Method for producing baking soda large in particle size

A technology of baking soda and large particle size, applied in the preparation of bicarbonate and other directions, can solve the problems of high process requirements, increase particle size, prolong crystallization time, etc., and achieve the effects of simple operation, increased product particle size, and prolonged residence time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

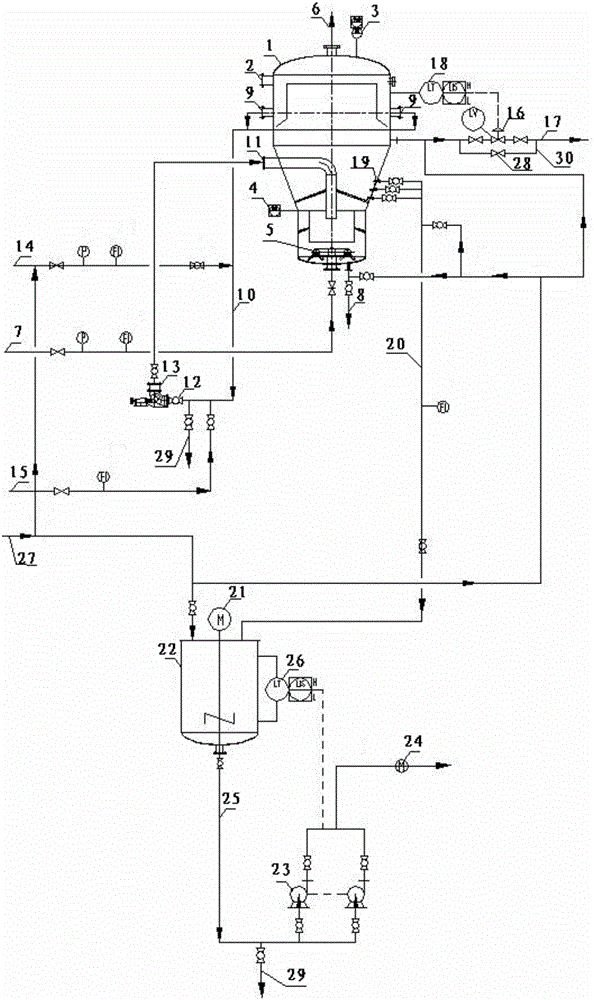

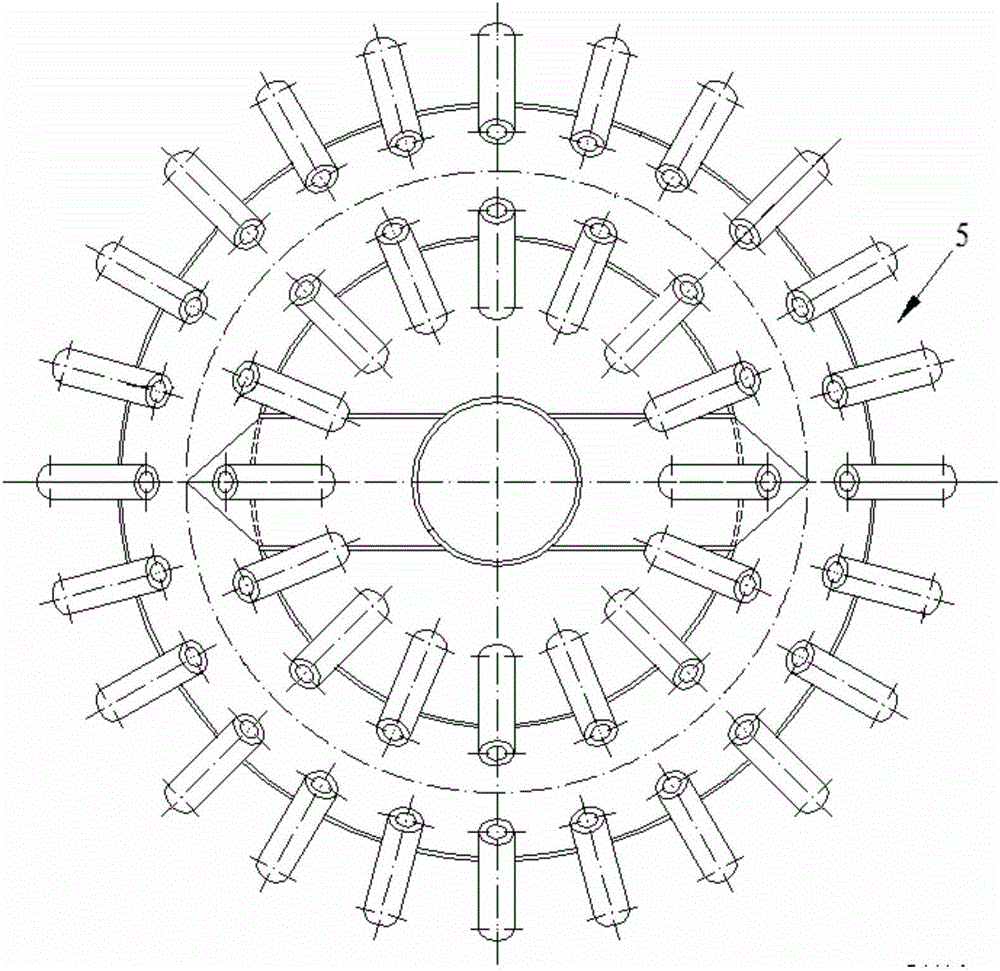

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

[0030] Such as figure 1 and figure 2 As shown, the device adopted in the present invention includes a reaction crystallizer 1 provided with a spare port 2, a first pressure gauge 3, a temperature control instrument 4 and a gas bubbler 5, and the gas bubbler 5 is made of a sintered tube, It is set as a highly symmetrical structure of inner and outer double rings, and the outer ring is provided with 24 evenly distributed bubbling ports, and the inner ring is provided with 16 evenly distributed bubbling ports. The reaction crystallizer 1 is set as a conical structure with a wide top and a narrow bottom. Under the action of circulating fluid, the products with smaller particle size float in the middle and upper part of the reaction crystallizer 1, and the products with larger particle size are distributed in the reaction crystallizer 1. the middle and lower part. A tai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com