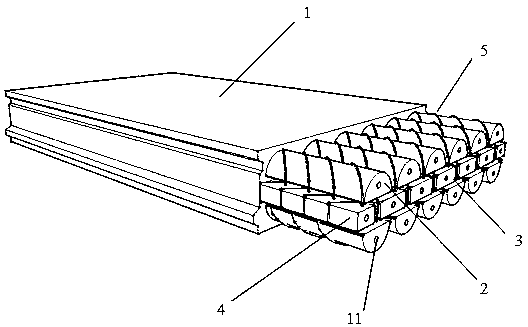

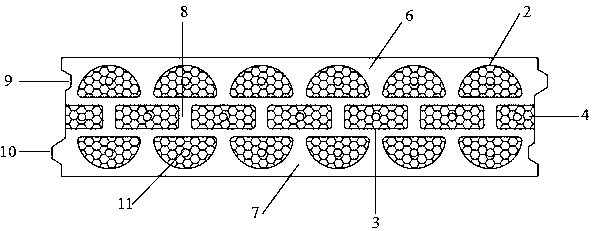

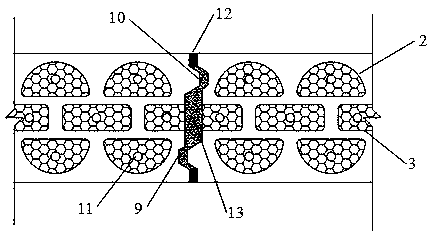

Self-heat-preservation outer wall board and outer wall for fabricated building

A self-insulation technology for buildings, applied in buildings, building components, building structures, etc., can solve problems that affect building functions, increase construction difficulty, and wall panel deformation, so as to save vibration and prevent cavity walls Strong effect of cracking and deformation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: 320 parts of grade 42.5 ordinary Portland cement; 56 parts of fly ash; 27 parts of silica fume; 48 parts of slag powder; 780 parts of sand; 966 parts of crushed stone; 24 parts of calcium sulfoaluminate-calcium oxide expansion agent; 6 parts of lightly burned magnesium oxide; 9.5 parts of 5mm steel fiber; 17.5 parts of 12mm steel fiber; 142 parts of water. The expansion of fresh concrete is 686mm, the air content is 2.8%, T 500 It is 7.8s, there is no bleeding phenomenon, and the self-compacting performance is excellent; after curing in water for 14 days, the shrinkage rate of concrete dried in air for 60 days is 85με, there is no crack on the surface, and the apparent quality is excellent.

Embodiment 2

[0029] Example 2: 375 parts of grade 42.5 ordinary Portland cement; 63 parts of fly ash; 32 parts of silica fume; 52 parts of slag powder; 750 parts of sand; 948 parts of crushed stone; 27 parts of calcium sulfoaluminate-calcium oxide expansion agent; 8 parts of lightly burned magnesium oxide; 9 parts of 5mm steel fiber; 21 parts of 12mm steel fiber; 150 parts of water. The expansion of fresh concrete is 655mm, the air content is 1.9%, T 500 It is 5.3s, there is no bleeding phenomenon, and the self-compacting performance is excellent; after curing in water for 14 days, the shrinkage rate of concrete dried in air for 60 days is 71με, there is no crack on the surface, and the apparent quality is excellent.

Embodiment 3

[0030]Example 3: 358 parts of 52.5 grade Portland cement; 52 parts of fly ash; 35 parts of silica fume; 50 parts of slag powder; 760 parts of sand; 942 parts of crushed stone; 28 parts of calcium aluminate-calcium oxide expansion agent; 7 parts of light-burned magnesium oxide; 10.5 parts of 5mm steel fiber; 19.5 parts of 12mm steel fiber; 146 parts of water. The expansion of fresh concrete is 670mm, the air content is 2.2%, T 500 It is 7.1s, there is no bleeding phenomenon, and the self-compacting performance is excellent; after curing in water for 14 days, the shrinkage rate of concrete dried in air for 60 days is 59με, there is no crack on the surface, and the apparent quality is excellent.

[0031] The prefabricated insulation pieces 2, 3 and 4 are prepared from aerogel-gypsum-based cementitious material-fiber composite materials, the examples are as follows:

[0032] Example 1: 480 parts of gypsum; 90 parts of 42.5 grade Portland cement; 115 parts of fly ash; 20 parts of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com