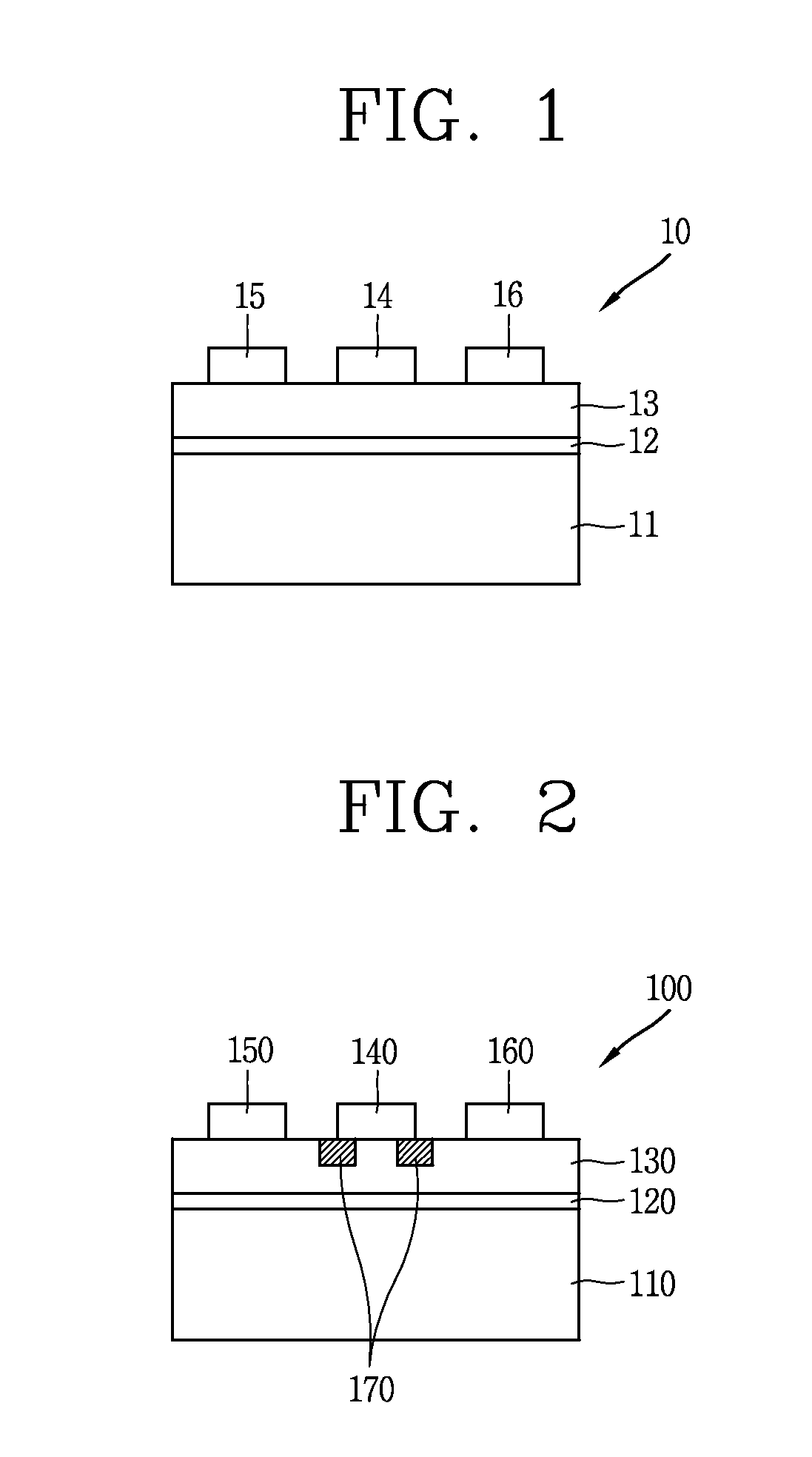

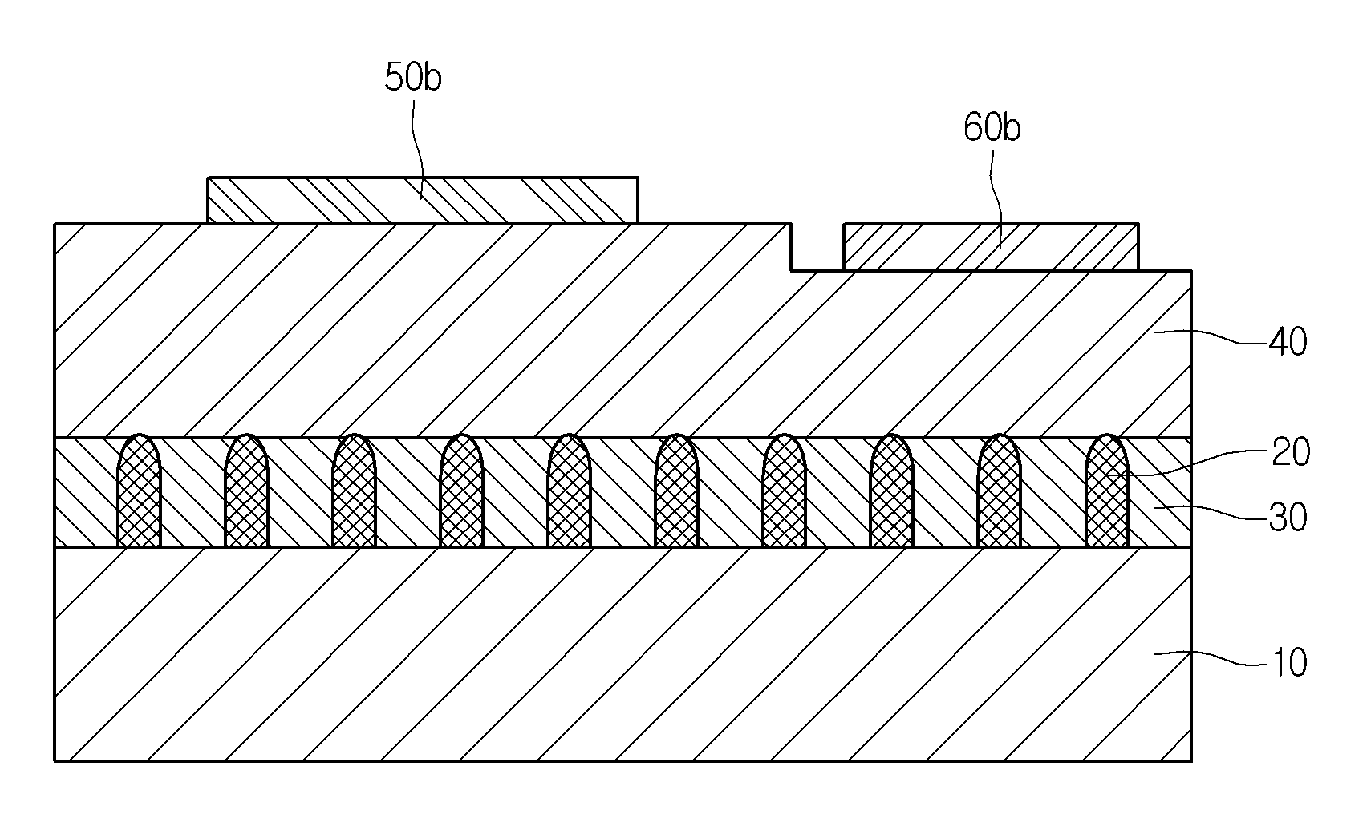

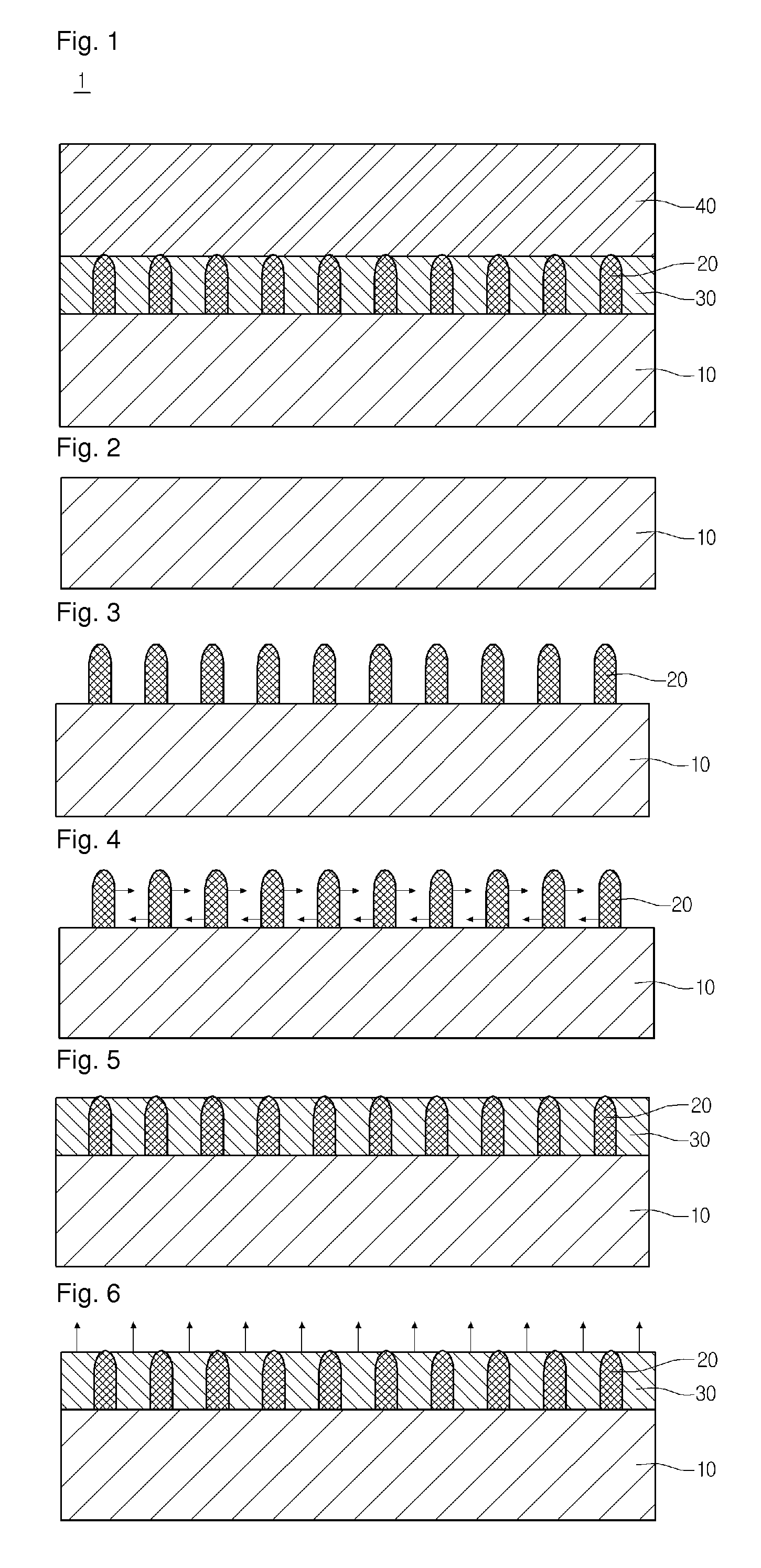

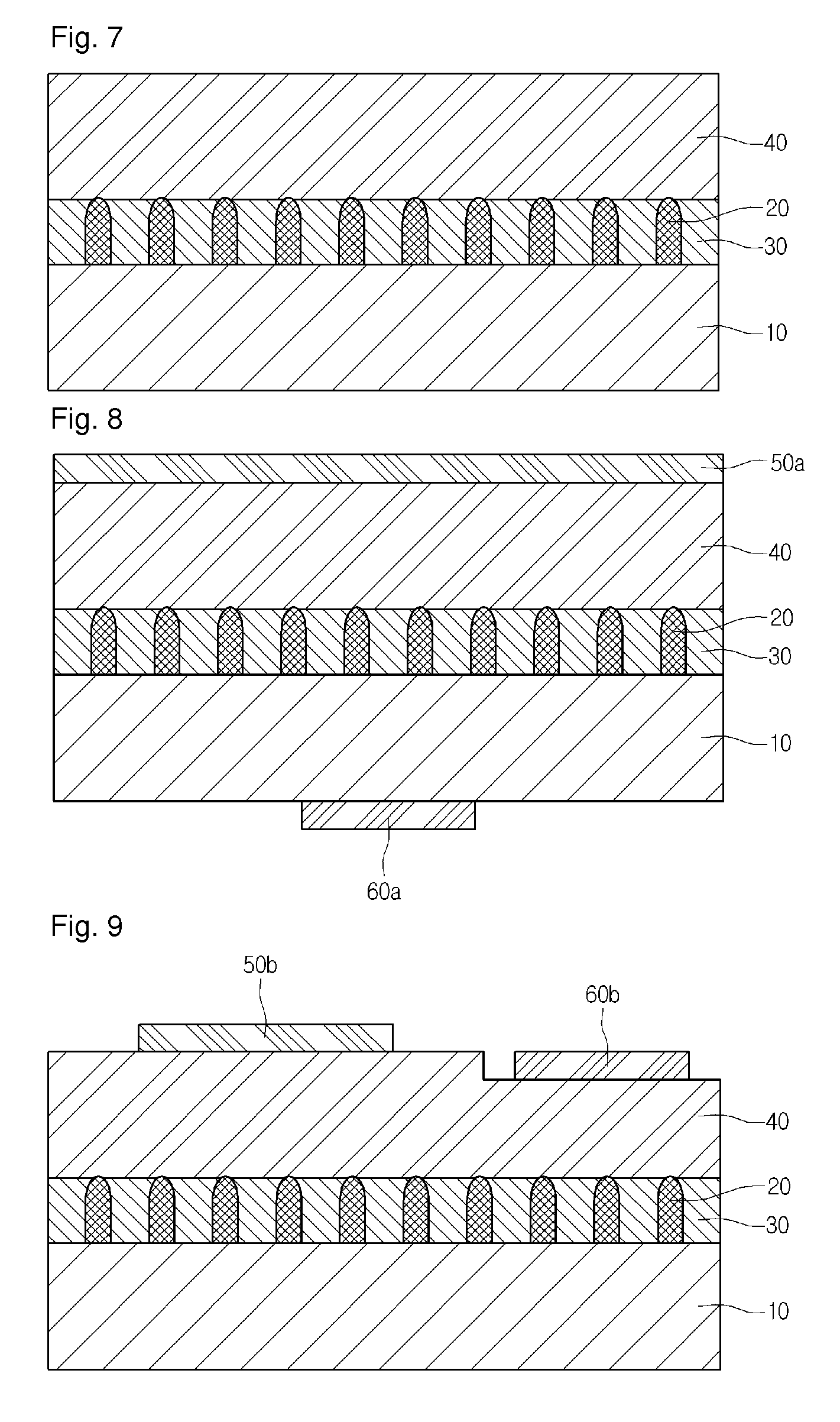

Semiconductor device and method for growing semiconductor crystal

ActiveUS20140054610A1Reduce processing costsCrystal growthSemiconductor/solid-state device manufacturingSemiconductor devicesCrystallographyDevice material

A semiconductor device comprises a base substrate, a pattern on the base substrate, a buffer layer on the base substrate, and an epitaxial layer on the buffer. The pattern is a self-assembled pattern. A method for growing a semiconductor crystal comprises cleaning a silicon carbide substrate, forming a self-assembled pattern on the silicon carbide substrate, forming a buffer layer on the silicon carbide substrate, and forming an epitaxial layer on the buffer layer. A semiconductor device comprises a base substrate comprising a pattern groove and an epitaxial layer on the base substrate. A method for growing a semiconductor crystal comprises cleaning a silicon carbide substrate, forming a self-assembled projection on the silicon carbide substrate, forming a pattern groove in the silicon carbide, and forming an epitaxial layer on the silicon carbide.

Owner:LX SEMICON CO LTD

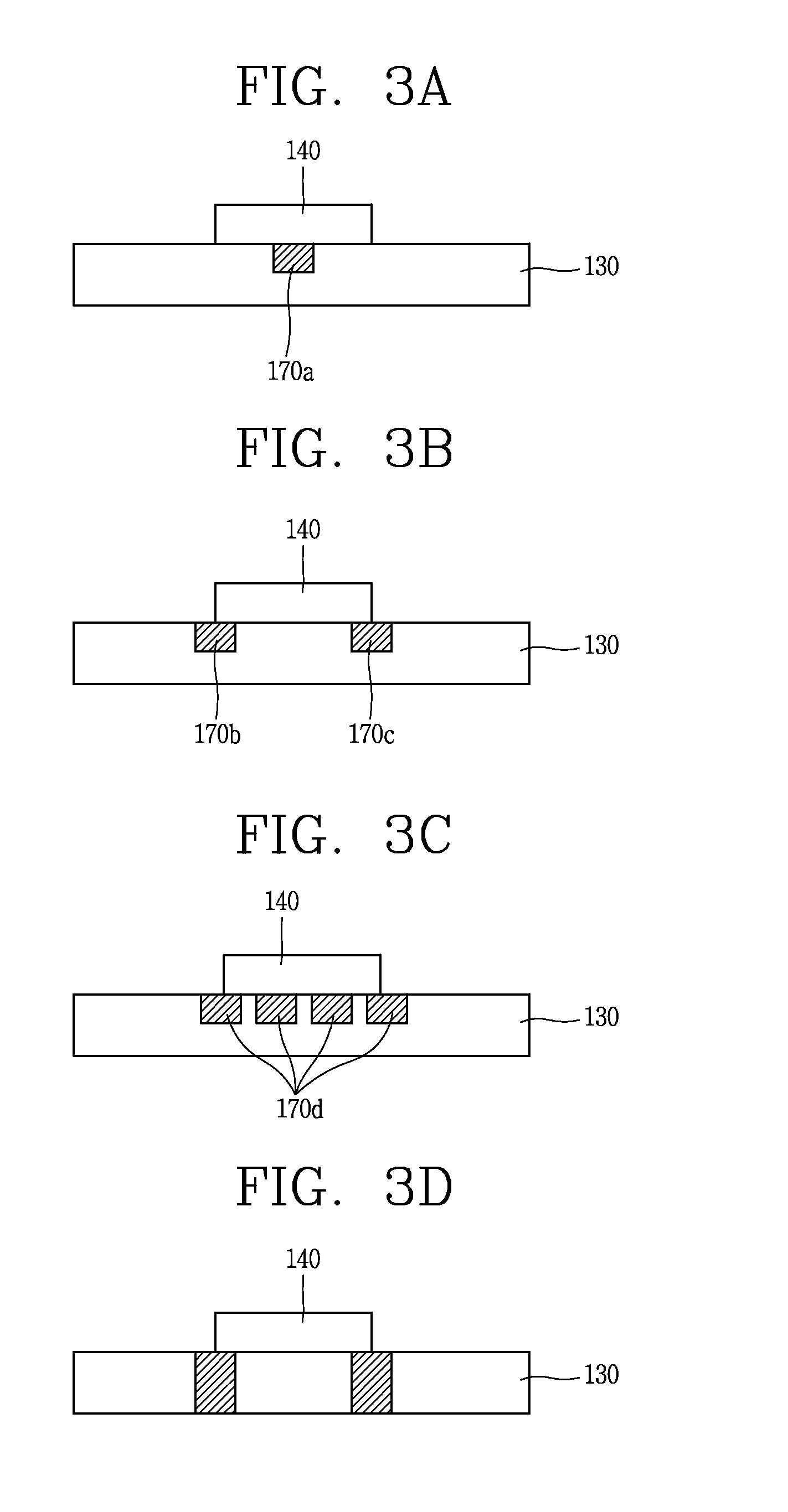

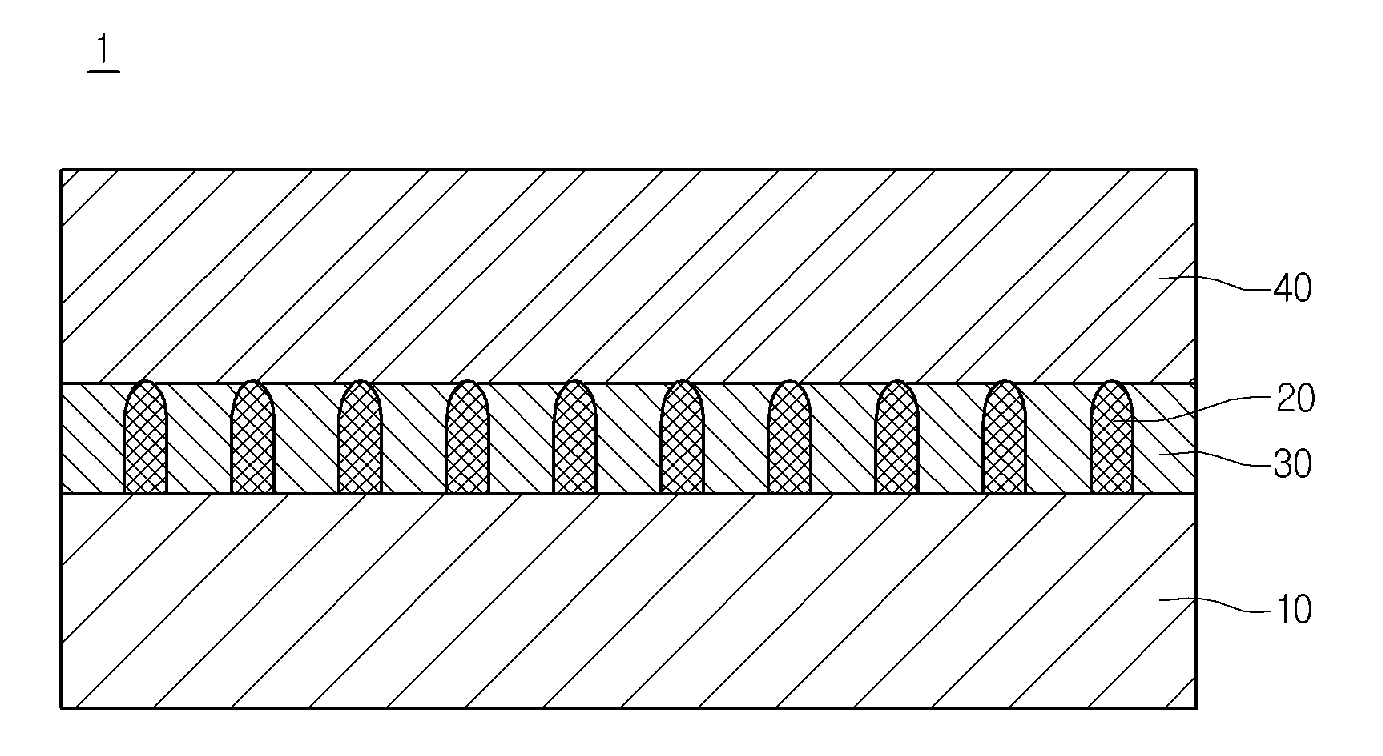

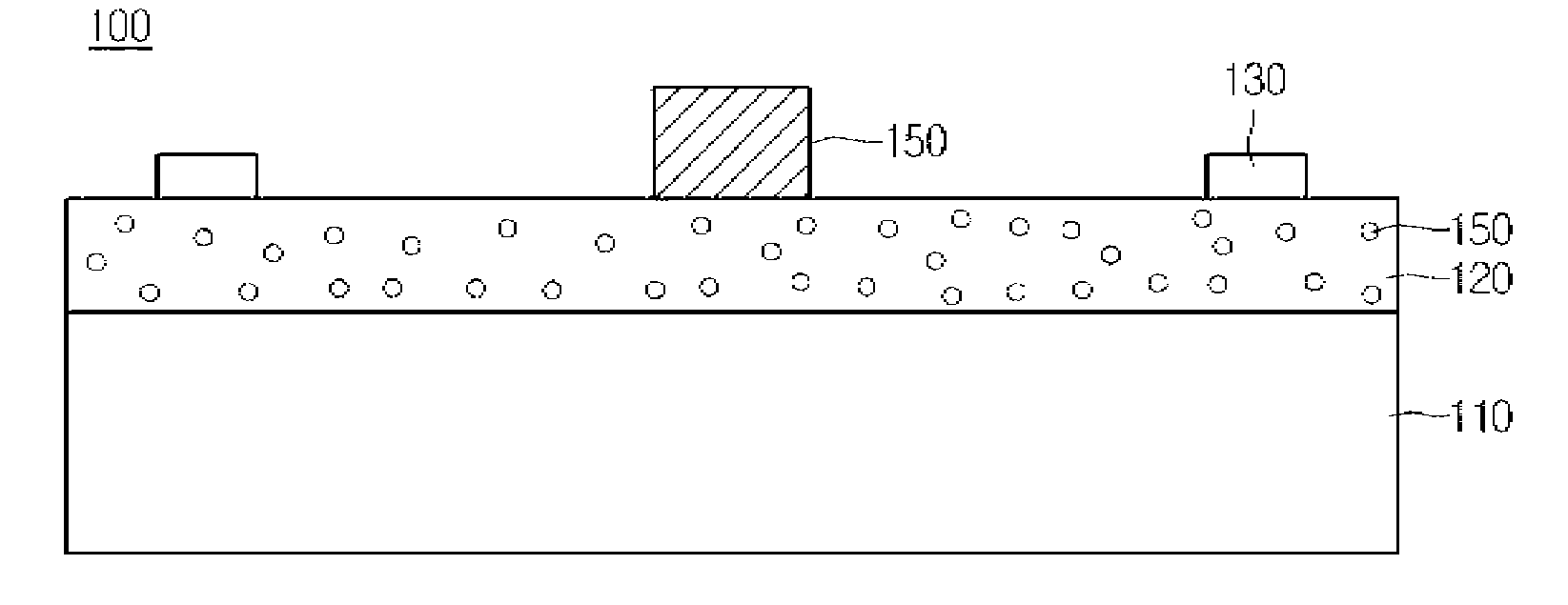

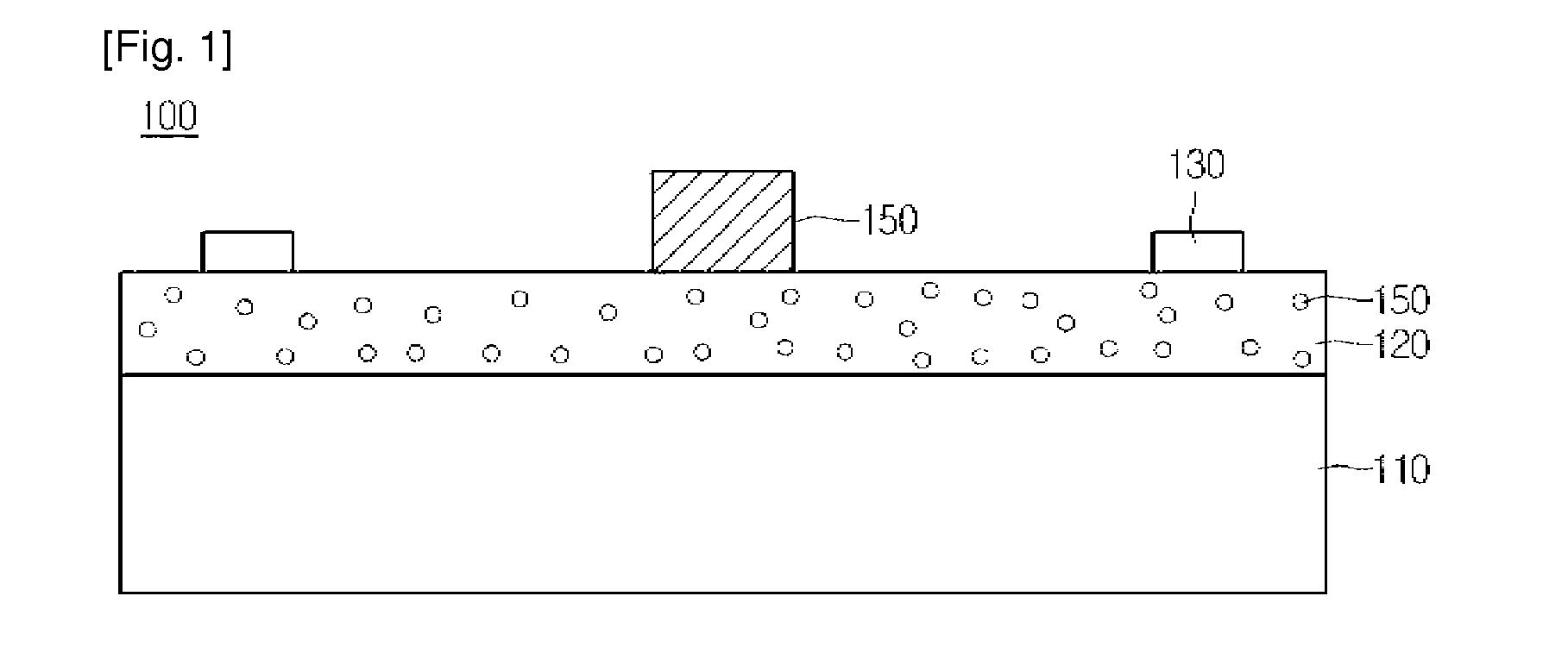

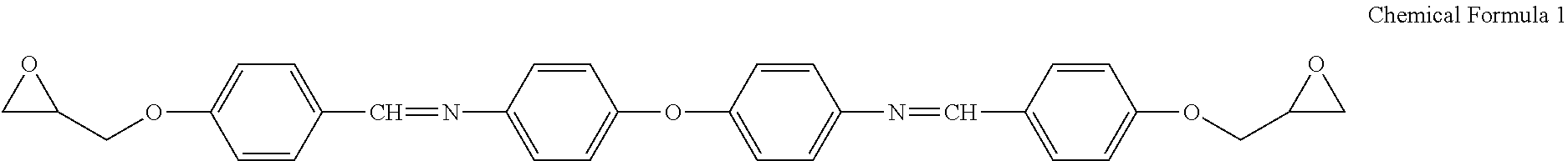

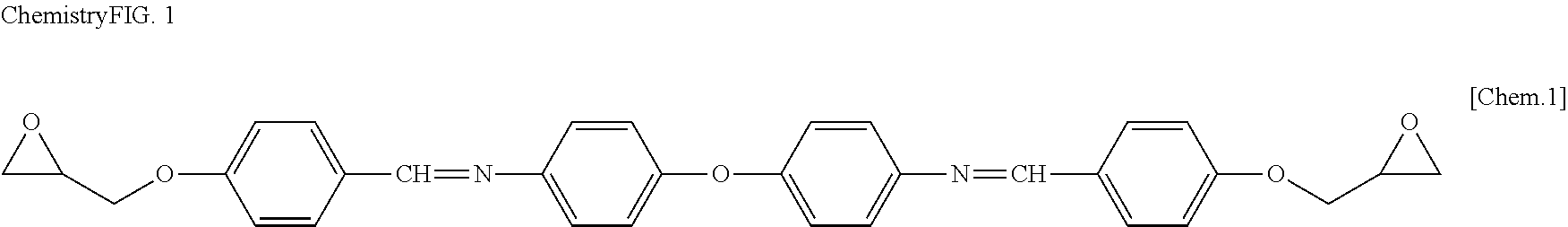

Epoxy resin compound and radiant heat circuit board using the same

InactiveUS20140290996A1Improve cooling effectImprove thermal conductivityHeat-exchange elementsCircuit susbtrate materialsEpoxyRadiant heat

Disclosed are an epoxy resin compound and a radiant heat circuit board using the same. The epoxy resin compound mainly includes an epoxy resin, a curing agent, and an inorganic filler. The epoxy resin includes a crystalline epoxy resin and a rubber additive to disperse the inorganic filler into the epoxy resin. The epoxy resin is used on a printed circuit board as an insulating material, so that a substrate having a high heat radiation property is provided.

Owner:LG INNOTEK CO LTD

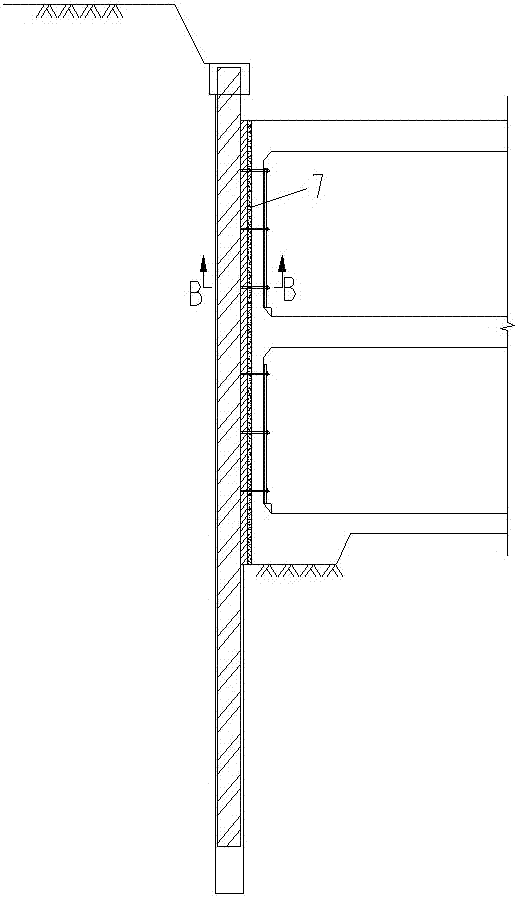

Underground structure outer wall composite wall adopting HCMW construction method and construction method thereof

PendingCN107326923AImprove waterproof performanceExtended permeation pathArtificial islandsUnderwater structuresRebarReinforced concrete

The invention discloses an underground structure outer wall composite wall adopting the HCMW construction method. The underground structure outer wall composite wall adopting the HCMW construction method comprises a cement-soil mixed pile wall, a levelling course and an underground structure outer wall. The cement-soil mixed pile wall comprises multiple cement-soil mixed piles which are continuously and mutually engaged. Reinforced concrete precast piles are inserted in the multiple cement-soil mixed piles at intervals or continuously. The levelling course is arranged on the inner wall of the cement-soil mixed pile wall. The underground structural outer wall is arranged on the inner wall of the levelling course and comprises reinforcing steel bars and concrete mixed with a waterproof compacting agent. The invention further provides a construction method of the underground structure outer wall HCMW construction method composite wall. In this way, the underground structure outer wall composite wall adopting the HCMW construction method is simple and reasonable in structure, a foundation pit is omitted, so that a series of defects of the foundation pit are avoided, the waterproof performance is improved, the procedure is simplified, construction is convenient and the construction period is shortened.

Owner:CHANGZHOU ARCHITECTUAL RES INST GRP CO LTD +2

Method for controlling crystalline products in wet flue gas desulfurization slurry pool

A method for controlling the crystalline products in a wet flue gas desulfurization slurry pool belongs to the technical field of flue gas desulfurization. The method comprises the following steps thaA method for controlling the crystalline products in a wet flue gas desulfurization slurry pool belongs to the technical field of flue gas desulfurization. The method comprises the following steps thaver high saturation of calcium sulfite in the liquid phase for synchronizing the yield and growth of gypsum crystal in the slurry, to prevent excessive production of gypsum fine crystal and to facilitver high saturation of calcium sulfite in the liquid phase for synchronizing the yield and growth of gypsum crystal in the slurry, to prevent excessive production of gypsum fine crystal and to facilitate the dehydration of the crystalline products.ate the dehydration of the crystalline products.t: for an absorber which has a flue gas purification channel on top, a raw flue gas inlet in the middle and a slurry pool at bottom, the saturation of calcium sulfite in a liquid phase in the slurry pt: for an absorber which has a flue gas purification channel on top, a raw flue gas inlet in the middle and a slurry pool at bottom, the saturation of calcium sulfite in a liquid phase in the slurry pool can be quickly reduced by controlling the required volume of injected oxygen in the slurry pool and the oxygen supply is kept constantly in a proper state to prevent semi-hydrated gypsum and crystool can be quickly reduced by controlling the required volume of injected oxygen in the slurry pool and the oxygen supply is kept constantly in a proper state to prevent semi-hydrated gypsum and crystal scale generated due to inadequate filling of oxygen in the slurry pool from causing scale to block the vessel wall and pipe wall of the slurry pool and to provent the crystalline products from dehyal scale generated due to inadequate filling of oxygen in the slurry pool from causing scale to block the vessel wall and pipe wall of the slurry pool and to provent the crystalline products from dehydrating difficultly; the injection amount of the limestone slurry in the slurry pool is controlled to control the fluctuation range of the pH value of the gypsum slurry in the slurry pool to prevent odrating difficultly; the injection amount of the limestone slurry in the slurry pool is controlled to control the fluctuation range of the pH value of the gypsum slurry in the slurry pool to prevent o

Owner:YONKER ENVIRONMENTAL PROTECTION

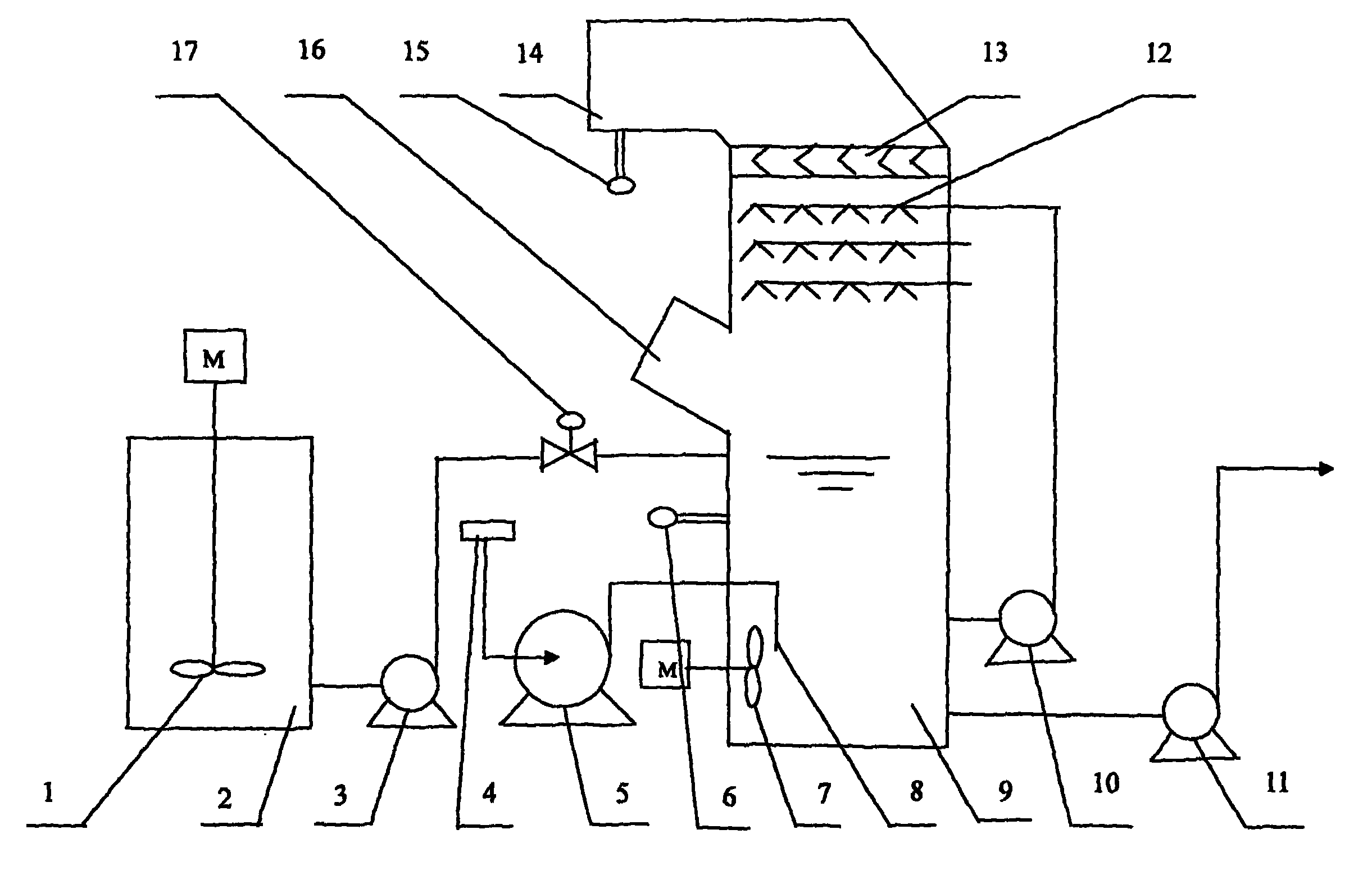

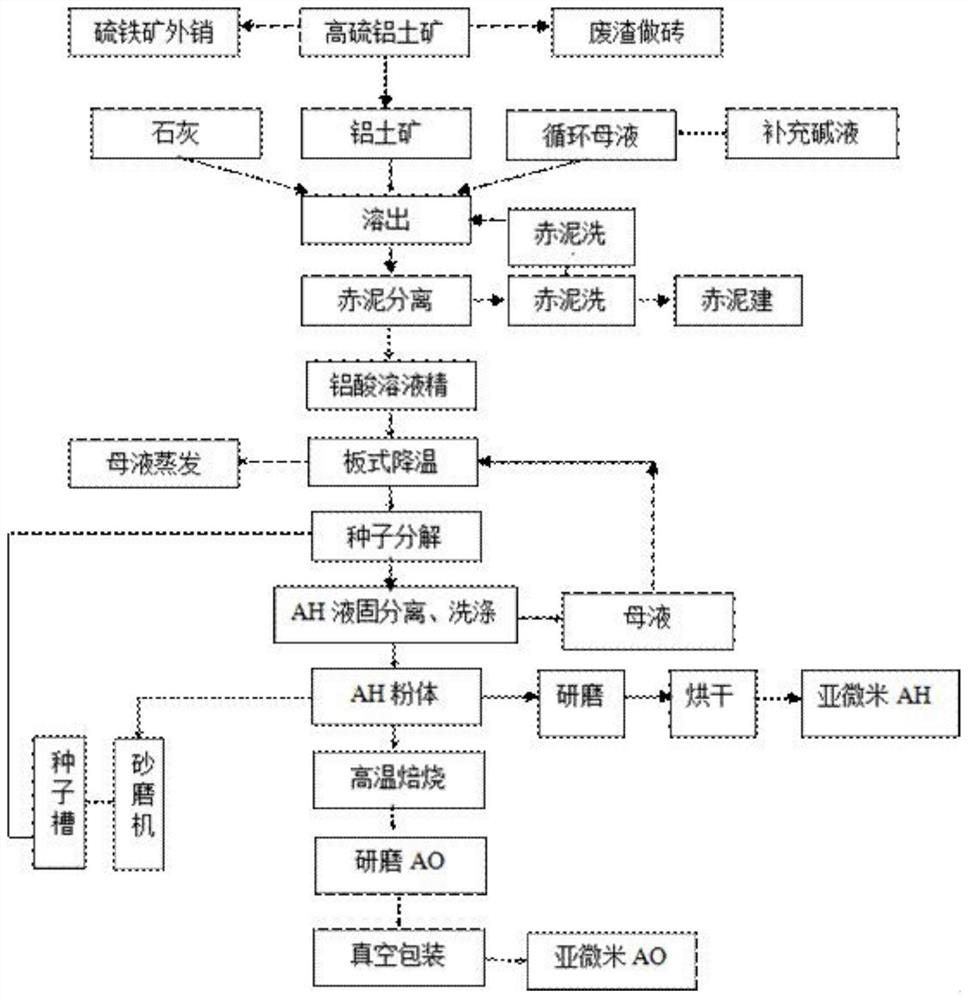

Sand mill method for producing submicron aluminum hydroxide and aluminium oxide

InactiveCN113683107AUniform particle sizeRaise quality standardsAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationMother liquorOxide

The invention relates to the technical field of aluminum oxide, and discloses a sand mill method for producing submicron aluminum hydroxide, which comprises the following raw materials in parts by weight: 50 parts of high-sulfur bauxite, 2 parts of lime, 3 parts of circulating mother liquor, 5 parts of red mud washing liquor, 1 part of crystal seed and 0.7 part of sodium hydroxide. The crystal seed comprises the following raw materials in parts by weight: 1 part of aluminum hydroxide and 1.2 parts of water. According to the invention, the seeds prepared by a sand mill method are added to realize the purpose of submicron aluminum hydroxide with high quality standard, reasonable crystal structure and uniform granularity, the raw material bauxite is desulfurized, the generated sodium aluminate solution is filtered and purified, and the aluminum hydroxide seeds with certain granularity and concentration prepared by the sand mill method are added to prepare the submicron aluminum hydroxide. The aluminum hydroxide seeds and the sodium aluminate solution are subjected to enhanced crystallization, agglomeration, crystal growth and crystal qualitation, so that new submicron aluminum hydroxide and aluminum oxide materials are prepared, and the purposes of high-quality standard, reasonable crystal form structure and uniform particle size of the submicron aluminum hydroxide and aluminum oxide materials are achieved.

Owner:丁军

Method of manufacturing photoelectric conversion device

InactiveUS8207011B2Reduce distanceIncrease probabilityFinal product manufactureSemiconductor/solid-state device manufacturingHigh frequency powerReactive gas

Owner:SEMICON ENERGY LAB CO LTD

Epoxy resin compound and radiant heat circuit board using the same

ActiveUS9357630B2Improve cooling effectImprove thermal conductivitySemiconductor/solid-state device detailsPrinted circuit aspectsEpoxyRadiant heat

Disclosed are an epoxy resin compound and a radiant heat circuit board using the same. The epoxy resin compound mainly includes an epoxy resin, a curing agent, and an inorganic filler. The curing agent comprises epoxy adducts formed to add the curing agent to a crystalline epoxy resin. The epoxy resin is used on a printed circuit board as an insulating material, so that a substrate having a high heat radiation property is provided.

Owner:LG INNOTEK CO LTD

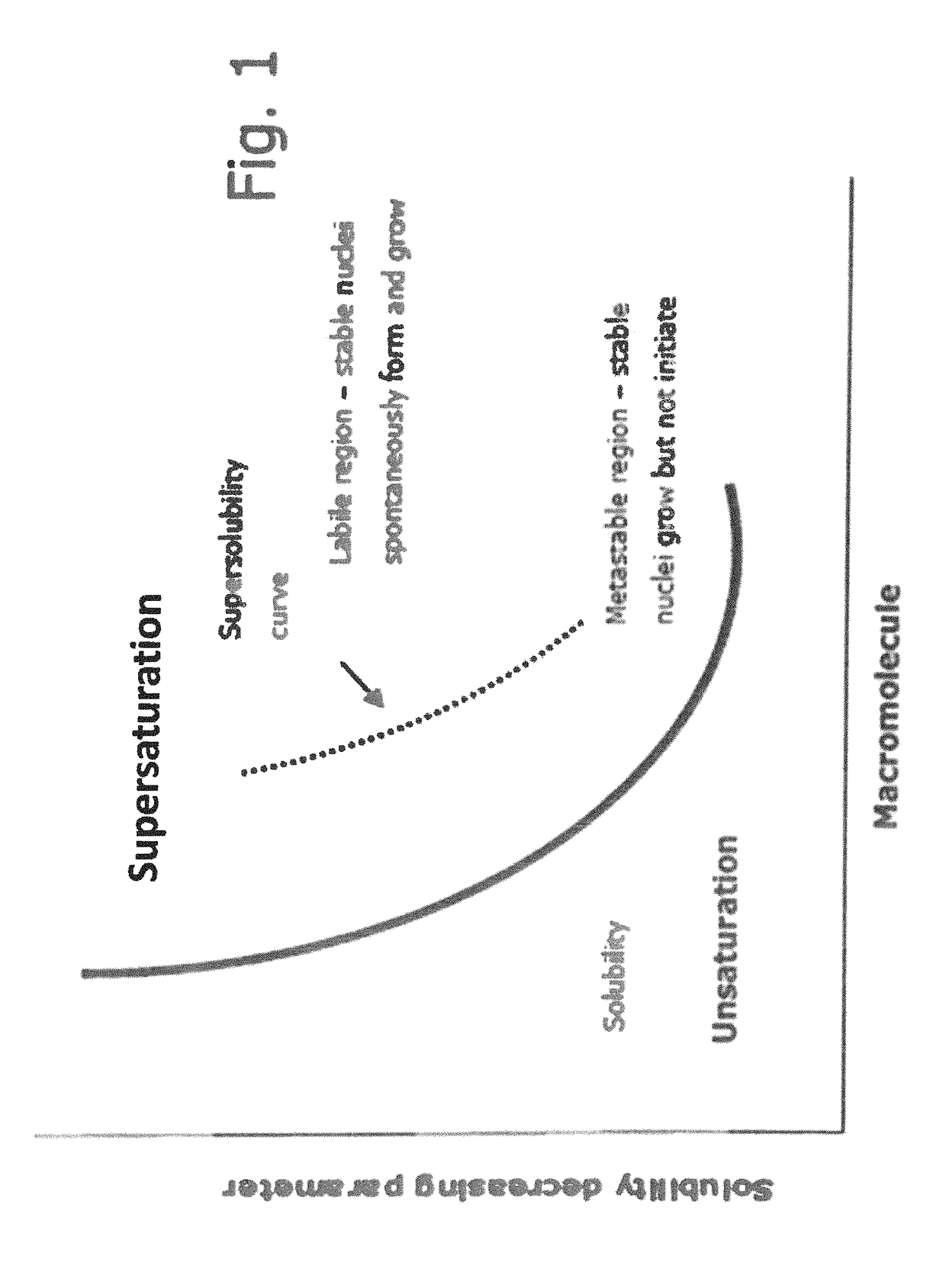

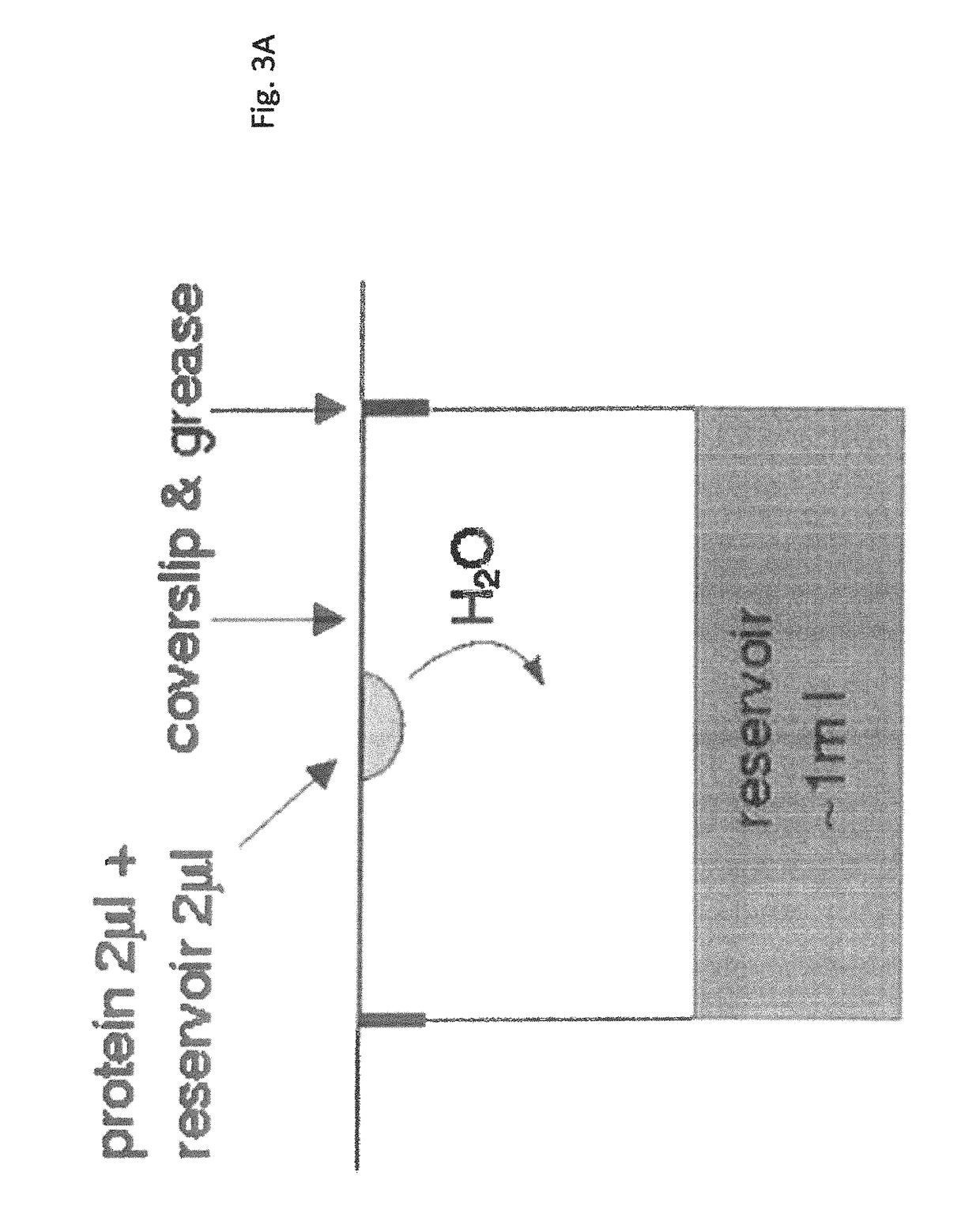

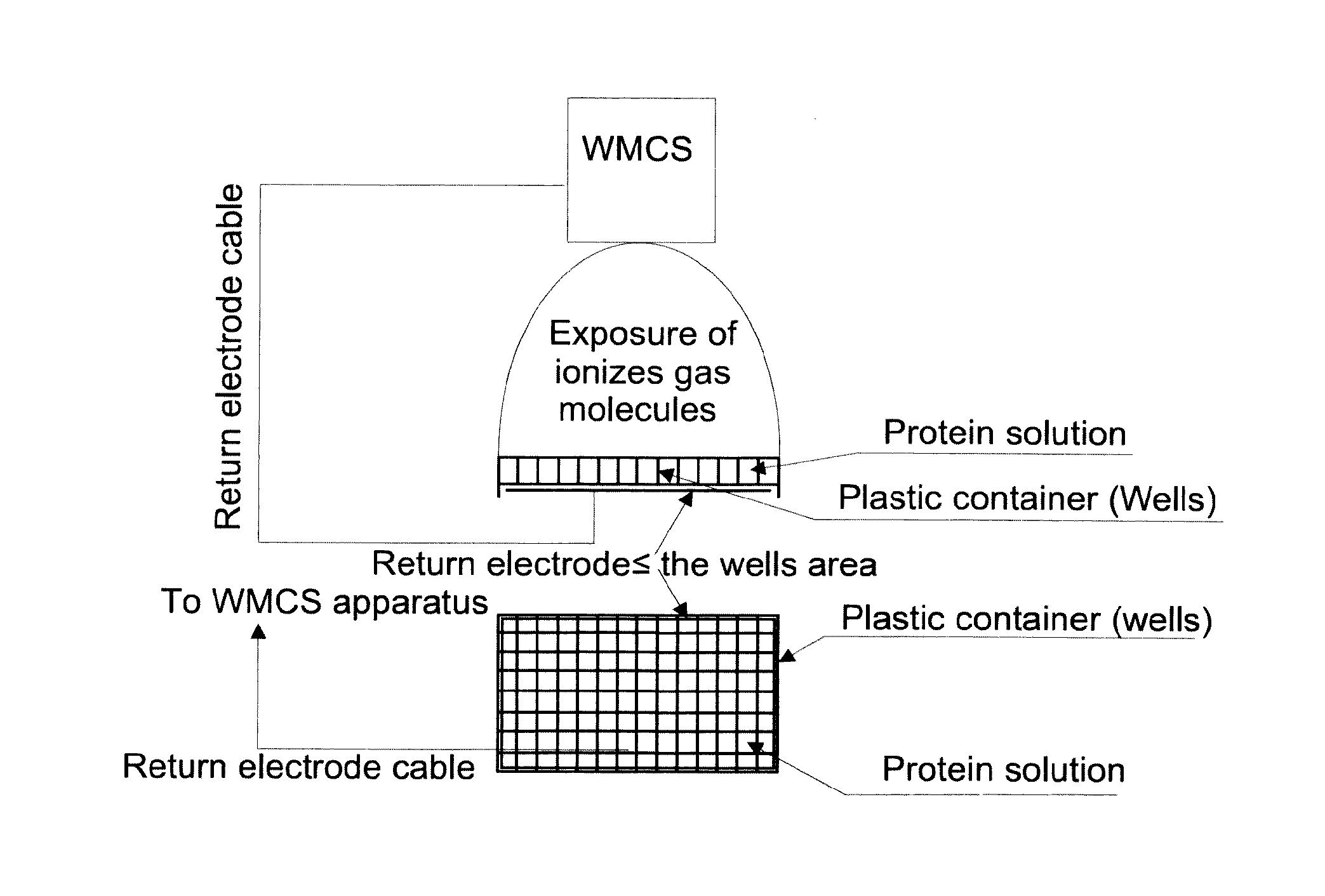

Method for preparing high quality crystals by directing ionized gas molecules through and/or over a saturated solution comprising a protein

ActiveUS10060048B2Improve diffractionGood diffraction qualityPolycrystalline material growthFrom normal temperature solutionsPower flowX-ray

Disclosed is a method for facilitating preparation of high quality crystals suitable for X-ray crystallographic studies. The method comprises that an electric charge or current is provided to a saturated solution of the molecule to be crystallized, preferably via a jet of gaseous ions. Also disclosed is an assembly for carrying out the method of the invention.

Owner:WETLING IP CCG LTD

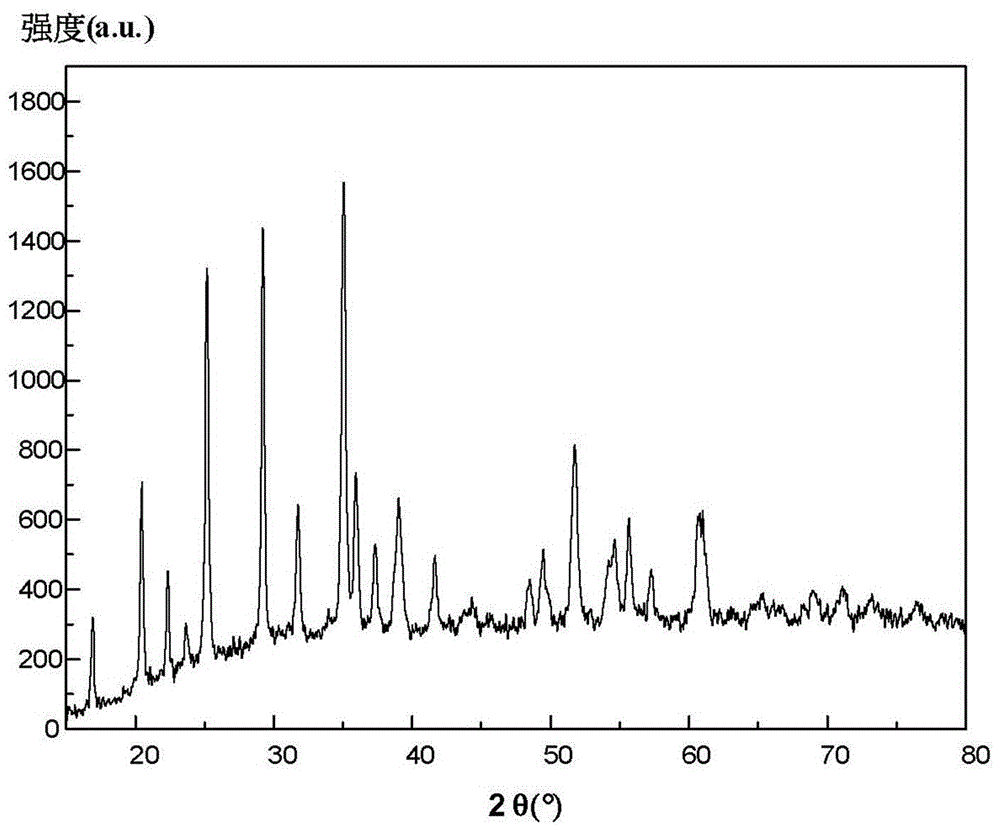

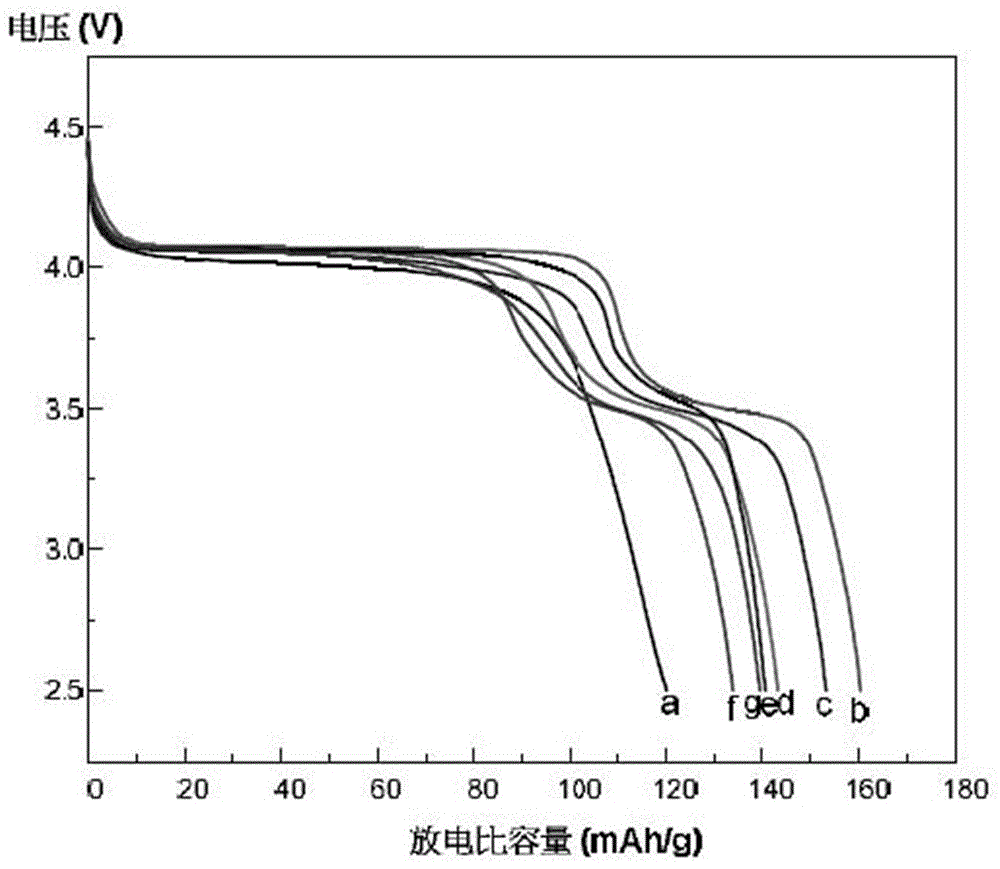

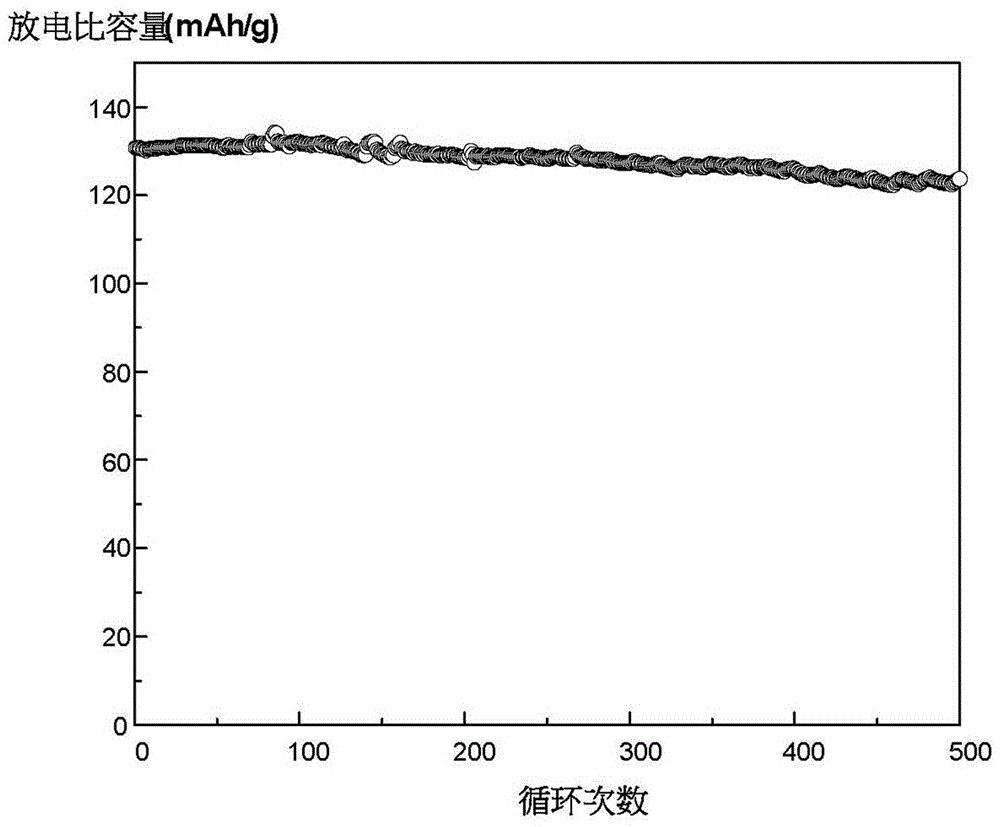

Preparation method of lithium manganese phosphate and lithium manganese phosphate/carbon composite material

ActiveCN105098178BReduce defectsGood orientationElectrode thermal treatmentSecondary cellsCarbon compositesPhysical chemistry

The invention relates to a preparation method of lithium manganese phosphate, which includes the following steps: mixing and dissolving a divalent manganese source, a lithium source and a phosphate source in a solvothermal reaction medium to form a mixed solution. The solvothermal reaction medium includes an organic solvent. and a co-solvent; and subjecting the mixed solution to a solvothermal reaction to obtain the reaction product lithium manganese phosphate. The invention also relates to a preparation method of lithium manganese phosphate / carbon composite material.

Owner:JIANGSU HUADONG INST OF LI ION BATTERY +1

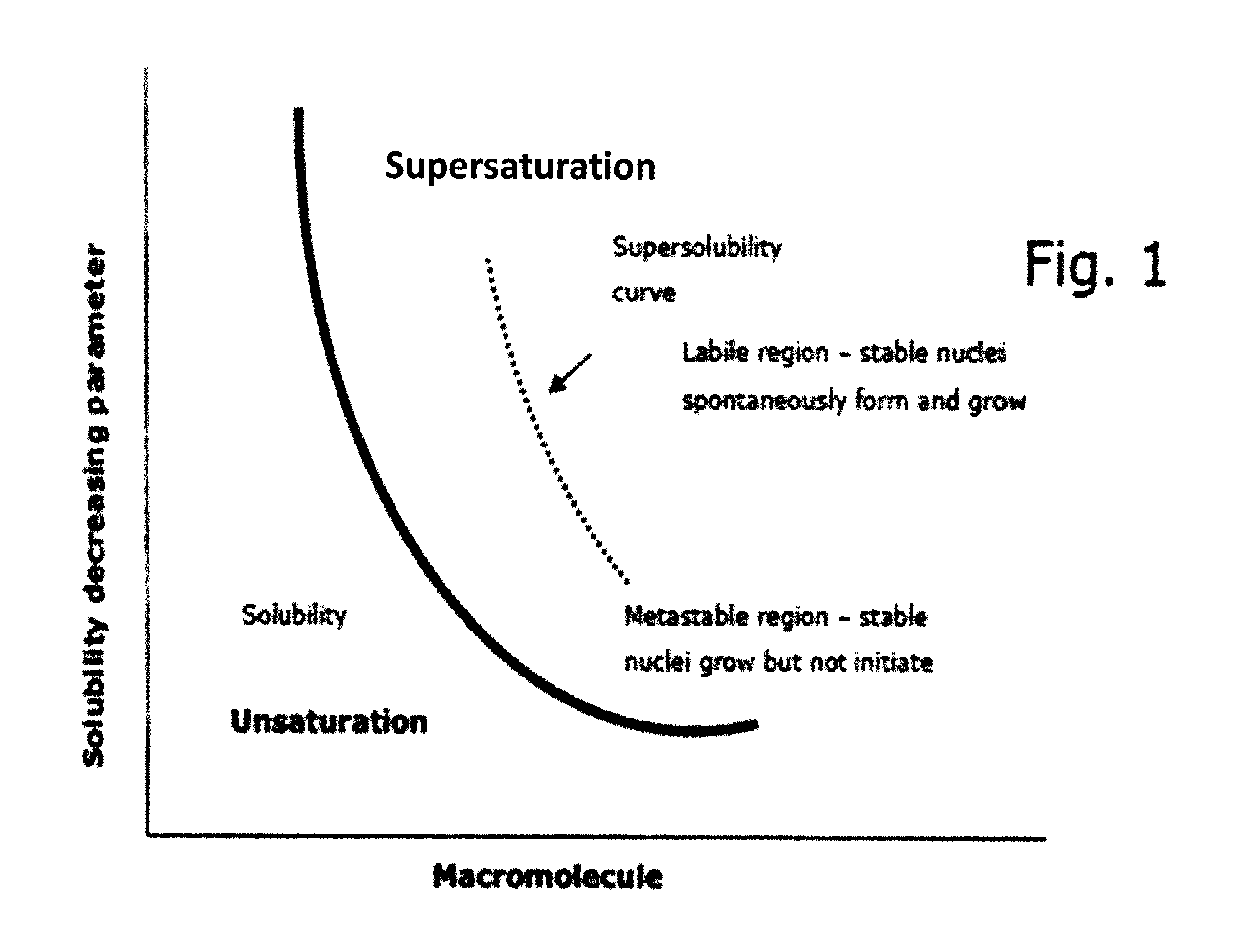

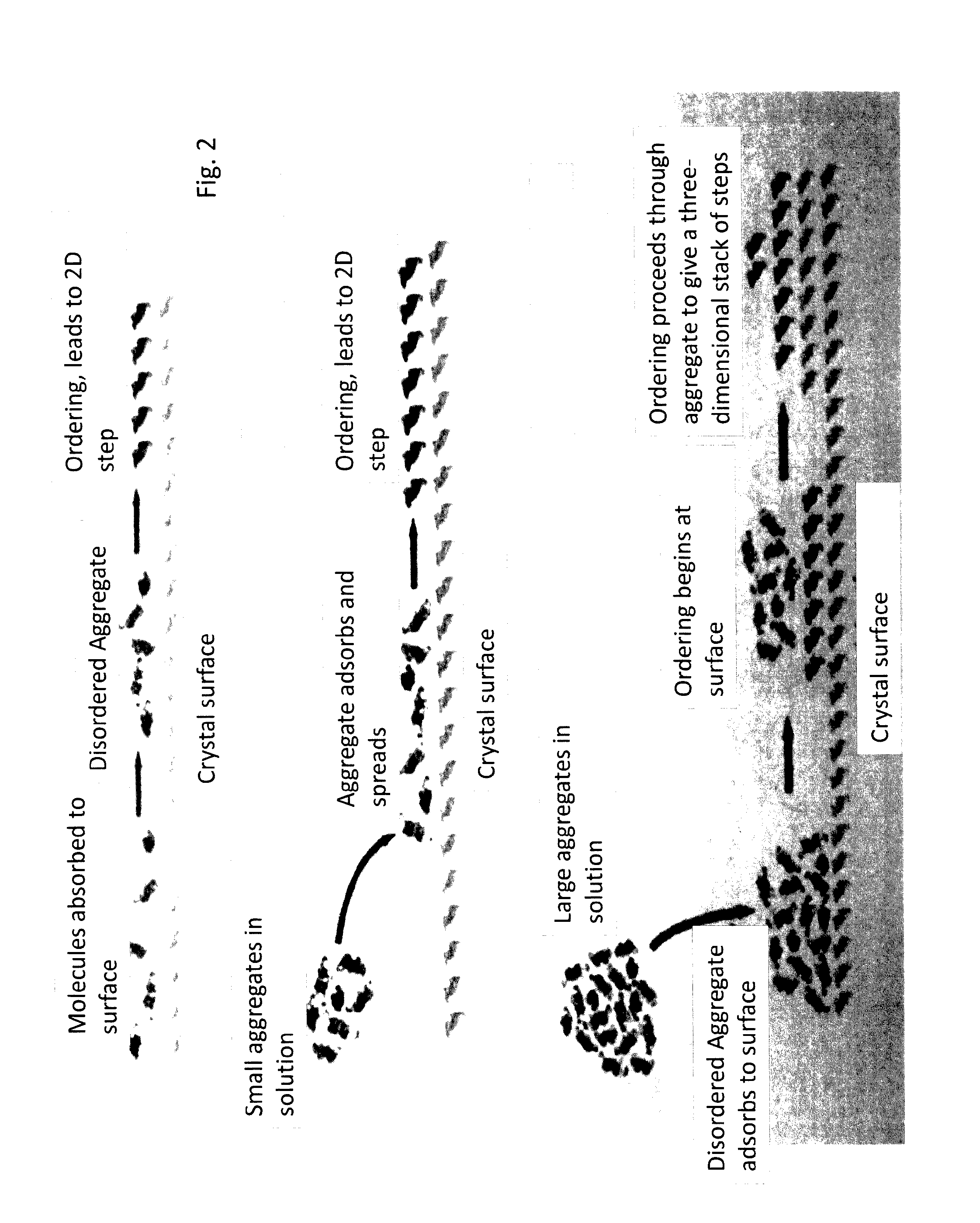

Crystallisation and Crystal Growth

ActiveUS20150284874A1Facilitating crystal formation crystalFacilitating crystal crystal growthPolycrystalline material growthFrom normal temperature solutionsX-rayCrystal growth

Disclosed is a method for facilitating preparation of high quality crystals suitable for X-ray crystallographic studies. The method comprises that an electric charge or current is provided to a saturated solution of the molecule to be crystallized, preferably via a jet of gaseous ions. Also disclosed is an assembly for carrying out the method of the invention.

Owner:WETLING IP CCG LTD

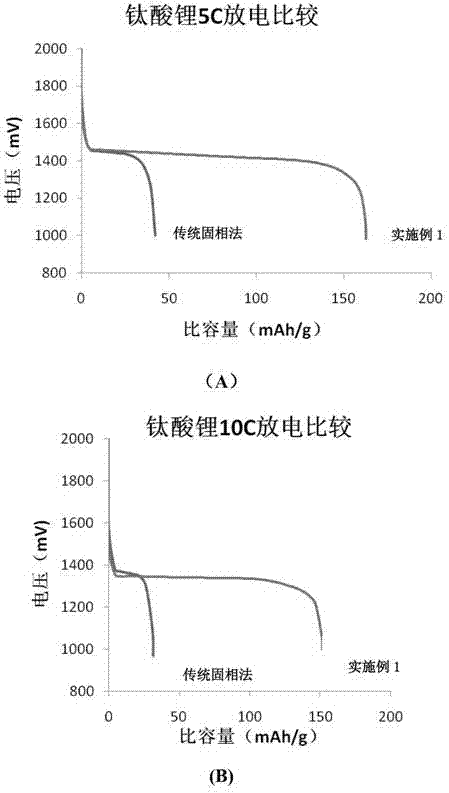

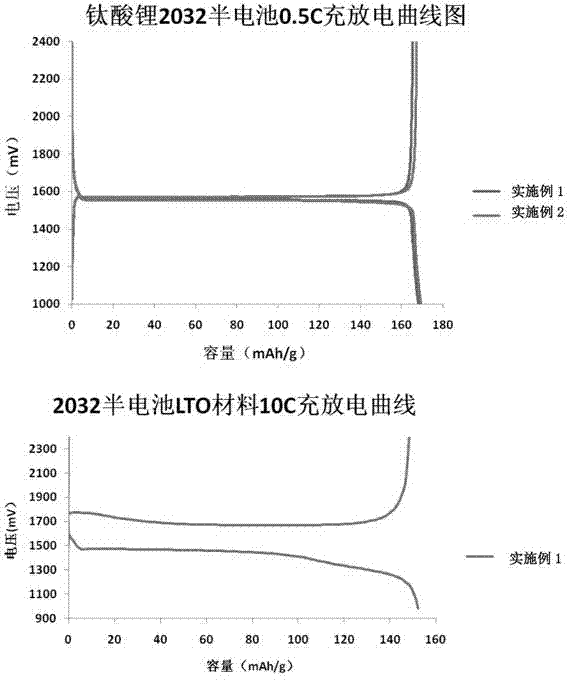

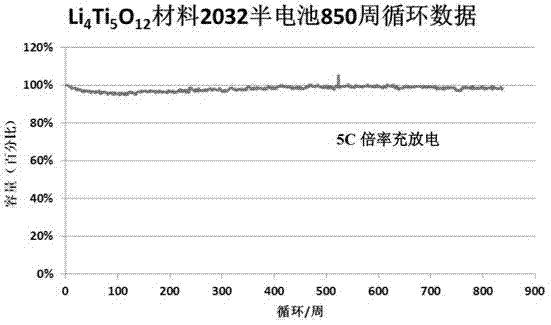

Method for preparing nano-lithium titanate cathode material

ActiveCN102832382BLow production and processing time and energy consumptionLow costMaterial nanotechnologyCell electrodesAir atmosphereStructural formula

The invention discloses a method for preparing a nano cathode material of a lithium ion battery at a low cost. A basic structural formula of the cathode material of the lithium ion battery is Li4Ti5O12 with a cubical spinel structure. The method is characterized by comprising the following steps of (1) sufficiently mixing a lithium salt precursor, TiO2 and a carbon precursor in a water, aqueous solution or solvent environment to obtain a precursor suspension; (2) grinding the precursor suspension; (3) drying the precursor suspension to obtain a precursor mixture; (4) carrying out calcinations on the precursor mixture in an inert atmosphere or inert and air atmosphere; and (5) smashing and grading the clacinated product to obtain a Li4Ti5O12 cathode material or Li4Ti5O12 / C composite cathode material. The Li4Ti5O12 cathode material and the Li4Ti5O12 / C composite cathode material have excellent electrochemical performance. The invention also provides a nano-electrochemically active cathode material with low cost and uniform particle size distribution produced by the method, and electrodes and batteries manufactured by the nano-electrochemically active cathode material.

Owner:LONG POWER SYST SUZHOU

Nitride semiconductor device using selective growth and manufacturing method thereof

ActiveUS8841179B2Reduce and remove leakage currentImproved breakdown voltage characteristicsSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialEngineering

A semiconductor device including a first GaN layer, an AlGaN layer, a second GaN layer, a gate electrode, a source electrode, and a drain electrode sequentially stacked on a substrate, capable of improving a leakage current and a breakdown voltage characteristics generated in the gate electrode by locally forming a p type GaN layer on the AlGaN layer, and a manufacturing method thereof, and a manufacturing method thereof are provided. The semiconductor device includes: a substrate, a first GaN layer formed on the substrate, an AlGaN layer formed on the first GaN layer, a second GaN layer formed on the AlGaN layer and including a p type GaN layer, and a gate electrode formed on the second GaN layer, wherein the p type GaN layer may be in contact with a portion of the gate electrode.

Owner:LG ELECTRONICS INC

Semiconductor device and method for growing semiconductor crystal

ActiveUS9269776B2Reduce processing costsCrystal growthSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorMaterials science

Owner:LX SEMICON CO LTD

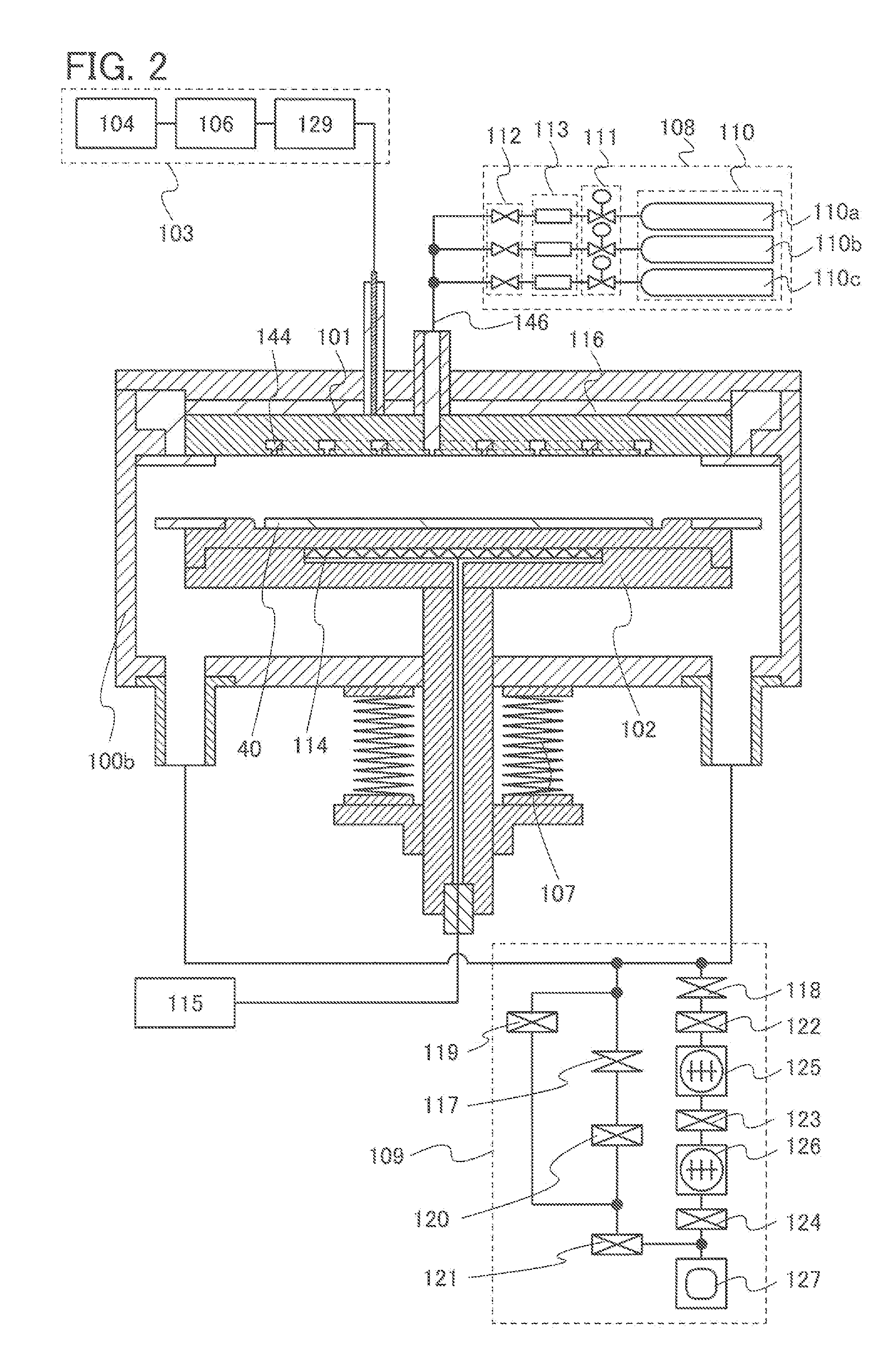

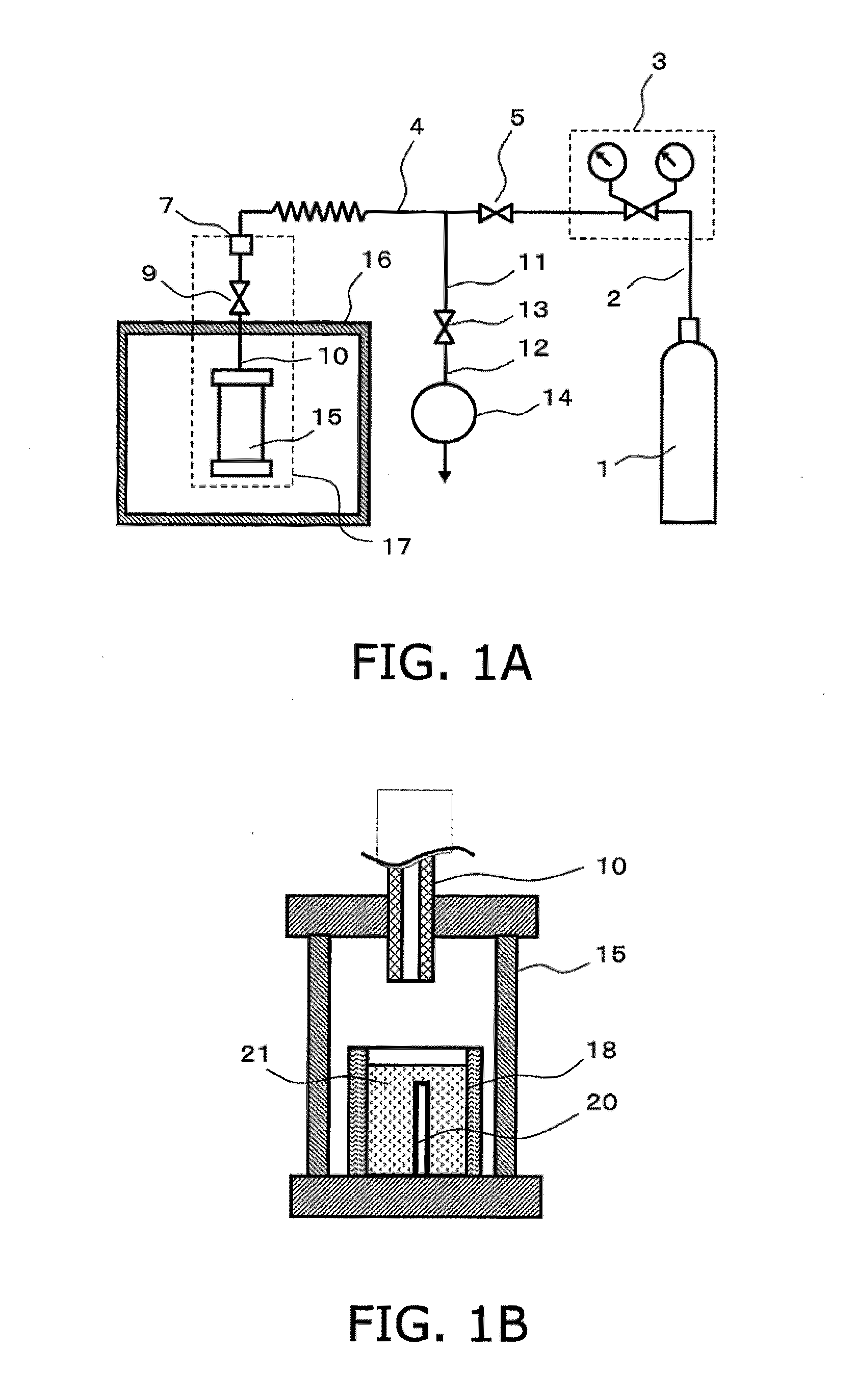

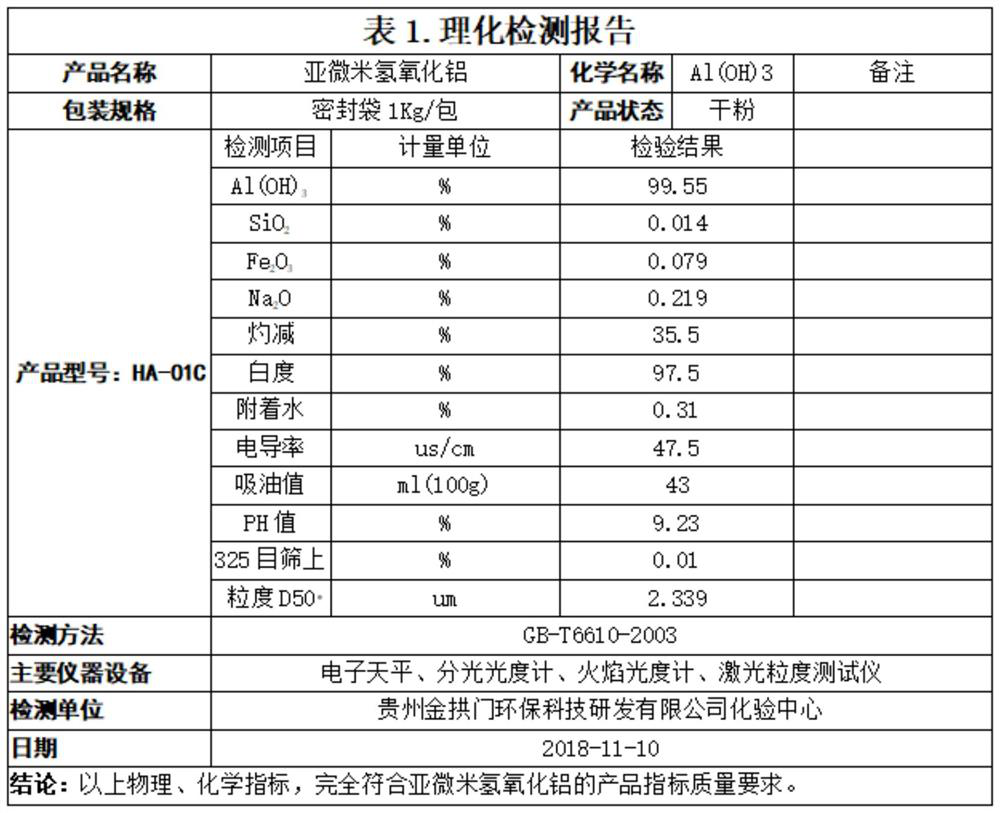

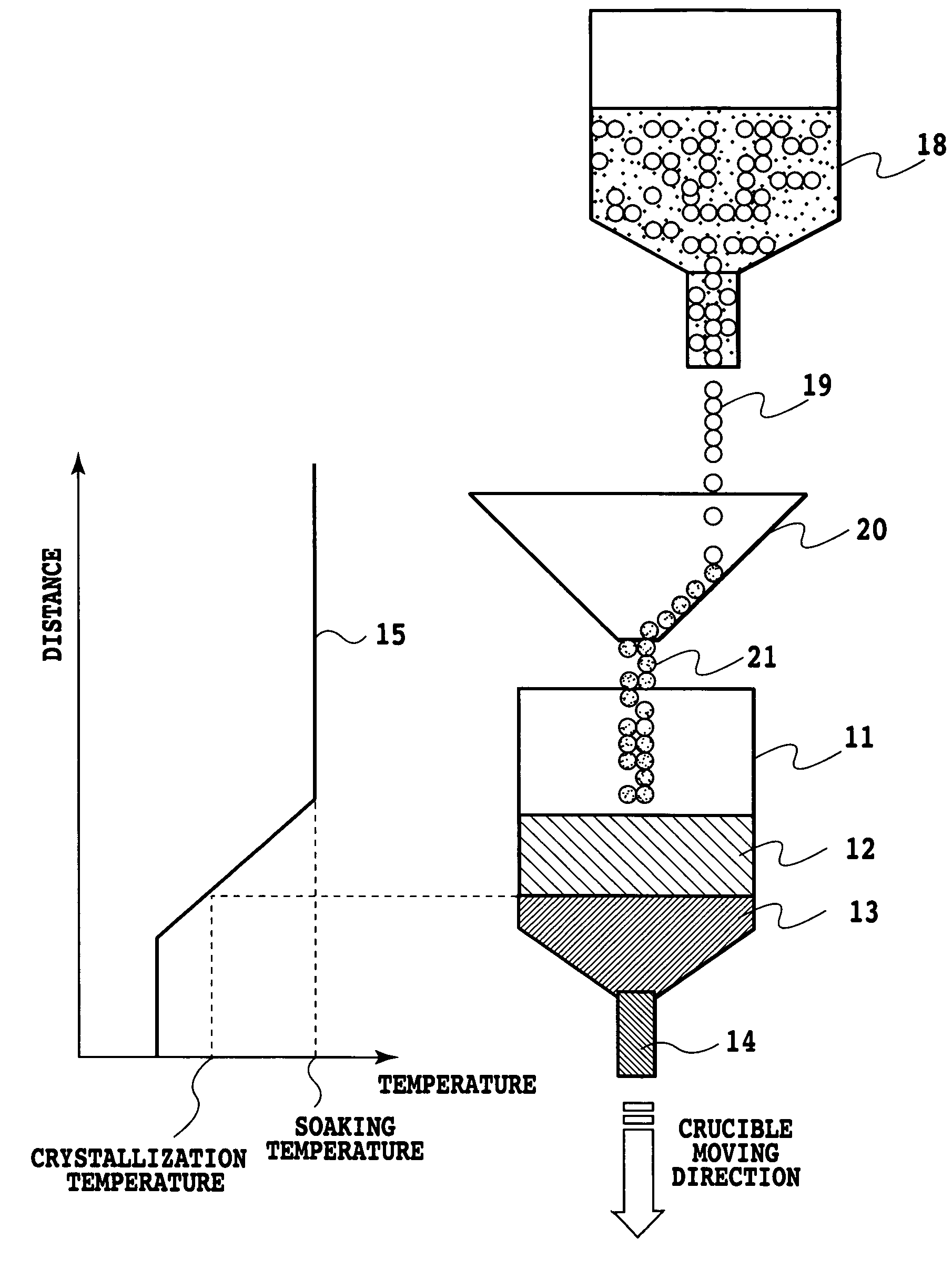

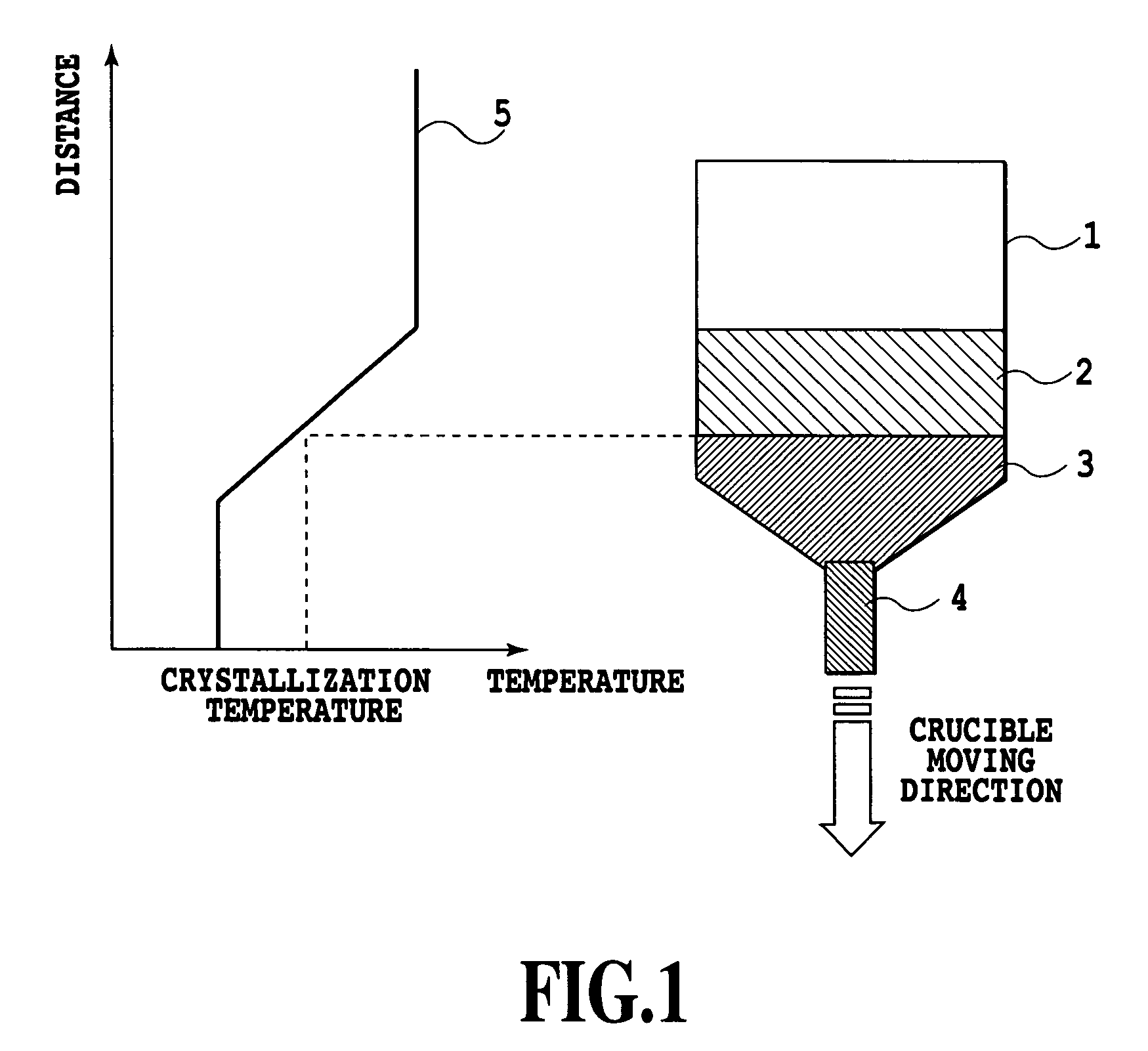

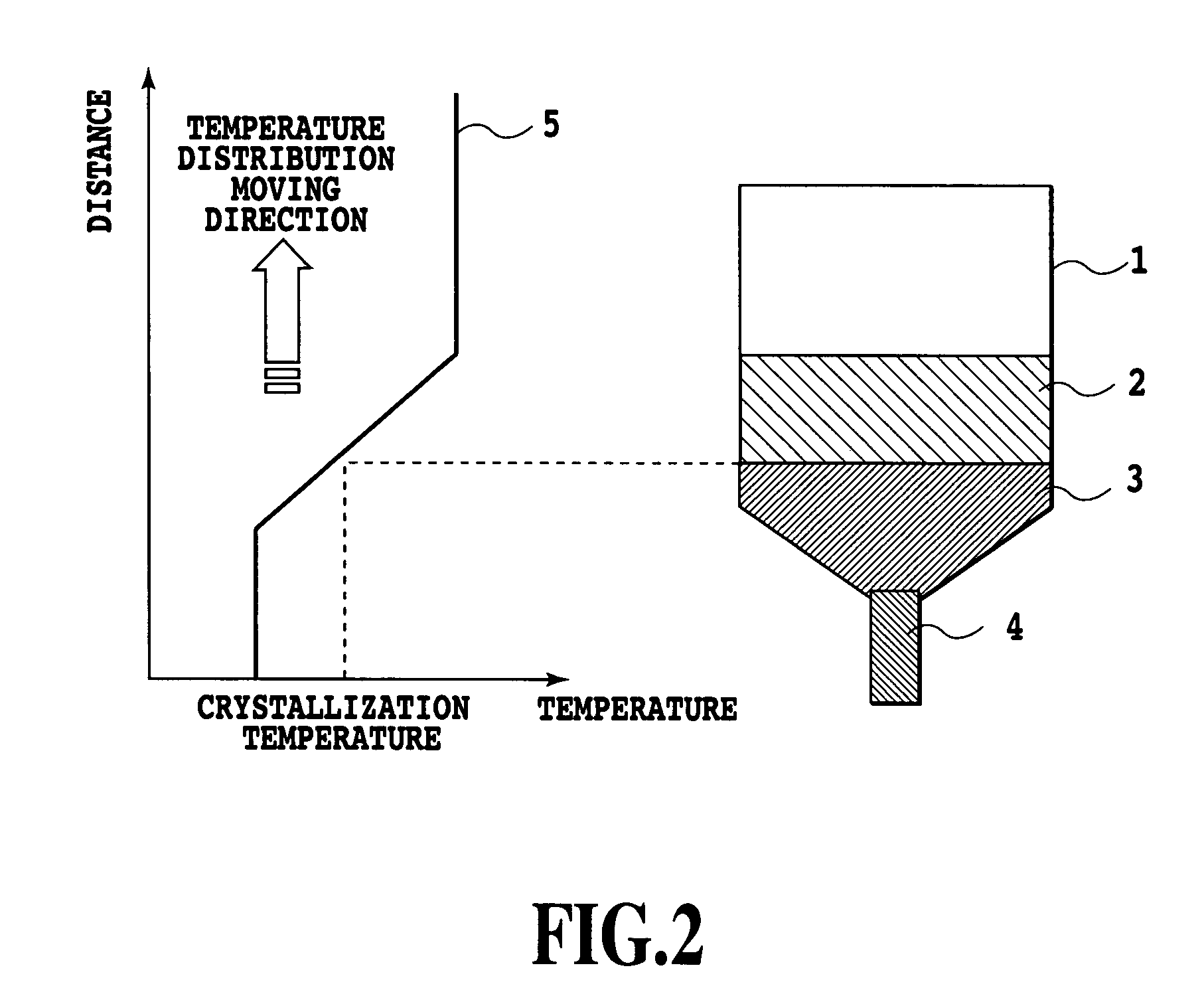

Method and apparatus for producing crystals

ActiveUS7591895B2Keeping crystal qualityKeeping composition uniformAfter-treatment apparatusPolycrystalline material growthCrucibleRaw material

A method and an apparatus for producing crystals wherein crystal quality can be kept and a crystal composition is uniformed from a growth early stage to a growth last stage are provided. In an apparatus for producing crystals wherein the crystals 13 are grown from a liquefying raw material 12 in a crucible retained in a furnace and slowly cooling the raw material 12 in the crucible 11 from below upward, the apparatus comprises a raw material supply apparatus 18 which supplies a resupply raw material, and a reflection plate 20 placed above the crucible 11, which liquefies the resupply raw material 19 supplied from the raw material supply apparatus 18 and drops it as a liquid into the crucible.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com