Method for efficient flotation production of KCL through sequential separation of sylvite ore

A technology of potassium salt and ore, which is applied in the field of KCl production, can solve the problems of high construction investment and production costs, low KCl recovery rate, and large amount of flotation materials, so as to reduce flotation intensity, improve technical and economic effects, and reduce construction costs. The effect of investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

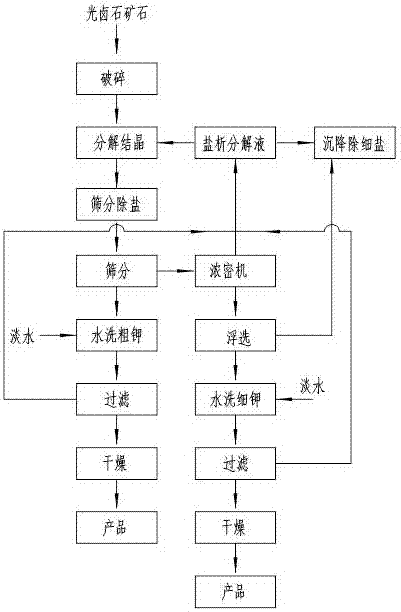

[0034] figure 1 Shown, when the method for producing KCL by stage-by-stage separation and high-efficiency flotation of potassium salt ore is applied to the washing and processing of carnallite ore, carry out according to the following steps:

[0035] 1. Preparation of carnallite block with reasonable particle size: the carnallite ore mined from underground is crushed into a block with a particle size of 5mm by crushing equipment, so as to facilitate the decomposition of carnallite;

[0036] 2. Preparation of carnallite slurry: use magnesium chloride saturated mother liquor, potassium washing mother liquor, salt washing mother liquor and water to prepare a carnallite decomposition solution with a magnesium chloride content of 22%, and decompose the carnallite block into carnallite material with the decomposition solution pulp;

[0037]3. Screening and desalting: According to the KCl and NaCl material composition, particle size distribution and screening performance, the decomp...

Embodiment 2

[0044] figure 1 Shown, when the method for producing KCL by stage-by-stage separation and high-efficiency flotation of potassium salt ore is applied to the washing and processing of carnallite ore, carry out according to the following steps:

[0045] 1. Preparation of carnallite block with reasonable particle size: the carnallite ore mined from underground is crushed into a block with a particle size of 15mm by crushing equipment, so as to facilitate the decomposition of carnallite;

[0046] 2. Preparation of carnallite slurry: use magnesium chloride saturated mother liquor, potassium washing mother liquor, salt washing mother liquor and water to prepare a carnallite decomposition solution with a magnesium chloride content of 18%, and decompose the carnallite block into carnallite material with the decomposition solution pulp;

[0047] 3. Screening and desalting: According to the KCl and NaCl material composition, particle size distribution and screening performance, the deco...

Embodiment 3

[0051] figure 1 Shown, when the method for producing KCL by stage-by-stage separation and high-efficiency flotation of potassium salt ore is applied to the washing and processing of carnallite ore, carry out according to the following steps:

[0052] 1. Preparation of carnallite blocks with a reasonable particle size: the carnallite ore mined from the ground is broken into blocks with a particle size of 10mm by crushing equipment, so as to facilitate the decomposition of carnallite;

[0053] 2. Preparation of carnallite slurry: use magnesium chloride saturated mother liquor, potassium washing mother liquor, salt washing mother liquor and water to prepare a carnallite decomposition solution with a magnesium chloride content of 20%, and decompose the carnallite block into carnallite material with the decomposition solution pulp;

[0054] 3. Screening and desalting: According to the material composition, particle size distribution and screening performance of KCl and NaCl, the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com