Method for preparing nano-lithium titanate cathode material

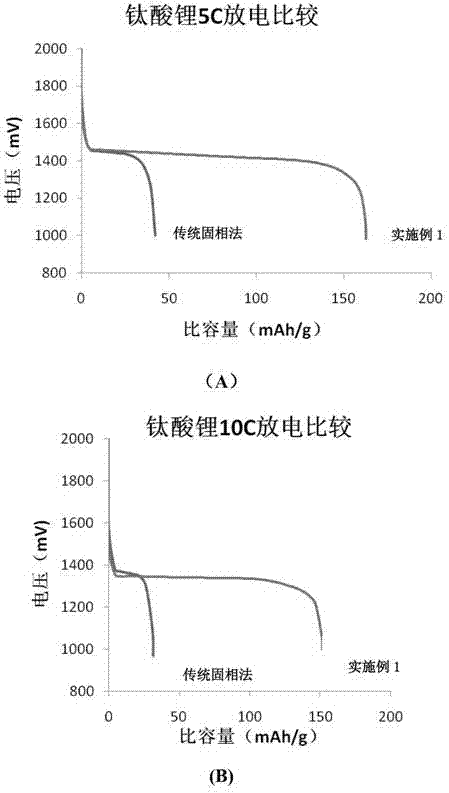

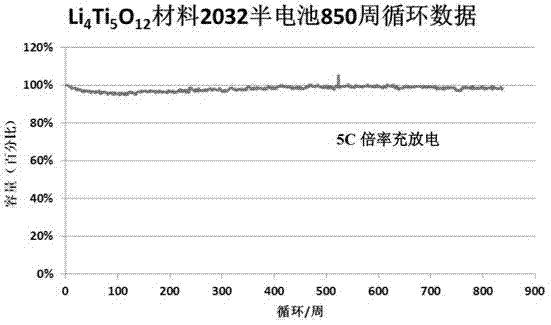

A negative electrode material and nano-scale technology, applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problems of loss of continuity of electron conduction of the pole piece, difficulty in large-scale industrial production, and increase in raw material costs. Uniform particle size distribution, excellent electrochemical performance, and the effect of inhibiting crystal growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

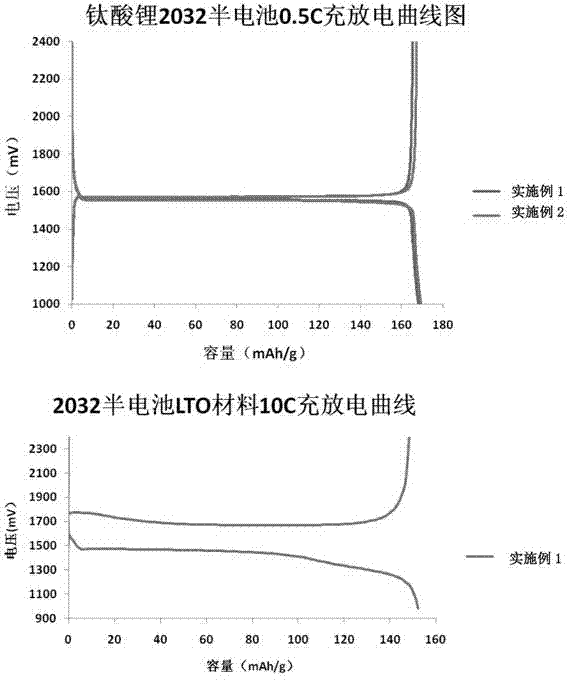

[0051] Example 1Li 4 Ti 5 o 12 Synthesis of / C Composite Anode Active Materials

[0052] In a specific embodiment of the present invention, Li 4 Ti 5 o 12 / C composites are synthesized by the following process:

[0053] (1) Weigh 1288g Li 2 CO 3 , 3480gTiO 2 With 286gPVA, the weighed raw materials are mixed to make the PVA uniformly dispersed in the raw materials. Transfer to a high-energy grinder, add 35L of water and grind for 3 hours to obtain a precursor suspension.

[0054] (2) Drying at 110°C to obtain the precursor.

[0055] (3) The precursor was calcined in a calciner at 800°C in N2 for 2 hours and 15 minutes, and the product was crushed and classified to obtain a black-gray Li 4 Ti 5 o 12 / C Composite.

Embodiment 2

[0056] Example 2Li 4 Ti 5 o 12 Synthesis of negative electrode active materials

[0057] In a specific embodiment of the present invention, Li 4 Ti 5 o 12 Materials are synthesized by the following process:

[0058] (1) Weigh 1288g Li 2 CO 3 , 3480gTiO 2 With 286gPVA, the weighed raw materials are mixed to make the PVA uniformly dispersed in the raw materials. Transfer to a high-energy grinder, add 35L of water and grind for 3 hours to obtain a precursor suspension.

[0059] (2) Drying at 110°C to obtain the precursor.

[0060] (3) Put the precursor in a push plate calciner at 800 °C 2 Calcined under the condition of medium heat preservation for 15 minutes, and then calcined under the condition of 800°C in air for 2 hours. The product is crushed and classified to obtain white Li 4 Ti 5 o 12 Negative material.

[0061] figure 1 A schematic diagram showing the synthesis process of the material of Example 2 of the present invention in a pusher-type calciner, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com