Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58 results about "Anode polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

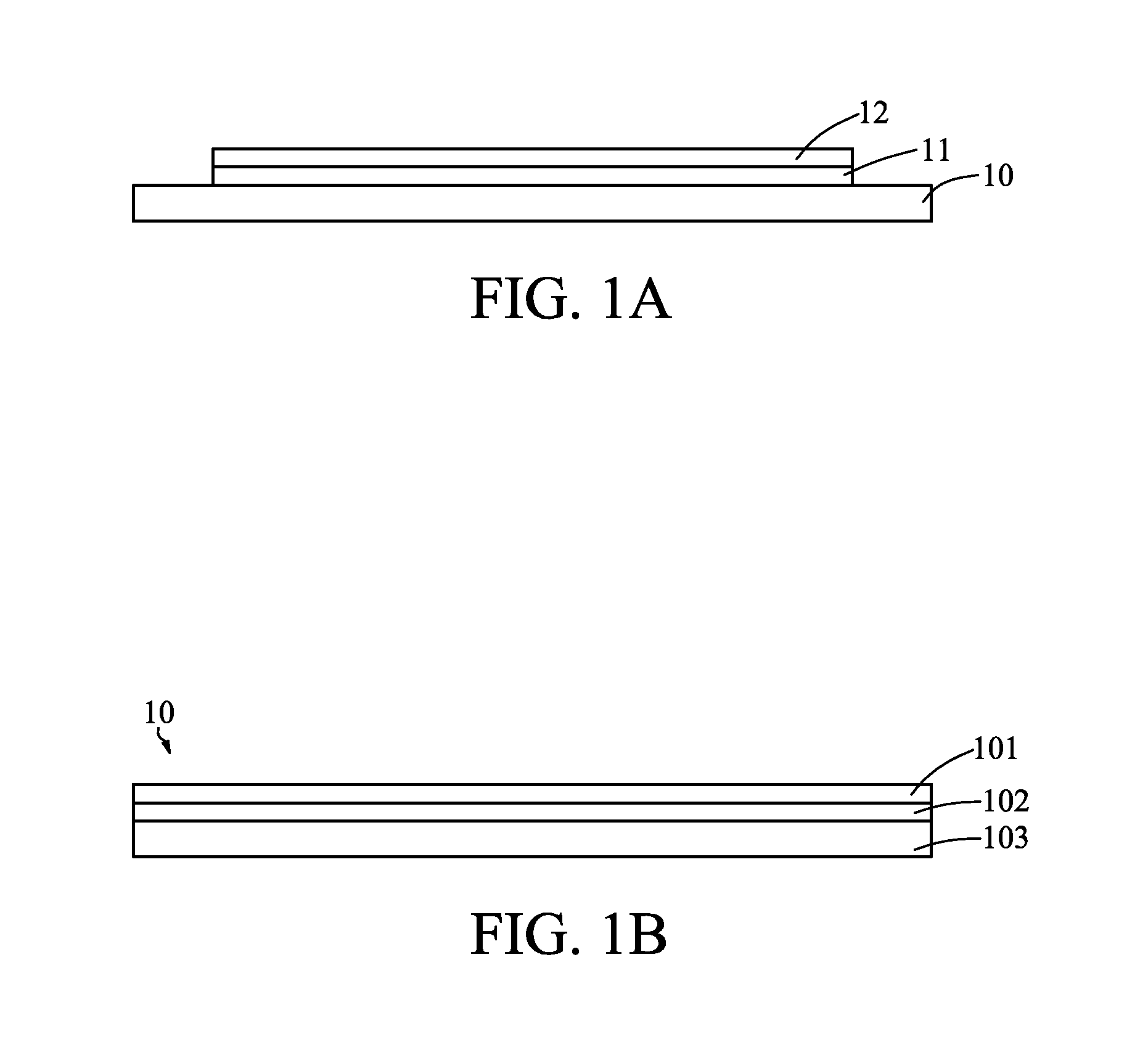

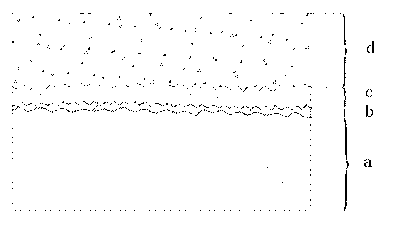

Anode on a pretreated substrate for improving redox-stability of solid oxide fuel cell and the fabrication method therof

ActiveUS20120021332A1Improve redox abilityDrag minimizationLiquid surface applicatorsMolten spray coatingOptoelectronicsHigh pressure

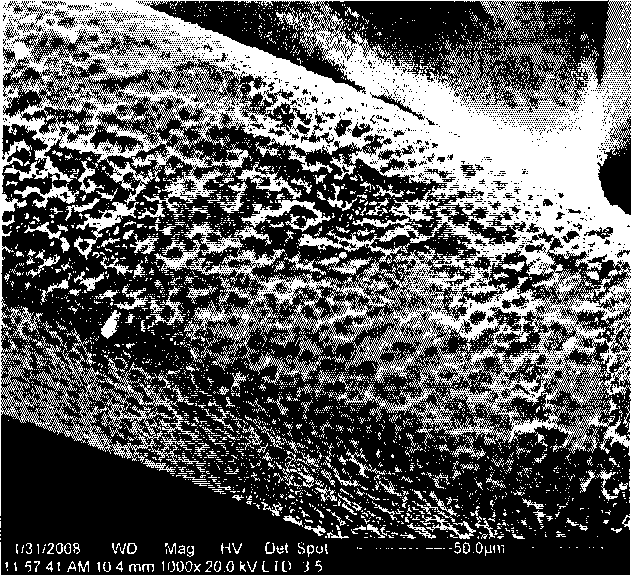

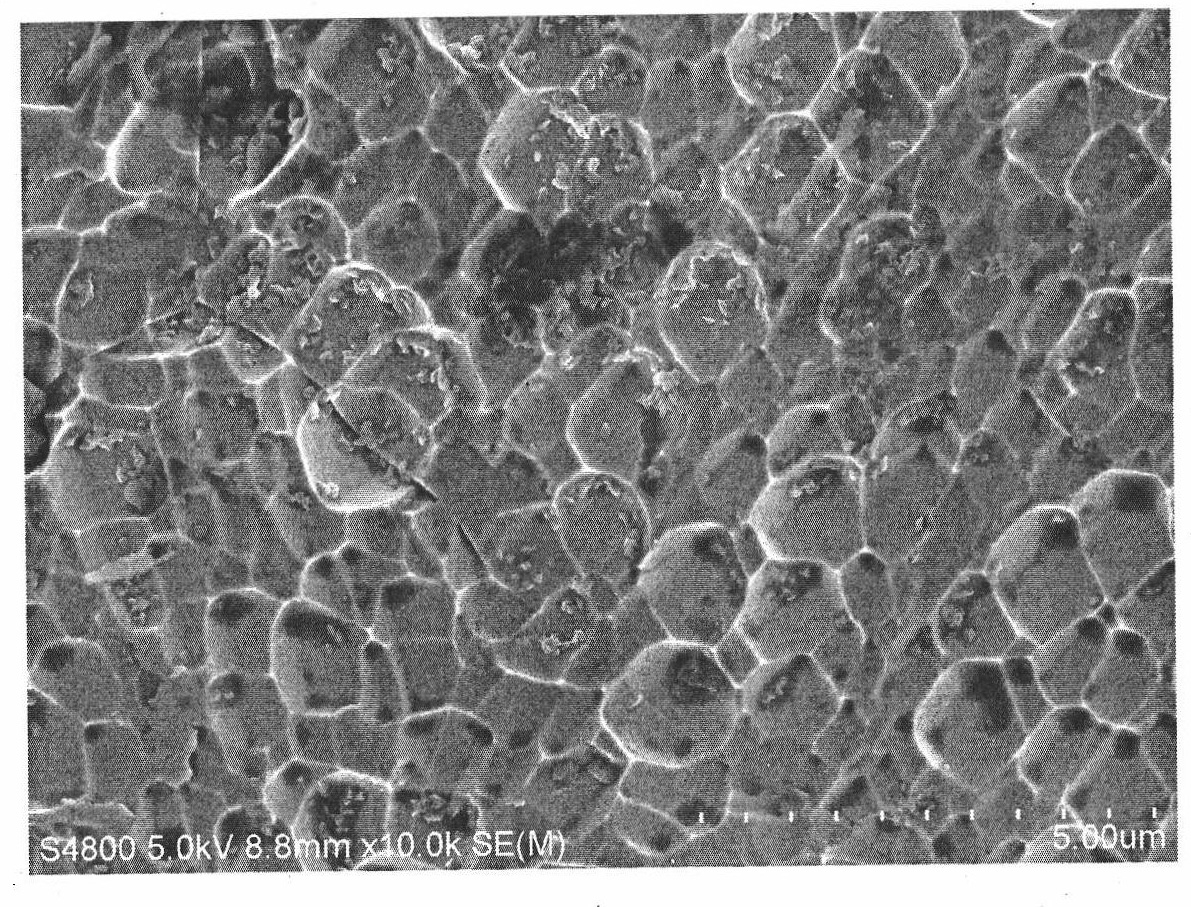

The disclosure provides a double-layer anode structure on a pretreated porous metal substrate and a method for fabricating the same, for improving the redox stability and decreasing the anode polarization resistance of a SOFC. The anode structure comprises: a porous metal substrate of high gas permeability; a first porous anode functional layer, formed on the porous metal substrate by a high-voltage high-enthalpy Ar—He—H2—N2 atmospheric-pressure plasma spraying process; and a second porous anode functional layer, formed on the first porous anode functional layer by a high-voltage high-enthalpy Ar—He—H2—N2 atmospheric-pressure plasma spraying and hydrogen reduction. The first porous anode functional layer is composed a redox stable perovskite, the second porous anode functional layer is composed of a nanostructured cermet. The first porous anode functional layer is also used to prevent the second porous anode functional layer from being diffused by the composition elements of the porous metal substrate.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Preparation method of biological activity protein or polypeptides coating biology bracket

The invention relates to a preparation method of a bioactive protein or polypeptide coat biological bracket. The method of anode polarization is adopted, a bracket body is taken as the anode, and is inserted into bioactive protein or polypeptide solution together with the cathode; under the action of the electric field of a power supply, the bioactive protein or polypeptide is ionized to have negative electrification to move towards the anode of the bracket and evenly coats on the surface of the bracket. The preparation method provided by the invention dose not need to additionally prepare a medicine loading coat, has no obvious interface, can envelop a bioactive protein or polypeptide coat on the whole bracket body or part surface of the bracket through the function of anode polarization; the bioactive protein or polypeptide has stable enveloping amount and is not easily eluted, has safe use, simple operation and low cost, and is suitable for large-scale production in industry.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

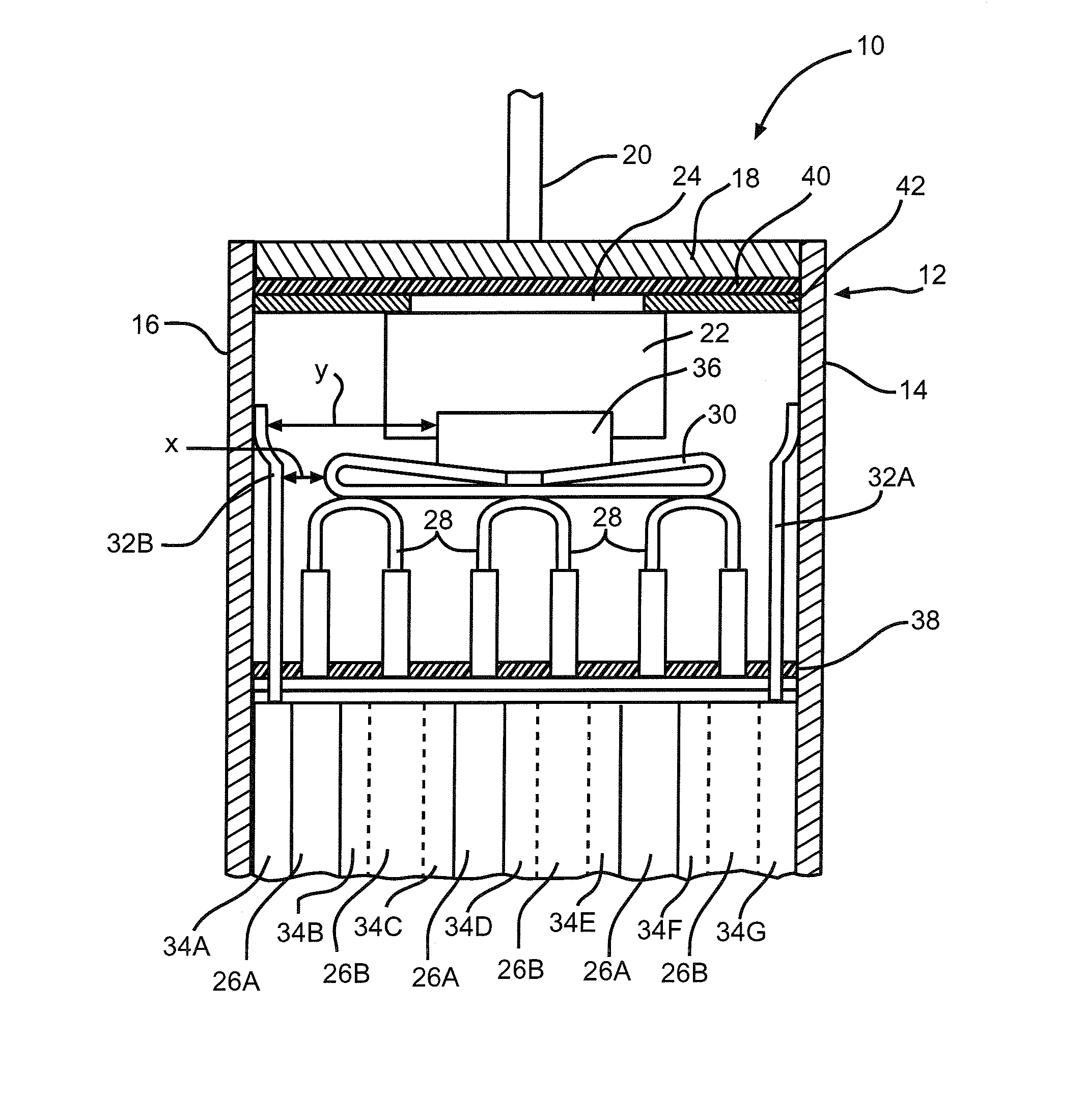

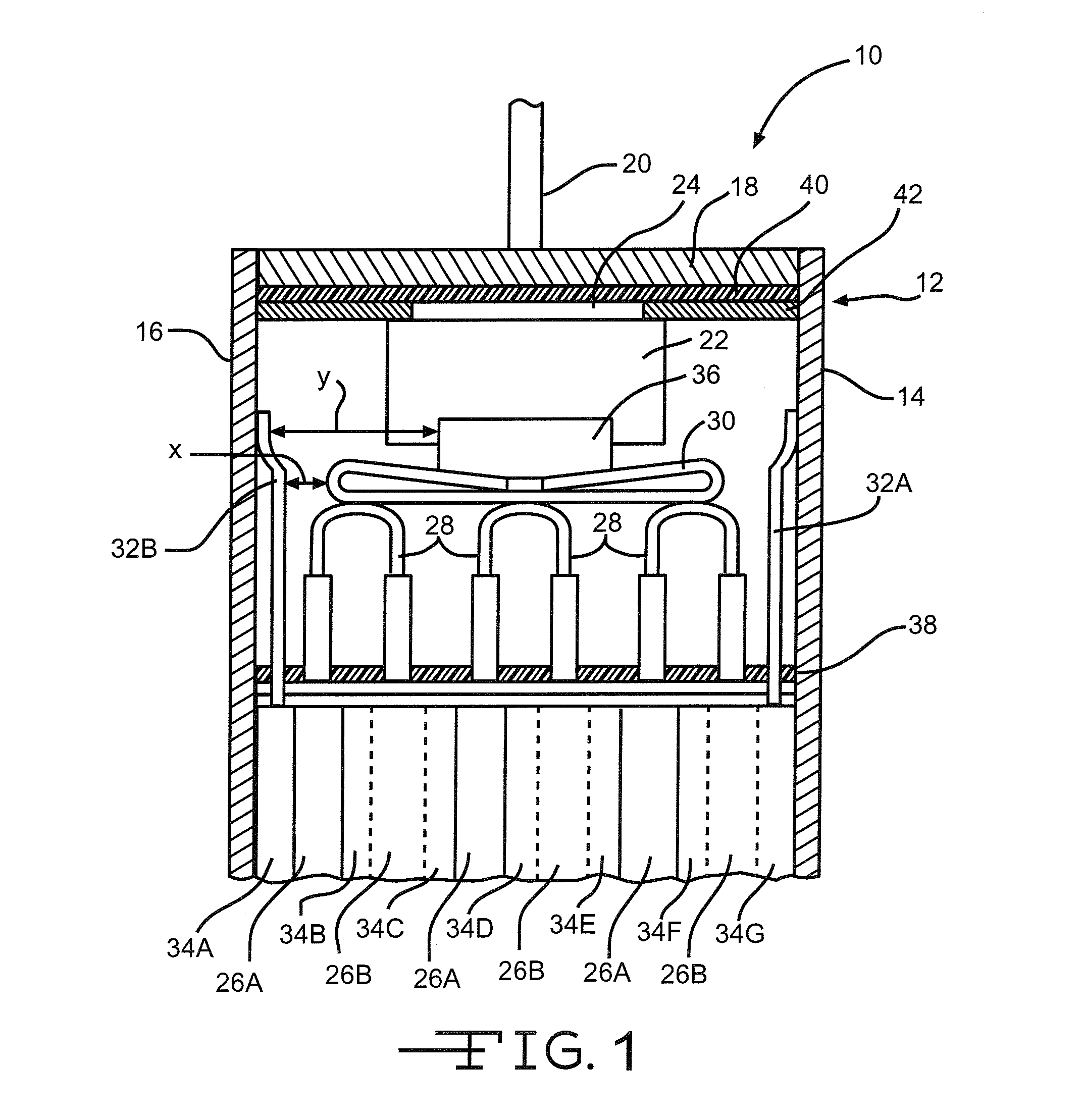

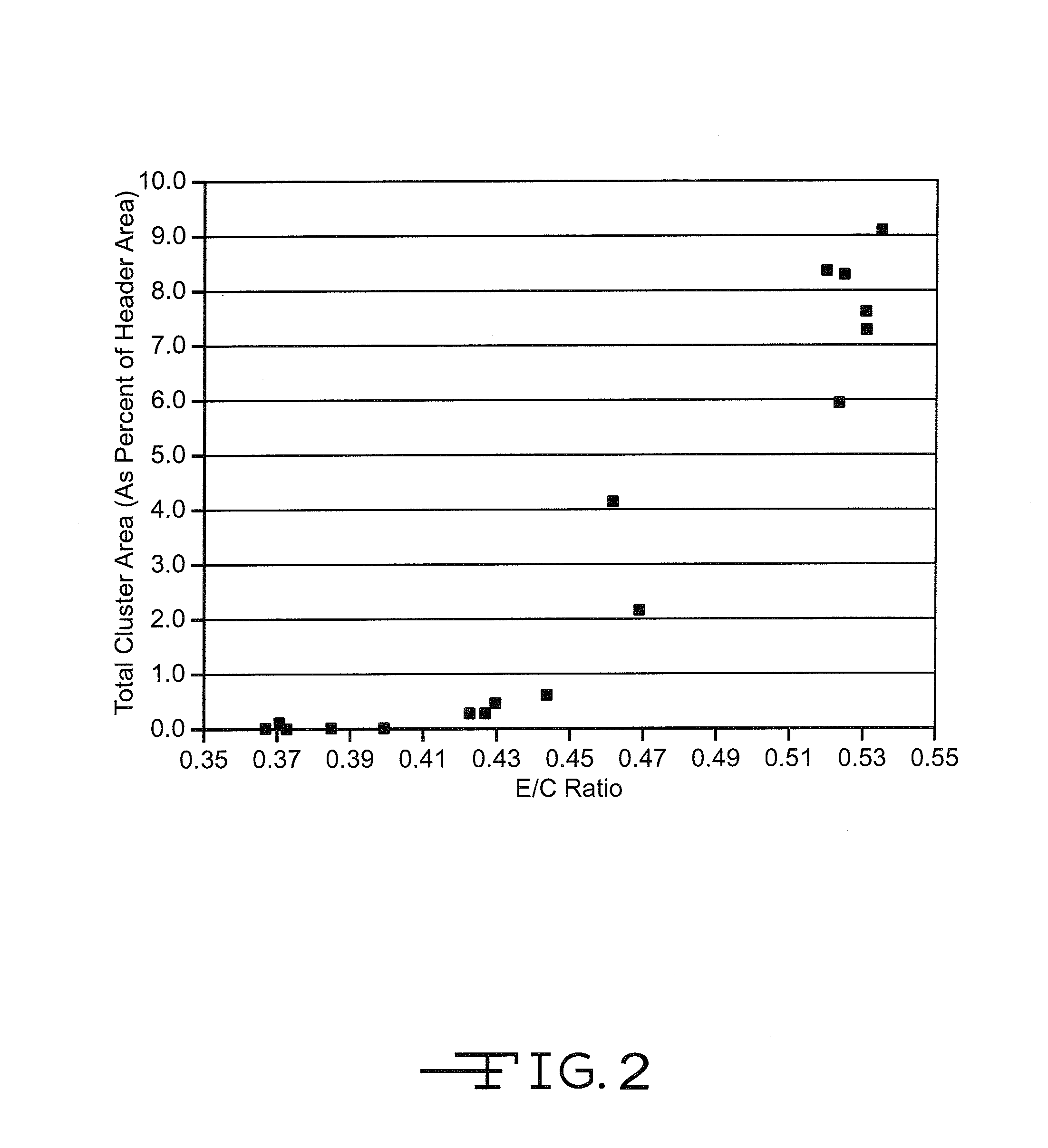

Prevention of lithium deposition in nonaqueous electrolyte cells by electrolyte-to-cathode weight ratio

InactiveUS7432001B1Avoid problemsLimited amountSilver accumulatorsOrganic electrolyte cellsLithiumHigh rate

The prevention of lithium clusters from bridging between the negative and positive portions of a cell during discharge is described. This is done by limiting the amount of electrolyte in the cell, thereby eliminating excess electrolyte pooling above the cell stack. It is in this excess electrolyte that a relatively higher Li+ ion concentration can occur, creating an anodically polarized region resulting in the reduction of lithium ions on the negative and positive surfaces as the concentration gradient is relaxed. Typically, a lithium ion concentration gradient sufficient to cause lithium cluster formation is induced by the high rate, intermittent discharge of a lithium / silver vanadium oxide (Li / SVO) cell.

Owner:WILSON GREATBATCH LTD

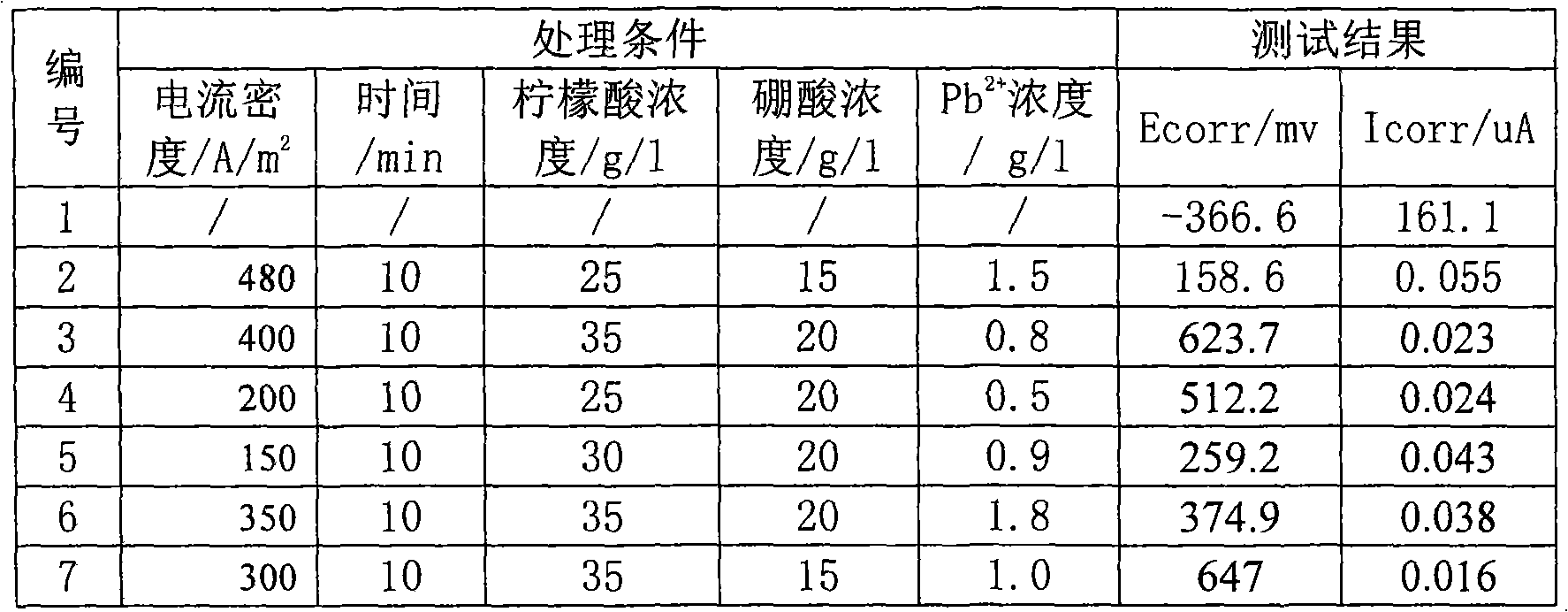

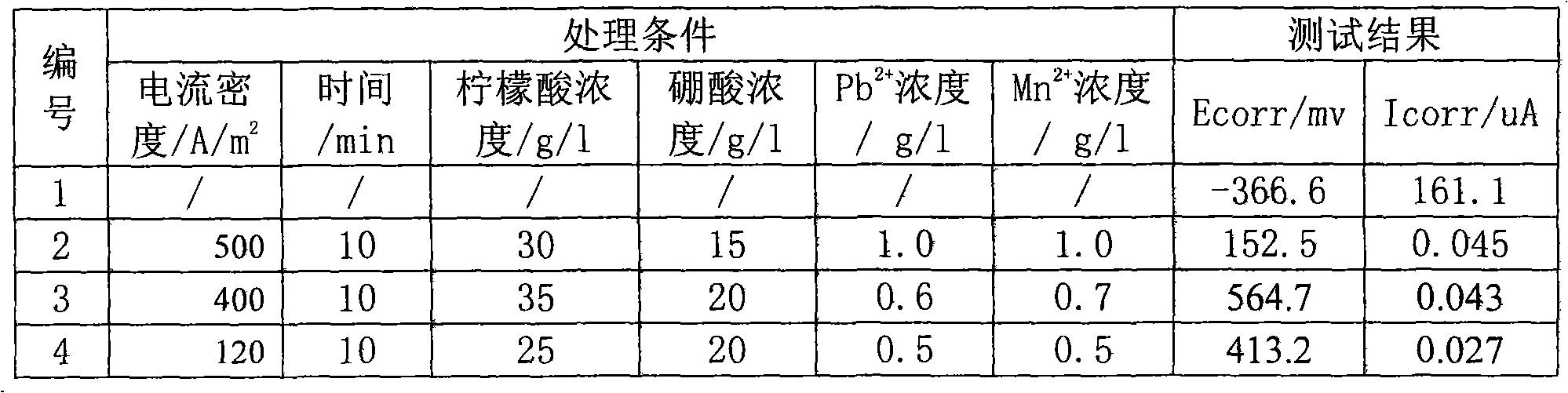

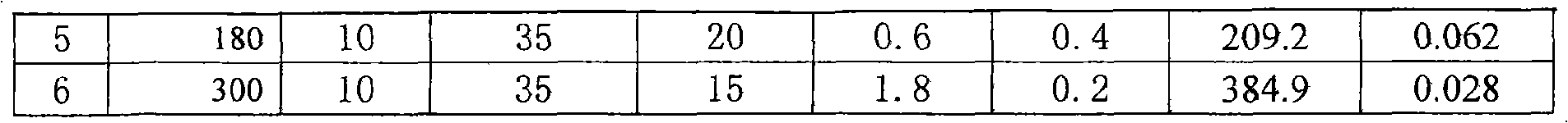

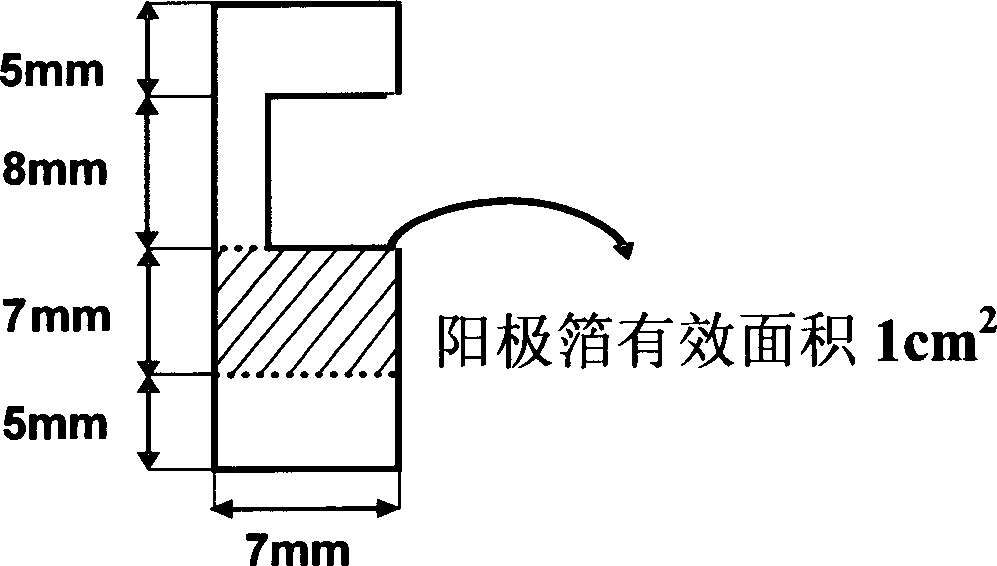

Surface modification process for stainless steel

InactiveCN101289758AImprove corrosion resistanceEasy to operateAnodisationAnode polarizationPhysical property

The method for modifying the surface of rustless steel belongs to the metal surface processing technique. The method comprises the steps of: pre-processing a rustless steel product through a normal method and then taking the rustless steel product as an anode to carry out anode polarization treatment, wherein the treatment process is to process the surface of the rustless steel by adding citrate and nitrate additive into electrolyte solution of citric acid and boric acid and controlling the current concentration and the polarization time. The corrosion resistance of the rustless steel product processed through the method is greatly improved while the self physical properties such as the surface color, the lustrousness, the strength, the electricity conductivity, the heat conductivity and the like are not changed. The method has simple technique and equipment and convenient operation, and is easy to industrialize.

Owner:KINGRAY NEW MATERIALS SCI & TECH

Preparation method of dielectric film of aluminum electrolytic capacitor

InactiveCN1805088AExtended temperature rangeImprove securityAnodisationElectrolytic capacitorsDielectricPre treatment

The invention relates to a method for preparing the dielectric film of aluminum electrolytic capacitor. First, processing pretreatment on the anode foil; processing anode polarization inside the ion liquid to attain the dielectric film. The invention has better corrosive resistance, and its voltage resistance can reach 90V. The invention is easy and clear, and the aluminum electrolytic capacitor made from said invention has high safety and the voltage resistance more than 40V.

Owner:SHANGHAI JIAO TONG UNIV

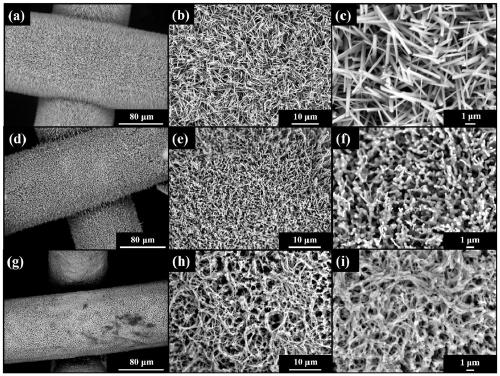

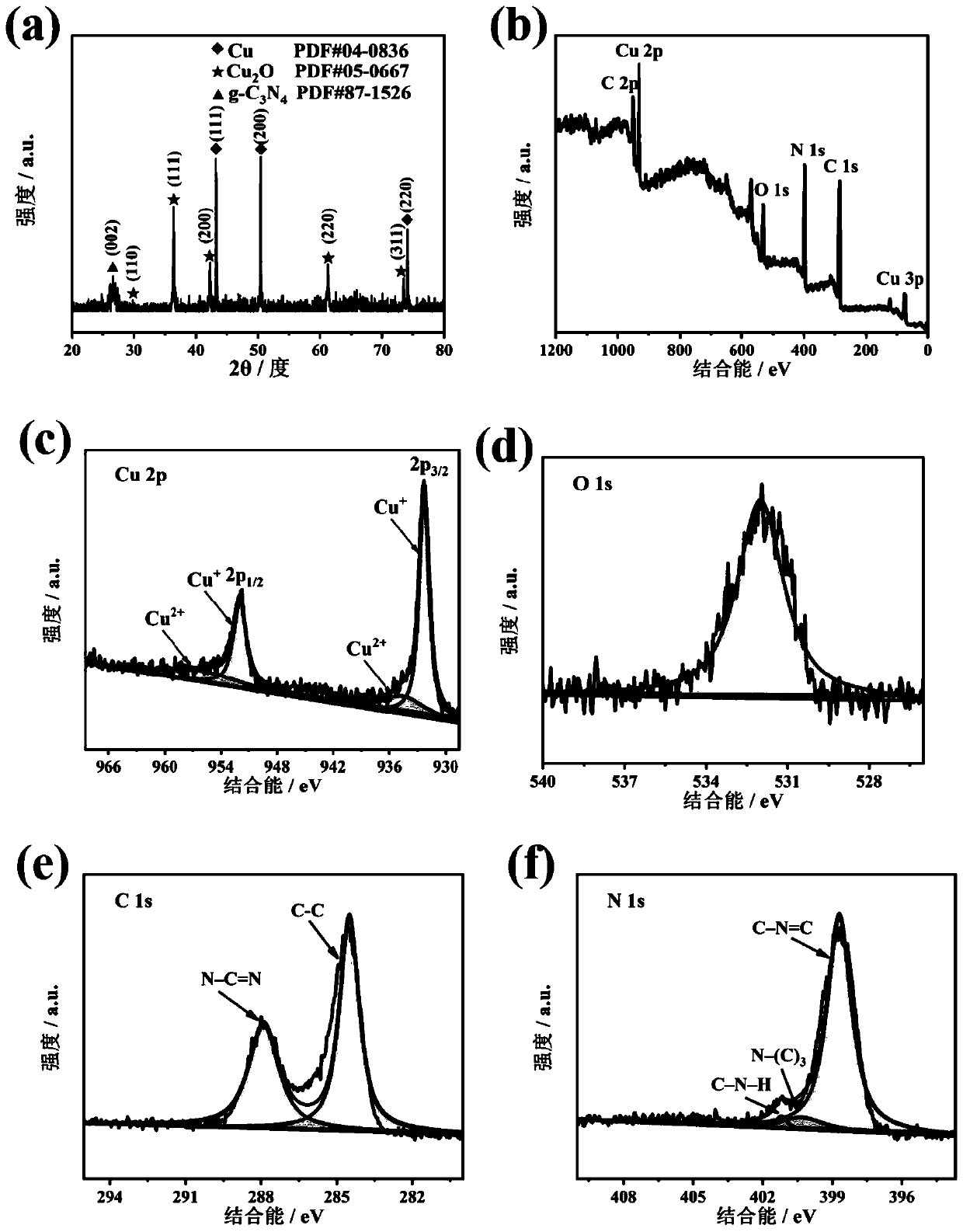

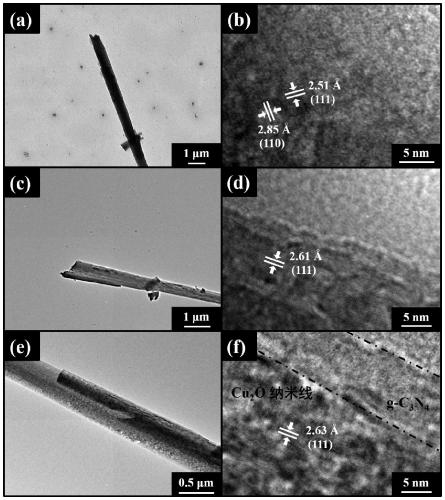

Cuprous oxide nanowire array composite carbon nitride loaded copper mesh composite material and preparation method and application thereof

InactiveCN111266127AShort synthesis timeEasy to solveCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsYarnTube furnace

The invention discloses a cuprous oxide nanowire array composite carbon nitride loaded copper mesh composite material and a preparation method and application thereof. The preparation method comprisesthe following steps: (1) carrying out anodic polarization on clean copper yarns in a sodium hydroxide solution by adopting constant current to prepare a Cu (OH) 2 nanowire array / copper mesh; (2) carrying out high-temperature annealing treatment on the Cu (OH) 2 nanowire array / copper net under the protection of an inert atmosphere to prepare a Cu2O nanowire array / copper net; (3) uniformly spreading graphite-like phase carbon nitride precursor powder on the surface of the Cu2O nanowire array / copper net, putting the Cu2O nanowire array / copper net into a tubular furnace, introducing nitrogen, heating to 480-520 DEG C, and keeping the temperature for 3-5 hours; and after cooling, taking out the sample, and carrying out ultrasonic treatment in water to obtain the target product. The operation process is simple, the material synthesis time is obviously shortened, and the feasibility is high. In addition, the composite material is applied to photocatalytic preparation of methanol, the cost islow, and the yield of the prepared methanol is high.

Owner:广东鼎诚电子科技有限公司

Electrolyte for aluminum-air battery and aluminum-air battery

InactiveCN110165339AImprove performanceReduce corrosion efficiencyFuel and primary cellsHybrid cell detailsDissolutionAnode polarization

The invention discloses an electrolyte for an aluminum-air battery and the aluminum-air battery, and the battery comprises an aluminum alloy negative electrode, an air positive electrode and the electrolyte. The aluminum alloy negative electrode contains the following raw materials in percentage by weight: 2.0-8.0% of Al, 0.02-0.08% of Pb, 0.05-0.1% of In, 0.01-0.1% of Ga, and 0.1-2.0% of Mg. According to the electrolyte for the aluminum-air battery and the aluminum-air battery, an electrolyte corrosion inhibitor is added into the electrolyte to promote precipitation of aluminum hydroxide, thereby avoiding the anode passivation caused by a condition that aluminum hydroxide is not discharged in time, and guaranteeing the normal work of the battery. The aluminum alloy negative electrode contains Al, Pb, In, Ga and Mg, so the open-circuit potential is obviously reduced, the self-corrosion is reduced, the electrode surface corrosion and dissolution are uniform, a passive film is not likelyto be formed in an alkaline medium, and anode polarization is reduced. Manganese dioxide is adopted in an air positive electrode to serve as a catalyst, so the price is low, and the good applicationprospect is achieved.

Owner:TONGREN UNIV

Surface roughening method of metal material

The invention relates to a surface roughening method of a metal material. According to the method, the metal material is subjected to anodic polarization in an electrolyte; the surface roughness of the metal material is increased by the anodic dissolution effect; the electrolyte is a water-based solution of sodium chloride of 0.02 to 100 g / L; and the anodic polarization mode is to externally add current or couple a cathodic dissimilar metal material. The method has the biggest advantages of environmental friendliness, high efficiency, energy conservation and low cost.

Owner:SOUTH CHINA UNIV OF TECH

External corrosion proof technology of oil field oil water well annular tube

The invention relates to an oil field oil water well casing outer corrosion protection technique applied in epoxy cold taping and zinc anode. Its feature is adopting combining technique of using anticorrosion coating and epoxy cold taping to isolate casing outer corrosive medium and affording protecting current for the casing by sacrificed anode polarization. The anticorrosion coating includes epoxy coal pitch and epoxy cold taping. The sacrificed anode is zinc alloy. Each component weight percentages are that Fe 0.0023%, Cu 0.005%, Pb 0.0044%, Si less than 0.01%, Al 0.55%, Cd 0.072%, rest Zn. The standard is 168*142*500. The distributions are that each 100m is one group; each group has five branches, which is set on the casing by locking device. The technique is applied in oil field underground casing corrosion damage, solves the problem that impressed current cathode protection needs power supply.

Owner:PETROCHINA CO LTD

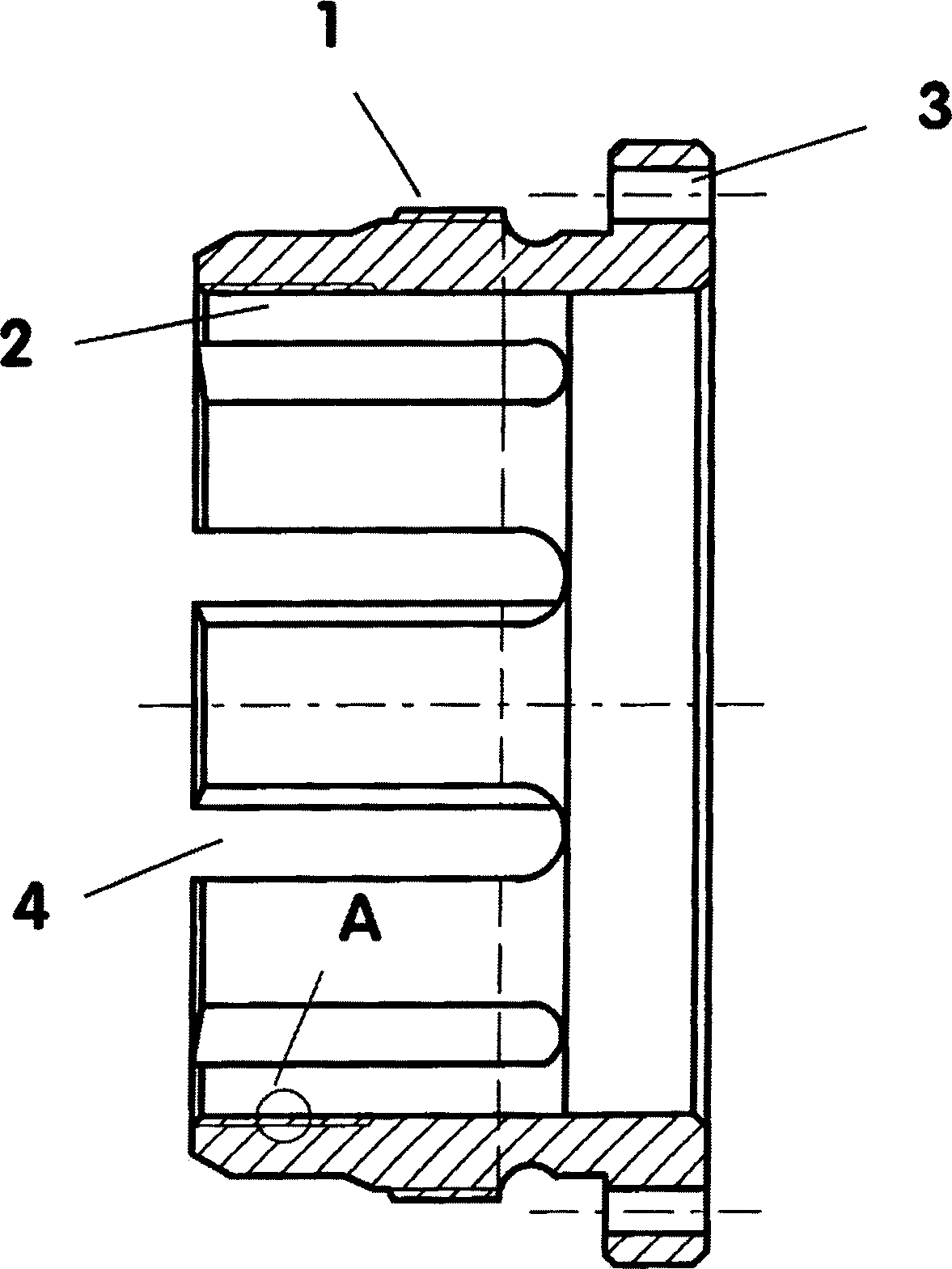

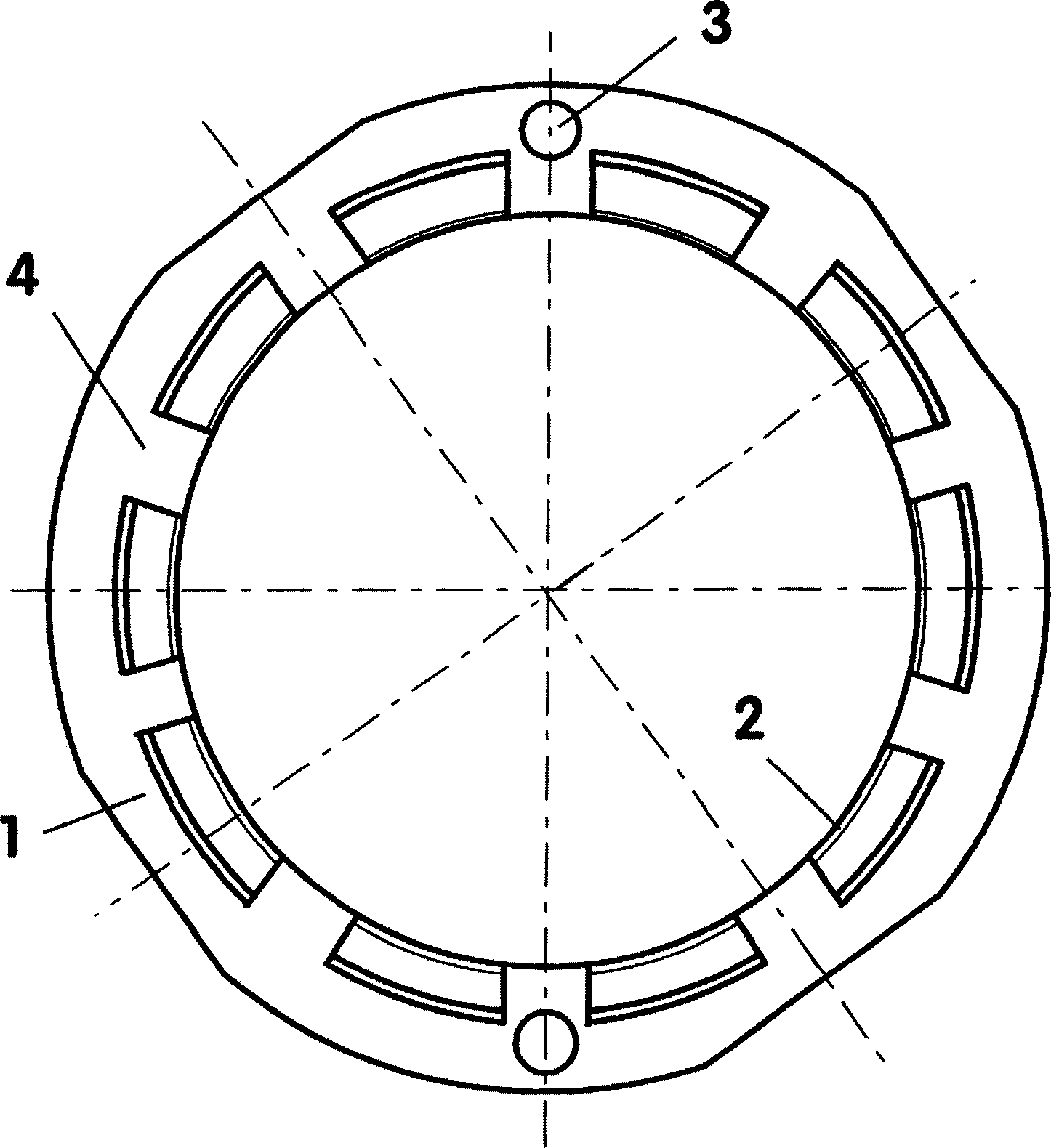

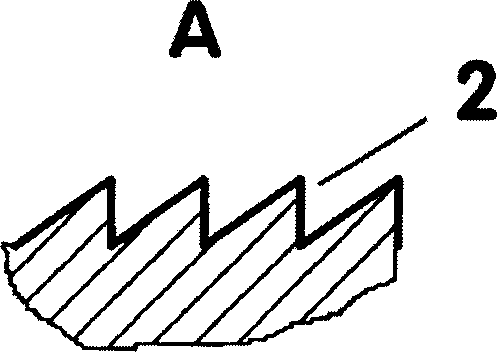

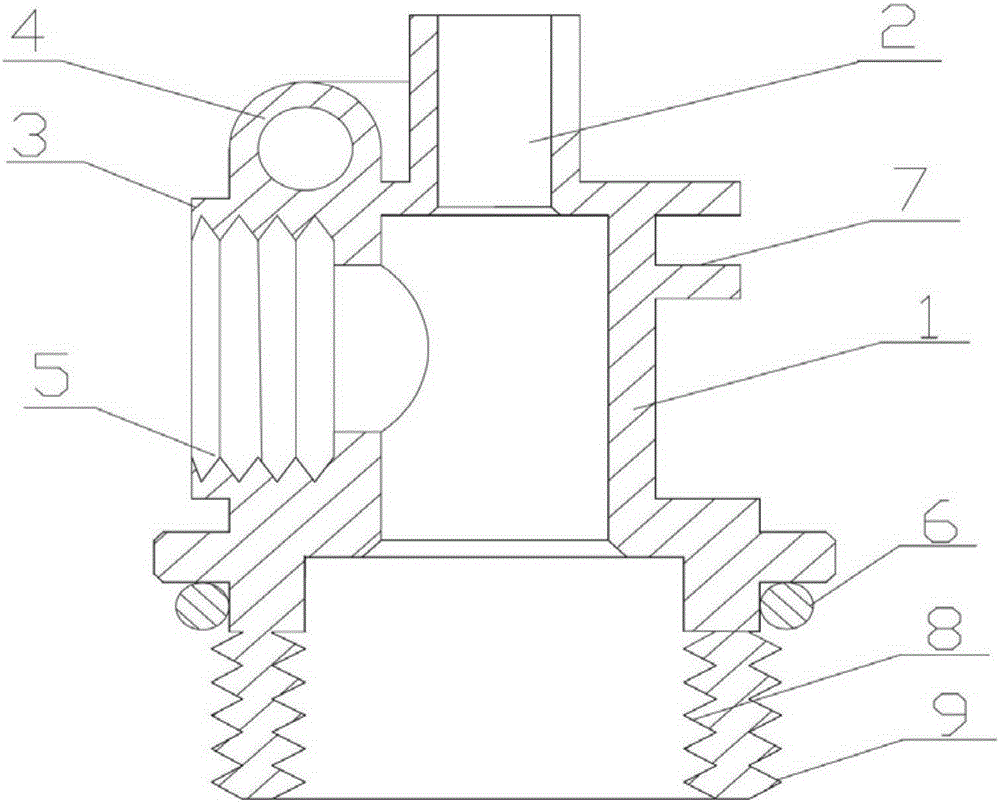

Anode polarization and coloration treatment method of aluminum alloy extinguisher valve body

ActiveCN105177668AAvoid corrosionExtended service lifeSurface reaction electrolytic coatingChemical compositionFire extinguisher

The invention discloses an anode polarization and coloration treatment method of an aluminum alloy extinguisher valve body. The aluminum alloy extinguisher valve body is composed of a valve body, a press-type valve core hole, a nozzle, a grip fixing hole, a nozzle internal thread, a seal ring, a grip fixing bracket, an internal thread and an external thread. The valve body is made of a 6061 aluminum alloy. The 6061 aluminum alloy comprises the following chemical components: 0.8-1.2% of Mg, 0.4-0.8% of Si, 0.15-0.4% of Cu, 0.7% of Fe, 0.15% of Mn, 0.25% of Zn, 0.04-0.35% of Cr, 0.15% of Ti and the balance of aluminum. Compared with the copper valve body, the aluminum alloy extinguisher valve body has lower cost; the surface-polarized oxidation film can well avoid the corrosion of the extinguishing agent, thereby greatly prolonging the service life of the extinguisher; and the aluminum alloy extinguisher valve body has the advantages of simple production technique, light weight, long storage life and high reliability. Compared with the conventional aluminum alloy press forging, the aluminum alloy multiple-ram forging adopted by the invention reduces the production steps, and is capable of greatly enhancing the material utilization ratio, reducing the equipment investment, lowering the energy consumption and greatly enhancing the production efficiency.

Owner:MAANSHAN TIANRUI IND

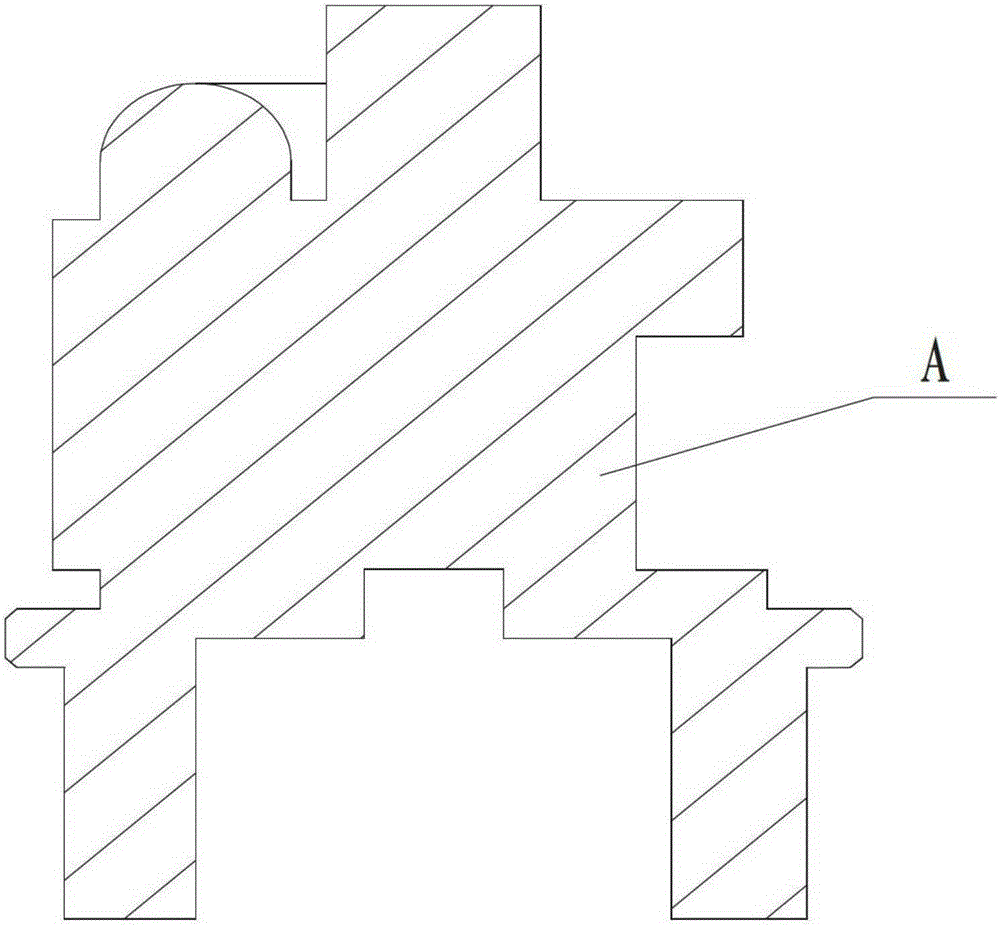

Double-face light ultrathin electrolytic copper foil for lithium battery and preparing method of double-face light ultrathin electrolytic copper foil

ActiveCN109082688AUniform thicknessReduce warpageElectrode carriers/collectorsElectroforming processesElectrolysisCopper foil

The invention belongs to the technical field of electrolytic copper foil production, and particularly relates to double-face light ultrathin electrolytic copper foil for a lithium battery and a preparing method of the double-face light ultrathin electrolytic copper foil. The method comprises the following steps that a titanium anode coated with a platinum family metal element or oxide of the platinum family metal element and a titanium cathode barrel are provided; the titanium anode and the titanium cathode barrel are immersed in a pretreatment composition containing gelatin and one or more organic sulfide sulfonate; anode polarization and cathode polarization are used for activating the surface of a titanium cathode; and a copper electrolyte is utilized for preparing the electrolytic copper foil on the activated surface of the titanium cathode. According to the method, the more uniform and cleaner titanium anode and the more uniform and cleaner titanium cathode are provided, the pretreatment composition wraps the surface of a base body before electrolytic copper foil production, and it is ensured that high surface additive concentration is achieved at the early stage of electrolysis.

Owner:ZHEJIANG YONGTAI TECH CO LTD +1

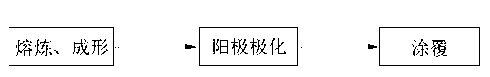

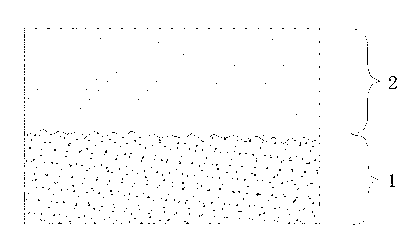

Biological medical controllable all-degradable material and preparation method thereof

The invention discloses a biological medical controllable all-degradable material and a preparation method thereof. The preparation method of the material comprises the following steps: 1) smelting and forming; 2) anodic polarization; and 3) coating. The material disclosed by the invention comprises a pure magnesium or magnesium alloy base and a functional film covered on the base surface with degradation protection and self-degradation characteristics; and the integral material has the characteristic of controllable all-degradable absorption, and satisfies the serious requirements for ideal characteristics of degradable biological materials. The invention provides a preferred scheme for solving the contradiction between biodegradable characteristic utilization and degradation rate control of the absorbable biological material, especially medical magnesium alloy; and the related material and technique are not only suitable for common medical appliance products, but also have competitive edges in manufacturing of high-end medical appliance products, such as implantation instruments, especially secondary-operation-free implantation substances.

Owner:SOUTH CHINA UNIV OF TECH

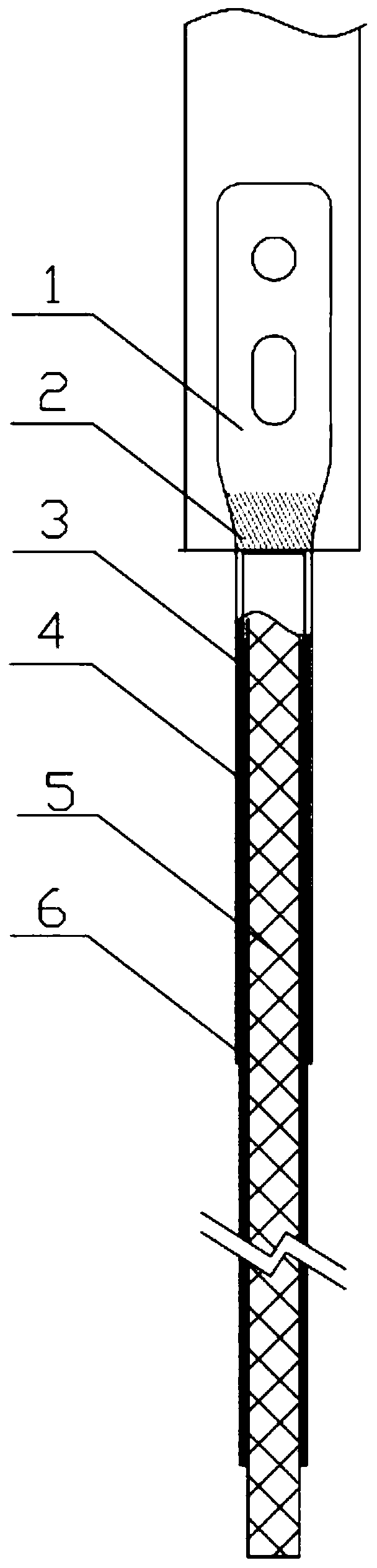

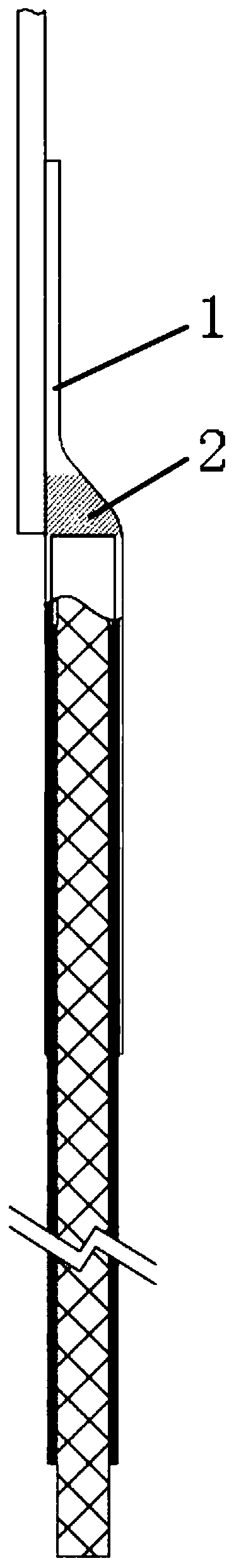

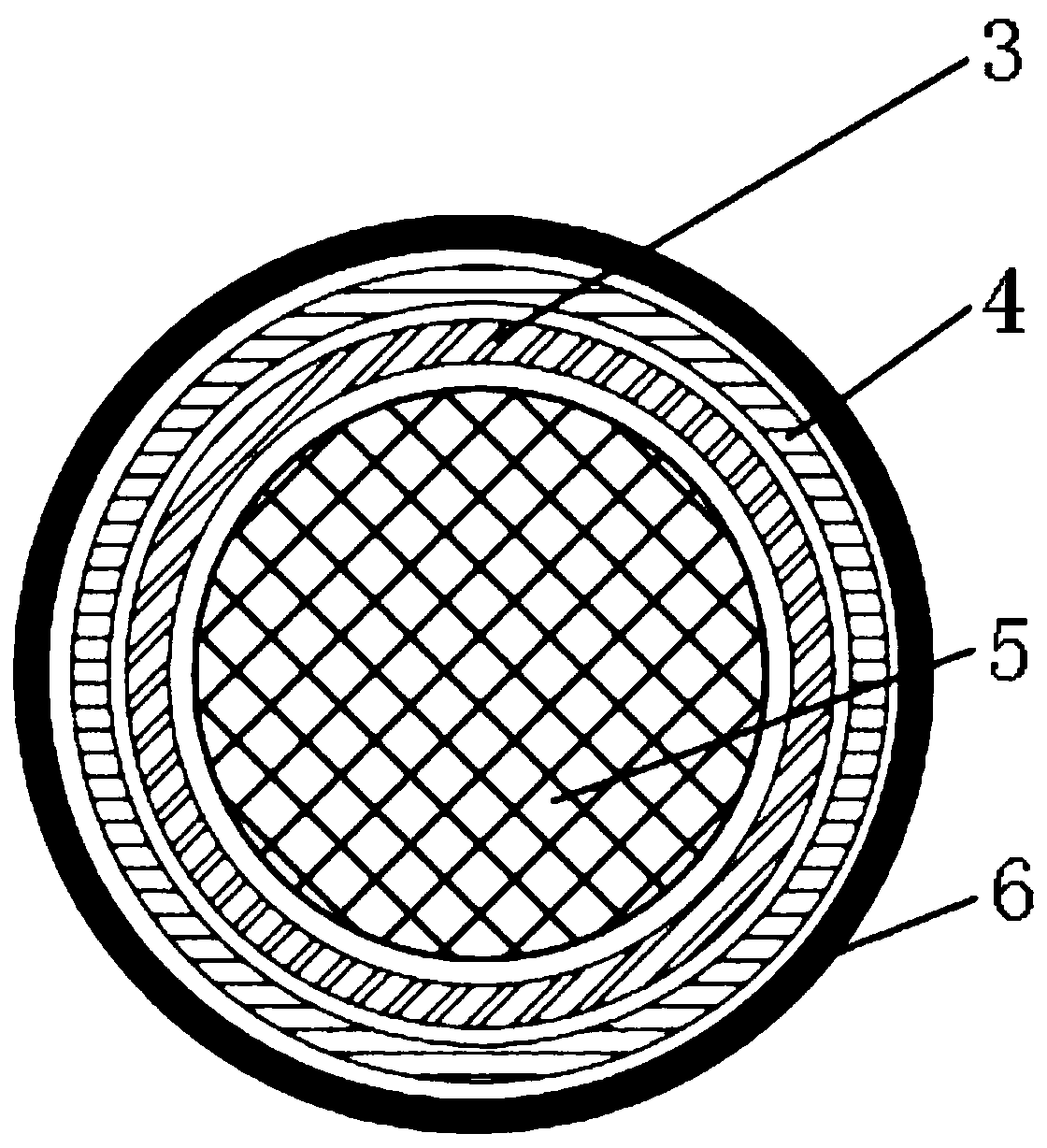

Corrosion-resistant flexible graphite down lead and preparation method thereof

PendingCN110581379APrevent or delay entryInto isolationContact member manufacturingConnection contact member materialAtmospheric airElectrical connection

The invention relates to a corrosion-resistant flexible graphite down lead and a preparation method thereof. A corrosive medium in the atmosphere can be effectively prevented or delayed from enteringa metal-graphite interface by a stainless steel connecting piece with a semi-sealed structure, a heat-shrinkable insulating sleeve completely wraps the part, except the connecting end, of the flexiblegraphite body, entering of the corrosive medium in the atmosphere and soil can be effectively isolated, local corrosion can be blocked due to lack of the corrosive medium, and long-term effective electrical connection is guaranteed. The flexible graphite body contains a water-soluble corrosion inhibitor, so that even if water and the corrosive medium enter when the sealed structure has defects, the added corrosion inhibitor can passivate the surface of the metal and form a film on the surface to prevent cations on the surface of the metal from diffusing into the corrosive medium, or characteristic adsorption in the anode area, the anode surface area is reduced, and the anode inhibition type corrosion inhibitor increases anode polarization, so that the self corrosion potential of the metalelectrode moves to a positive direction, the corrosion current density is reduced, corrosion is slowed down, and effective electrical connection is ensured.

Owner:成都英华科技有限公司

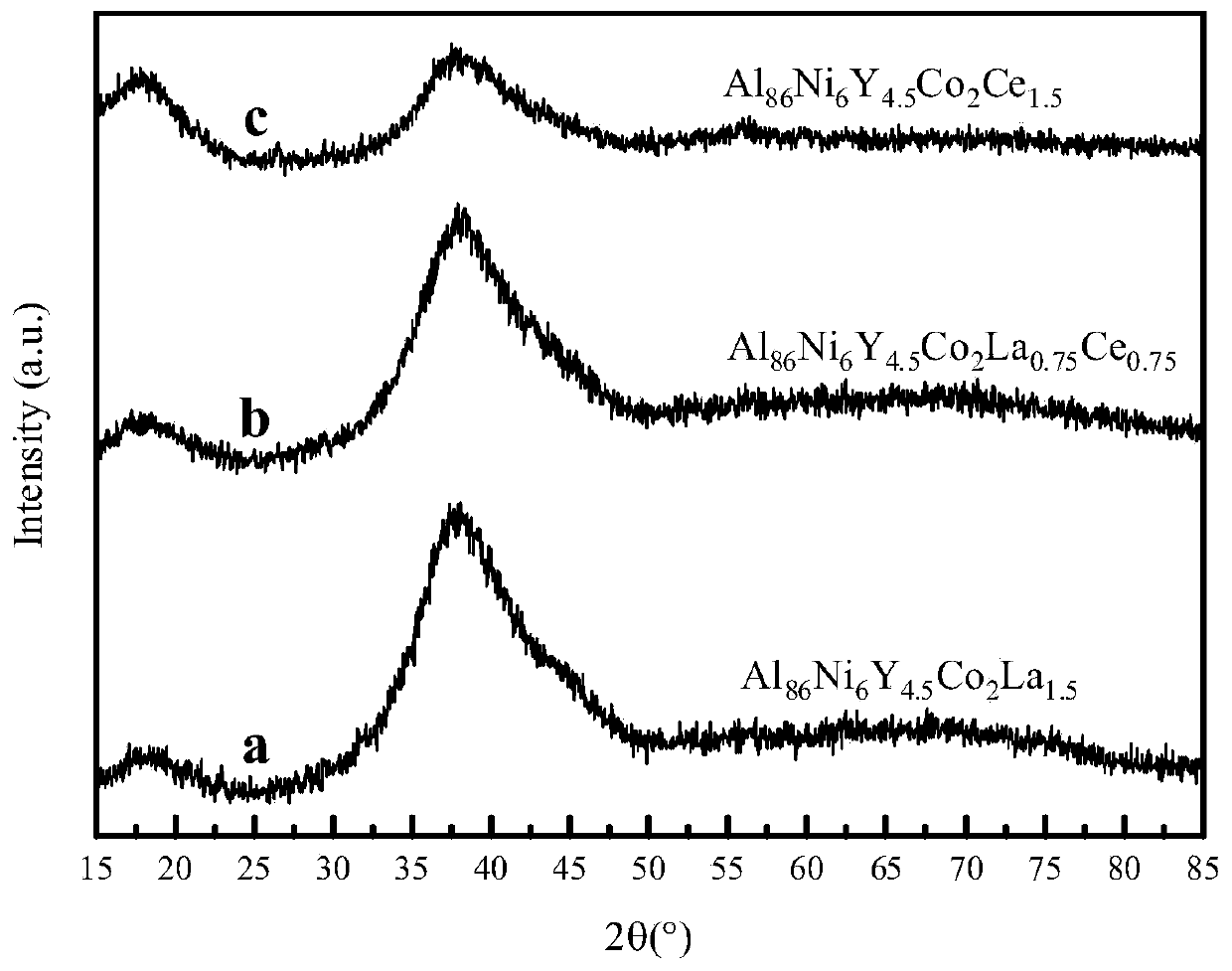

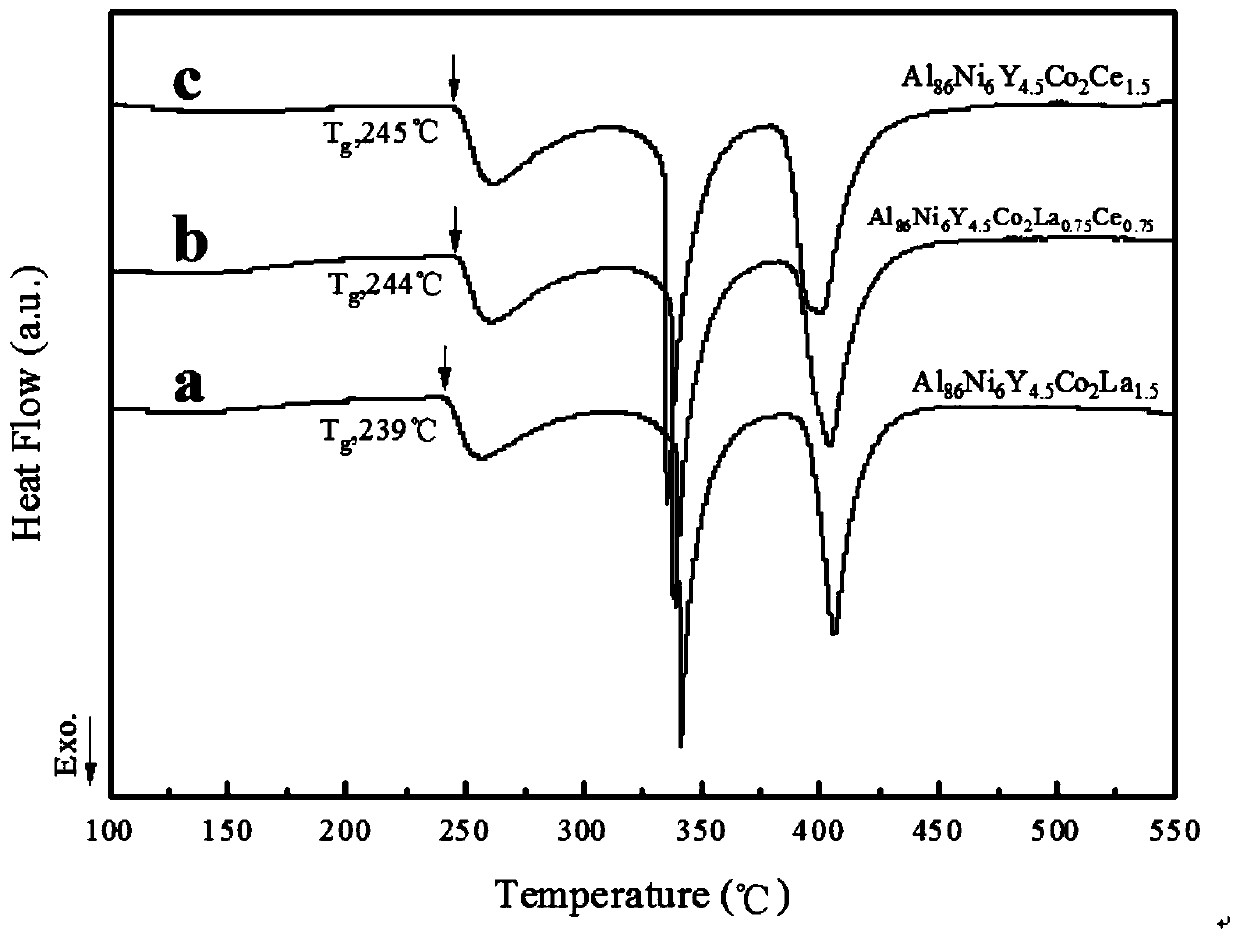

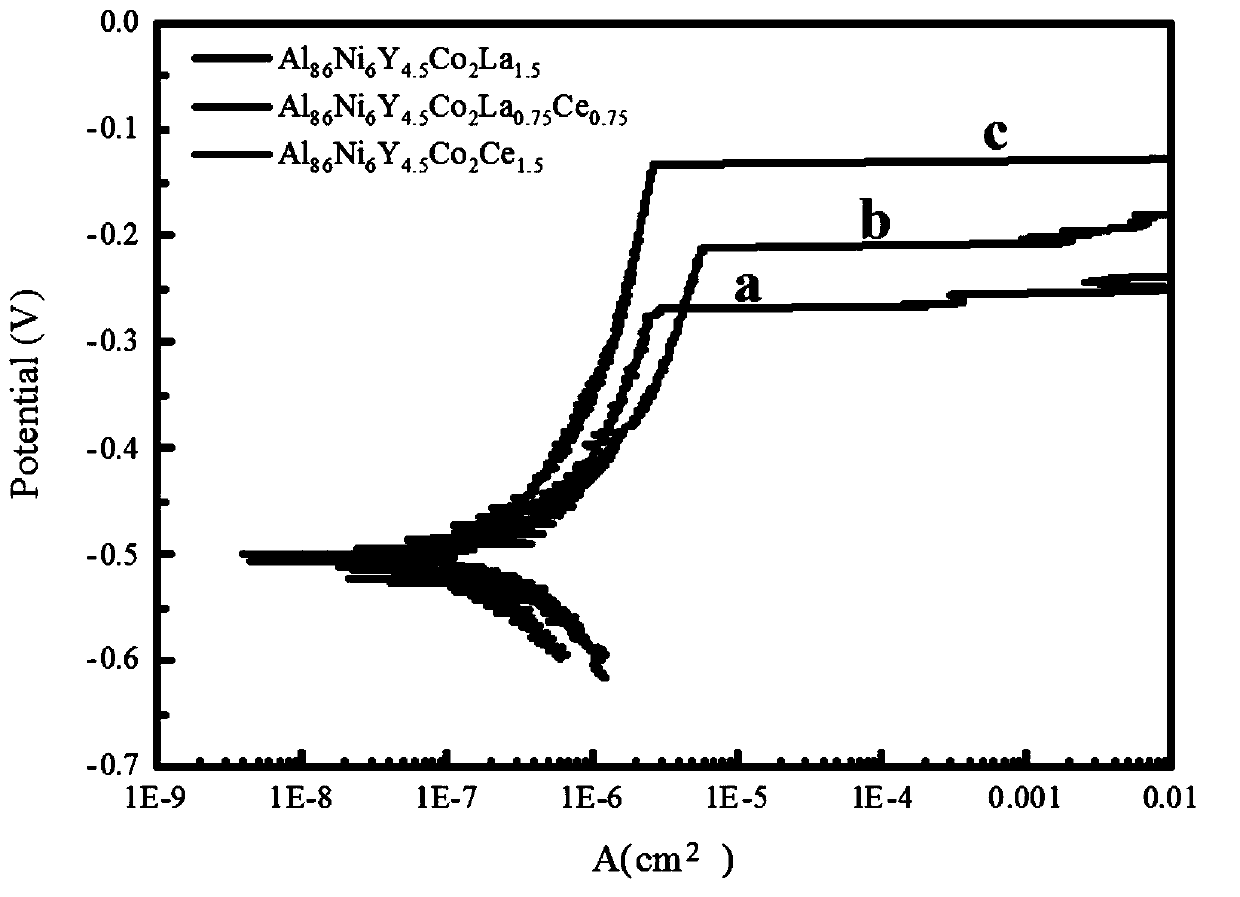

High-corrosion-resistance Al-TM-RE amorphous aluminum alloy

InactiveCN110938786AHigh glass forming abilityImprove corrosion resistanceCu elementAnode polarization

The invention discloses a high-corrosion-resistance Al-TM-RE amorphous aluminum alloy, and belongs to the technical field of amorphous alloy materials. The designed Al-TM-RE amorphous aluminum alloy comprises chemical components including, by mole percent, 85-87% of Al, 5.5-6.5% of Ni, 1.5-2.5% of Co, 4.0-5.0% of Y and 0.5-1.5% of RE, wherein RE is Ce or a combination of La and Ce. The Al-TM-RE amorphous aluminum alloy is high in amorphous forming ability, and also has high corrosion resistance. Compared with a traditional Al-TM-RE pentabasic aluminum-based amorphous alloy system, the pittingpotential is increased by 60-140 mVSCE in a 3.5wt.% NaCl solution environment, a passivation film formed by anode polarization is thicker, and the corrosion resistance is better.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

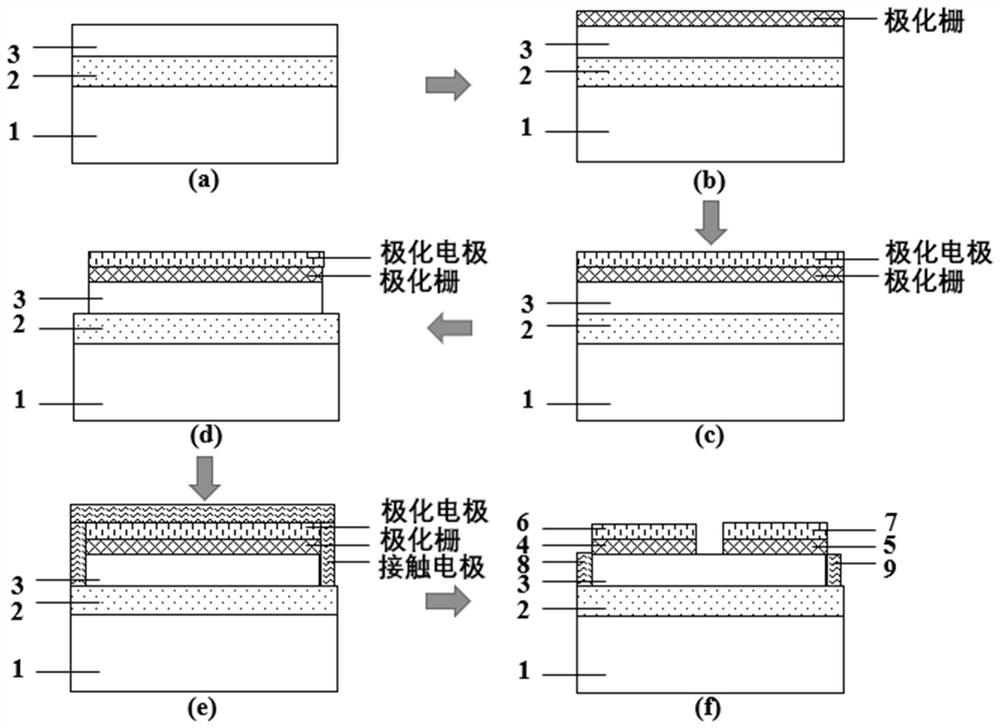

PN junction memory device based on ferroelectric doping

ActiveCN113140675AImplement storage state switchingAvoid damageElectrical apparatusElectrical polarityPulse voltage

The invention discloses a PN junction memory device based on ferroelectric doping, and mainly aims to solve the problem that the existing PN junction memory device cannot realize switching of different conduction types. The device comprises a substrate (1), an insulating oxide layer (2) and a channel layer (3) from bottom to top, an anode (8) and a cathode (9) are arranged on two sides of the channel layer, an anode polarization grid (4) is arranged on the left of the upper portion of the channel layer, and a cathode polarization grid (5) is arranged on the right of the channel layer; an anode polarization electrode (6) and a cathode polarization electrode (7) are arranged on the upper portion of the anode polarization grid and the upper portion of the cathode polarization grid respectively, pulse voltages with different polarities are applied to the two polarization electrodes (6 and 7), and switching of PN junctions between different storage states is achieved by changing the application sequence of positive and negative pulses. According to the invention, the storage function of the PN junction memory device is expanded, the damage to the channel in the technological process is reduced, the power consumption is reduced, the on-state current and durability of the device are improved, and the method can be used for manufacturing a nonvolatile memory.

Owner:XIDIAN UNIV

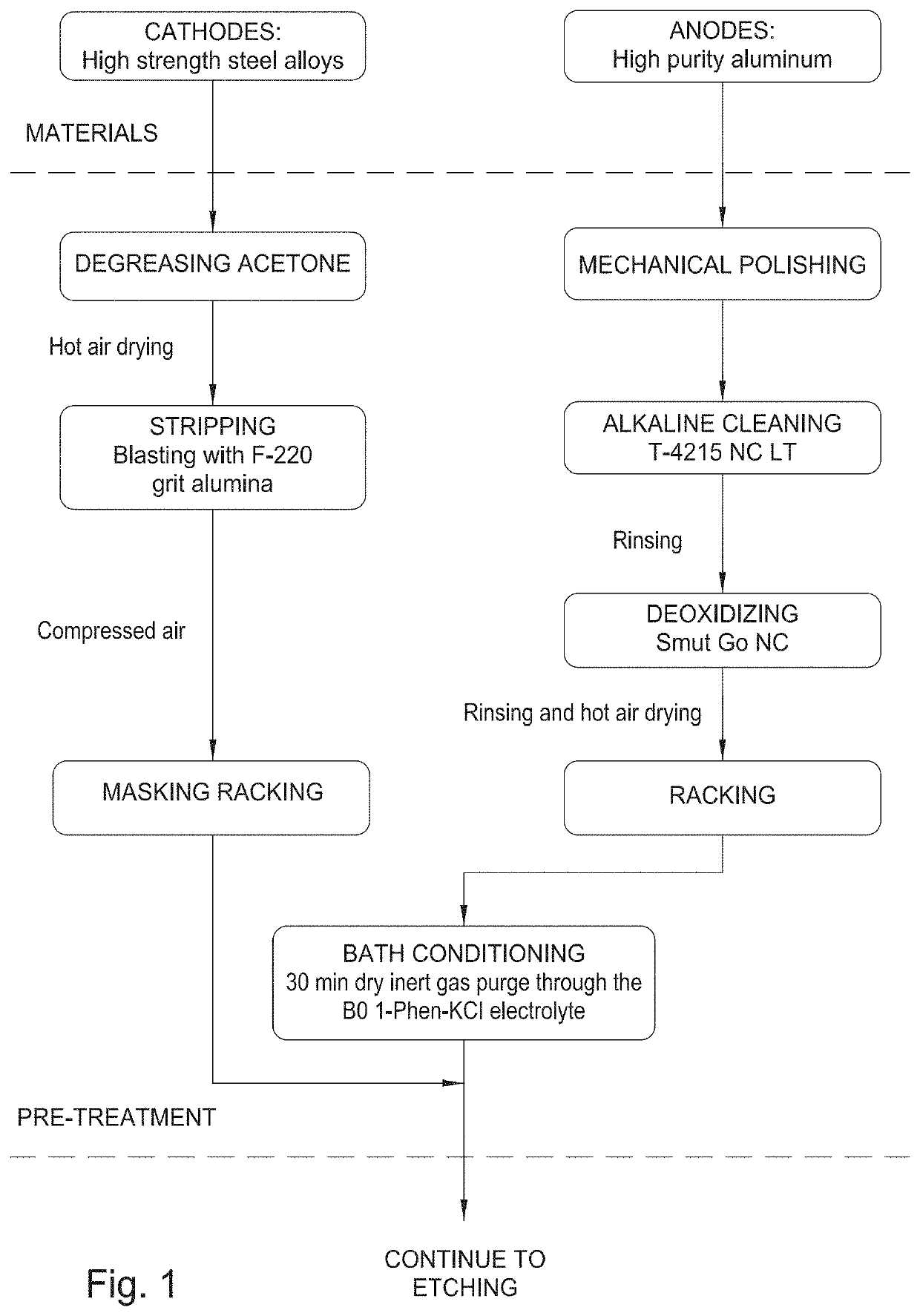

Environmentally friendly aluminum coatings as sacrificial coatings for high strength steel alloys

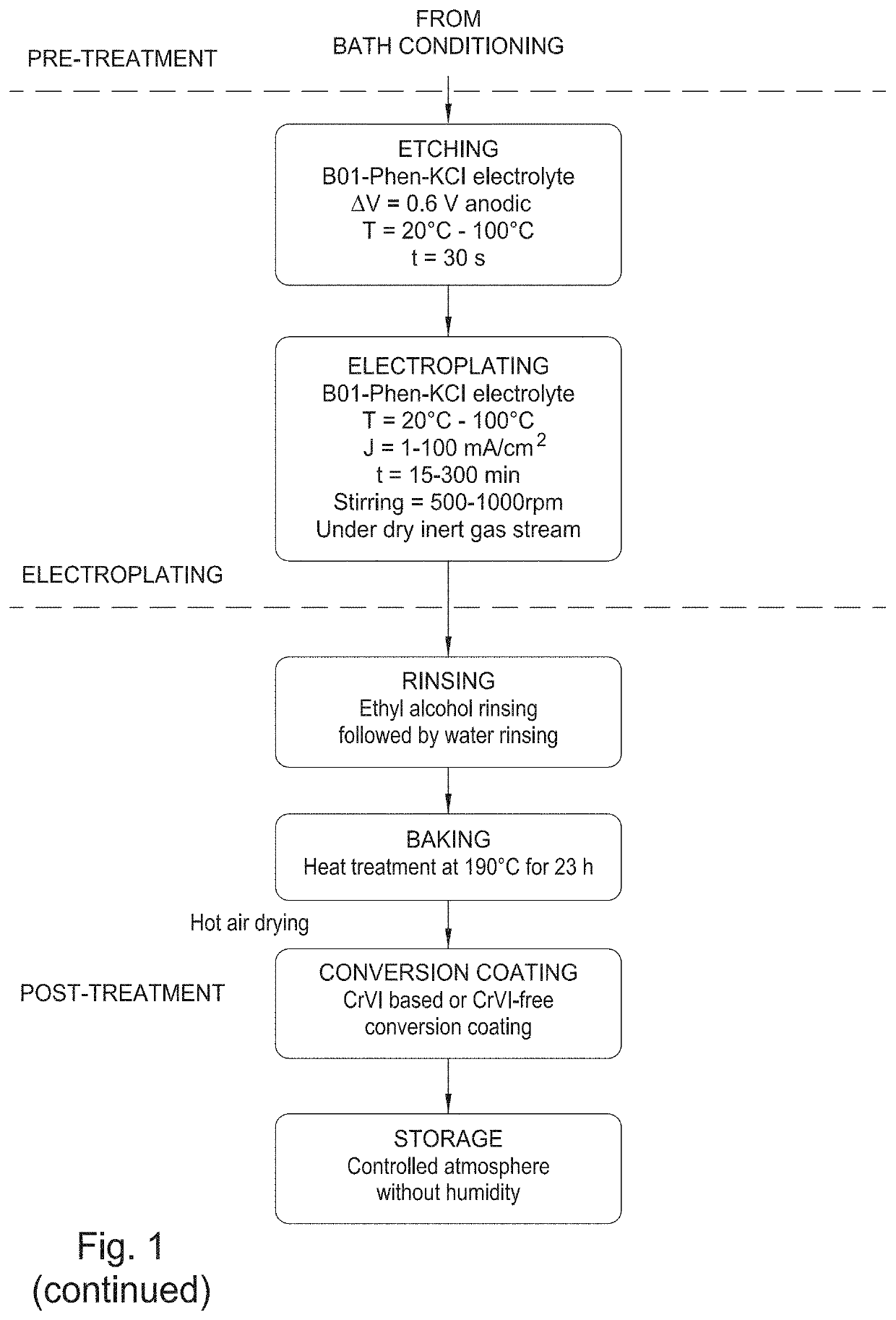

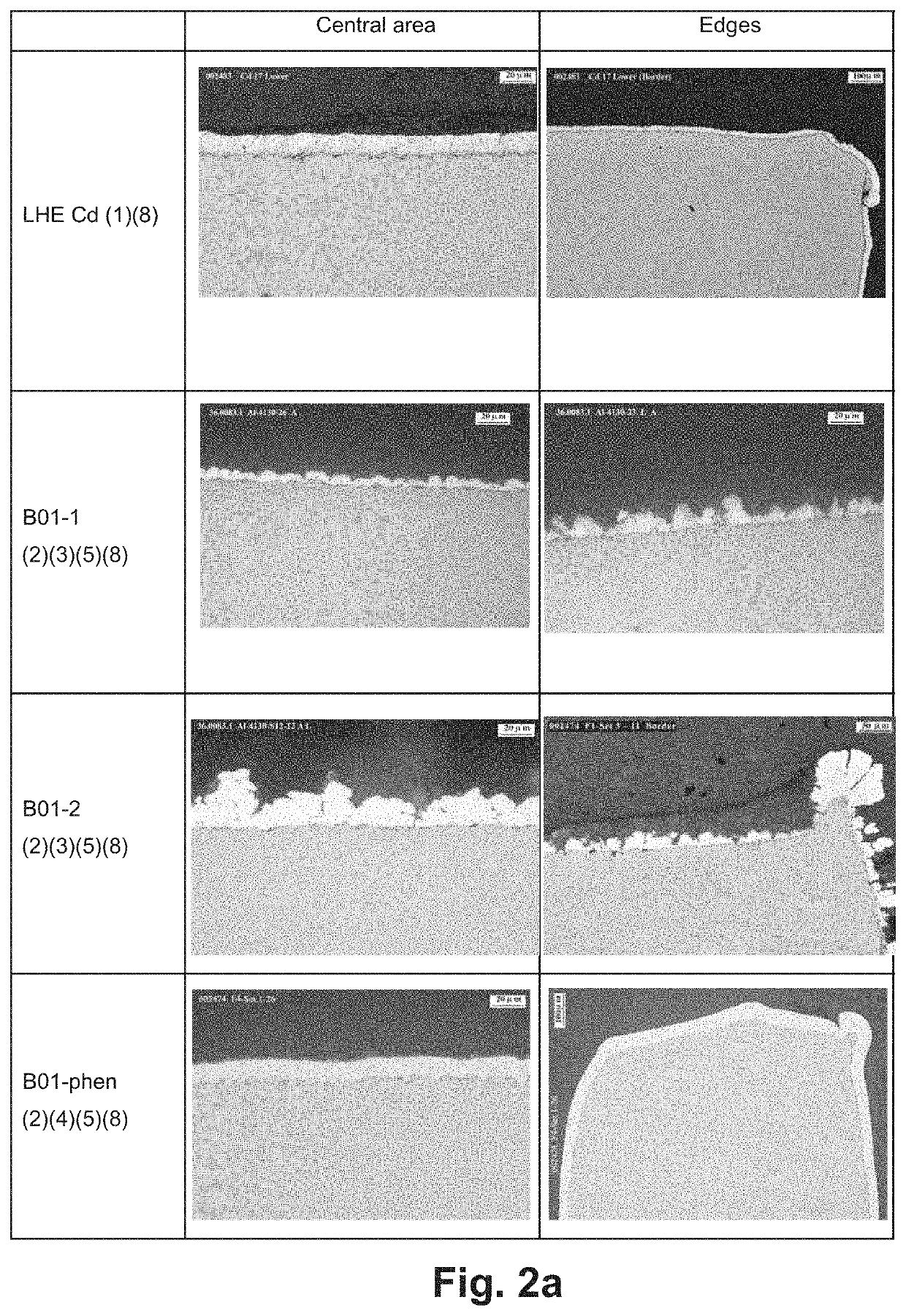

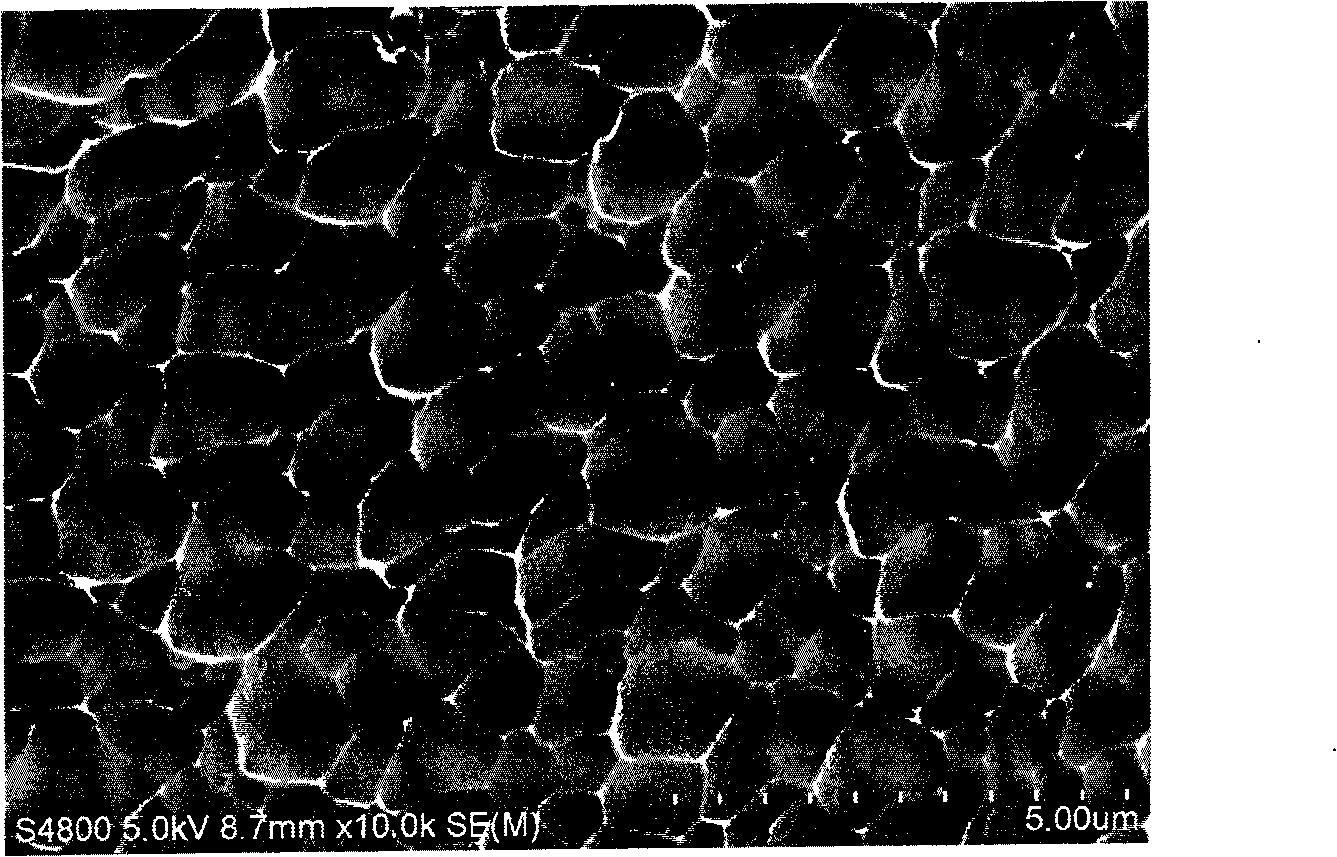

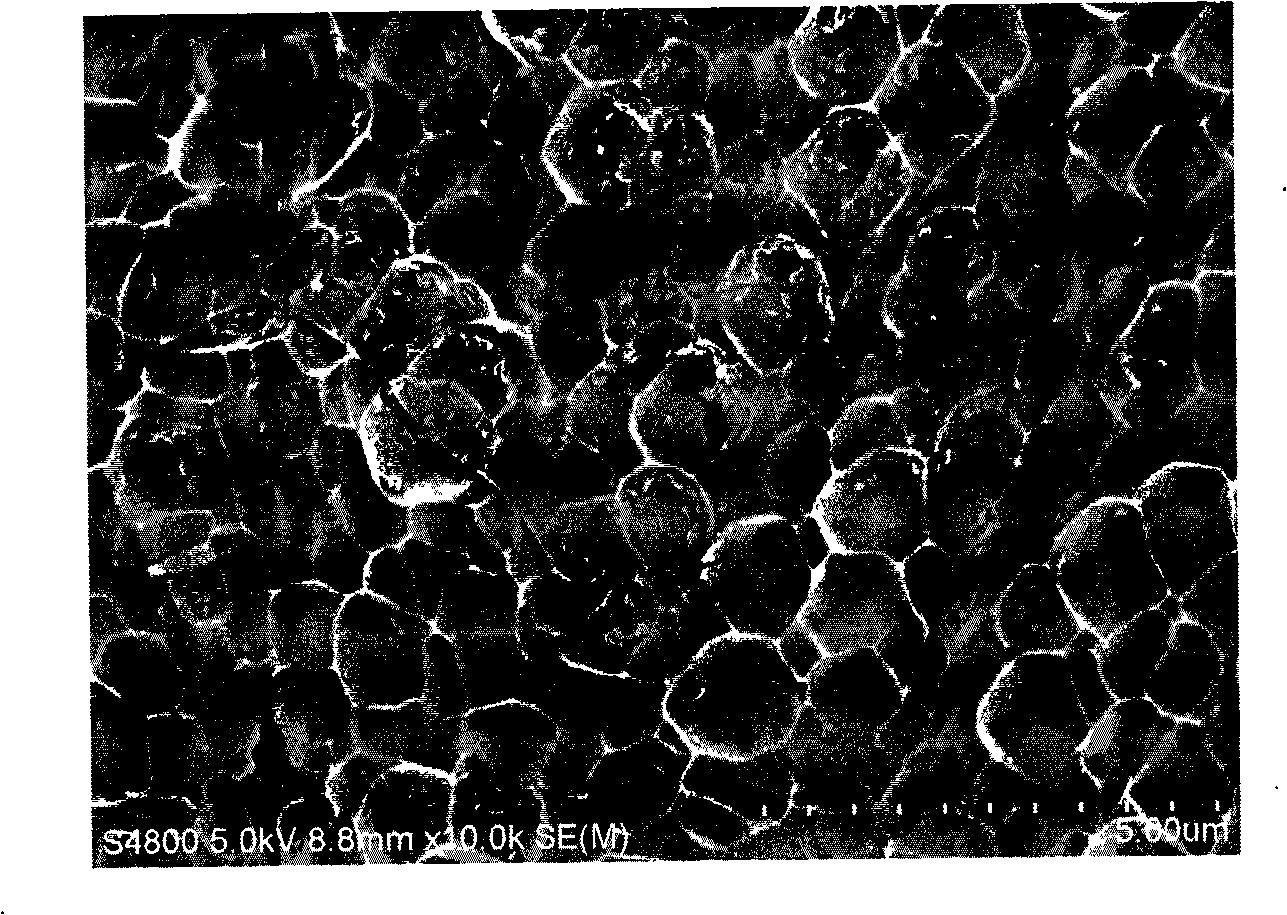

Electroplating process is described for coating a ferrous alloy steel cathode substrate with an aluminum coating, the process comprises: a) immersing an aluminum anode substrate in a plating bath formulation comprising: a source of aluminum, an ionic liquid, a brightening agent, and a metal-salt compound; b) etching the cathode substrate by immersing it into the aluminum plating bath and conducting an anodic polarization step; c) electroplating the etched cathode substrate with the aluminum plating bath formulation; and d) rinsing with alcohol and water, and drying. Preferably, the process further comprises a heat treatment applied to the aluminum coated ferrous steel alloy obtained in step d).

Owner:THE BOEING CO

Preparation method of gene coatings of medical device

ActiveCN101491468APrevent restenosisPrevent vascular diseaseStentsBlood vesselsSide effectPercent Diameter Stenosis

The invention relates to a method for preparing a gene-coated medical apparatus. The method utilizes the anode polarization principle, uses a medical apparatus body as an anode, and places the anode and the cathode of a power supply into solution of gene or oligonucleotide for anode polarization reaction so as to obtain the medical apparatus of which the surface carries a gene coating. The method is simple and feasible, does not need to introduce matrix loaded with the gene, and avoids inflammation and side effects brought by the substrate; the apparatus body is evenly coated with the gene or the oligonucleotide, the gene or the oligonucleotide coating has good stability, the activity is not influenced by a technical process, and the gene or the oligonucleotide is easily and slowly released into vascular cells so as to express in vascular wall cells; and the medical apparatus can prevent and treat inflammation reaction and restenosis in the medical apparatus more effectively.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

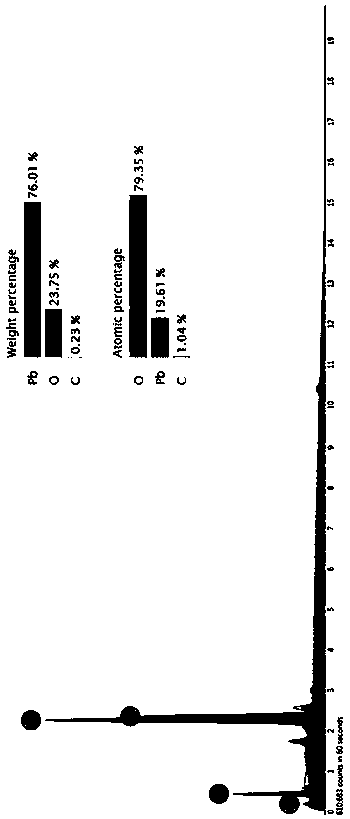

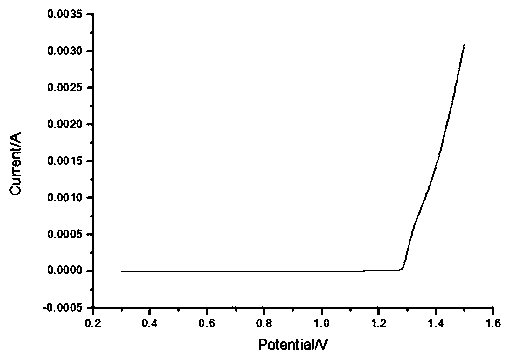

Method for measuring and calculating HPbO2<-> oxidation reaction rate constant and diffusion coefficient in alkaline solution

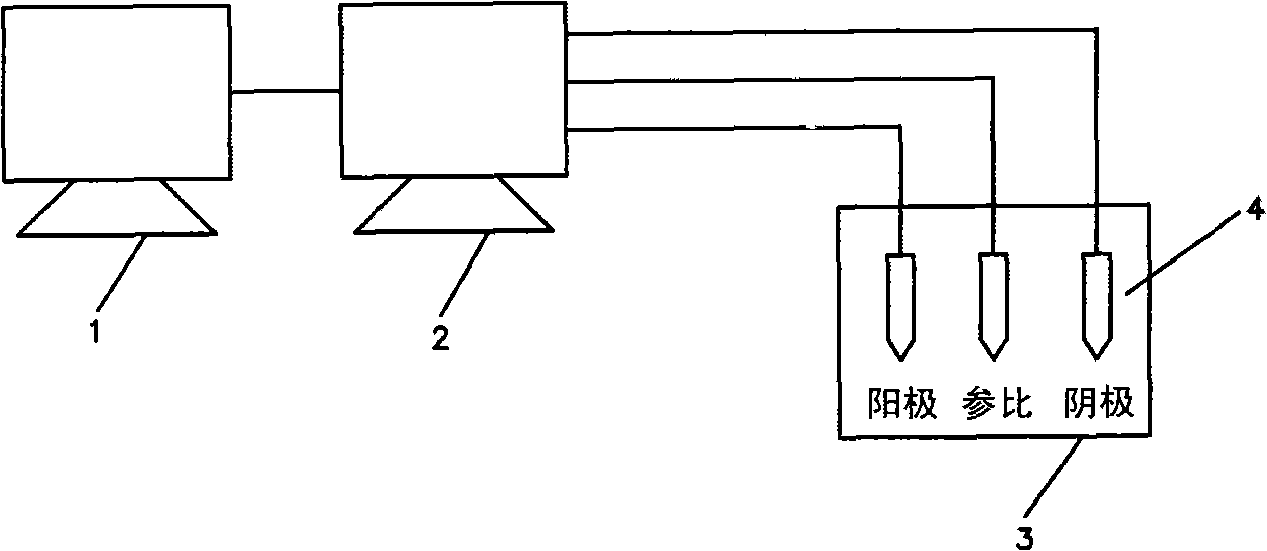

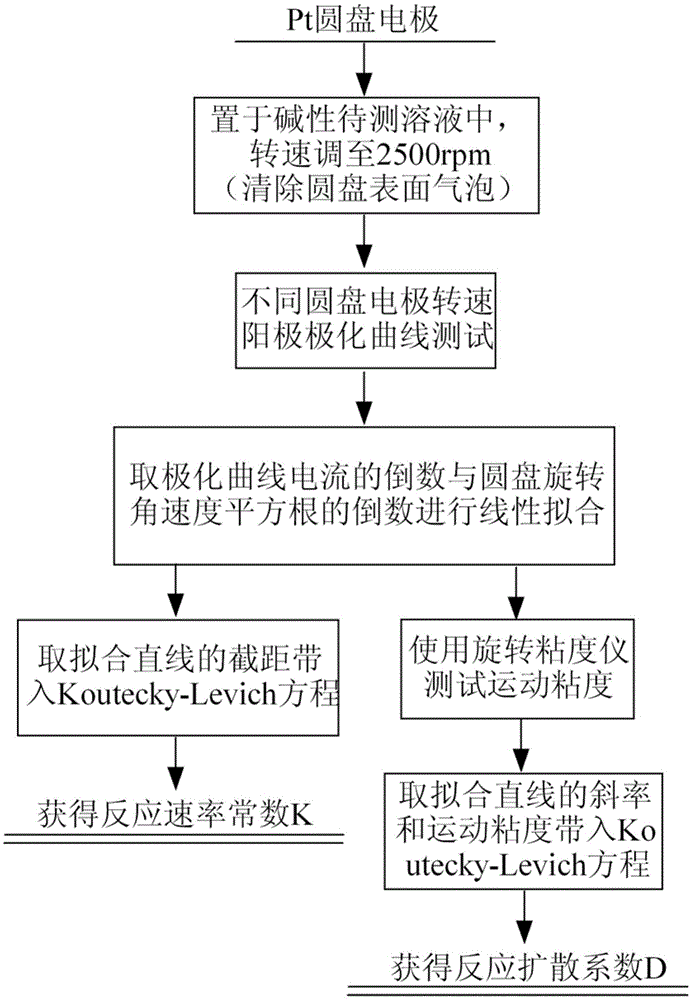

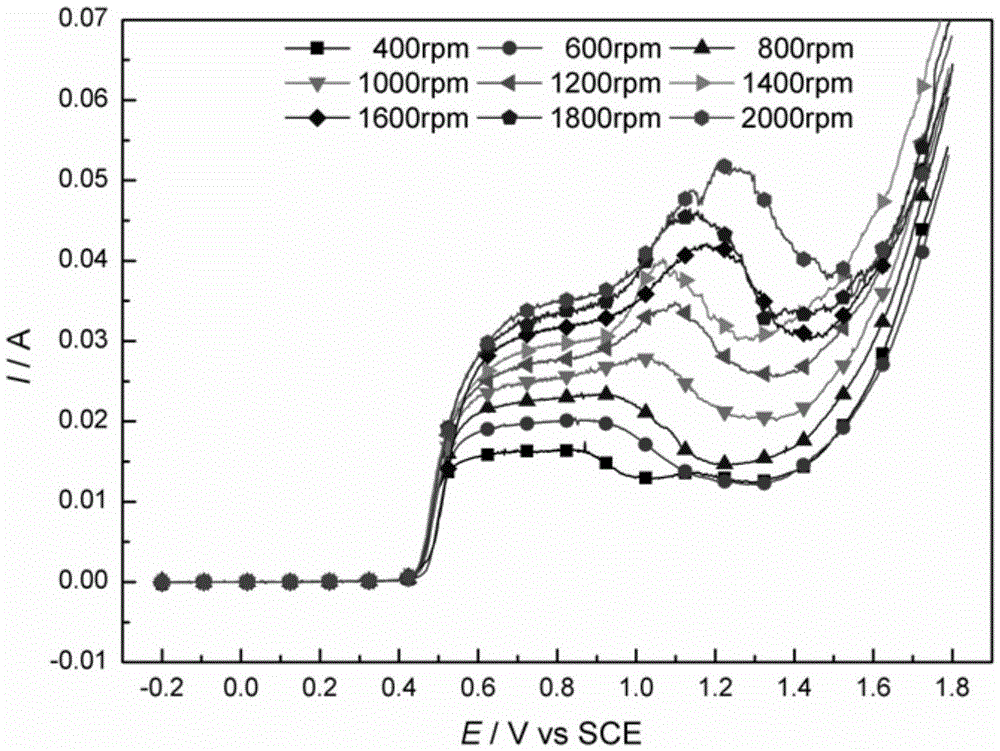

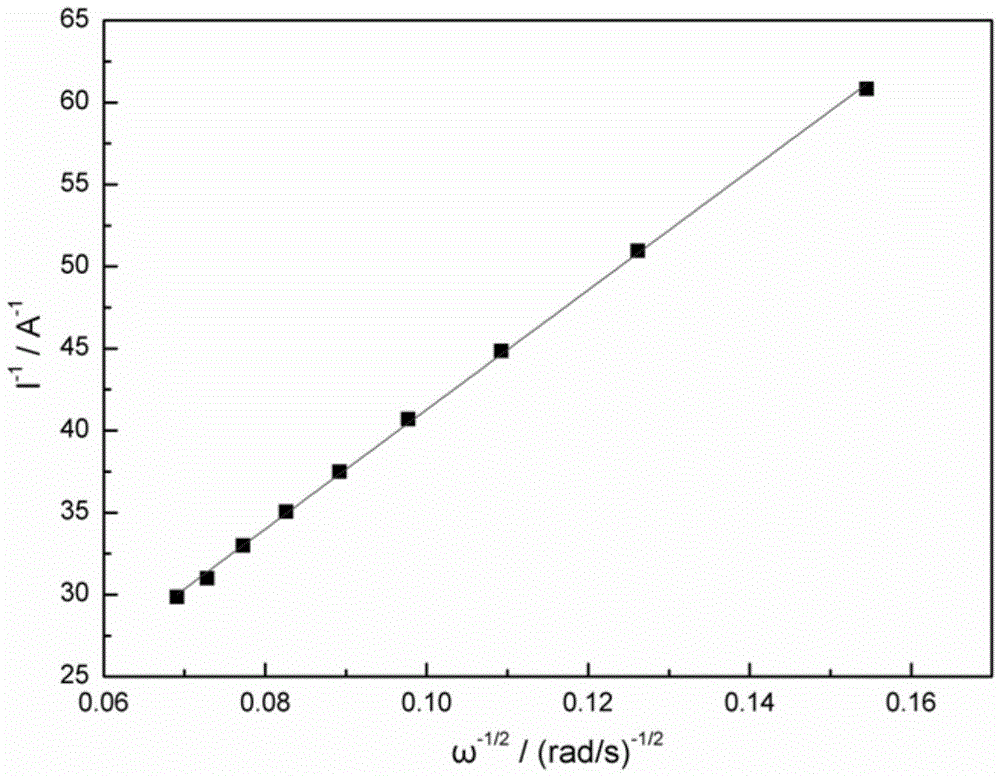

The invention relates to a method for measuring and calculating an HPbO2<-> oxidation reaction rate constant and diffusion coefficient in an alkaline solution, and belongs to the technical field of preparation of lead oxide. The method comprises the steps: firstly, adopting a three-electrode system, placing a Pt disk electrode in an alkaline solution of HPbO2<->, then adjusting the rotating speed of the Pt disk electrode, and obtaining tested anode polarization curves at the speed; selecting corresponding current values when a potential is 0.7 V in the rotation speeds of the Pt disk electrode from the tested anode polarization curves obtained from different rotation speeds of the Pt disk electrode, and carrying out linear fitting of reciprocals I<-1> of the current values with reciprocals [omega]<-1 / 2> of the square roots of rotation angular speeds of the Pt disk electrode, wherein a fitting straight line is represented by a Koutecky-Levich equation I<-1>=(nAFKC)<-1>+1.61(nAFC)<-1>D<-2 / 3>[nu]<1 / 6>[omega]<-1 / 2>; and measuring and calculating to obtain an intercept value H and a slope value S of the fitting straight line, and respectively calculating the reaction rate constant K and the diffusion coefficient D. The measuring and calculating method can relatively accurately test the HPbO2<-> oxidation reaction rate constant and diffusion coefficient in the alkaline solution.

Owner:KUNMING UNIV OF SCI & TECH

Lithium ion battery and anode piece

InactiveCN102610821AHigh resistivityIncrease Positive PolarizationSecondary cellsNon-aqueous electrolyte accumulator electrodesElectrical batteryLithium-ion battery

The invention belongs to the technical field of lithium ion batteries and particularly relates to an anode piece of a lithium ion battery. The anode piece comprises an anode current collector and an anode diaphragm coated on the anode current collector; the anode diaphragm comprises an anode active substance, a bonding agent and a conductive additive; the anode diaphragm further comprises a positive temperature coefficient material which is (VmR1-m)2)3, wherein R is at least one of Cr, Ba, Al, In, Ga, Sr and Pb, and m is not smaller than 0.5 and not more than 1; and the positive temperature coefficient material accounts for 4.5-30% relative to the total weight of the anode diaphragm. According to the invention, because the anode piece comprises the positive temperature coefficient material, the impedance of the anode diaphragm increases at high temperature to result in the increase of anode polarization, in a charging process, anode potential decreases, corresponding anode oxidation capacity decreases therewith, and thus, the high-temperature cycle performance of the lithium ion battery is increased. In addition, the invention further discloses a lithium ion battery comprising the anode piece.

Owner:NINGDE AMPEREX TECH +1

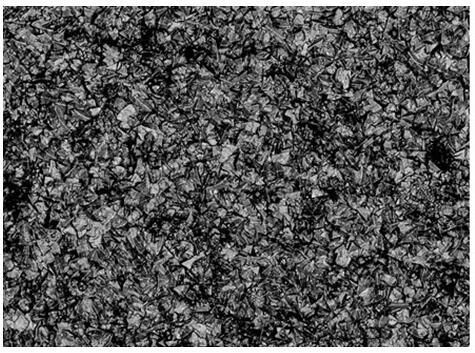

Preparation method of titanium-coated aluminum-based beta-PbO2-graphene composite electrode

ActiveCN109295481ACovalent bond functionalization processing optimizationSmall sizeCellsElectrolytic coatingsLead nitrateAnode polarization

Owner:KUNMING UNIV OF SCI & TECH

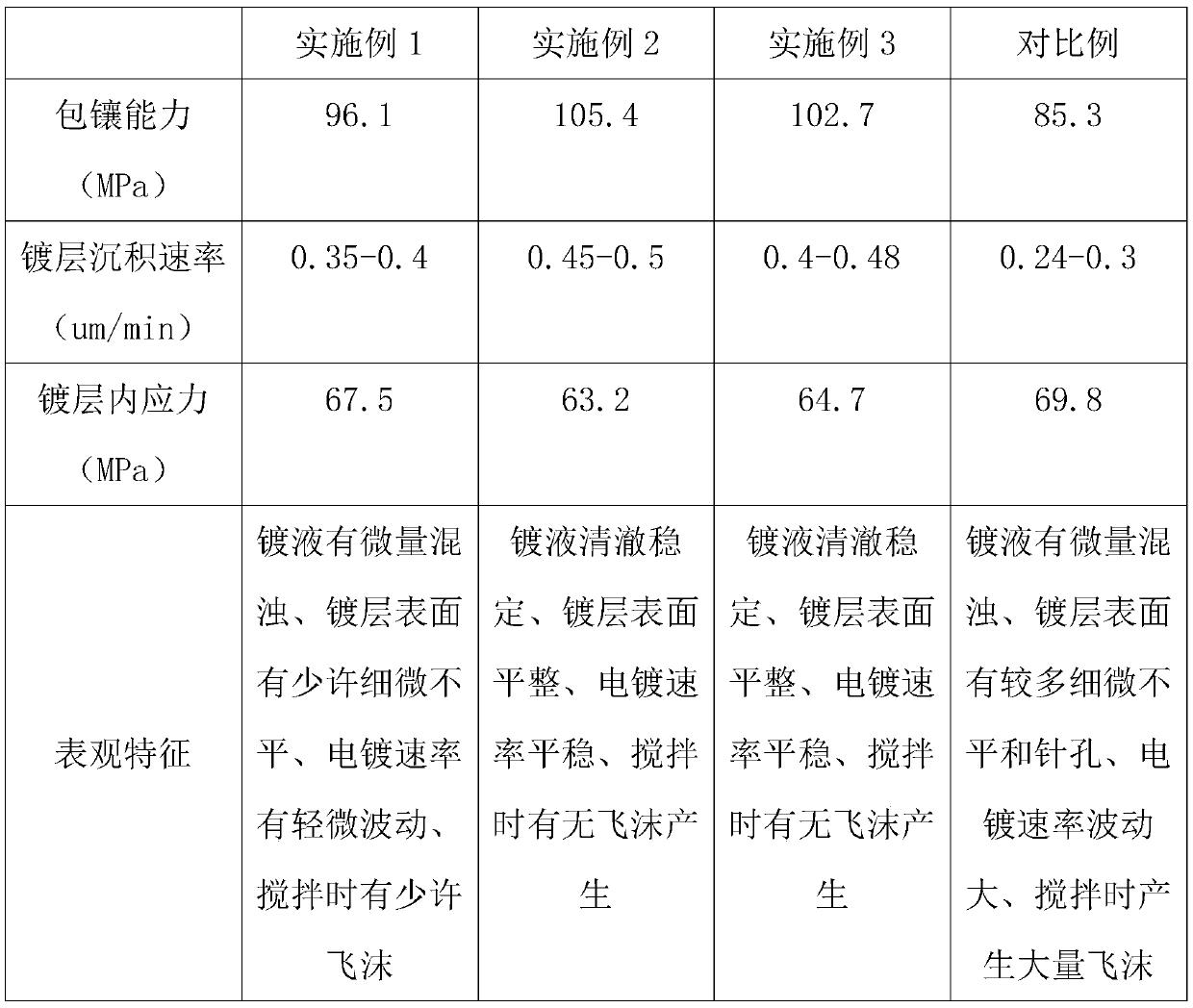

Electroplating solution for diamond cutting line and preparation method of electroplating solution

The invention discloses an electroplating solution for a diamond cutting line and a preparation method of the electroplating solution, and particularly relates to the technical field of electroplating. The electroplating solution comprises a solute with the following concentration: main salt 300-500 g / L, conductive salt 20-30 g / L, a complexing agent 3-5 ml / L, a stress relieving agent 8-12 ml / L, anelectroplating stabilizer 25-30 ml / L, a plating layer refiner 8-15 ml / L, an anode activator 5-10 ml / L, diamond micro-powder 10-15 g / L, other auxiliaries 35-45 ml / L, and a buffering agent, wherein a solvent used by the solute is water. According to the technical scheme, the anode polarization phenomenon is eliminated or reduced in the electroplating process by using the anode activator, then the normal dissolution of the anode is promoted, thus the current density of the anode is improved, meanwhile, the soluble anode is used for conducting electricity and controlling the distribution of current on the surface of a cathode, discharge metal ions can be supplemented into the plating solution, and in addition, a leveling agent and a wetting agent are used for solving the problem that a plating layer formed by electroplating easily have tiny unevenness and pinholes.

Owner:信丰崇辉科技有限公司

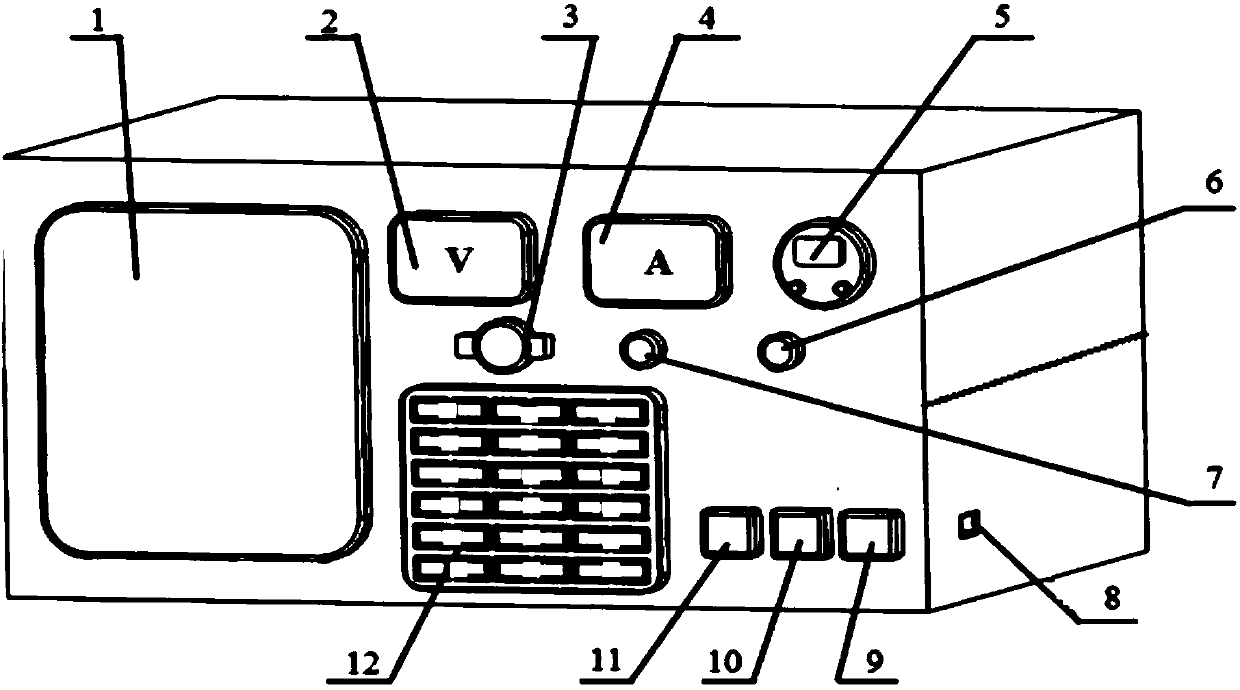

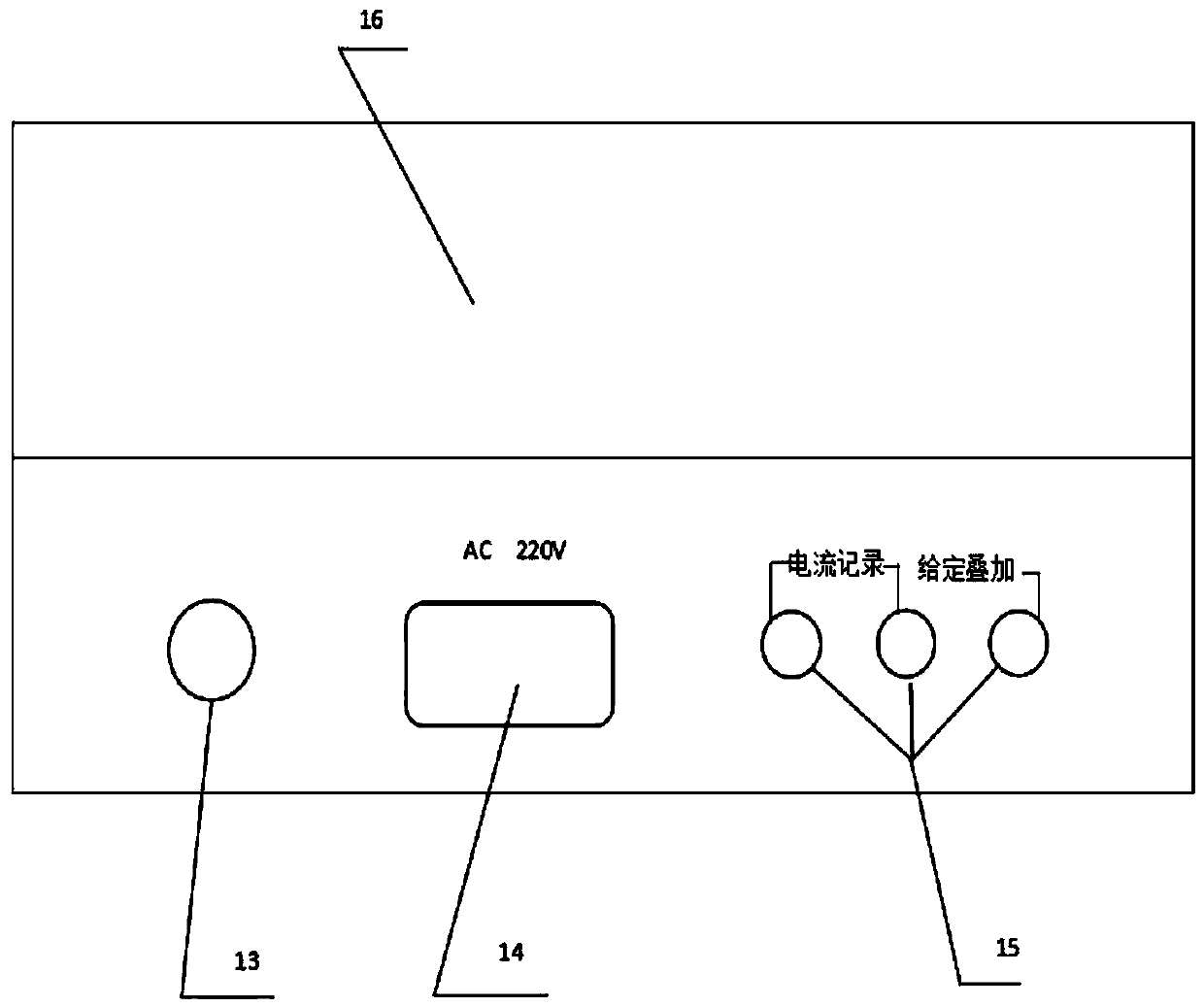

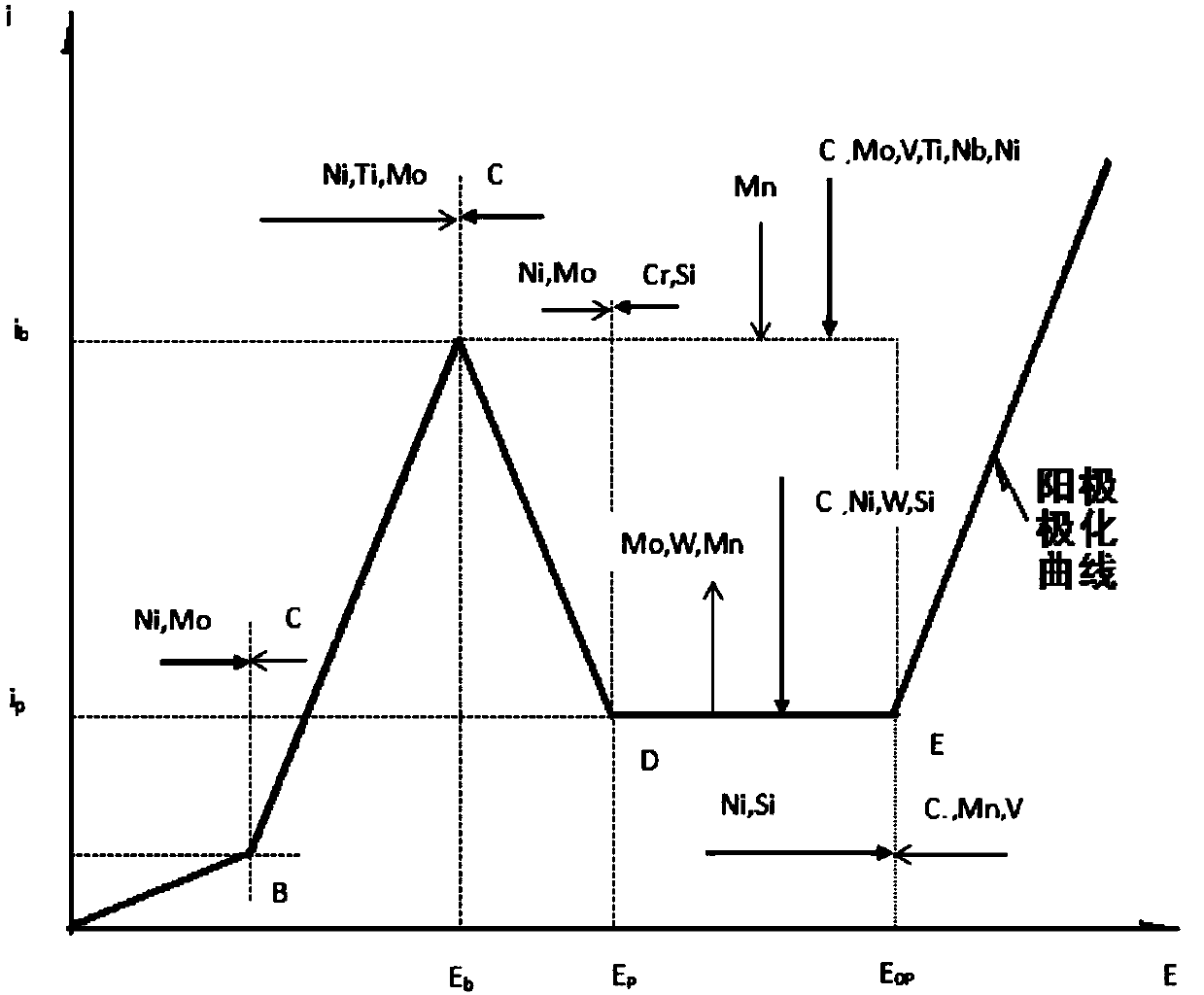

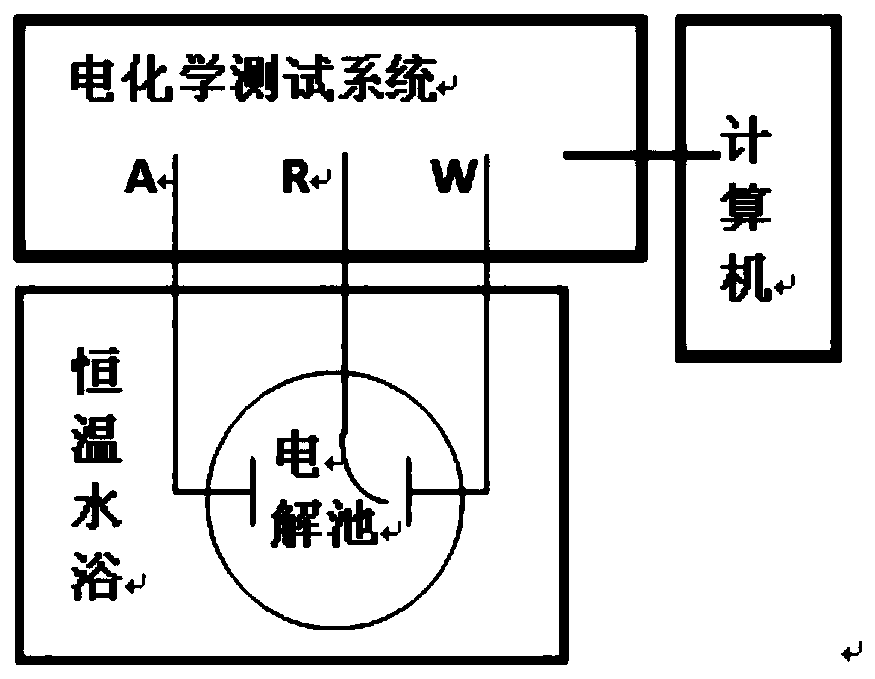

Electrochemical method and device for structural steel designation sorting

ActiveCN107607606AAchieve the purpose of sortingLow costMaterial electrochemical variablesLiquid-crystal displayMetallurgy

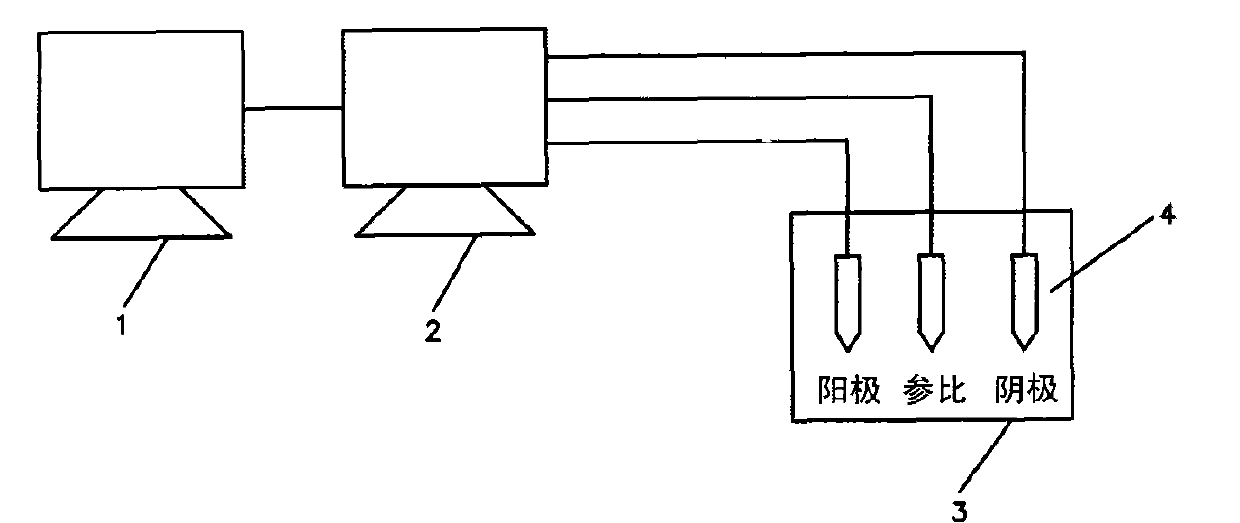

The invention relates to an electrochemical method and device for structural steel designation sorting. The invention mainly aims to provide an electrochemical method for rapid and accurate sorting ofstructural steel designation and a device for realizing the method. The method is characterized by mainly comprising the following main steps: conducting electrochemical experiment on structural steel with unknown designation, performing measurement to obtain an anode polarization curve of the structural steel with unknown designation in a special electrolyte solution, analyzing characteristic parameters of the anode polarization curve, then carrying out comparison with standard anode polarization curve characteristic parameters of structural steel with known designation in a standard sampledatabase, and performing recognition, thus obtaining the designation of the steel. The device comprises an electrochemical testing module and a polarization curve recognition module. The electrochemical testing module includes a three-electrode electrolytic tank, test circuit and a motor stirring circuit. The polarization curve recognition module includes a 89C51 chip, an analog-digital conversionchip and a liquid crystal display circuit.

Owner:NORTHEAST GASOLINEEUM UNIV

Preparation method of gene coatings of medical device

ActiveCN101491468BPrevent restenosisPrevent vascular diseaseStentsBlood vesselsSide effectPercent Diameter Stenosis

The invention relates to a method for preparing a gene-coated medical apparatus. The method utilizes the anode polarization principle, uses a medical apparatus body as an anode, and places the anode and the cathode of a power supply into solution of gene or oligonucleotide for anode polarization reaction so as to obtain the medical apparatus of which the surface carries a gene coating. The methodis simple and feasible, does not need to introduce matrix loaded with the gene, and avoids inflammation and side effects brought by the substrate; the apparatus body is evenly coated with the gene orthe oligonucleotide, the gene or the oligonucleotide coating has good stability, the activity is not influenced by a technical process, and the gene or the oligonucleotide is easily and slowly released into vascular cells so as to express in vascular wall cells; and the medical apparatus can prevent and treat inflammation reaction and restenosis in the medical apparatus more effectively.

Owner:LEPU MEDICAL TECH (BEIJING) CO LTD

Process for chemically plating nickel on magnesium alloy

PendingCN112941495AReduce pollutionReduce health impactLiquid/solution decomposition chemical coatingSaturated calomel electrodeAnode polarization

The invention relates to a process for chemically plating nickel on a magnesium alloy. The process comprises the following steps that step 1, the surface of a magnesium alloy part is polished, ground and degreased; then the magnesium alloy part is put into a chemical nickel plating solution with the temperature of 80-90 DEG C and the pH value of 5-6, the magnesium alloy part to be plated is taken as an anode, a stainless steel plate is taken as a cathode, and a saturated calomel electrode is taken as a reference electrode; a potential of-0.4 to-1.0 is applied and polarization is carried out for 30-120 s; step 2, external voltage is removed, the magnesium alloy part subjected to anodic polarization is directly subjected to chemical nickel plating in the chemical nickel plating solution, plating is conducted for 30-50 min, a compact and bright plating layer is obtained, and the thickness of the plating layer is 8-15 microns; and 3, the plated magnesium alloy part is taken out, washed with deionized water, rinsed and naturally air-dried. According to the process for chemically plating nickel on the magnesium alloy, zinc immersion or passivation treatment is not needed, the process is simplified, and the cost is reduced; and the magnesium alloy is suitable for large-scale mass production.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

The high nickel copper anode adopts the process of periodic reverse current electrolysis

ActiveCN113652716BEvenly dispersedHigh purityPhotography auxillary processesElectrolysis componentsOXALIC ACID DIHYDRATEElectrolytic agent

The invention provides a process for electrolysis of high nickel copper anode by periodic reverse current. Among them, the periodic reverse current can ensure the maximum use efficiency of electrolytic copper. By modifying the cathode copper sheet, the impurities and oxide film on the surface of the copper sheet are reduced. The treatment agent contains oxalic acid, which can be complexed by nickel ions. , reduce the concentration of nickel ions in the solution, improve the purity of the cathode copper after electrolysis, and purify the circulating electrolyte to reduce the waste of resources. The leveling agent can control the growth of grains, refine the grains, and make the surface of the cathode copper produced more flat. At the same time, it can effectively promote the reduction of copper ions and speed up the progress of electrolysis. The brightener can improve the brightness of the cathode copper electrode plate and effectively promote the shedding of anode slime, avoid the occurrence of anode polarization, speed up electrolysis, and improve production efficiency.

Owner:江西新金叶实业有限公司

Process for electrolyzing high nickel-copper anode by adopting periodic reverse current

ActiveCN113652716AEvenly dispersedHigh purityPhotography auxillary processesElectrolysis componentsOXALIC ACID DIHYDRATEElectrolytic agent

The invention provides a process for electrolyzing a high nickel-copper anode by adopting periodic reverse current, wherein the periodic reverse current can guarantee the maximum use efficiency of electrolytic copper, a cathode copper sheet is modified, impurities and an oxidation film on the surface of the copper sheet are reduced, a treatment agent contains oxalic acid components, nickel ions can be complexed through oxalic acid, the concentration of the nickel ions in a solution is reduced, the purity of the electrolyzed cathode copper is improved, and a circulated electrolyte is circularly purified, so that the waste of resources is reduced. A leveling agent can control the growth of crystal grains, so that the crystal grains are refined, and the surface of the produced cathode copper is smoother. Meanwhile, the reduction effect of copper ions can be effectively promoted, and the electrolysis progress is accelerated. A brightening agent can improve the brightness of a cathode copper electrode plate and effectively promote anode mud to fall off, the anode polarization phenomenon is avoided, the electrolysis speed is increased, and the production efficiency is improved.

Owner:江西新金叶实业有限公司

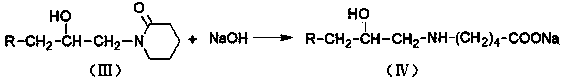

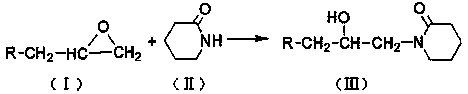

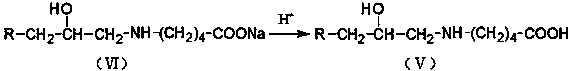

Method for synthesizing beta-isoalkanol amino valeric acid cyclohexylamine

InactiveCN104030933AStrong rust resistanceImproved anodic polarization propertiesOrganic compound preparationAmino-carboxyl compound preparationAlkanePtru catalyst

The invention discloses a method for synthesizing beta-isoalkanol amino valeric acid cyclohexylamine. The method comprises the steps: with toluene as a solvent and zinc chloride as a catalyst, after a reaction of epoxyalkane and valerolactam is completed under a stirring condition, carrying out reduced pressure distillation to remove the solvent and unreacted materials, and thus obtaining a colorless liquid beta-isoalkanol valerolactam; adding a sodium hydroxide solution, carrying out a hydrolysis reaction, and thus obtaining a beta-isoalkanol amino sodium valerate solution; and then slowly adding an acid solution, adjusting the pH to about 1.0, adding the precipitated beta-isoalkanol amino valeric acid into cyclohexylamine, and thus obtaining beta-isoalkanol amino valeric acid cyclohexylamine, wherein the reaction is easily carried out. The synthetic product has multiple active adsorption centers, can improve the anode polarization performance, and inhibits corrosion; and the synthetic product also has characteristics of binding amino, carboxyl and cyclohexylamine salt with metals, and has a strong rust prevention effect.

Owner:YANTAI HENGDIKE ENERGY TECH

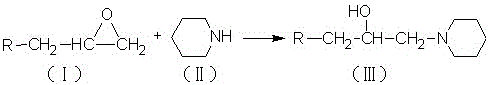

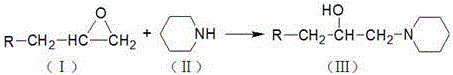

A kind of synthetic method of β-piperidinyl alcohol

The invention discloses a method for synthesizing beta-piperidinol. Piperidine and epoxyalkane are adopted to undergo a reaction, ring opening of epoxyalkane is controlled by adding a catalyst zinc chloride, and the reaction is allowed to be easily carried out. The synthetic product has multiple active adsorption centers, can improve the anode polarization performance, inhibits corrosion, and belongs to an anodic type corrosion inhibitor.

Owner:山东蓝盟防腐科技股份有限公司

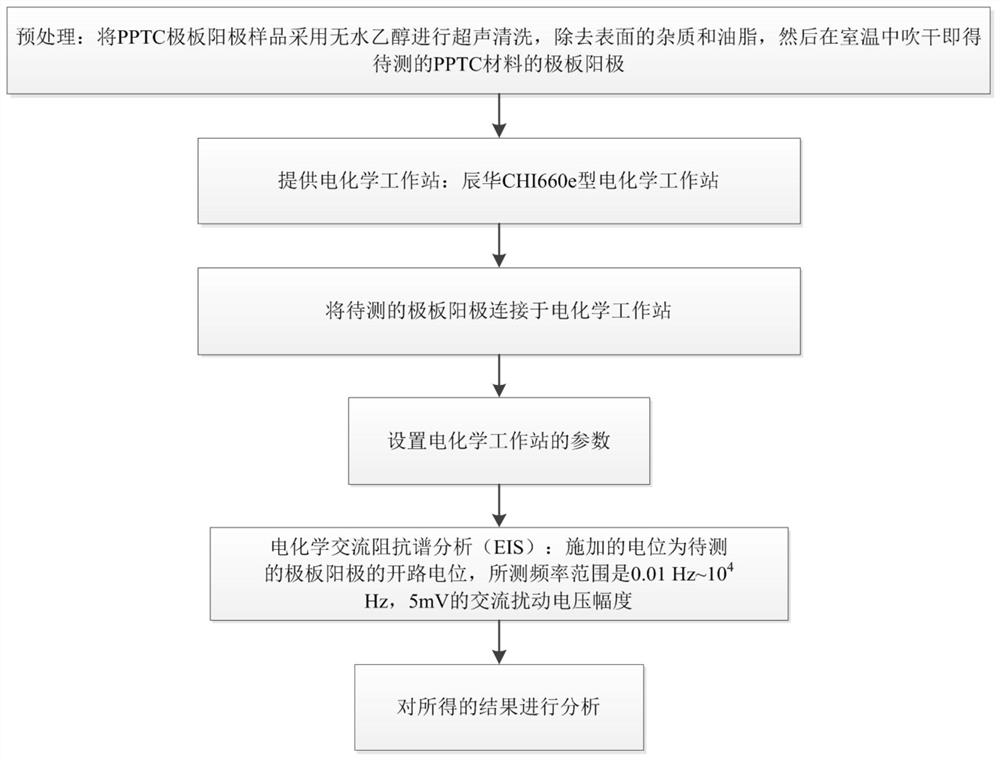

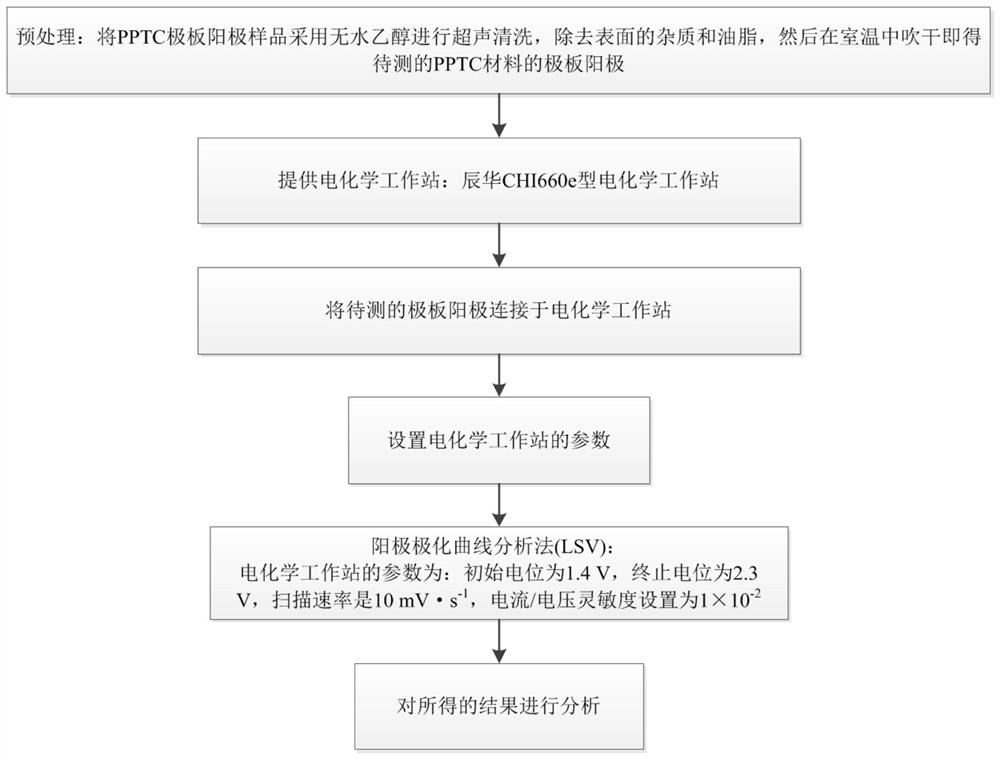

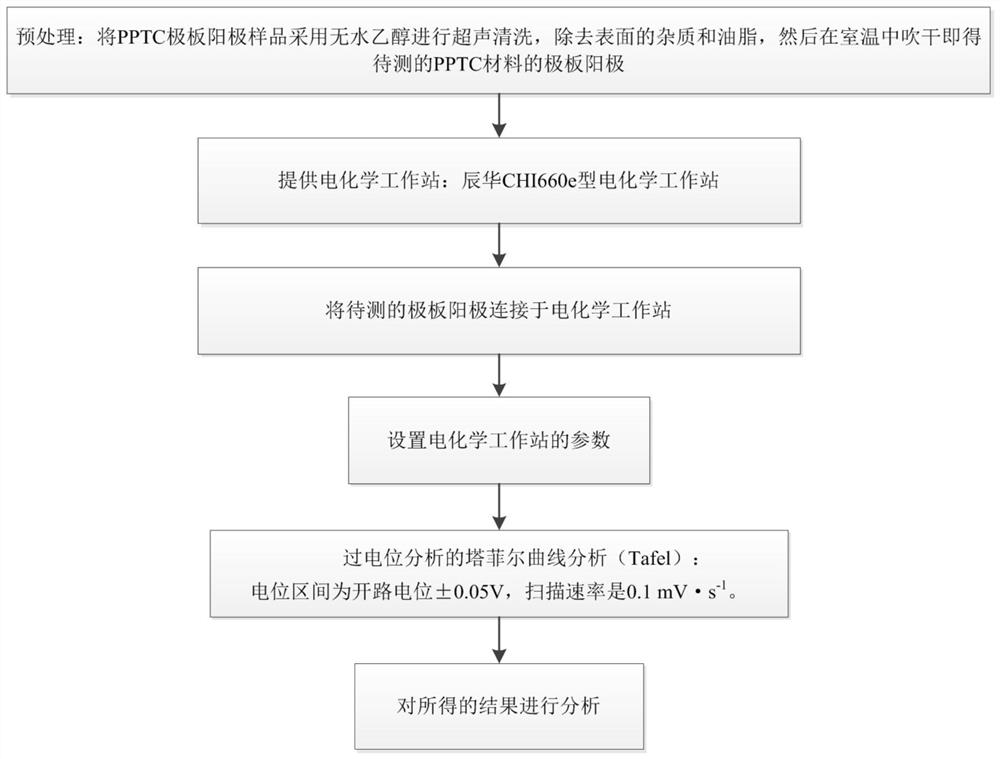

Method for testing electrochemical performance of polar plate anode based on novel material PPTC

PendingCN111948120AIncreased electrochemical detection rateWeather/light/corrosion resistanceMaterial electrochemical variablesElectrolytic agentImpedance spectrum

The embodiment of the invention discloses a method for testing the electrochemical performance of a polar plate anode based on a novel material PPTC, and the method comprises the following steps: pretreatment: carrying out the ultrasonic cleaning of a PPTC polar plate anode sample through employing absolute ethyl alcohol, and then carrying out the blow-drying at room temperature, thereby obtaininga to-be-tested polar plate anode of a PPTC material; providing an electrochemical workstation, wherein the workstation adopts three electrodes and an electrolyte; connecting the anode of the polar plate to be detected to an electrochemical workstation; setting parameters of an electrochemical workstation; carrying out an electrochemical performance test on an electrode through an electrochemicalperformance characterization method, wherein the characterization method comprises one or more of electrochemical alternating-current impedance spectroscopy (EIS) analysis, anodic polarization curve analysis (LSV), Tafel curve analysis of overpotential analysis or Mott-schakus curve analysis of flat potential analysis; and evaluating the electrochemical performance. The method has the characteristics of simplicity in operation, high detection rate and the like.

Owner:ZHAOQING LEOCH BATTERY TECH

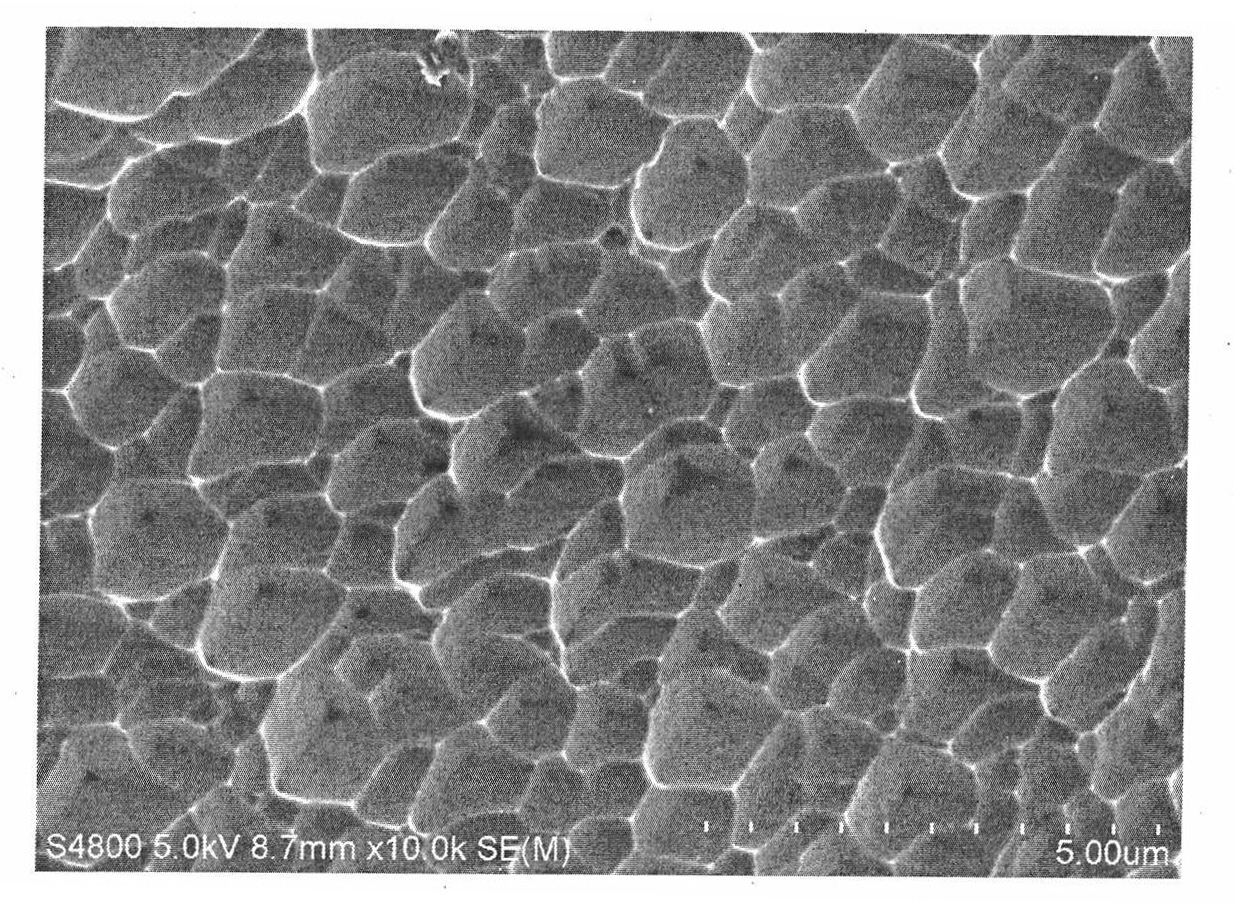

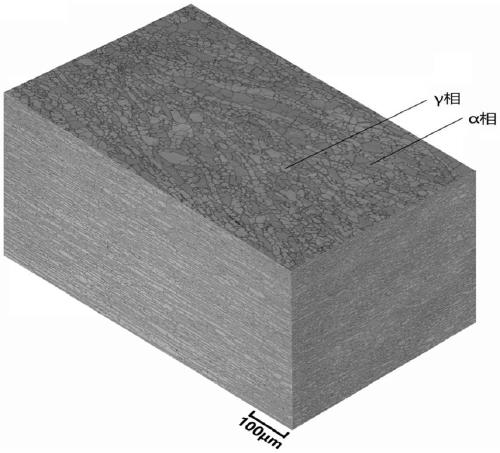

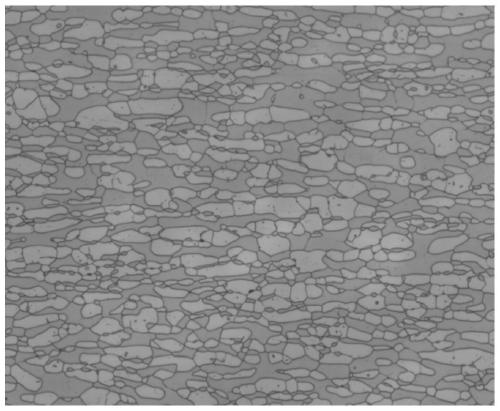

Separation method of two-phase structure in duplex stainless steel, reticular ferrite microporous material

ActiveCN108728892BDifferent dissolution effectsDifferent corrosion resistanceMetallurgyPhysical chemistry

The invention discloses a separation method of two-phase texture in two-phase stainless steel and a network ferrite cellular material and belongs to the technical field of stainless steel. The problemthat in the prior art, the single texture structure cannot be obtained from the two-phase stainless steel is solved. According to the separation method, the two-phase stainless steel is placed in a mixed solution of copper sulfate and hydrochloric acid to be subjected to electrokinetic potential anodic polarization, a double-peak polarization curve is obtained, the two-phase stainless steel is subjected to constant potential polarization in the mixed solution of the copper sulfate and the hydrochloric acid under an electric potential value corresponding to a dissolution peak with a high electric potential value, a ferritic phase of the two-phase stainless steel is obtained, and an Austenite phase of the two-phase stainless steel is obtained under an electric potential value correspondingto a dissolution peak with the low electric potential value. By the adoption of the separation method, the network ferrite cellular material can be prepared.

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com