Solar cell module and method of fabricating the same

A technology of solar cells and substrates, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as solar cell electrode erosion and reduce the performance of solar cell devices, and achieve the effect of stability and reliability assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the description of the embodiment, it should be understood that when a certain layer (or film), region, pattern or structure is referred to as being on another substrate, another layer (or film), another region, another welding When a pad or another pattern is "on" or "under", it may be directly or indirectly on or under the other substrate, layer (or film), region, pad or pattern, or it may There are one or more intermediate layers. This position of the layers is described with reference to the figures.

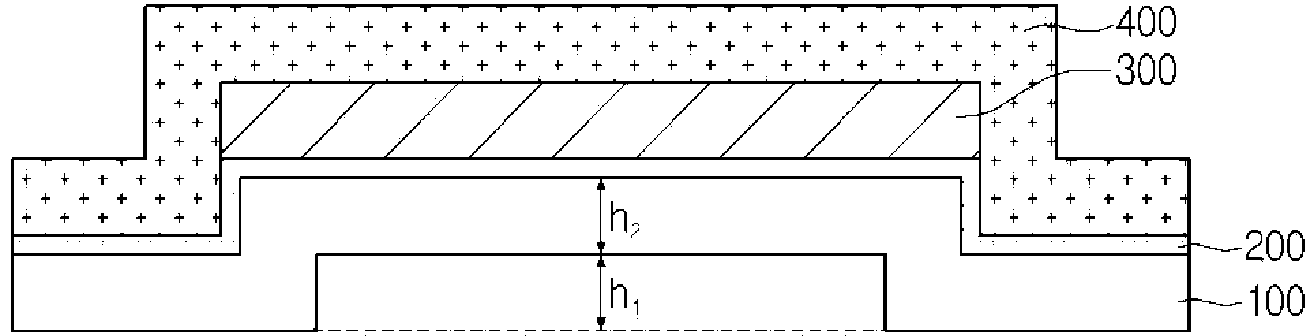

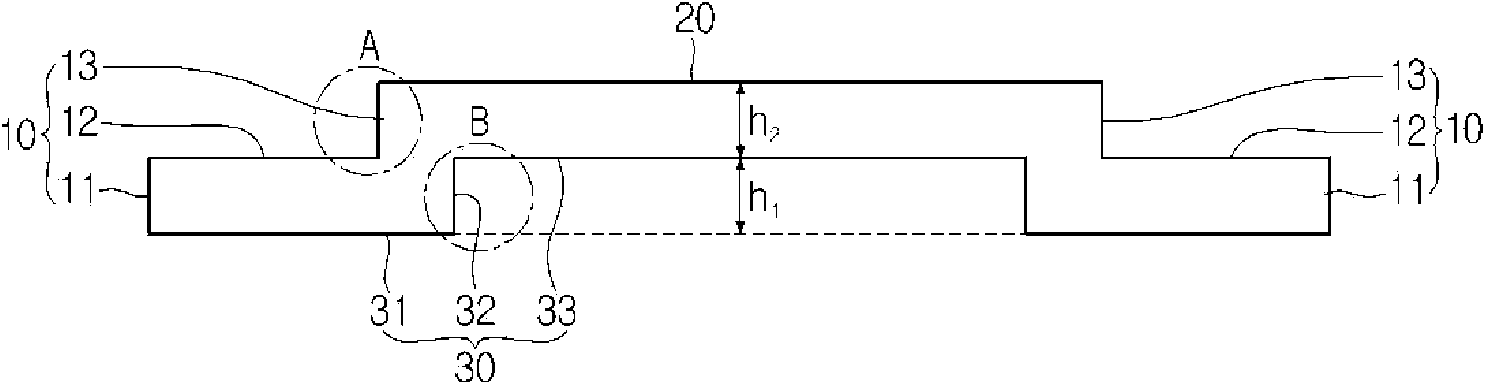

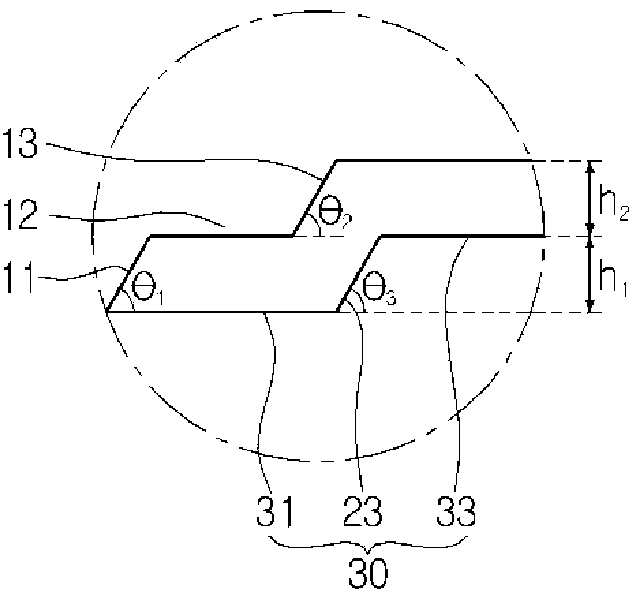

[0020] figure 1 and Figure 4 is a sectional view showing the solar cell module described in the embodiment, and figure 2 and image 3 is a cross-sectional view showing the supporting base described in the embodiment.

[0021] see figure 1 , the solar cell module described in this embodiment includes a supporting substrate 100 , a barrier layer 200 , a solar cell 300 and a protective layer 400 .

[0022] The supporting base 100 has a flat plate shape, and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com