Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

78 results about "Cathode polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cathodic Polarization. Definition - What does Cathodic Polarization mean? This is a corrosion control method where the potential of either the anode or the cathode, or both, is changed. This minimizes loss of metal and reduces the driving force of corrosion reaction.

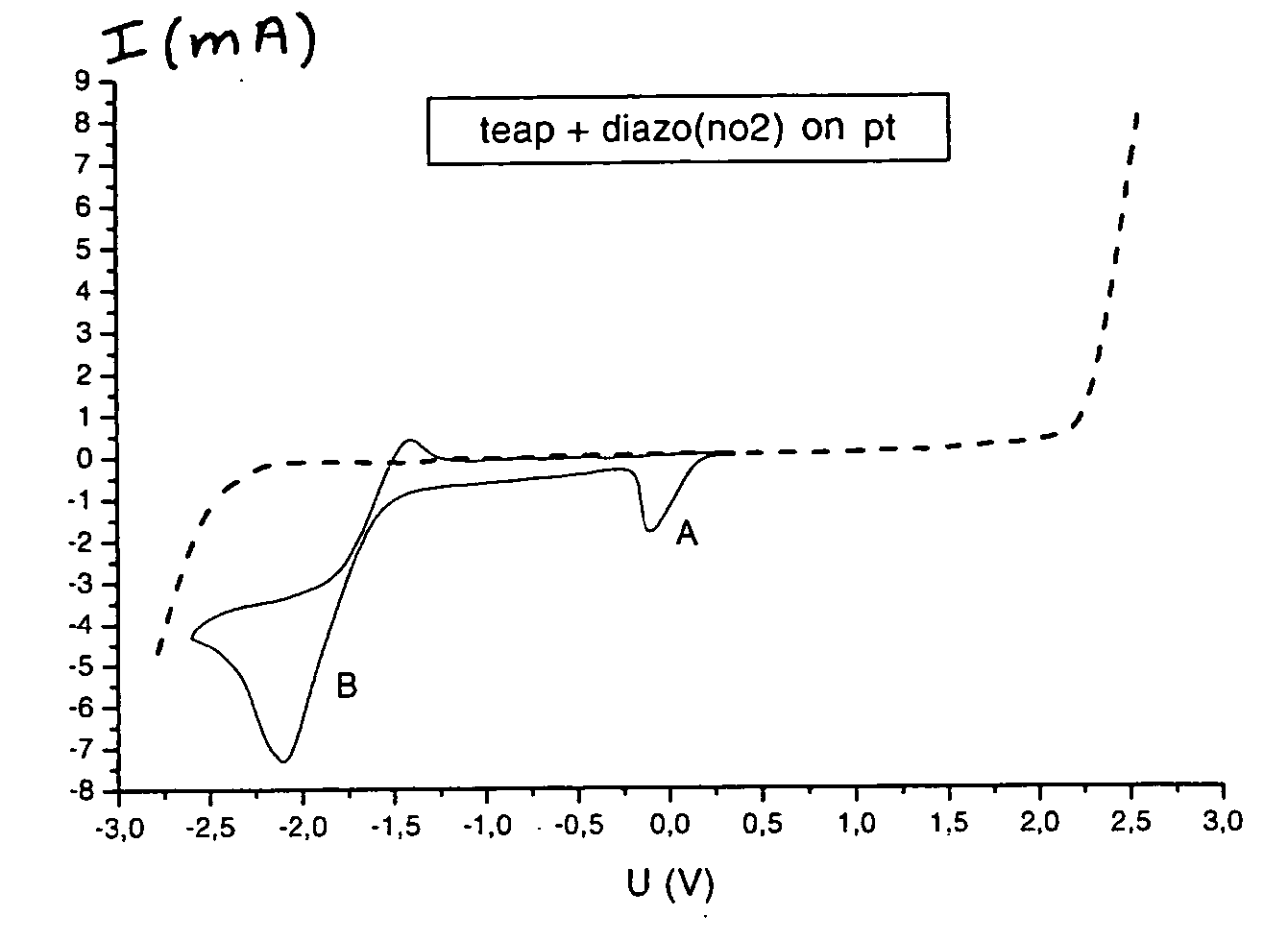

Method for grafting and growing a conductive organic film on a surface

ActiveUS20040248428A1High quality finishSurface reaction electrolytic coatingSemiconductor/solid-state device manufacturingOrganic filmElectricity

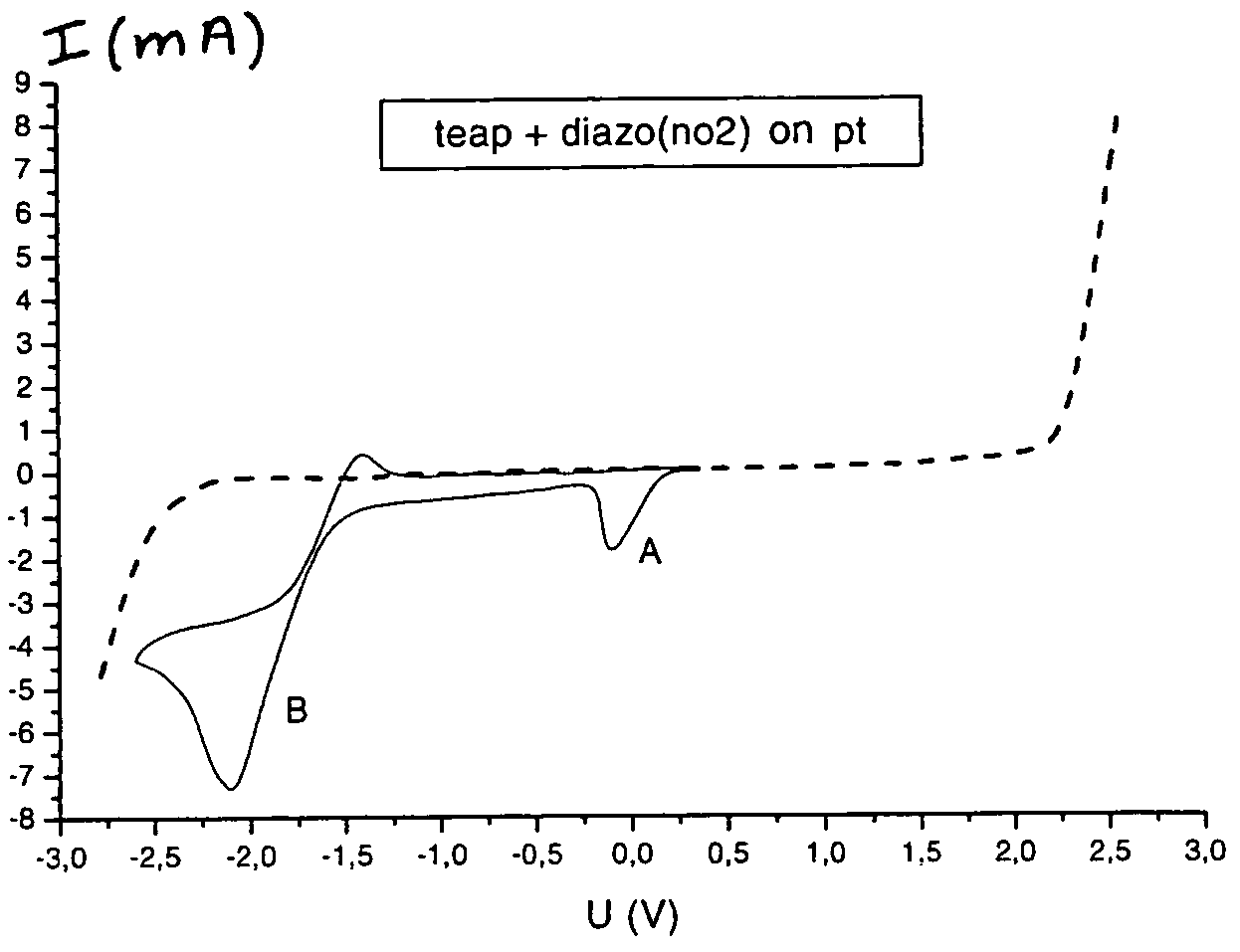

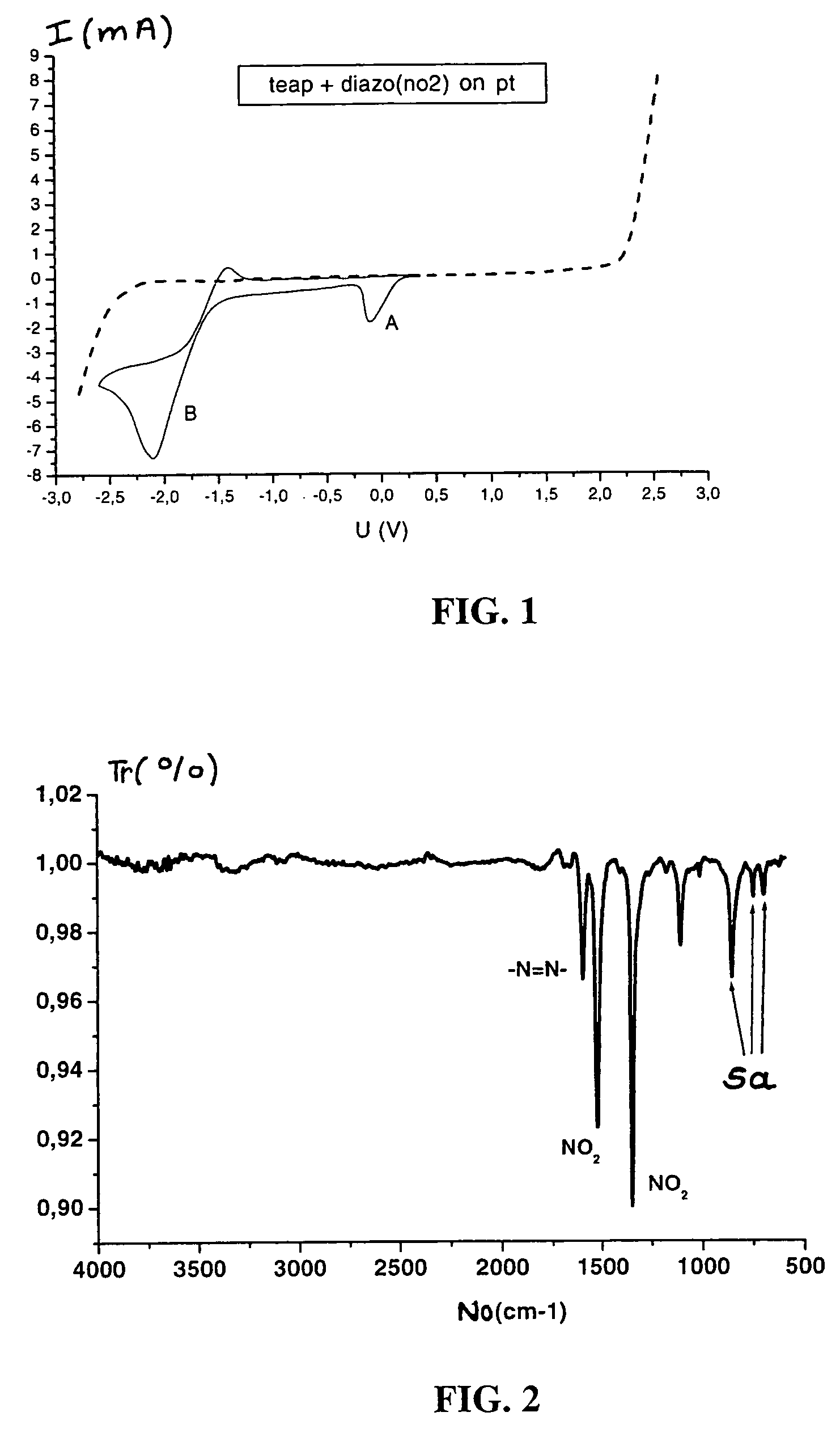

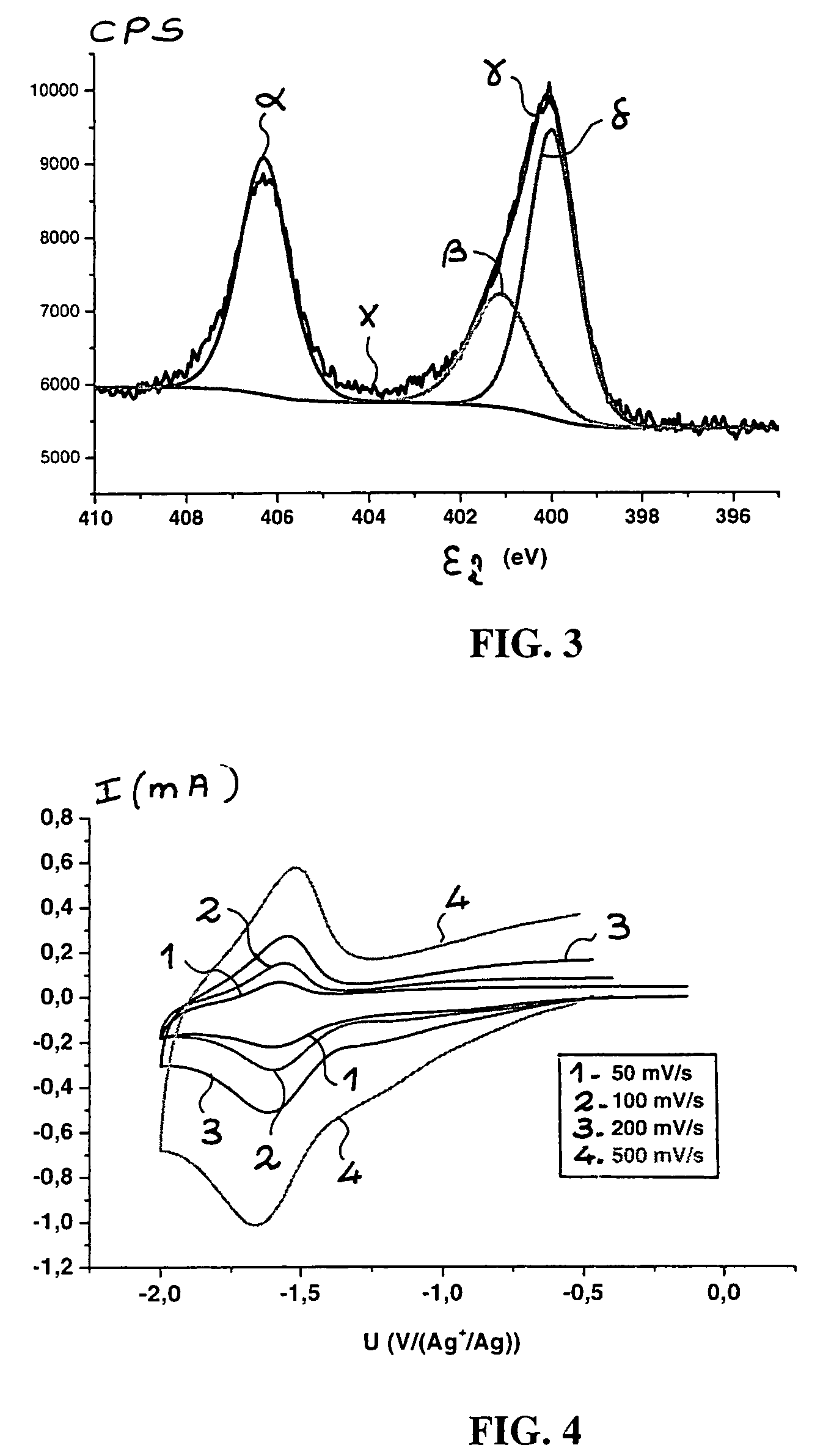

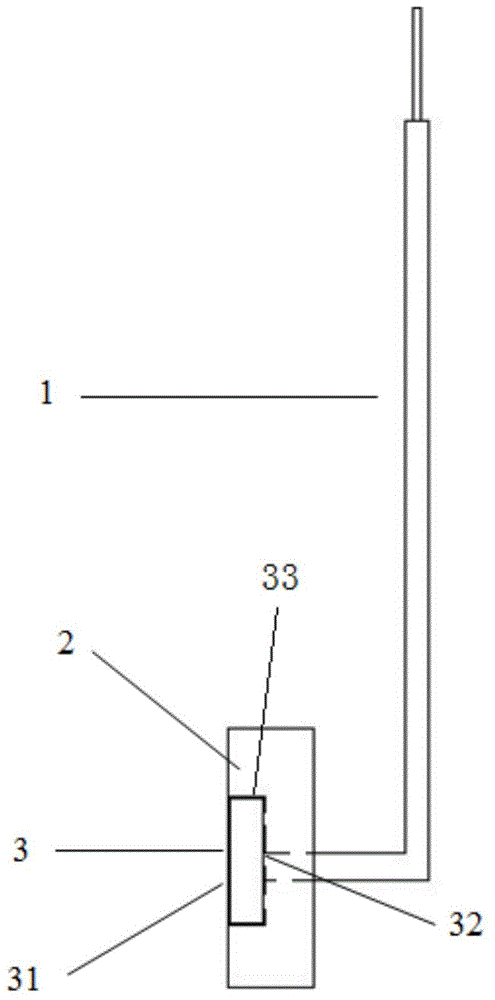

The present invention relates to a process for grafting and growing a conductive organic film on(to) an electrically conductive or semiconductive surface in which the grafting and growing of the film are performed simultaneously by electro-reduction of a diazonium salt that is a precursor of the said film on(to) the said surface cathodically polarized at a potential greater than or equal, in absolute value, to the electro-reduction potential of the diazonium salt relative to a reference electrode. The invention finds an application especially in the protection of surfaces, the manufacture of localized conductive coatings, of chemical sensors in the fields of chemistry and molecular biology, the manufacture of biomedical equipment, etc.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

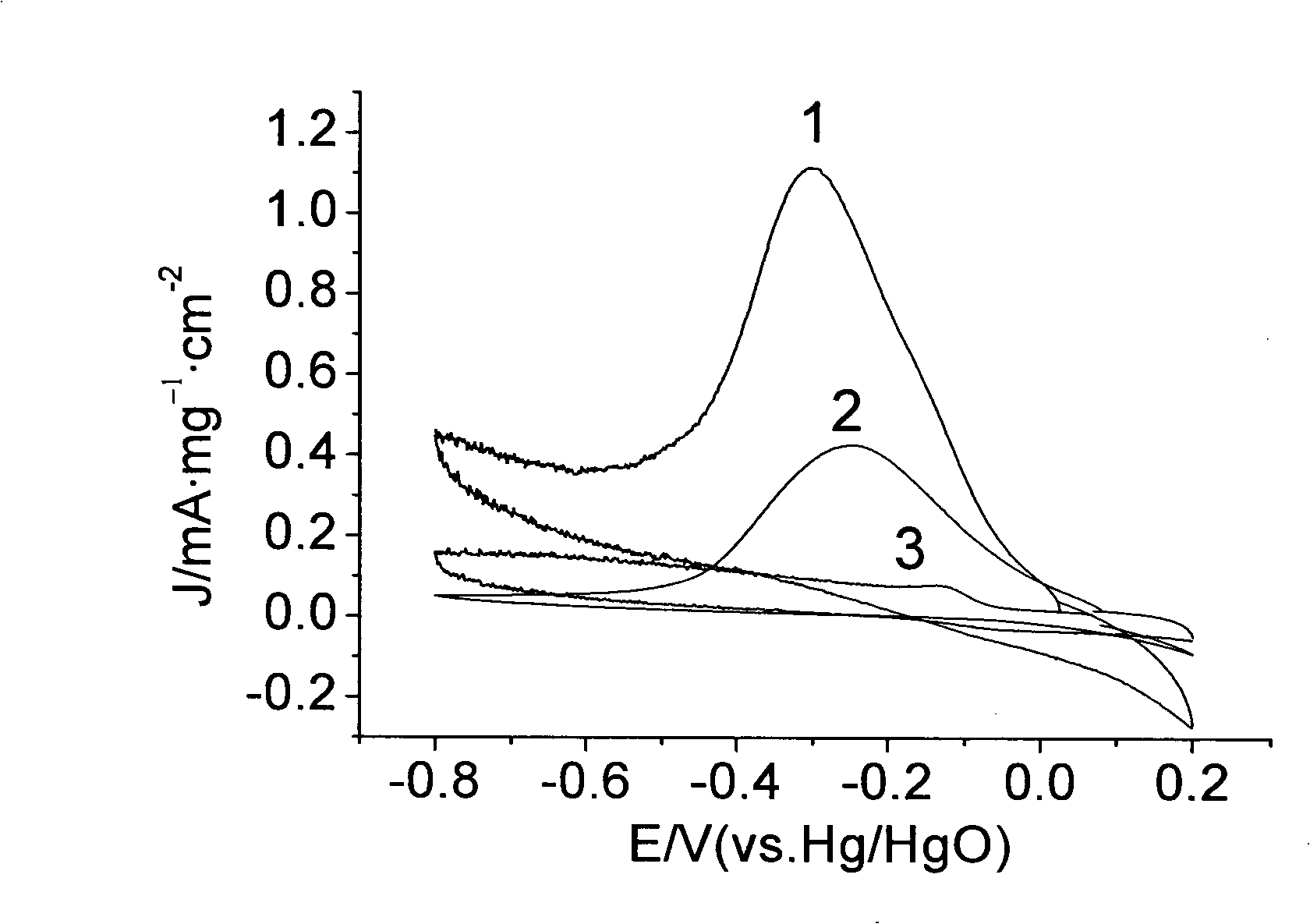

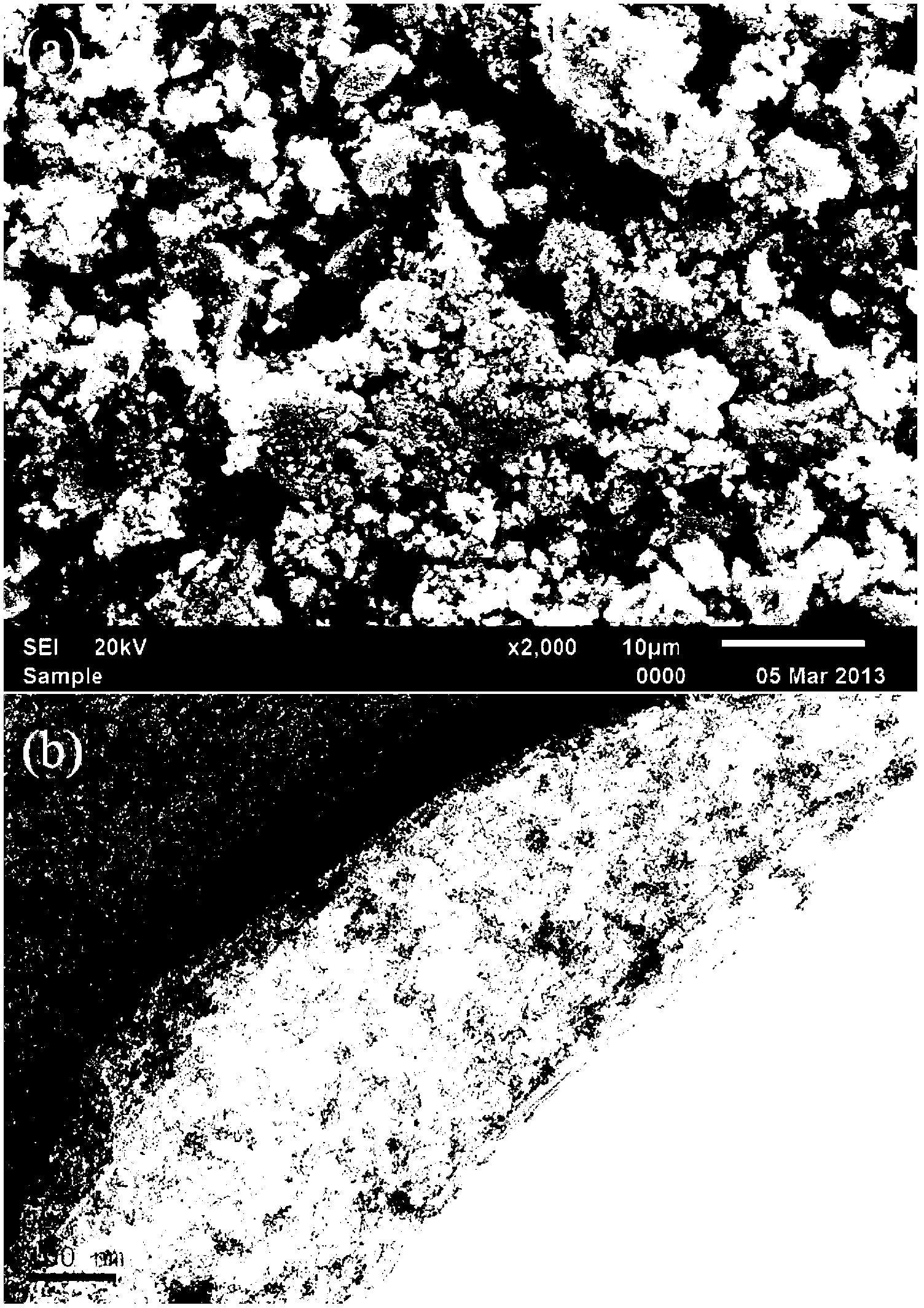

Application of manganese dioxide for preparing microorganism fuel cell cathode

InactiveCN101355170AGuaranteed uptimeHigh power outputCell electrodesMicrobial fuel cellMicroorganism

The invention discloses application of manganese dioxide for preparing a cathode of a microorganism fuel battery. The method comprises the following steps: the manganese dioxide is taken as a catalyst, the mixture of the catalyst, a conductive carbon material and a caking agent is coated on a conductive substrate to prepare the cathode of the microorganism fuel battery and a membrane composite cathode applied to the microorganism fuel battery. Compared with a non-catalytic electrode, MnO2 is taken as a cathode catalyst for remarkably increasing the reducing speed, reducing the polarization of the cathode and improving the energy output of the microorganism fuel battery; compared with the prior Pt catalyst, MnO2 has low price and wide source, and the microorganism fuel battery assembled by the catalyst of the cathode can operate stably for a long time and has high power output. The manganese dioxide for preparing the microorganism fuel battery electrode provides solid foundation for the commercial application of the microorganism fuel battery.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

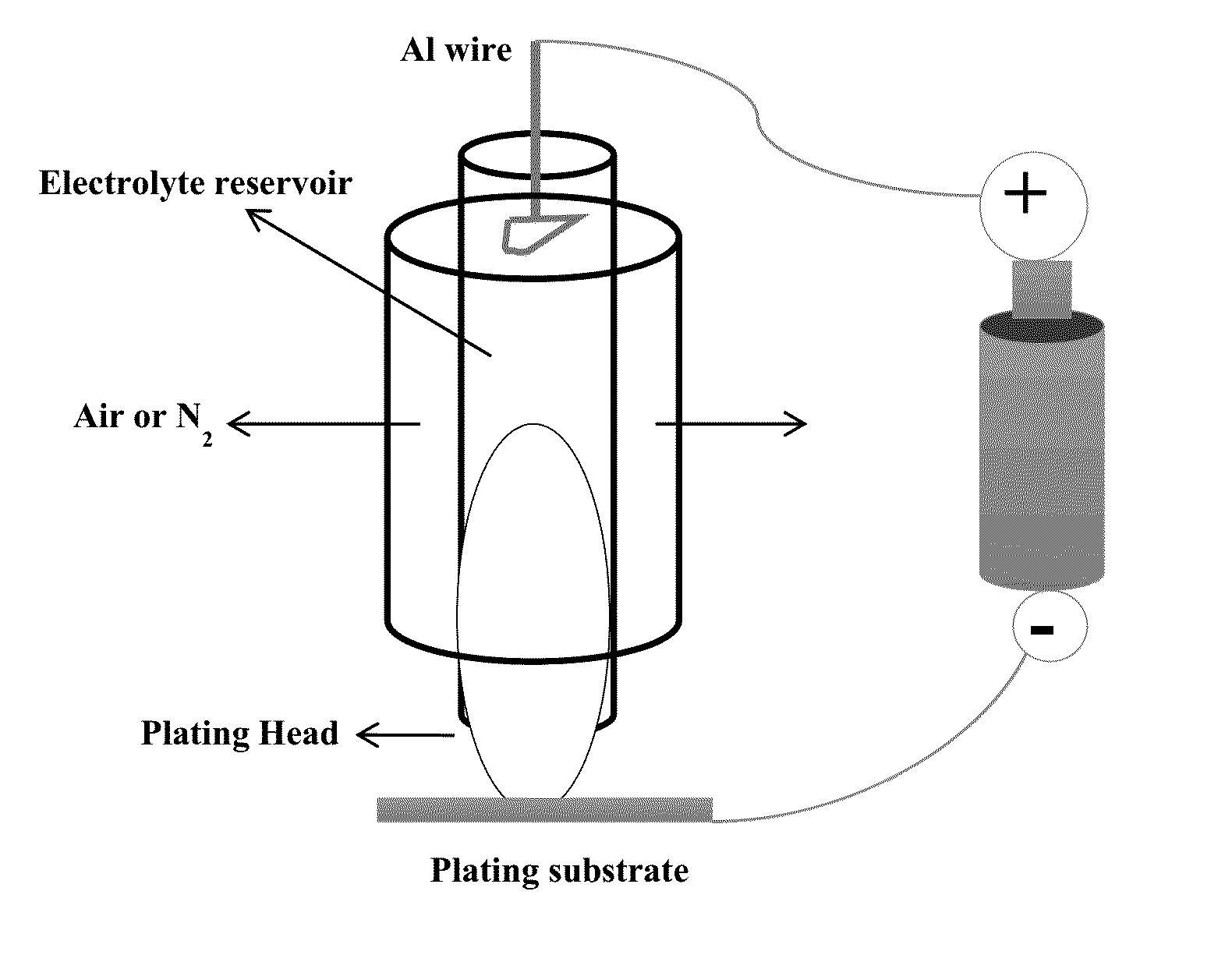

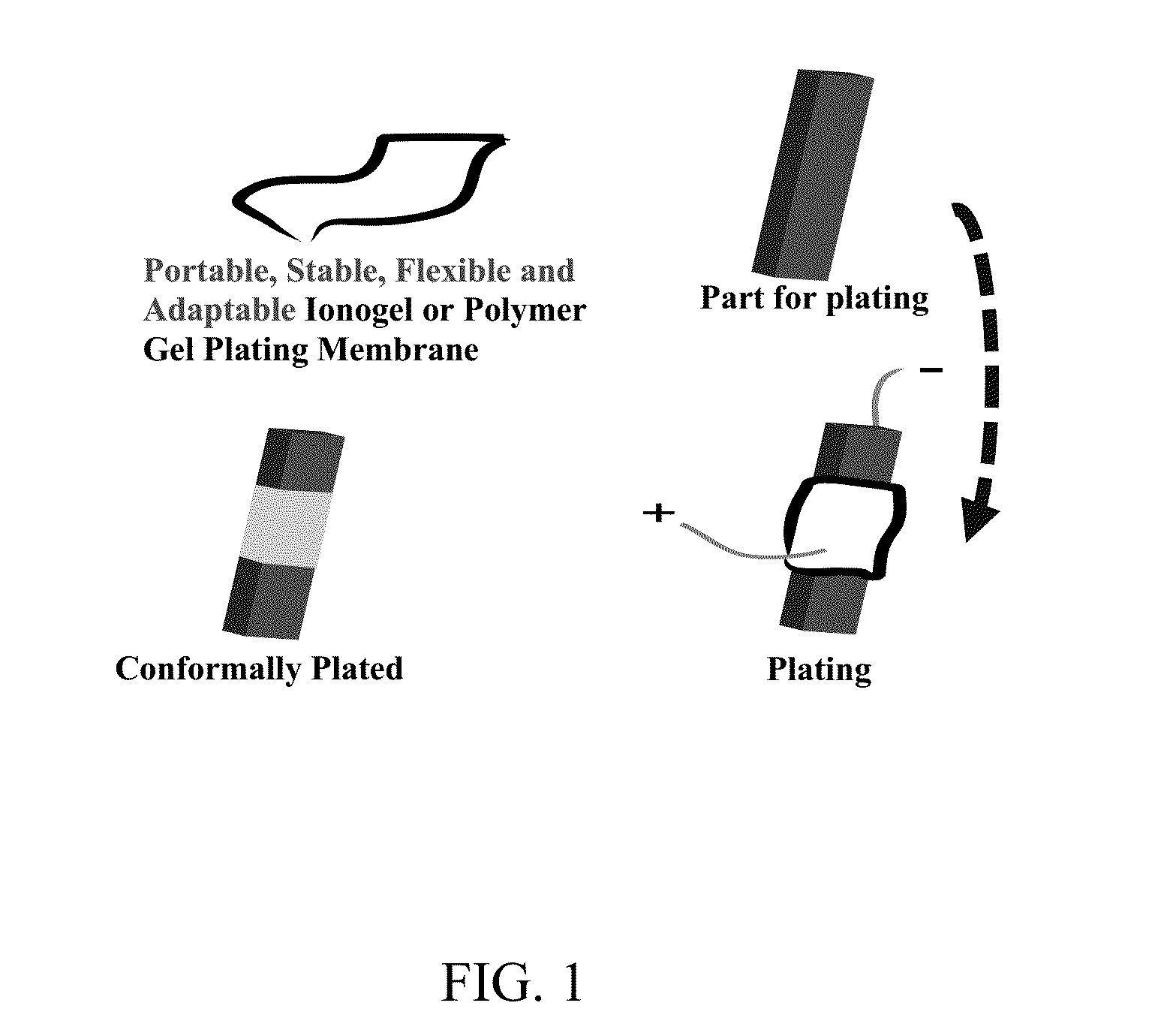

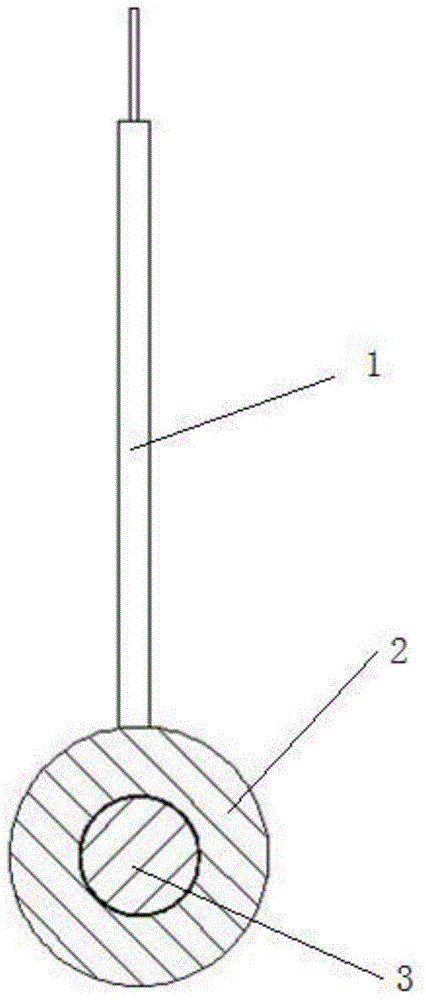

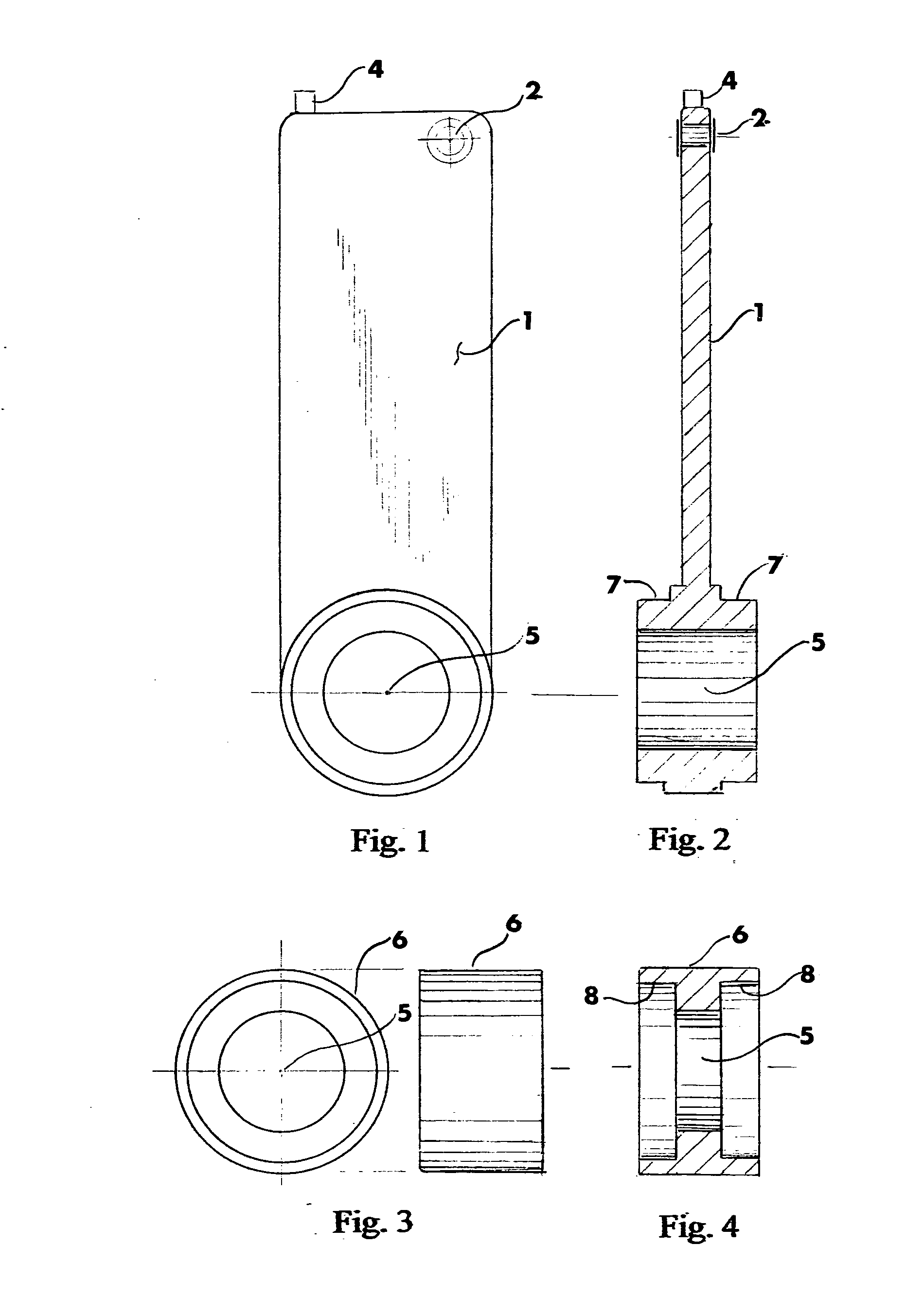

Aluminum deposition devices and their use in spot electroplating of aluminum

A method for spot electroplating aluminum onto a metallic substrate without submersion or dipping of the metallic substrate in an electroplating bath, the method comprising: (i) spot coating said metallic substrate with an aluminum ion-containing electrolyte contained within a protective structure possessing at least one aperture, and releasing said electrolyte from said at least one aperture onto said metallic substrate to form a coating of said electrolyte thereon, wherein said electrolyte is in contact with an anode; and (ii) applying a voltage potential between the anode and metallic substrate polarized as cathode when the aluminum ion-containing electrolyte is released from said aperture and forms a coating on the metallic substrate, to produce a coating of aluminum on the substrate. Devices, such as brush and ball pen plating devices, for achieving the above-described method are also described.

Owner:UT BATTELLE LLC +1

Solid oxide fuel cell cathode material and application thereof

InactiveCN101599546AControl formationSimple processCell electrodesFuel cell detailsFuel cellsTitanium

The invention relates to a solid oxide fuel cell, in particular to a transition element titanium or scandium-doped LSM (La0.8Sr0.2MnO3-Delta) cathode material and an application thereof. The cathode material includes the following component: [La(1-x)Srx] (1-y)Mn(1-z)MzO(3+ / -delta), (X and Y are more than 0 but less than 1, Z is more than 0 but less than or equal to 1, and delta is more than -1 but less than 1), wherein M is titanium or scandium element. The solid oxide fuel cell cathode comprises 1-100 percent of the cathode material and 0-99 percent of electrolyte material according to the mass percent; and the electrolyte material is one or more of 5-20 mol percent of Y2O3 stabilized ZrO2, 5-20 mol percent of Sc2O3 stabilized ZrO2, SmxCe(1-x)O2, GdxCe (1-x)O2, YxCe(1-x)O2, LaxCe(1-x)O2 and La(1-x)SrxGa(1-y)MgyO3 (X and Y are more than 0 but less than 1). The activity of catalytic oxygen reduction reaction of the LSM cathode material can be enhanced, the reaction process of oxygen on the surface of the cathode material is quickened, and the cathode polarization is reduced, therefore, the output power of the solid oxide fuel cell is effectively improved, and the output performance of a 600 DEG C battery is enhanced by twice than that of the standard LSM battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

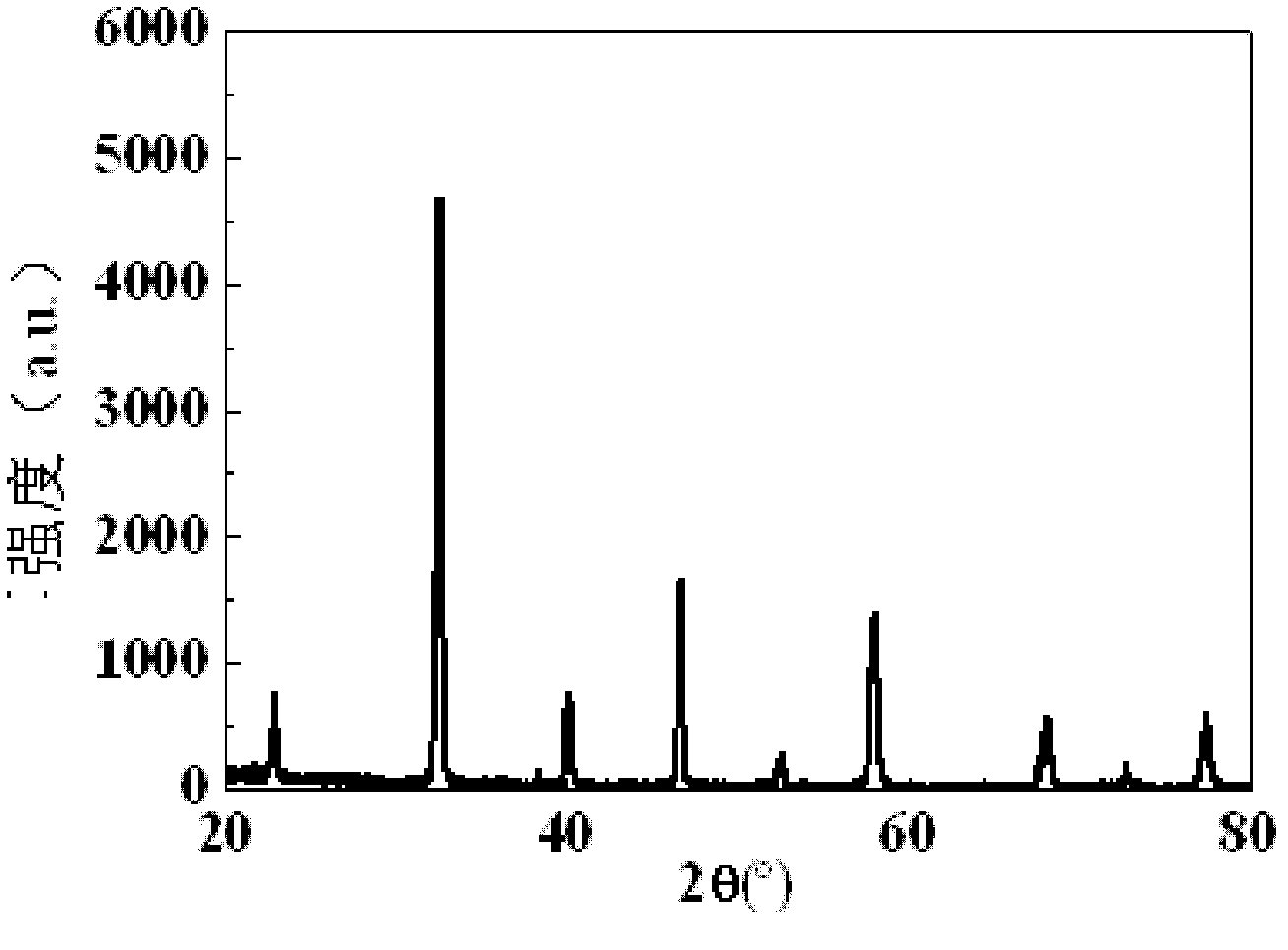

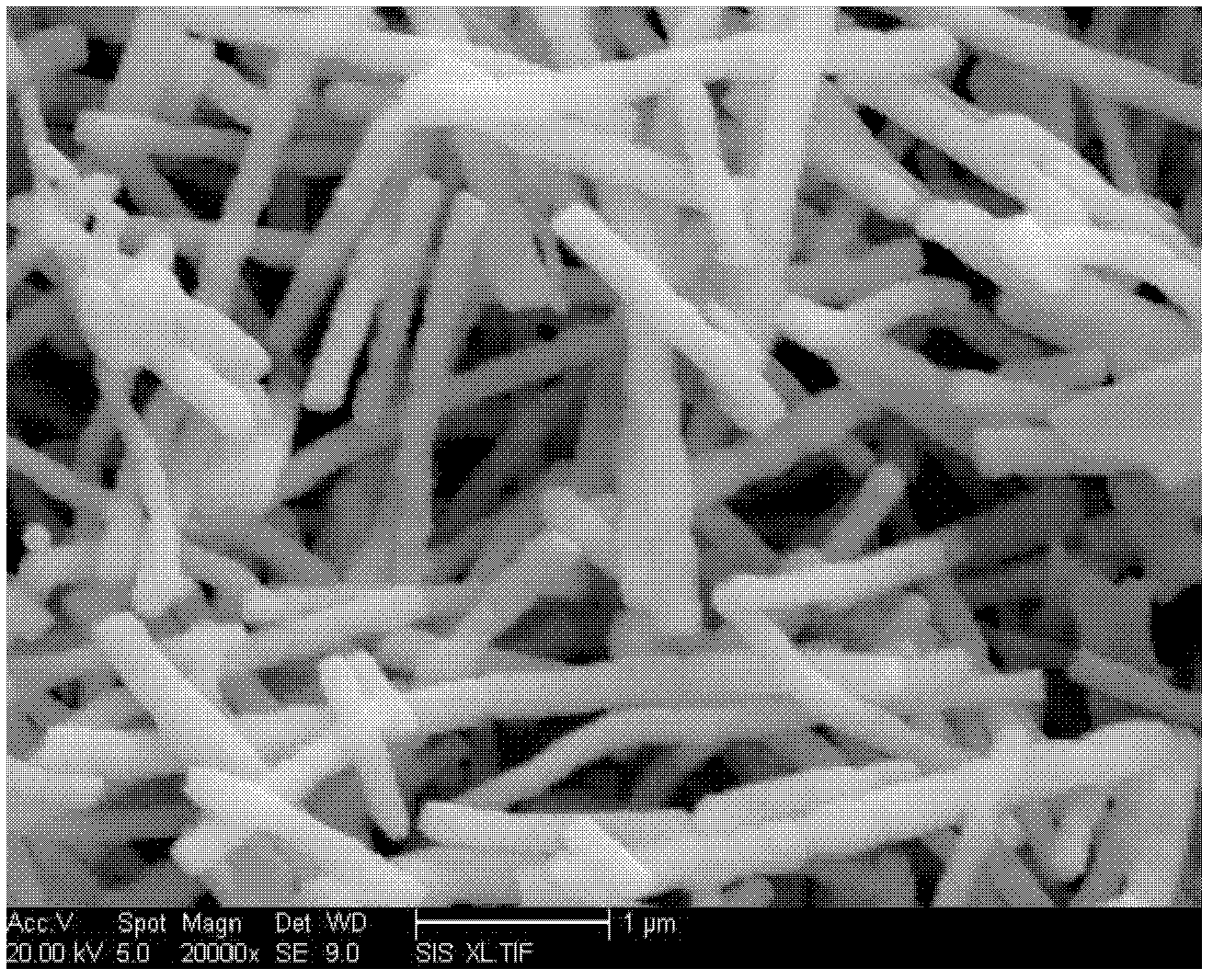

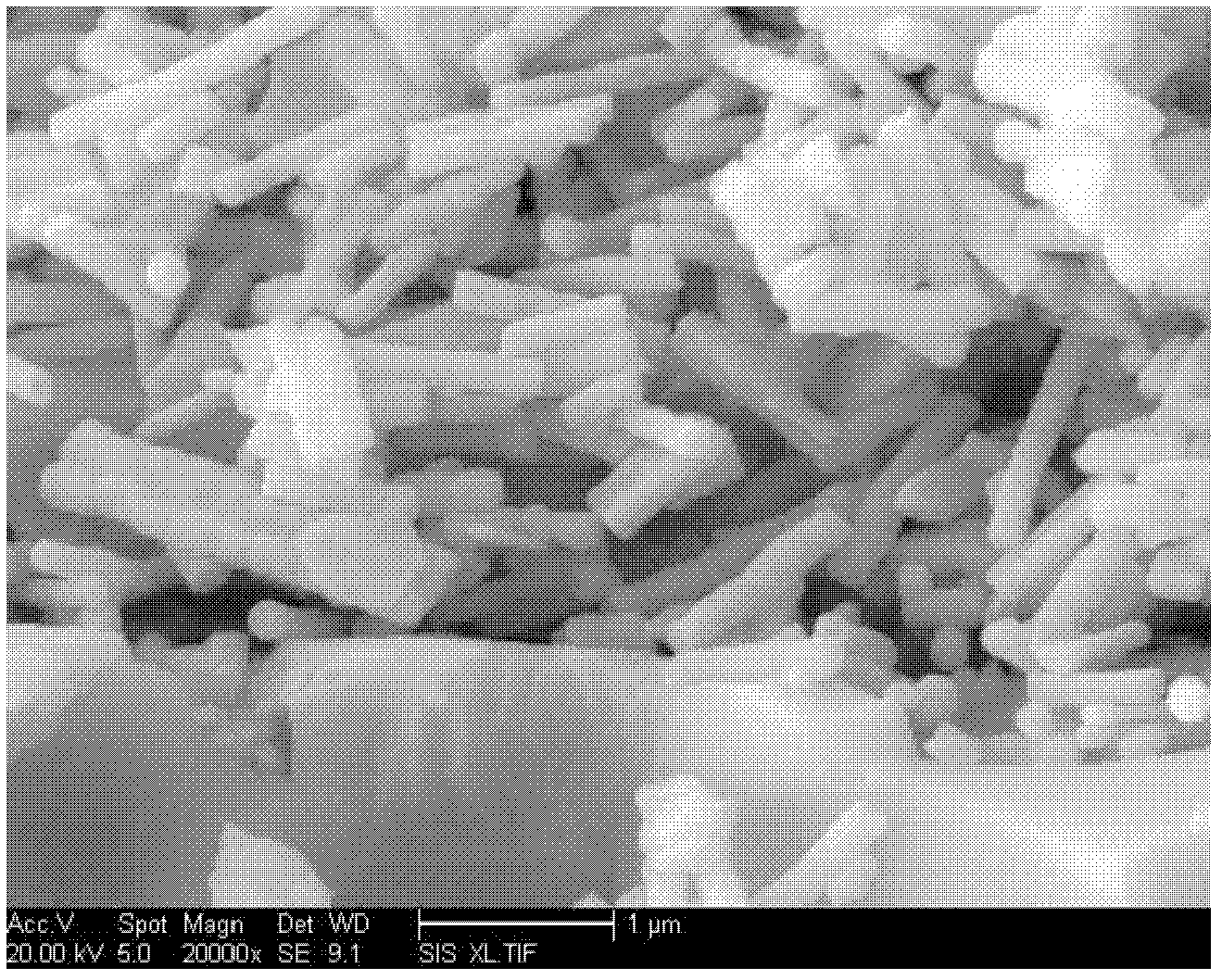

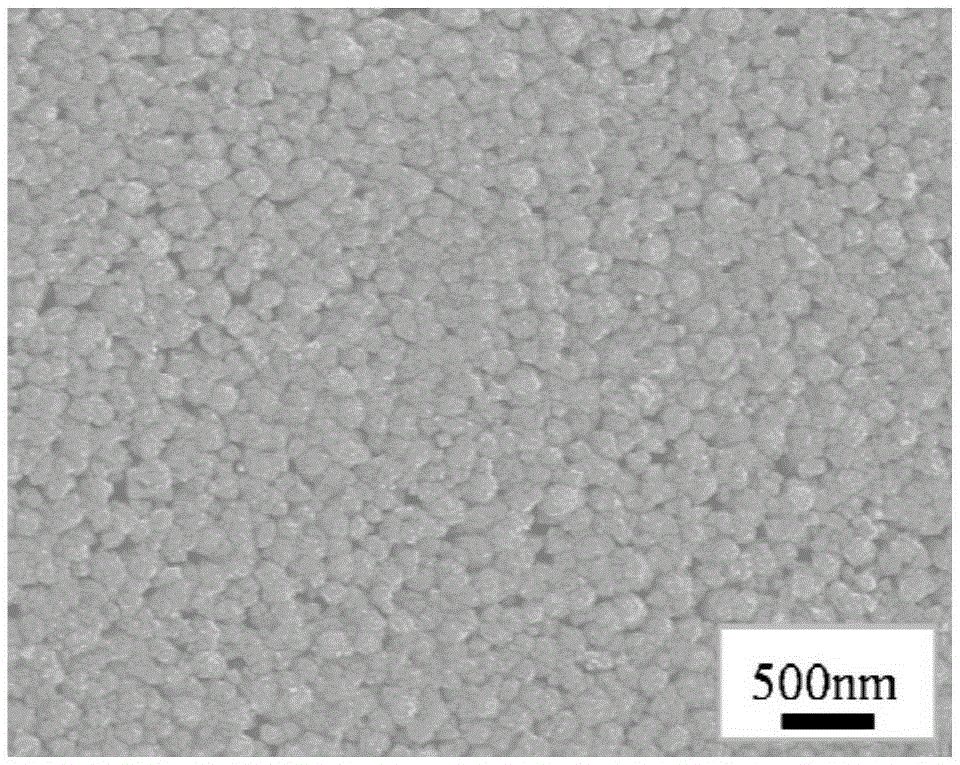

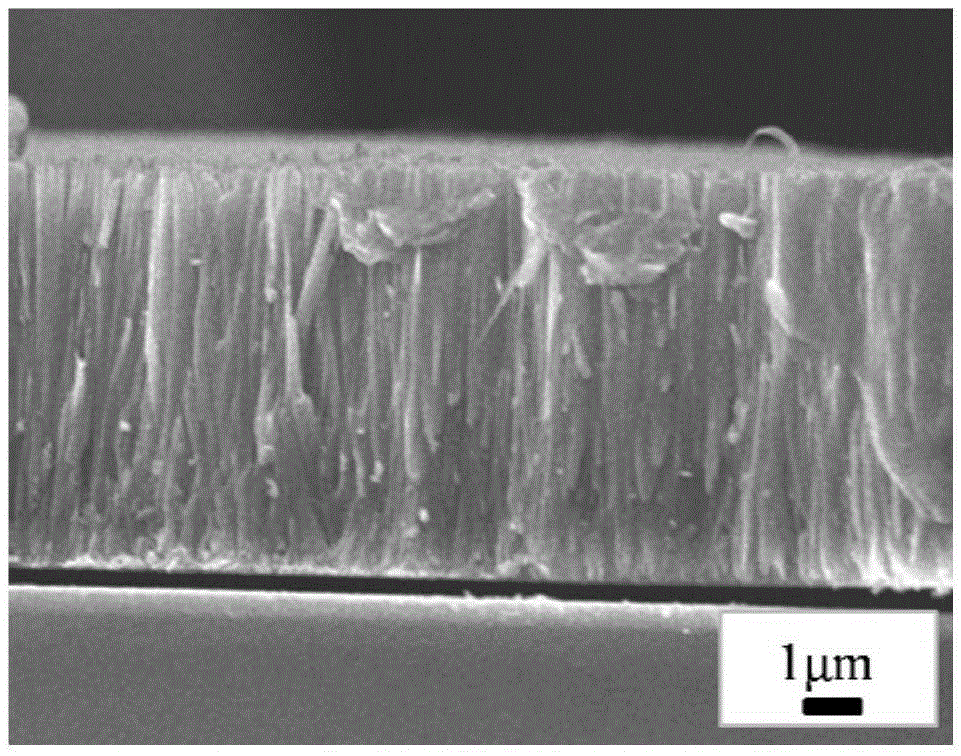

Intermediate-temperature solid oxide fuel cell one-dimensional nano composite cathode and preparation method thereof

ActiveCN102623716ALower polarization resistanceLow costMaterial nanotechnologyCell electrodesHigh resistanceElectrolysis

Disclosed are an intermediate-temperature solid oxide fuel cell one-dimensional nano composite cathode and a preparation method thereof, which relate to an intermediate-temperature solid oxide fuel cell cathode and a preparation thereof and resolve the technical problem of high resistance of exiting lanthanum strontium cobalt ferrite (LSCF) / gadolinia doped ceria (GDC) composite powder cathode polarization. Ce0.8Gd0.2O1.9 electrolyte sheets serve as a matrix of the cathode, the surface of the cathode is coated with nano rod shaped La0.8Sr0.2Co0.2Fe0.8O3 powder, and Ce0.8Gd0.2O1.9 nano granules are attached to a nano rod. The preparation method includes the steps of preparing nitrate to be a precursor solution, sintering after electrostatic spinning, obtaining nano rod shaped powder, coating the powder on electrolyte sheets for sintering, permeating a mixture liquid of gadolinium nitrate and cerium nitrate, and obtaining products after sintering; or mixing LSCF nano rod shaped powder and Ce0.8Gd0.2O1.9 nano powder to coat on electrolyte sheets for sintering, and obtaining products. The cathode and the preparation method thereof are used for intermediate-temperature solid oxide fuel cells.

Owner:HARBIN INST OF TECH

Method for preparing powder material with electrochemical cathode

ActiveCN103233246AA new and convenient method for preparing powder materialsAtomic clusterLithium-ion battery

The invention relates to the field of new materials, and discloses a method for preparing a powder material with an electrochemical cathode. By using an inert electrode as an anode, a massive metal, semiconductor and alloy as a cathode, and a lithium salt / sodium salt / quaternary ammonium salt organic solution, pyrrole, quaternary ammonium salt or piperidine ionic liquid or strongly alkaline water solution as an electrolyte, strong cathode polarization is carried out under constant voltage; under the action of the strong cathode voltage, the massive metal, semiconductor and alloy surface forms an unstable intermediate Mx+Ny- (M+ is an electrolyte cation, and N represents metal, semiconductor or alloy) and becomes corroded; the intermediate is very unstable in the electrolyte, and is quickly decomposed to generate an atomic cluster; the atomic cluster continues aggregate to obtain a nanoparticle sol; and finally, the sol is centrifuged / washed, and dried to obtain the powder material. The prepared powder material can be widely used in the fields of lithium ion batteries, supercapacitors, (electric) catalysis, biosensing, photovoltaic devices, micro-electronics and the like.

Owner:CENT SOUTH UNIV +1

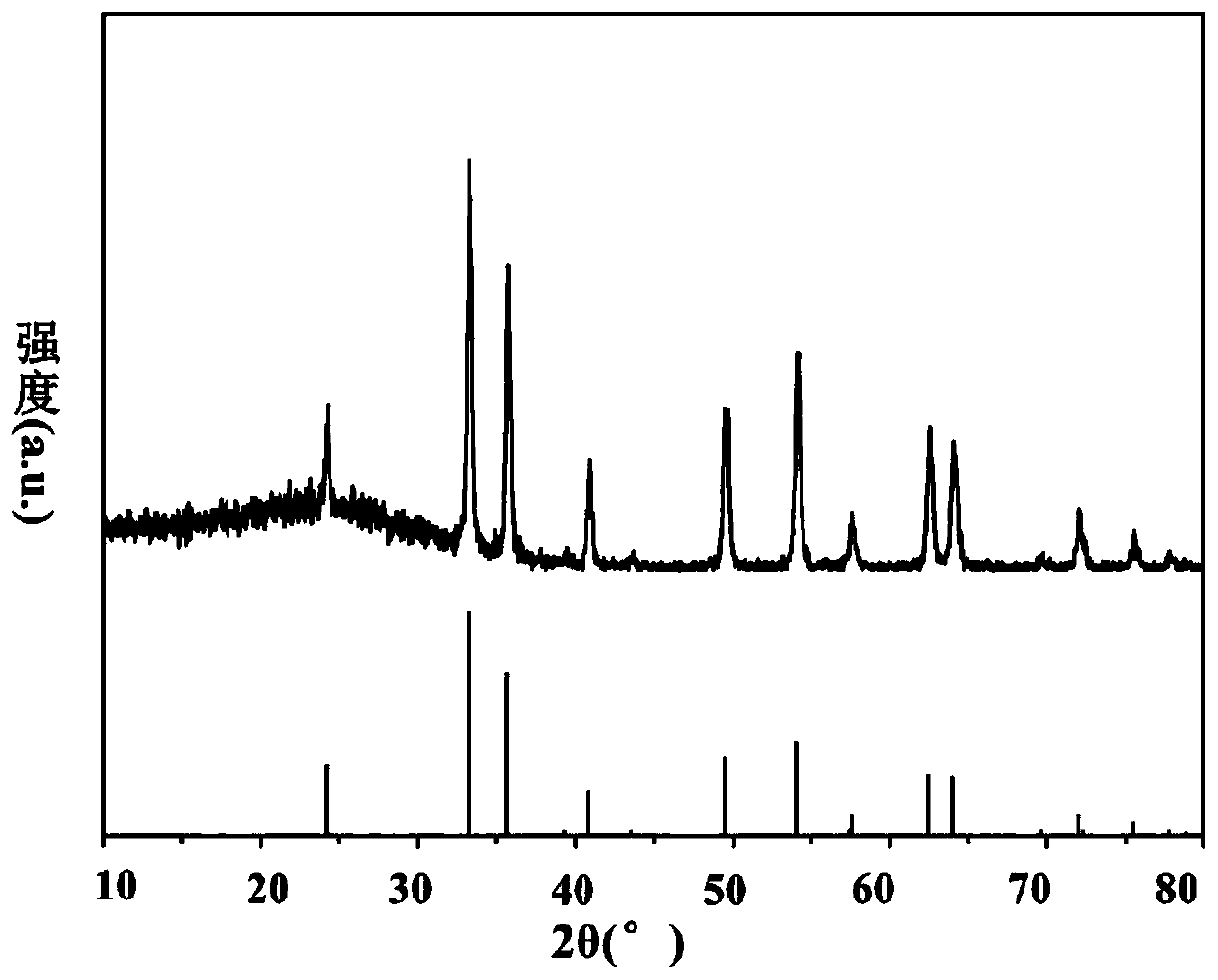

Mo2C/C nano composite material as well as preparation method thereof and lithium carbon dioxide battery cathode comprising Mo2C/C nano composite material as well as reparation method thereof

InactiveCN108808021AAlleviate Positive PolarizationEasy transferMaterial nanotechnologyFuel and secondary cellsLithiumHydrogen

The invention relates to a Mo2C / C nano composite material as well as a preparation method thereof and a lithium carbon dioxide battery cathode comprising the Mo2C / C nano composite material as well asa preparation method thereof, and belongs to the technical field of electrochemical energy. Ammonium molybdate is taken as a molybdenum source, and citric acid is taken as a carbon source to prepare the Mo2C / C nano composite material by utilizing reducing characteristics of hydrogen gas. A lithium carbon dioxide battery cathode plate is prepared through a coating method, the Mo2C / C nano compositematerial and PVDF are mixed as coating slurry for being coated on a current collector, so as to obtain the lithium carbon dioxide battery cathode containing the Mo2C / C nano composite material. The lithium carbon dioxide battery cathode containing the Mo2C / C nano composite material effectively relieves the battery cathode polarization problem, and reduces the charging over-potential of a lithium carbon dioxide battery, so that the lithium carbon dioxide battery can stably and efficiently operate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

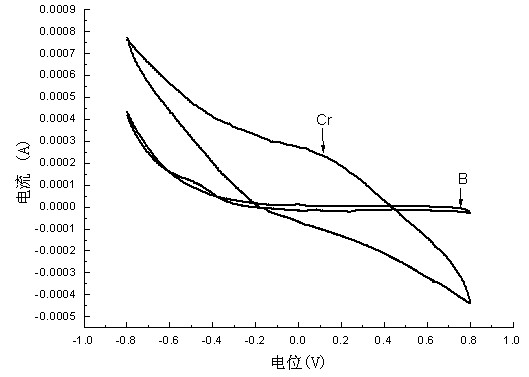

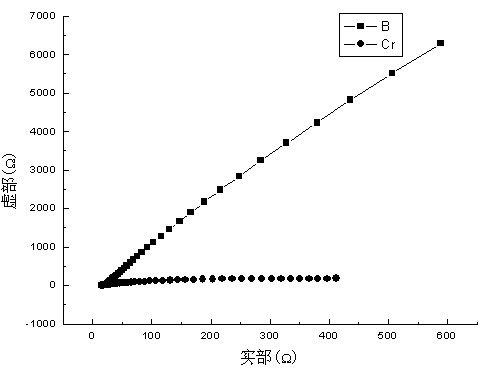

Surface modification method of carbon material and application thereof in microbial fuel cell

The invention discloses a surface modification method of a carbon material and application thereof in a microbial fuel cell. In the preparation method, the carbon material is subjected to surface modification treatment by using strong oxidative metal acid radical salt (such as potassium dichromate and the like), the surface characteristics of the carbon material are changed, and a microbial fuel cell cathode is prepared and applied to the microbial fuel cell. Compared with a noble metal catalyst such as platinum and the like, the strong oxidative metal acid radical salt modified carbon electrode material is low in price and greatly reduces the constructive cost of the microbial fuel cell; and compared with the unmodified carbon electrode, the strong oxidative metal acid radical salt modification can greatly improve the oxygen reduction rate of the cathode, reduce the polarization of the cathode and improve the electricity generation power of the cell. The application of the strong oxidative metal acid radical salt modified carbon electrode remarkably reduces the constructional cost of the microbial fuel cell, and good foundation and path are provided for the commercial application of the microbial fuel cell.

Owner:EAST CHINA UNIV OF SCI & TECH

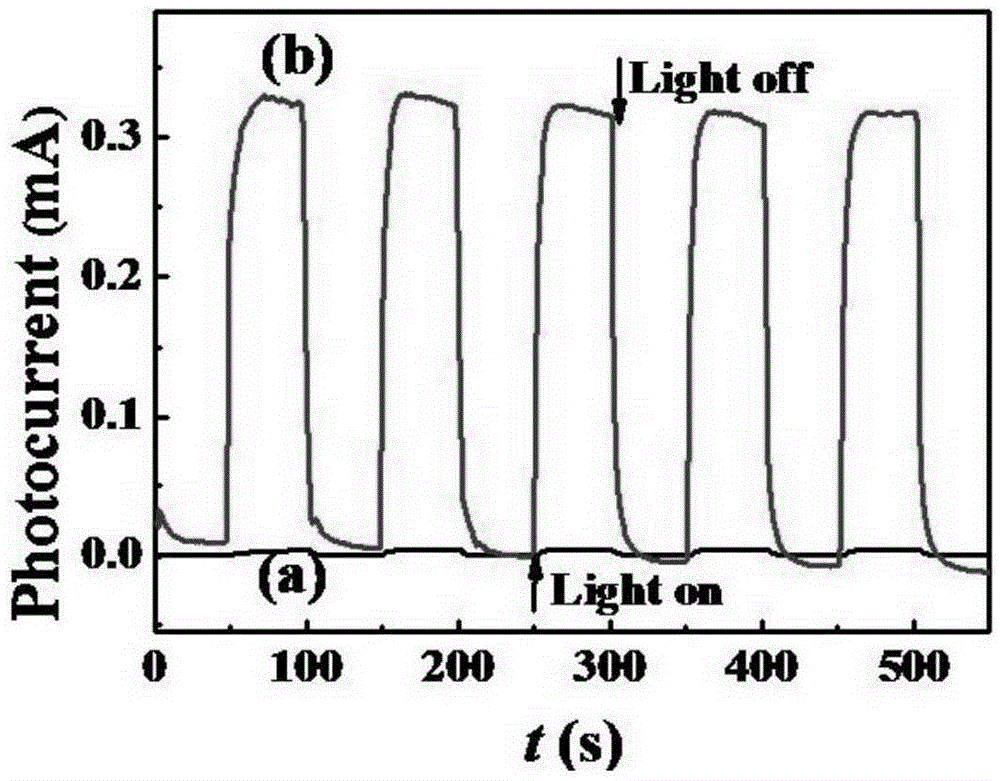

Method for preparing Bi2S3/TiO2 nanorod composite-film photo-anodes

InactiveCN105386061AOvercome effectivenessOvercoming the problem of easy recombination of photogenerated carriersElectrode potentialComposite film

The invention relates to a nanorod composite-film photo-anode, in particular to a method for preparing a Bi2S3 / TiO2 nanorod composite-film photo-anode. The method includes the steps of preparing a TiO2 seed film sample, preparing an FTO surface TiO2 nanorod array film, and preparing the Bi2S3 / TiO2 nanorod composite-film photo-anode. A hydrothermal method and a circulation dipping method are combined; and when a prepared Bi2S3 / TiO2 nanorod composite film is arranged in a mixed solution of Na2S of 0.1 mol / L and NaOH of 0.2 mol / L, and irradiation is carried out through white light, the electrode potential of 403# stainless steel, connected with the Bi2S3 / TiO2 nanorod composite film, in a NaCl solution of 0.5 mol / L can be reduced by 725 mV relative to the natural corrosion potential of the stainless steel, remarkable cathode polarization occurs, and it is indicated that the composite film has the good photoproduction cathode protection effect on the stainless steel. When irradiation is carried out again after illumination is stopped for a certain period of time, the electrode potential can still be reduced to a value the same as the previous value, and good stability is achieved.

Owner:XIAMEN UNIV

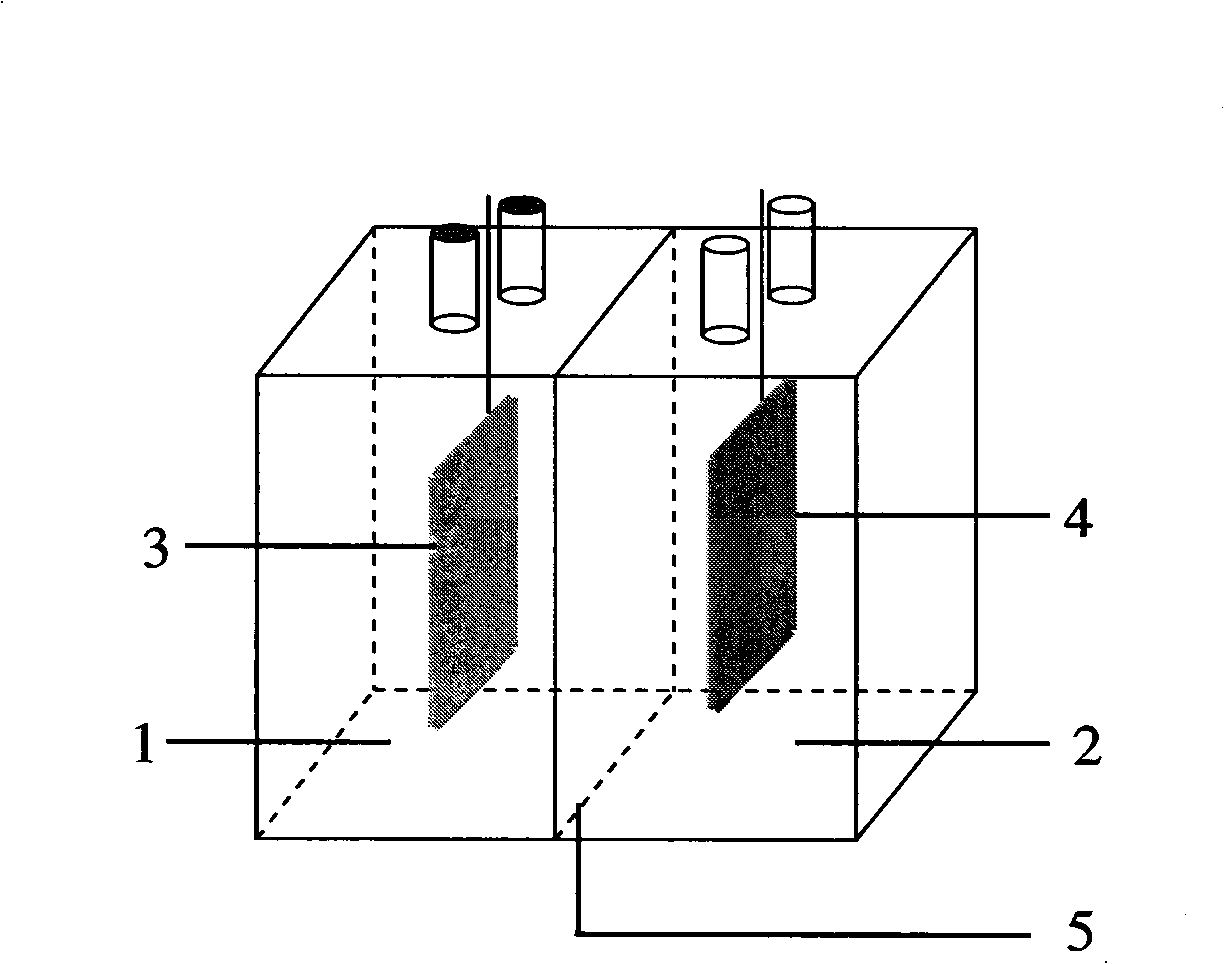

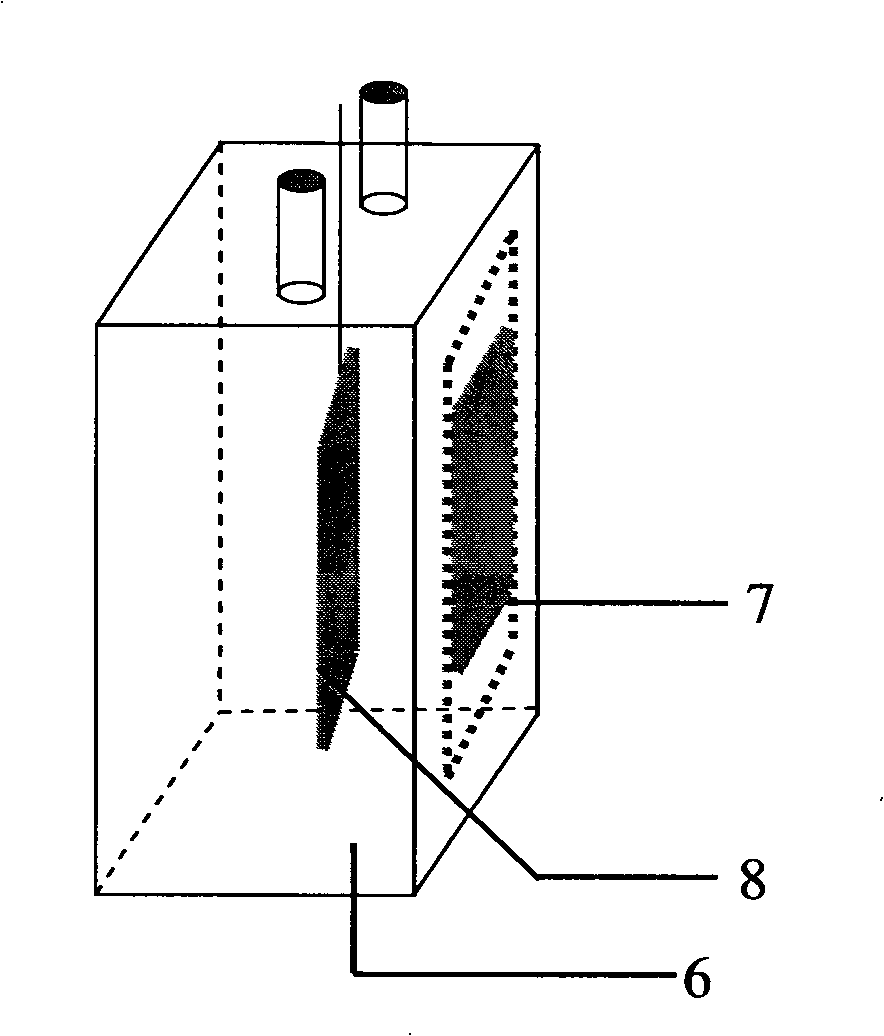

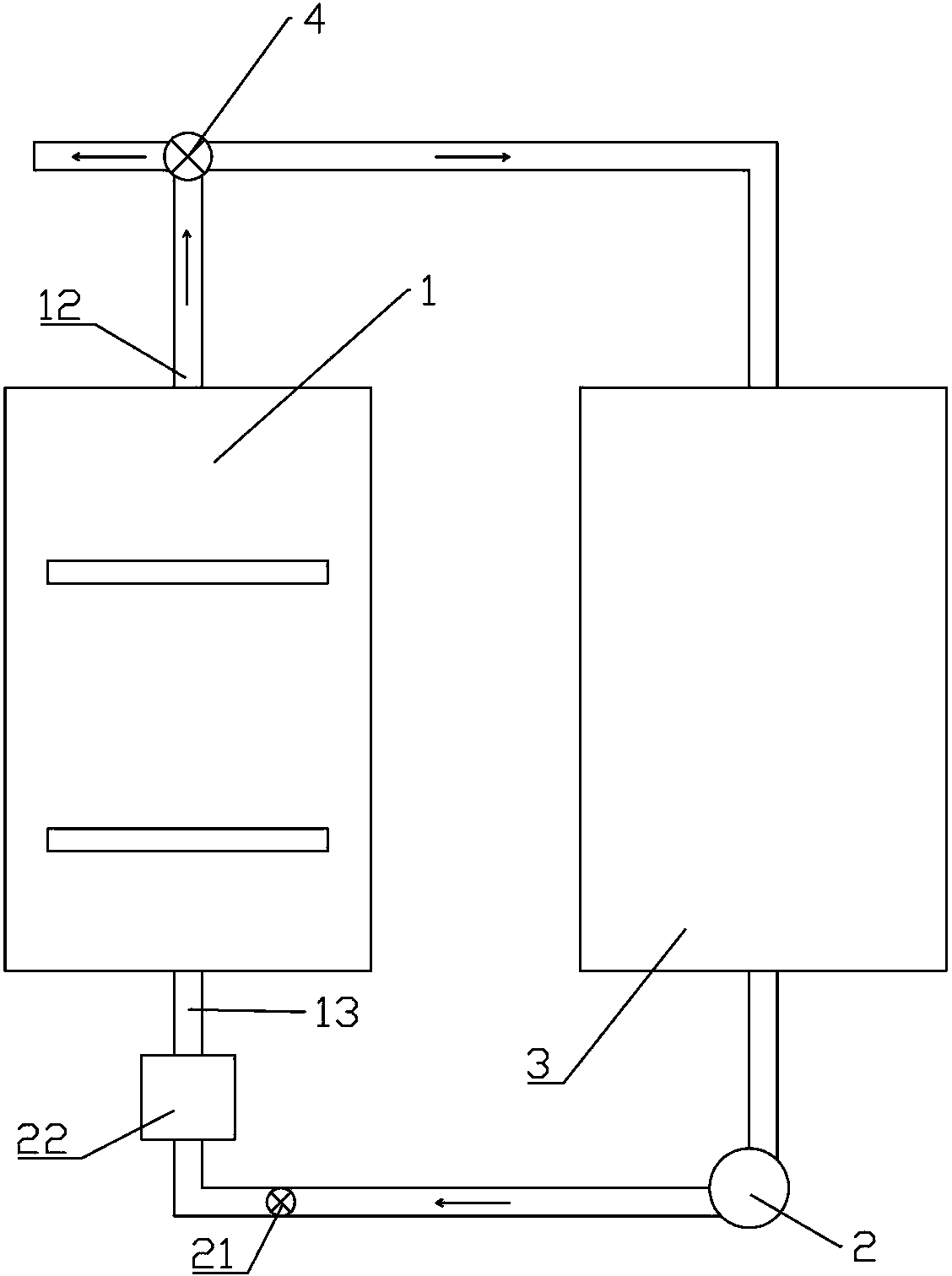

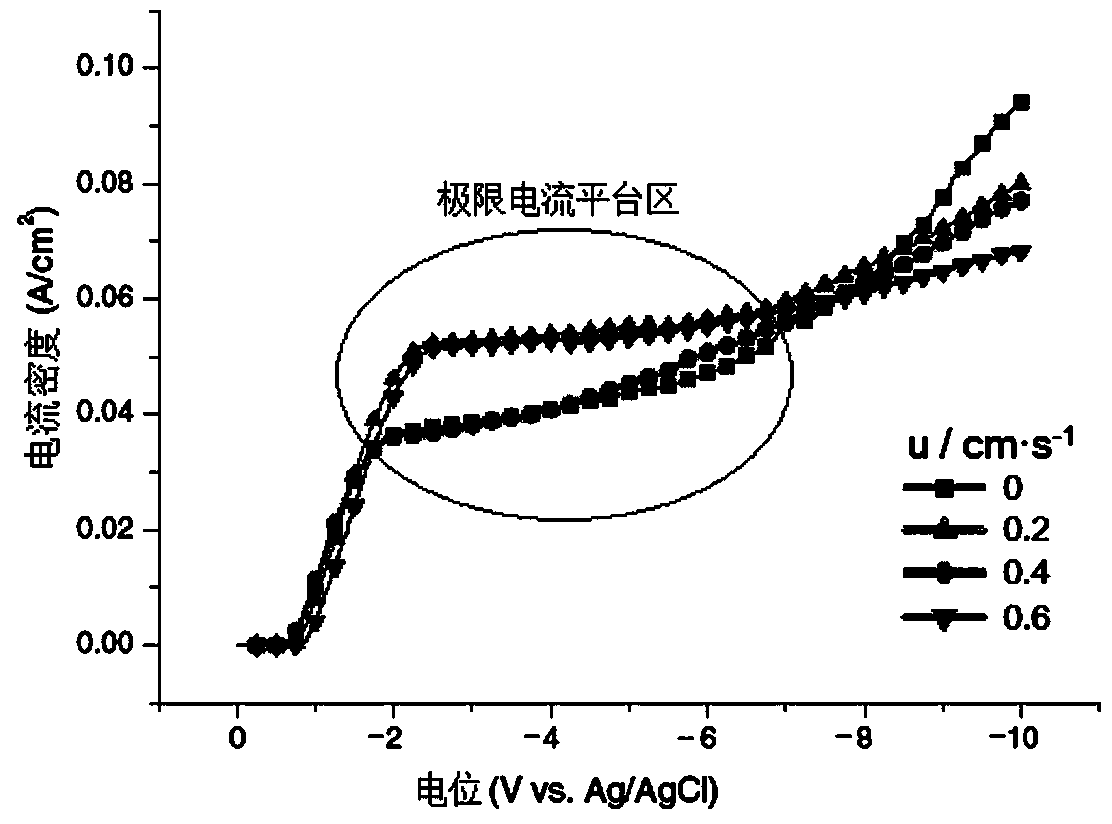

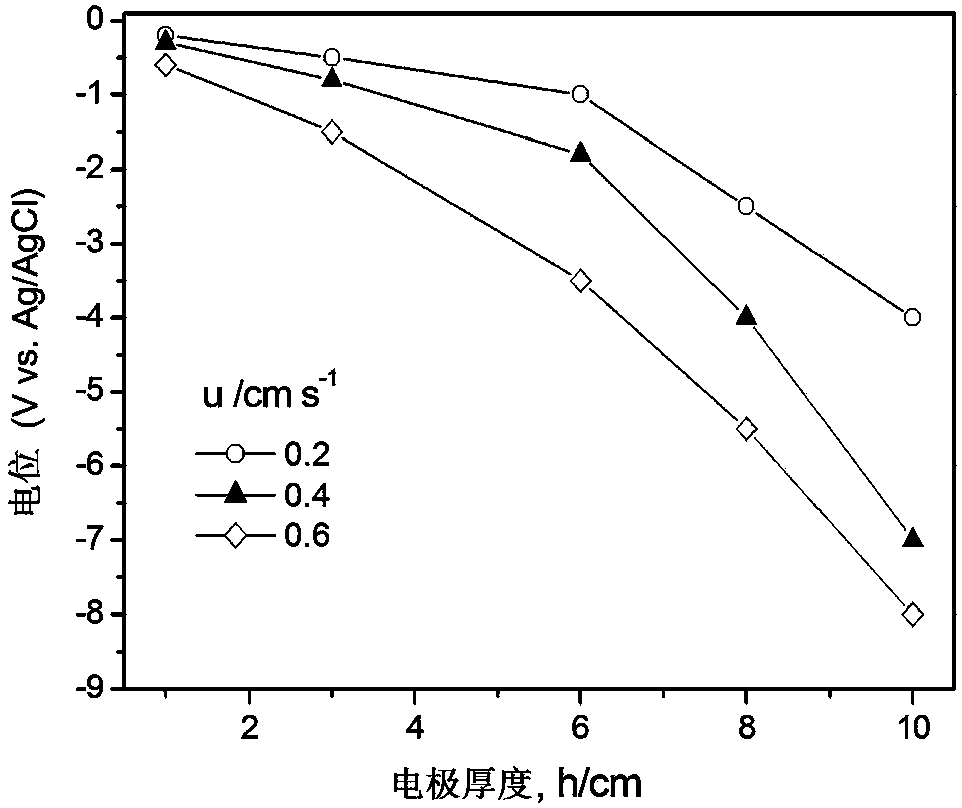

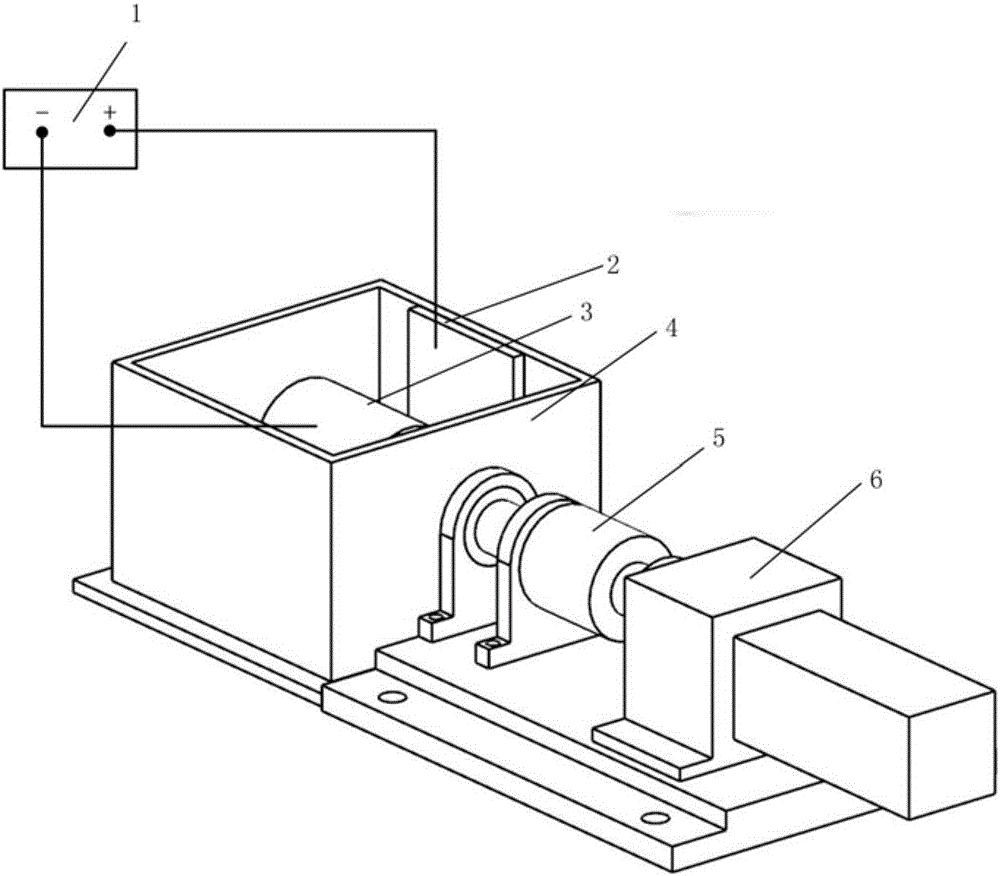

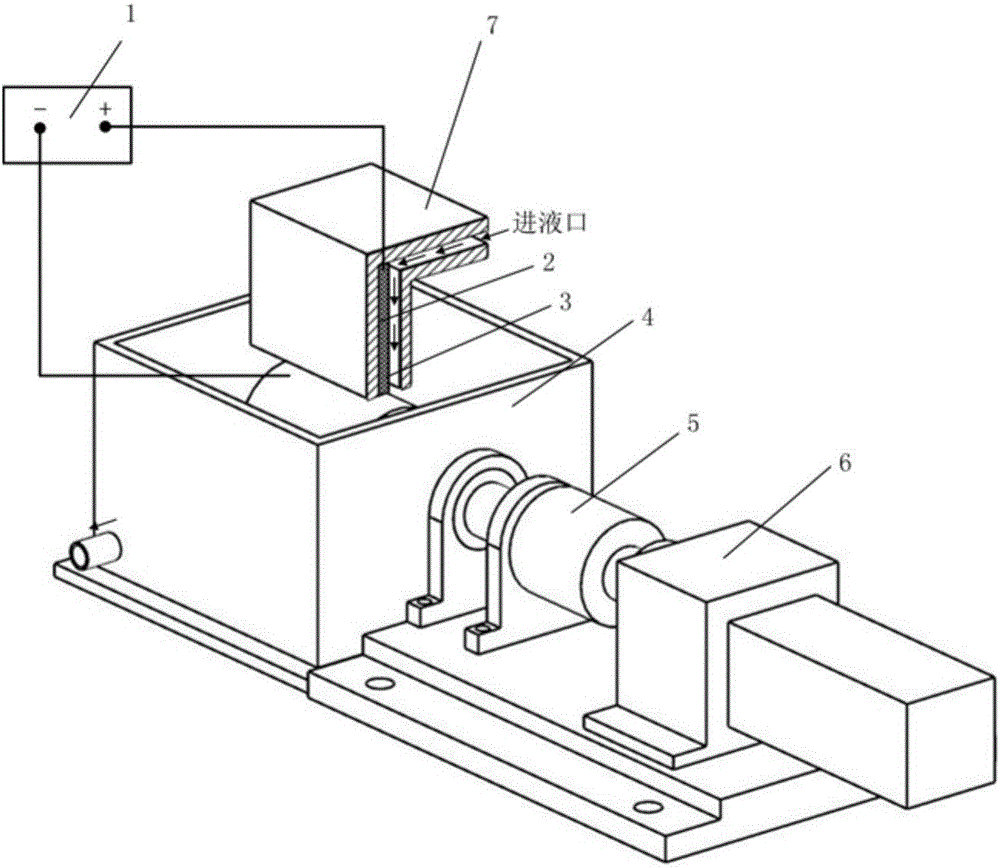

Electrochemical surface treatment method and electrochemical surface treatment device for porous metal material

ActiveCN103710735AUniform treatment effectEasy to handleElectrolytic inorganic material coatingElectrolytic agentMetallic materials

The invention discloses an electrochemical surface treatment method and an electrochemical surface treatment device for a porous metal material. The method comprises the following steps: on the basis of applying a compact metal material which is the same as a to-be-treated porous metal material as a working electrode, utilizing an electrochemical working station to measure a steady-state cathode polarization curve of the compact metal material in the working electrolyte, determining a platform zone of a current-potential curve, and obtaining limitation diffusion-controlled electrochemical treatment condition of electro-deposition reaction; on the basis of applying to-be-treated porous metal material as a working electrode, enabling the working electrolyte to perform single-direction or circulating flow in an electrolytic cell; applying the determined limitation diffusion-controlled electrochemical treatment condition to carry out electrochemical surface treatment on the porous metal material until a set value is reached. The electrochemical surface treatment method disclosed by the invention can be used for treating the inner surface of the porous metal material more effectively, so that the outer-layer surface and inner-layer surface of the porous structure of the metal material are more uniform in treatment effect, and therefore, a better electro-deposition treatment effect or electro-polishing effect is obtained.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

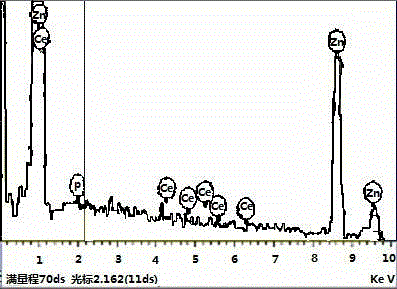

Method for preparing cerium-containing zinc coating

InactiveCN102719864AEasy maintenanceChanged cathodic polarization behaviorPhosphorous acidDC - Direct current

The invention discloses a method for preparing cerium-containing zinc coating. The method comprises the following main steps: (1) sulfate plating solution for ions to be plated is prepared, wherein the concentration of zinc sulfate is 50-300g / L, and the concentration of cerium sulfate is 0.2-4g / L; sodium citrate serving as rare earth complexing agent, with the concentration of 5-60g / L is added, and sodium hypophosphite with the concentration of 5-60g / L is added; dilute sulfuric acid is adopted to adjust the pH value of the plating solution to be 1-4; the temperature of the plating solution is controlled to be 15-60 DEG C; (2) the direct current electrodeposition method is adopted for plating; in a plating bath containing the plating solution, carbon steel used as the plated material is used as the cathode, a platinum sheet is adopted as the anode, direct current is introduced to the plating bath, the current density is 0.6-4 A / cm<2>, and the plating time is 1-6 min; and finally, the concentration of cerium in the prepared coating is 0.05-0.3 wt%. Aiming at the sulfate system of the DC (direct current) electrodeposition zinc coating, the sodium citrate and the sodium hypophosphite as the substances are adopted for promoting the deposition of cerium, so that the cathodic polarization behavior of cerium in deposition can be improved, the zinc coating containing trace cerium is finally obtained, and the corrosion resistance of the coating is obviously improved.

Owner:SHANGHAI UNIV

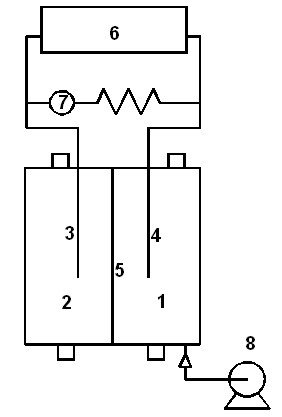

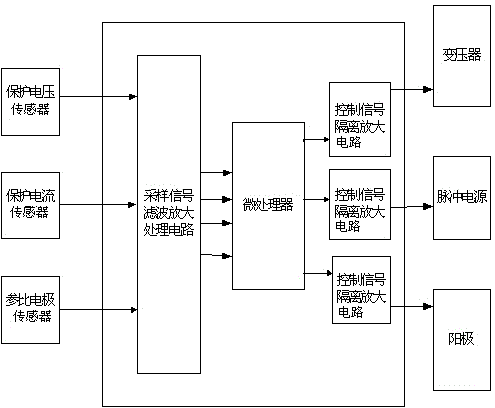

Oil casing pipe cathode protecting system based on pulse current power supply and building method thereof

InactiveCN104532263ASolve the problem that the short transmission distance makes it difficult to extend the protection depthImprovement of uneven current distribution and pitting corrosionThermodynamicsElectron flow

The invention discloses an oil casing pipe cathode protecting system based on pulse current power supply and a building method thereof. The oil casing pipe cathode protecting system comprises an oil well casing pipe. The oil well casing pipe is connected with an anode well system through a pulse power source. The oil well casing pipe is connected with a potential detector. The potential detector is connected with a reference electrode. When the oil well casing pipe carries out pulse current cathode protection, an anode is continuously dissolved, a large number of electrons are produced to continuously flow into the surface of the casing pipe through the stratum, and the electrons flowing into the surface of the casing pipe are gathered on the surface of the casing pipe, so that the potential on the surface of the casing pipe moves in the negative direction, and cathode polarization is produced. The capability of electrons released by a micro anode area on the surface of the oil well casing pipe is restrained; in addition, the larger the pulse current is, the more electrons are gathered, the more negative the potential on the surface of the casing pipe is, the weaker the electrons released by the micro anode area are; when potential polarization reaches a certain value, surface anode and cathode areas are equipotential, and corrosion is stopped. The potential detector monitors the protecting potential on the surface of the oil well casing pipe in real time through a protecting potential sensor, the protecting effect and the energy-saving effect are achieved, and the protecting depth of the oil well casing pipe is increased.

Owner:XI'AN PETROLEUM UNIVERSITY

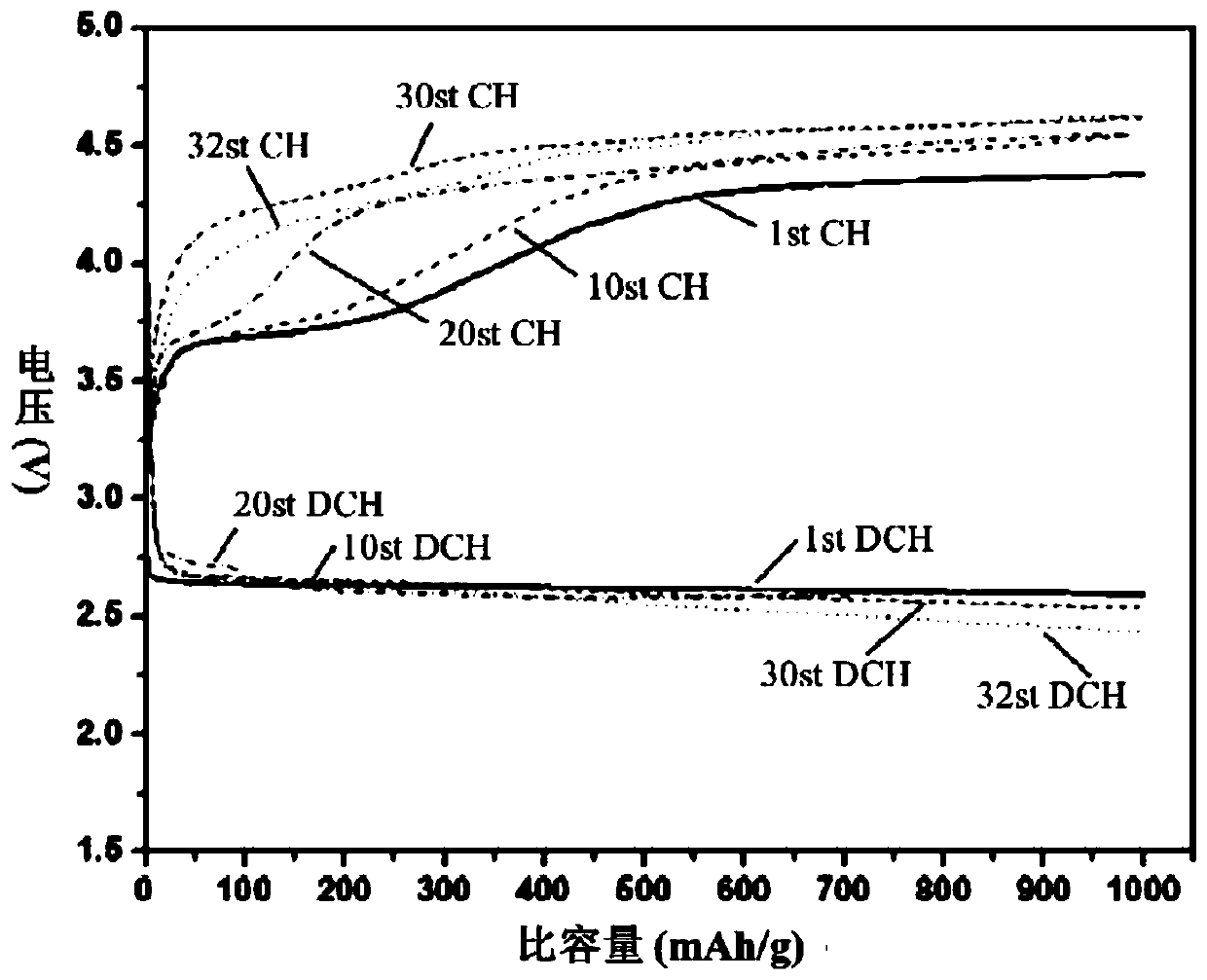

Lithium carbon dioxide battery cathode and preparation method thereof

ActiveCN109768287ALarge apertureEvenly distributedFuel and secondary cellsCell electrodesLithiumActive site

The invention relates to a lithium carbon dioxide battery cathode and a preparation method thereof. The lithium carbon dioxide battery cathode comprises a current collector and an electrode material layer disposed on the current collector, wherein the electrode material layer comprises three-dimensional pore structure metal compounds, a carbon material and a bonding material. By providing three-dimensional pore structure metal compounds in the electrode material layer, the lithium carbon dioxide battery cathode and preparation method thereof have the advantages that on the one hand, the three-dimensional pore structures make a larger specific surface area and more reactive active sites, thereby imparting good electrochemical performance to the lithium carbon dioxide battery; and on the other hand, the three-dimensional pore structure metal compounds have a large pore size and are uniformly distributed, which is favorable for ion transport in the electrolyte and diffusion of carbon dioxide gas to impart a good cycle life of the lithium carbon dioxide battery cathode and reduce the cathode polarization. The provision of the carbon material in the material layer can impart good electrical conductivity to the lithium carbon dioxide battery cathode, and further improve the electrochemical performance of the lithium carbon dioxide battery.

Owner:浙江硕亚油脂化工有限公司

Copper foil manufacturing process and negative current collector

ActiveCN109950546AGood adhesionImprove bending resistanceElectrode manufacturing processesElectrode carriers/collectorsHigh current densityElectrochemical response

The invention relates to the technical field of copper foils, in particular to a copper foil manufacturing process and a negative current collector. The manufacturing process comprises the following steps: (1) heating electrolyte solution; (2) adding an additive into the electrolyte; (3) carrying out electrochemical reaction; (4) stripping the copper layer from a titanium cathode. In the additive,gelatin plays an adsorption role and promotes the deposition of copper on the cathode; polyethylene glycol and hydroxyethyl cellulose are used as a surfactant combination, so that the current efficiency can be improved, and the particle size distribution range of copper is narrowed; triethanolamine and polyacrylamide can be adsorbed at the cathode, have a stronger cathode polarization effect, andcan enhance the inhibition effect of a high-current density region during copper deposition in cooperation with SPS (Sodium Polydithiodipropyl Sulfonate). Under the action of the additive, the prepared copper foil and the negative electrode slurry layer have good cohesiveness, and the cycle performance of the lithium battery can be improved.

Owner:HUBEI ZHONGYI TECH

Cathode material with composite phase structure of intermediate-low-temperature solid oxide fuel cell

PendingCN105932299AOptimizing the Oxygen Ion Transport PathwayImprove behaviorCell electrodesFuel cellsOxygen ions

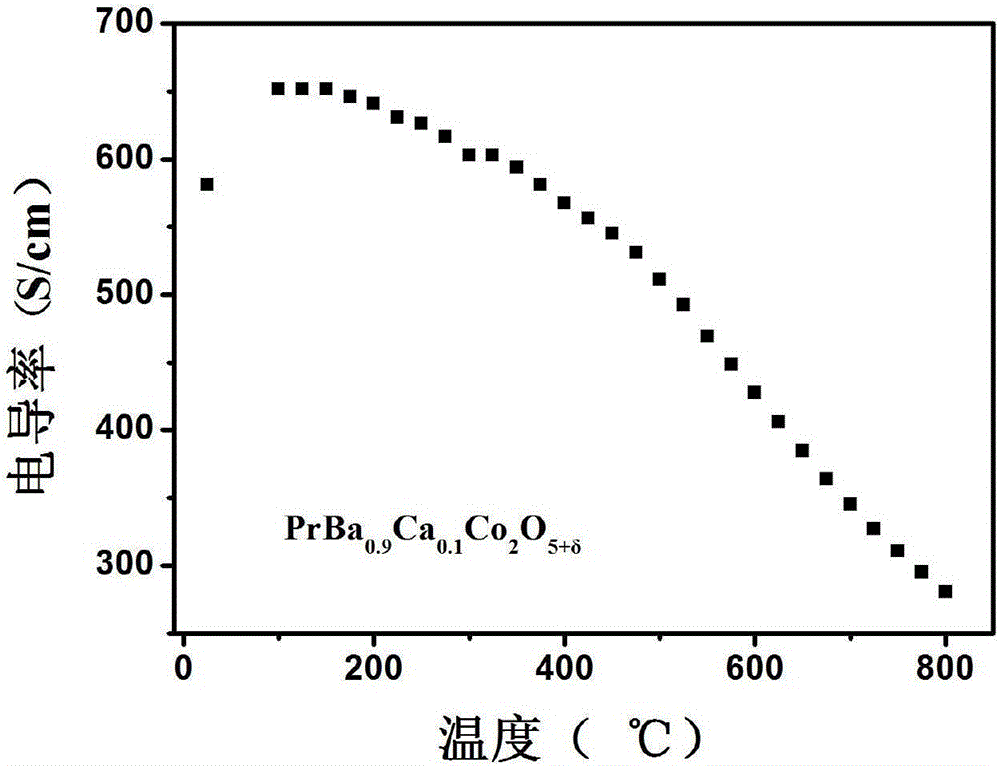

The invention provides a cathode material with a composite phase structure of an intermediate-low-temperature solid oxide fuel cell. The general formula of the cathode material is PrBa<1-x>Ca<x>Co<2>O<5+<delta>>, wherein x is greater than or equal to 0.001 and less than or equal to 1.0. According to the cathode material of the fuel cell provided by the invention, the calcium doping amount is optimized to optimize the oxygen ion transport path and behavior in the material so as to improve the oxygen catalytic reduction property of the material used as the cathode material of the intermediate-low-temperature solid oxide fuel cell (SOFC); the polarity impendence of the PrBa<1-x>Ca<x>Co<2>O<5+<delta>> (x is equal to 0.3) with the composite phase structure at a temperature of 600 DEG C is only 0.15<omega>.cm<2>, which is only 32% of that of the original sample; therefore, the requirement of the solid oxide fuel cell on the cathode polarity impedance can be satisfied; meanwhile, the cathode material is relatively high in conductivity; the conductivity of the material in the air at a temperature of 25 DEG C is not less than 500S / cm; and the conductivity of the material at a temperature of 25-800 DEG C is not less than 240S / cm, so that the requirement of the solid oxide fuel cell on the cathode conductivity (100S / cm) can be completely satisfied.

Owner:JIANGSU UNIV

Intermediate-temperature solid oxide fuel cell (LSCF) cathode material with brownmillerite structure

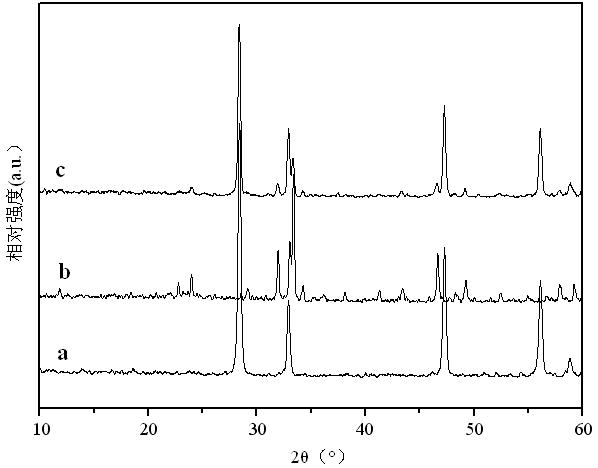

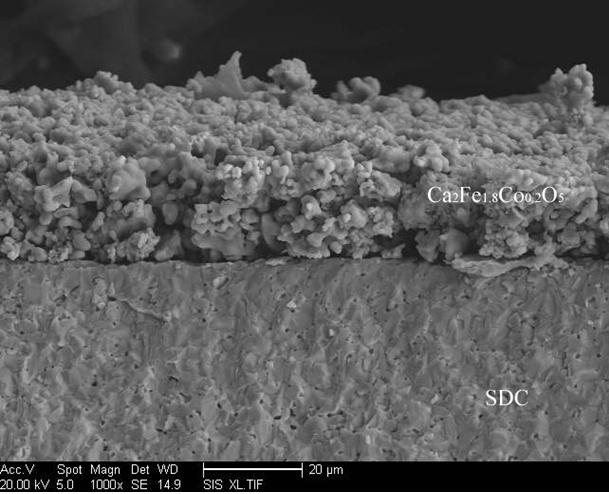

InactiveCN101794885AGood heat matchingHigh oxygen ion-electron mixed conductivityCell electrodesAlkaline earth metalThermal expansion

The invention relates to an intermediate-temperature solid oxide fuel cell (LSCF) cathode material with a brownmillerite structure, which belongs to the field of intermediate cathode materials. The invention solves the problem that the traditional cathode material is not suitable for working at moderate temperature. The product has the general formula of A2Fe2-xMxO5+ / -delta, wherein A is main group alkaline-earth metal, M is a transition metal element, x is larger than 0.1 and smaller than 1.0, and delta is equal to 0-0.01. The product expresses high oxygen ion and electron mixed electrical conductivity and low electrode polarization resistance at 500-800 DEG C, and a cathode polarization overpotential numerical value is smaller than that of the LSCF cathode material with a brownmillerite structure. The material is used as a cathode and expresses favorable thermal and chemical stability and oxygen catalytic reduction property below 800 DEG C. The product has a thermal expansion coefficient approaching to a solid electrolyte SDC material and is suitable for being used as a cathode material of the LSCF.

Owner:HEILONGJIANG UNIV

Method for grafting and growing a conductive organic film on a surface

ActiveUS7736484B2Improve conductivityHigh specific strength of interfaceSurface reaction electrolytic coatingElectrophoretic coatingsElectricityOrganic film

The present invention relates to a process for grafting and growing a conductive organic film on(to) an electrically conductive or semiconductive surface in which the grafting and growing of the film are performed simultaneously by electro-reduction of a diazonium salt that is a precursor of the said film on(to) the said surface cathodically polarized at a potential greater than or equal, in absolute value, to the electro-reduction potential of the diazonium salt relative to a reference electrode.The invention finds an application especially in the protection of surfaces, the manufacture of localized conductive coatings, of chemical sensors in the fields of chemistry and molecular biology, the manufacture of biomedical equipment, etc.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

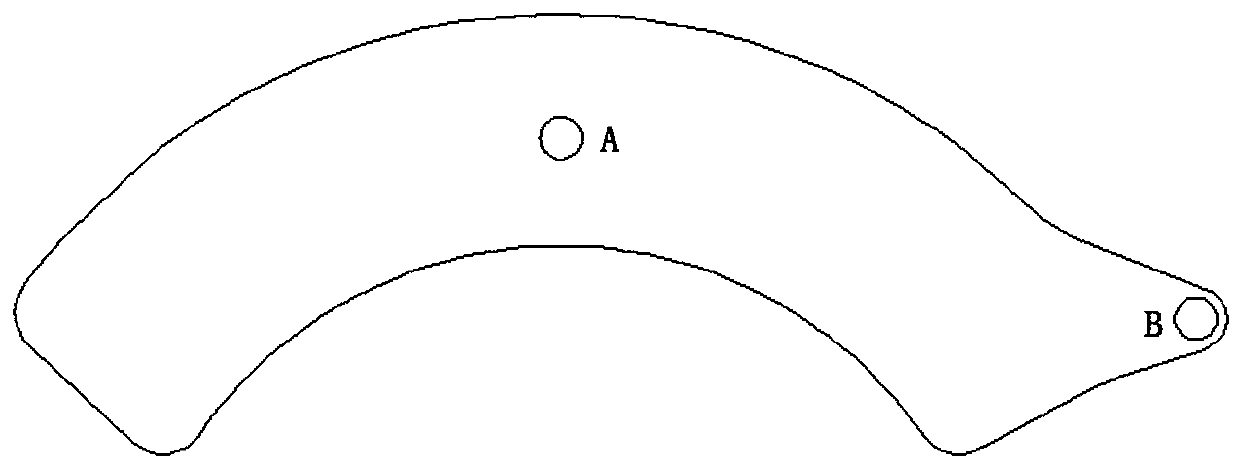

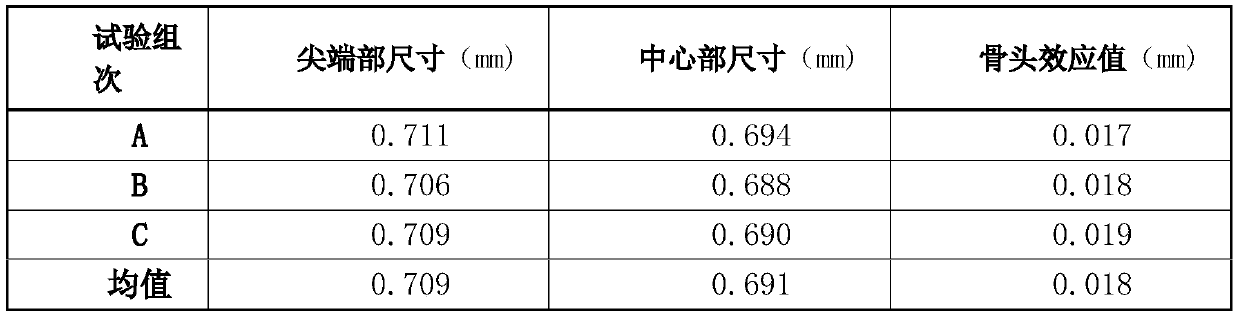

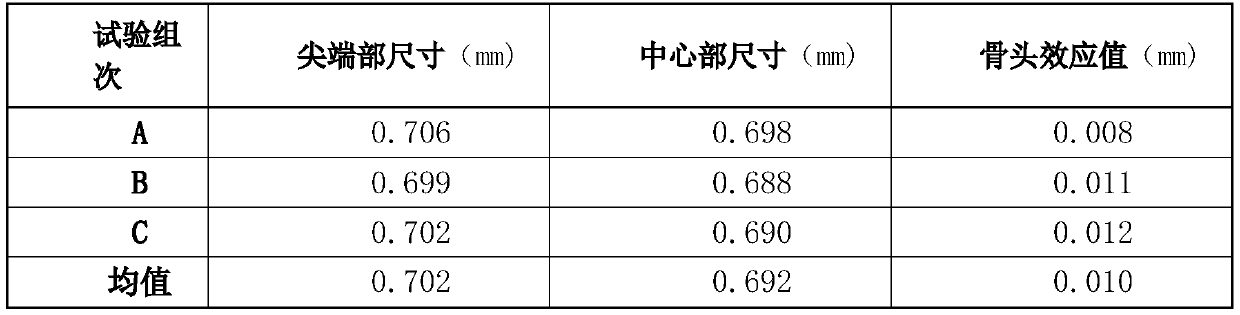

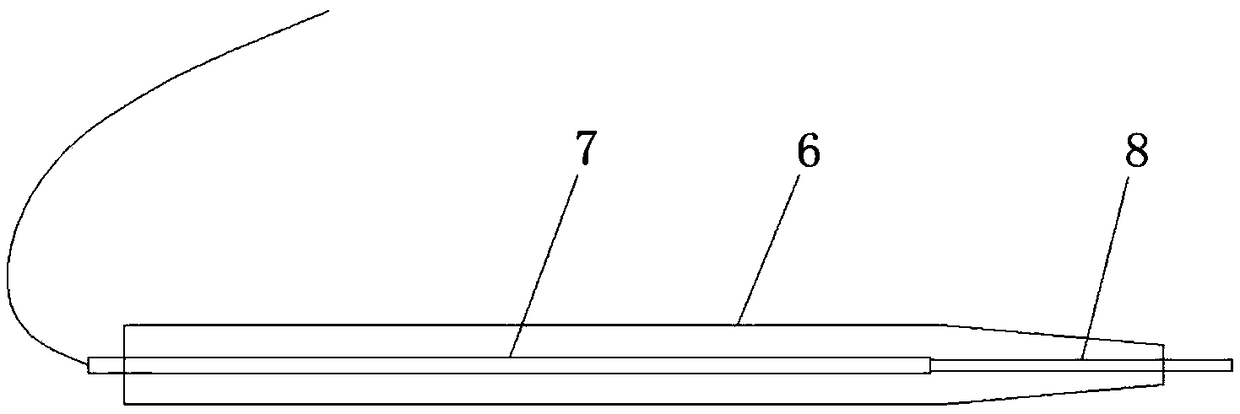

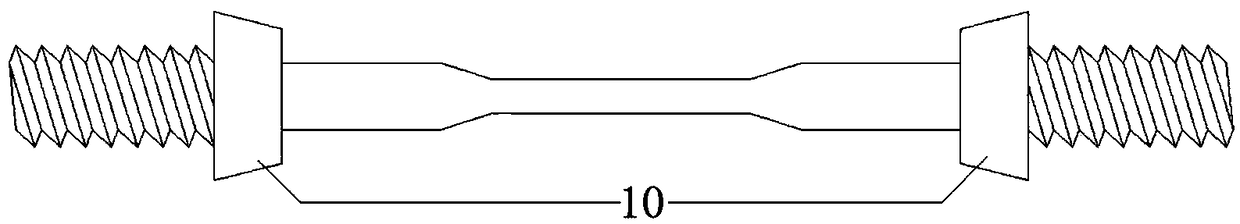

Crevice-corrosion-avoiding sample packaging method and structure in stainless steel pitting study

ActiveCN104990962AUndamagedAccurate electrochemical measurementsPreparing sample for investigationMaterial electrochemical variablesCathode polarizationCrevice corrosion

The invention provides a crevice-corrosion-avoiding sample packaging method in stainless steel pitting study. The method comprises the steps of working electrode cutting, prepassivation processing, packaging and passivation film removing. The method is characterized in that in the packaging step, before packaging materials are used for packaging a working electrode of a sample, a film adheres to the center of the working face of the working electrode, film is smaller than the working face of the working electrode, so that the edge where the film does not adhere is reserved on the periphery of the working face of the sample working electrode, after the packaging step is over, the film is removed, and in the passivation film removing step, a cathode polarization method is used for removing a passivation film. The invention further provides a crevice-corrosion-avoiding sample packaging structure in stainless steel pitting study.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID +1

Nickel-phosphorus alloy electroplating solution and use method thereof

The present invention discloses a nickel-phosphorus alloy electroplating solution. The solution comprises the following components: 200-250 g / L of nickel sulfate, 35-45 g / L of nickel chloride, 38-42 g / L of boric acid, 50-70 g / L of Sodium hypophosphite, 34-47 g / L of ammonium bifluoride, 1-2 g / L of a soluble salt of rare earth and 0.08-0.12 g / L of a surfactant. According to the present invention, a certain amount of rare earth elements are added to the electroplating solution of the present invention so as to significantly improve properties of the electroplating solution, the cathode polarizability during the electrodeposition process can be improved, the resulting electroplating layer has characteristics of compactness, uniformity, good bonding force, high hardness and excellent corrosion resistance, wherein the improved properties of the electroplating solution comprise improvement of current efficiency and improvement of dispersing ability.

Owner:GUANGZHOU HAIZHU DISTRICT JINSUIDA SURFACE TECH DEV CENT

Composite sacrificial anode

The invention relates to a composite sacrificial anode and belongs to the technical field of material protection. The composite sacrificial anode is prepared from 5.0wt%-35.0wt% of active metal particles, 5.0wt%-15.0wt% of n-type oxide, 3.0wt%-6.0wt% of double hydroxide, 0.5wt%-3.0wt% of a coupling agent, 1.0wt%-3.0wt% of a sulfhydryl compound and the balance of acrylic resin. The composite sacrificial anode can generate free electrons under the condition of natural illumination and can strengthen the polarization effect on a cathode of a protected metal material, compared with ordinary sacrificial anodes, the composite sacrificial anode has the advantage that consumption of the active metal particles can be reduced or delayed, and the material cost and the maintenance cost can be saved.

Owner:QUANZHOU ZHENJIANG SPORTS GOODS CO LTD

Method for oxidizing cultural relics in ironware

This invention describes a process for the dechlorination of iron antiquities, comprising the steps of: adding a cleaning agent and an amine inhibitor to an alkaline solution to prepare an alkaline dechlorination cleaning solution, and carrying out the cathode polarization dechlorination of iron antiquities in the said solution at a constant electric potential. This invention overcomes such problems as a certain degree of corrosion existing in the traditional dechlorination processes for iron antiquities or the damage to the intrinsic appearances of iron antiquities led by the abscission of the rusty layer resulting from hydrogen evolution caused by high local current in the electrochemical reduction method, and provides a rapid, effective and more protective process for the dechlorination of iron antiquities.

Owner:BEIJING UNIV OF CHEM TECH

Double-face light ultrathin electrolytic copper foil for lithium battery and preparing method of double-face light ultrathin electrolytic copper foil

ActiveCN109082688AUniform thicknessReduce warpageElectrode carriers/collectorsElectroforming processesElectrolysisCopper foil

The invention belongs to the technical field of electrolytic copper foil production, and particularly relates to double-face light ultrathin electrolytic copper foil for a lithium battery and a preparing method of the double-face light ultrathin electrolytic copper foil. The method comprises the following steps that a titanium anode coated with a platinum family metal element or oxide of the platinum family metal element and a titanium cathode barrel are provided; the titanium anode and the titanium cathode barrel are immersed in a pretreatment composition containing gelatin and one or more organic sulfide sulfonate; anode polarization and cathode polarization are used for activating the surface of a titanium cathode; and a copper electrolyte is utilized for preparing the electrolytic copper foil on the activated surface of the titanium cathode. According to the method, the more uniform and cleaner titanium anode and the more uniform and cleaner titanium cathode are provided, the pretreatment composition wraps the surface of a base body before electrolytic copper foil production, and it is ensured that high surface additive concentration is achieved at the early stage of electrolysis.

Owner:ZHEJIANG YONGTAI TECH CO LTD +1

Preparation method of 1-hydroxymethyl benzotriazole

InactiveCN103992284AGood corrosion inhibition effectReduce usageOrganic chemistryCopper electrodeCharge transfer resistance

The invention discloses a preparation method of 1-hydroxymethyl benzotriazole, which specifically comprises the following steps: mixing benzotriazole, sulfuric acid, water and a paraformaldehyde solution; slowly heating, starting stirring and carrying out heat-insulation reaction; when a white powdery substance is generated, continuously heating until the precipitate is completely dissolved; insulating heat and cooling to room temperature; filtering to obtain white needle-like 1-hydroxyl benzotriazole crystals; and drying to obtain the product. According to the preparation method of 1-hydroxymethyl benzotriazole disclosed by the invention, the synthesis process is relatively simple, the production time and the usage amount of synthesis raw materials are saved, the production efficiency is high, and the product yield is over 98.65%; the 1-hydroxymethyl benzotriazole produced by the method has a good corrosion inhibition effect on copper; and detection shows that the addition of the 1-hydroxymethyl benzotriazole enables the self-corrosion potential of copper to turn negative, the inhibition effect on cathode polarization is enhanced, the charge transfer resistance on the surface of a copper electrode is increased, and thus the corrosion inhibition effect is relatively good.

Owner:NANTONG BOTAO CHEM

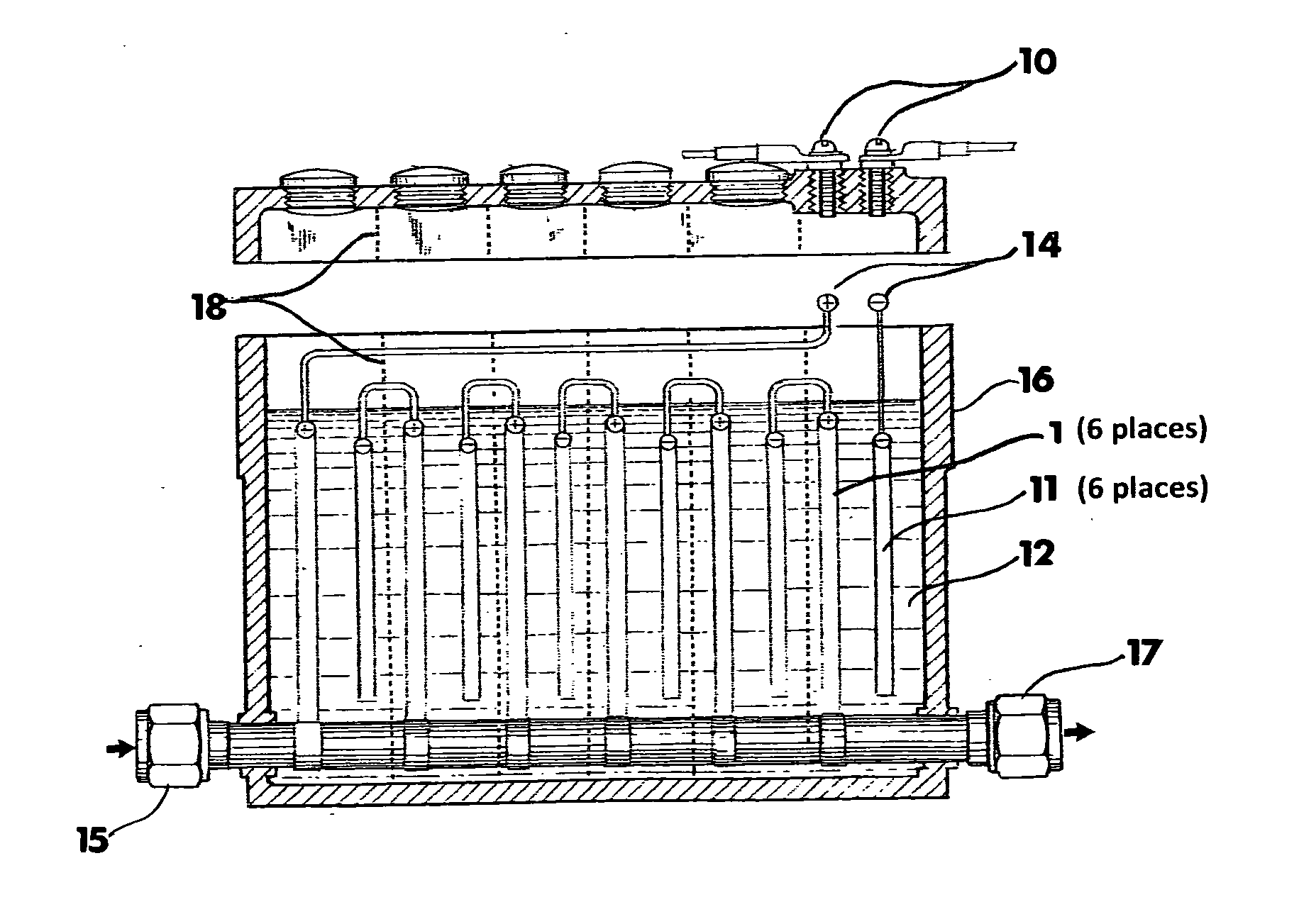

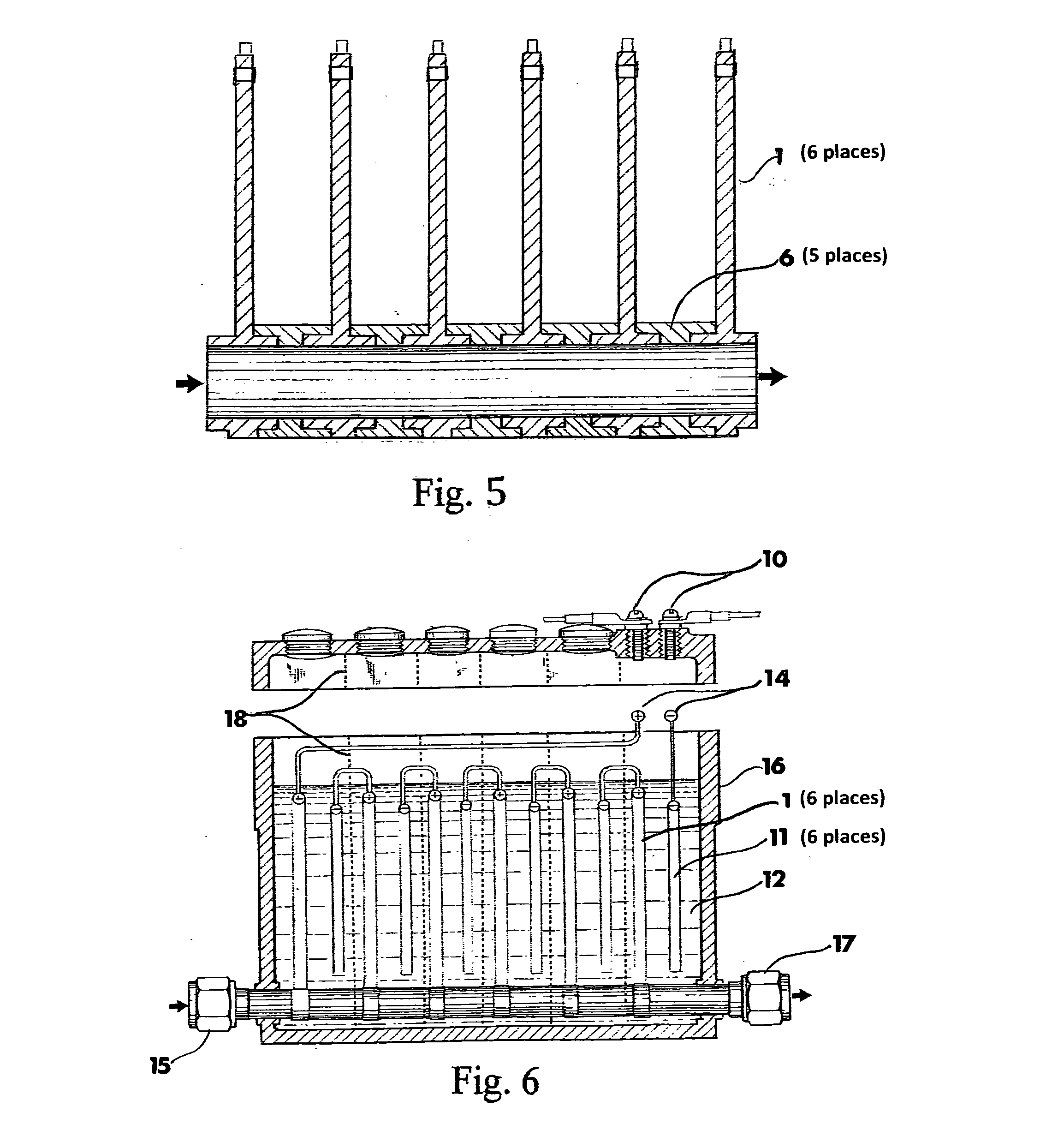

Battery cathode depolarization circuit

InactiveUS20130169237A1Internal electrical resistanceIncrease charging rateBatteries circuit arrangementsSecondary cells charging/dischargingElectricityElectrical battery

An electrical depolarization circuit is used to shorten the charging time of secondary cells by transferring a portion of the battery electrode cathode polarization charge into an ionic capacitor stream comprised of a gaseous ionic mixture of lower oxidative potential flowing within a tubular circuit passing through the battery electrolyte.

Owner:MCWHORTER EDWARD MILTON

Non-cyanide alkaline copper plating agent and using method thereof

InactiveCN105154929AEasy to handleSolve the worldwide problem of destroying pollutionCopper platingEcological environment

The invention discloses a non-cyanide alkaline copper plating agent and a using method thereof. The non-cyanide alkaline copper plating agent comprises the following substances: a pH regulator, a current stabilizer, a change agent and a complexing agent. By using the non-cyanide alkaline copper plating agent, sodium cyanide in the conventional cyanide copper plating solution can be replaced without changing the original process, and the totally non-cyanide alkaline copper plating process can be used to solve the multiple disadvantages existing in the conventional non-cyanide alkaline copper plating processes at home and abroad, thereby allowing the non-cyanide alkaline copper plating process to reach a cyanide copper plating level. The non-cyanide alkaline copper plating agent and the using method have the characteristics that the current efficiency and the deposition velocity are high; the cathode polarization capability and a binding force are good; a coating layer is exquisite, tamping-resistant and scratch-resistant, and has no brittleness; no bubble is generated under high temperature baking; the non-cyanide alkaline copper plating agent can be directly used for barrel plating and rack plating of steel and brass, and used for copper plating of zinc die castings, zinc alloys and aluminium alloys; the treatment on waste water is easy; the requirements of cleaning production are met; the long-standing worldwide problems of harms to persons, and damage and pollution to the ecological environment caused by cyanide are solved; and an international blank is filled.

Owner:钱宏彬

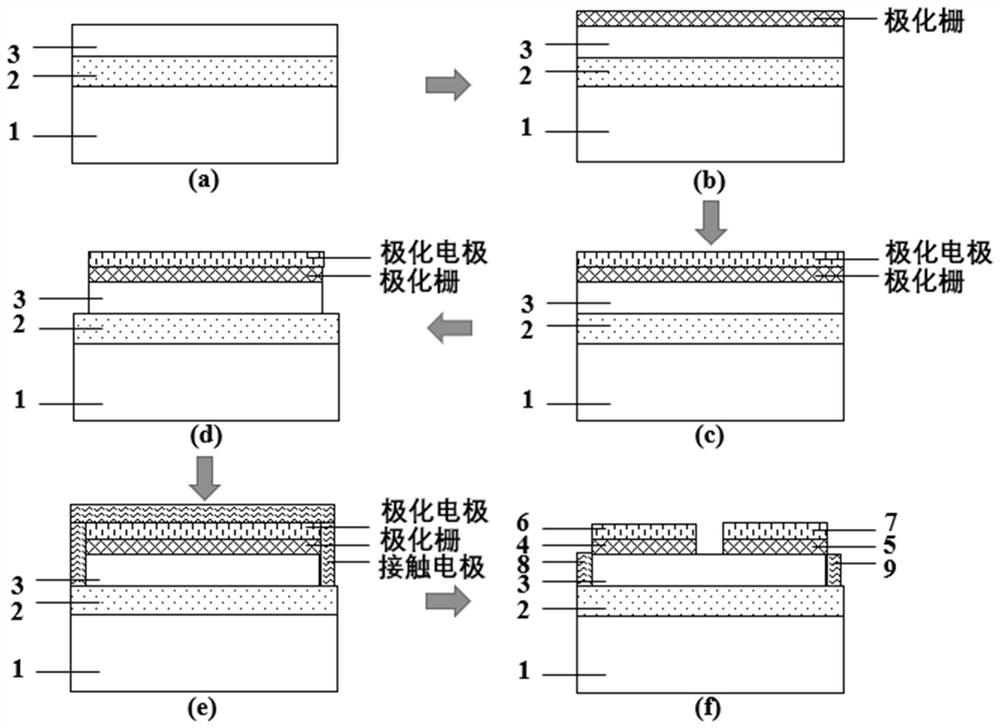

PN junction memory device based on ferroelectric doping

ActiveCN113140675AImplement storage state switchingAvoid damageElectrical apparatusElectrical polarityPulse voltage

The invention discloses a PN junction memory device based on ferroelectric doping, and mainly aims to solve the problem that the existing PN junction memory device cannot realize switching of different conduction types. The device comprises a substrate (1), an insulating oxide layer (2) and a channel layer (3) from bottom to top, an anode (8) and a cathode (9) are arranged on two sides of the channel layer, an anode polarization grid (4) is arranged on the left of the upper portion of the channel layer, and a cathode polarization grid (5) is arranged on the right of the channel layer; an anode polarization electrode (6) and a cathode polarization electrode (7) are arranged on the upper portion of the anode polarization grid and the upper portion of the cathode polarization grid respectively, pulse voltages with different polarities are applied to the two polarization electrodes (6 and 7), and switching of PN junctions between different storage states is achieved by changing the application sequence of positive and negative pulses. According to the invention, the storage function of the PN junction memory device is expanded, the damage to the channel in the technological process is reduced, the power consumption is reduced, the on-state current and durability of the device are improved, and the method can be used for manufacturing a nonvolatile memory.

Owner:XIDIAN UNIV

Electronickelling solution formula used for improving uniform distribution performance of neodymium-iron-boron manget coating and electronickelling method

Owner:NINGBO YUNSHENG +1

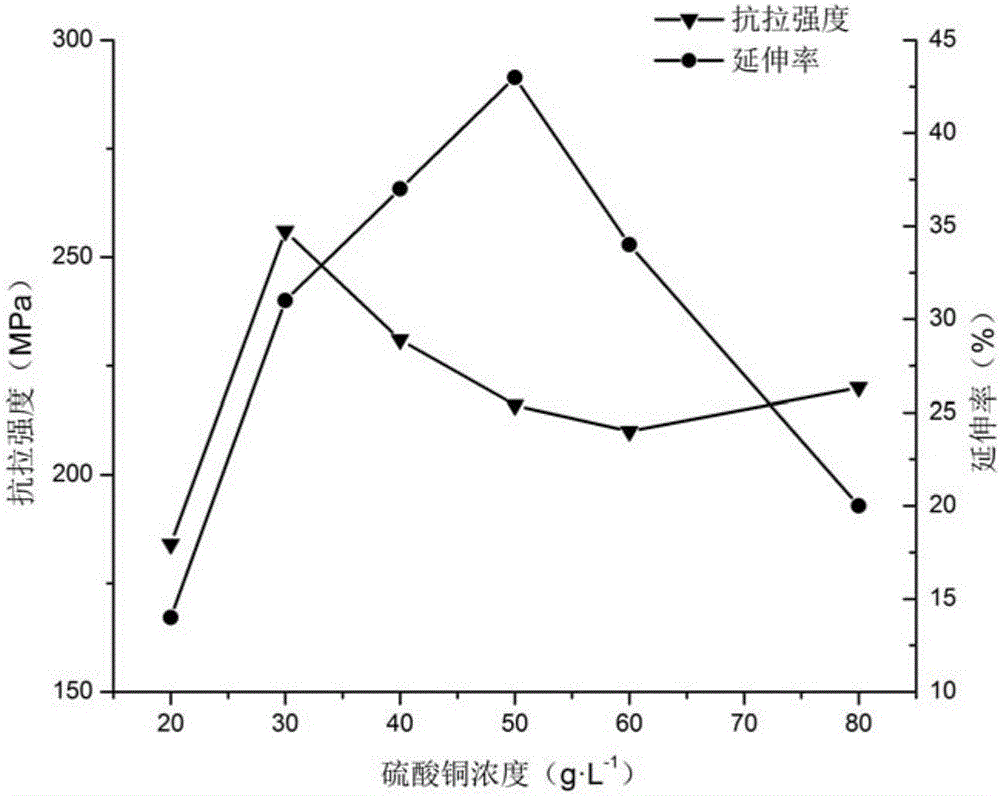

Additive-free method used for preparing high-mechanical-property electroformed copper layers at extremely low copper sulphate concentration

InactiveCN106567106AImprove mechanical propertiesGood dispersionElectroforming processesGrain structureMechanical property

The invention discloses an additive-free method used for preparing high-mechanical-property electroformed copper layers at an extremely low copper sulphate concentration. According to the additive-free method, extremely low copper concentration and high acid concentration are adopted to improve cathode polarization and solution dispersion capacity without adding any additives, and obtain a copper concentration range capable of preparing electroformed copper layers with excellent comprehensive mechanical properties in an extremely low copper concentration zone; a fliud flushing clamp with a positive pole is adopted to increase negative pole limiting current density, negative pole current density is increased to improve negative pole polarization further, and obtain electroformed copper layers with fine and uniform crystalline grain structures. The highest tensile strength of the electroformed copper layers prepared via the additive-free method can be 526MPa, the elongation percentage of the electroformed copper layers is increased to be 30%, the highest elongation percentage of the electroformed copper layers can be 43%, the tensile strength of the electroformed copper layers is 216MPa, and the electroformed copper with high strength and elongation percentage is capable of increasing reliability and prolonging service life of devices greatly.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

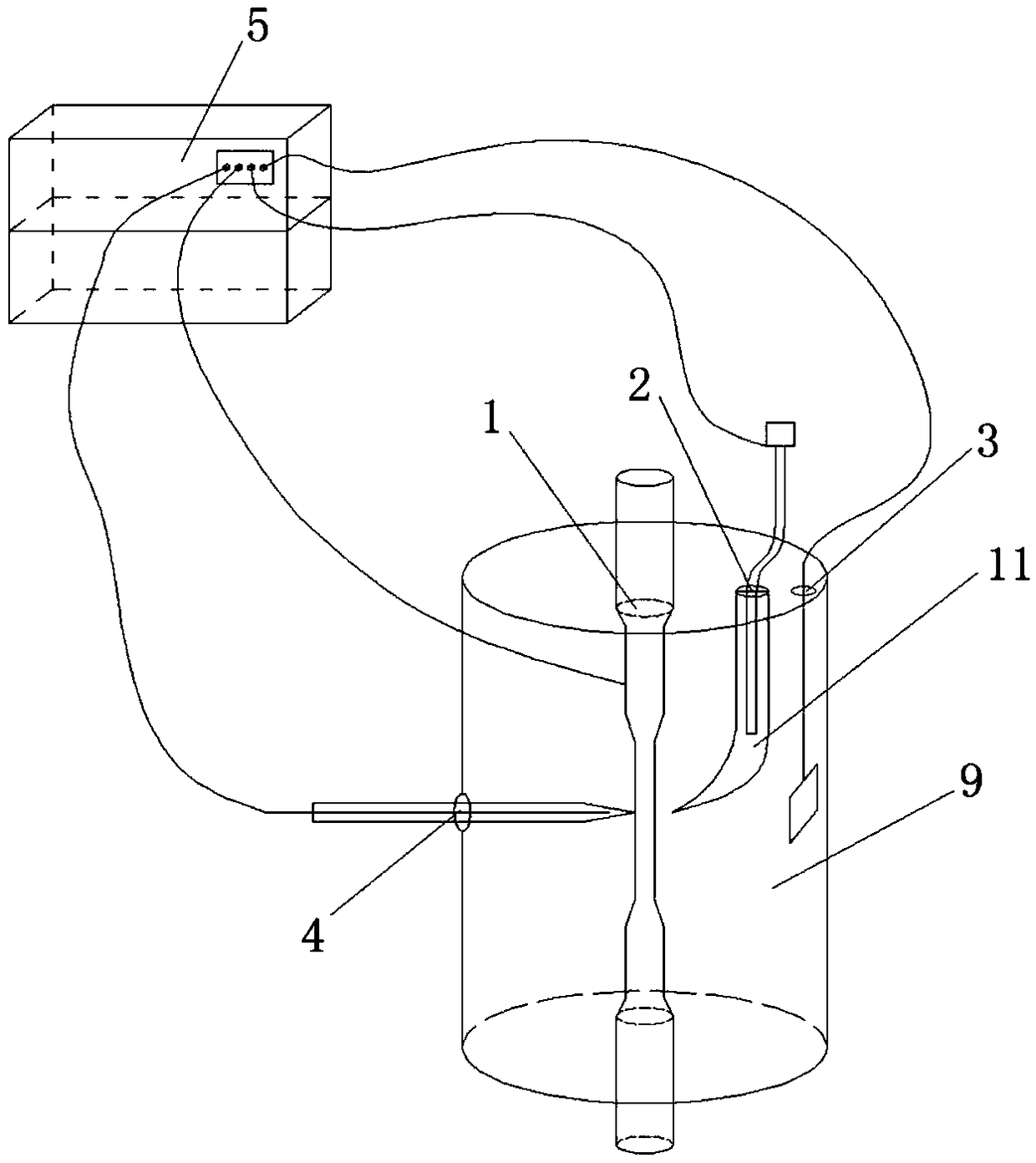

Monitoring method for dynamic change of pH value in interface micro-region during metal stress corrosion process

InactiveCN109187326AImprove stabilityGood reproducibilityWeather/light/corrosion resistanceTension stressCathode polarization

The invention discloses a monitoring method for the dynamic change of a pH value in an interface micro-region during a metal stress corrosion process. The principle of the invention is that the tensile stress is applied to a tensile metal sample, a polarization potential E1 is applied to a first working electrode under the combined action of the tensile stress and an electrolyte solution, and themetal undergoes stress corrosion; a cathodic polarized potential E2 is applied to a second working electrode during the stress corrosion process; the H<+> reduction reaction occurs on the second working electrode, and the obtained current data is the corrosion current of the first working electrode and the reduction current generated by the second working electrode; and the dynamic change of the reduction current is the dynamic change of the H<+> concentration in the micro-region. The monitoring method can monitor the dynamic change of the pH value of the interface micro-region of the metal / electrolyte solution in real time; the monitoring method has the advantages of good stability, fast response, high precision, good reproducibility and the like. The monitoring device is easy to manufacture, low in cost, easy to operate, easy to use, and has a wide range of applications.

Owner:XUZHOU NORMAL UNIVERSITY

Cathode powder of cylindrical basic zinc-manganese battery and preparation method of cathode powder

The invention provides cathode powder of a cylindrical basic zinc-manganese battery and a preparation method of the cathode powder. The cathode powder comprises the following component in part by weight: 80 to 90 parts of electrolytic manganese dioxide, 1 to 10 parts of graphite powder, 0.5 to 1 part of calcium stearate and 1 to 5 parts of ethanol. The cathode powder and the preparation method are low in raw material cost and have a simple preparation process; and by the preparation method, the surface state of cathode powder particles can be improved, porous particles are formed, and the conditions that the reaction area of a cathode is increased, discharge density is reduced, anodic polarization is relieved and the discharge performance of large current is improved are facilitated, so that the battery is particularly suitable for large-current electrical appliances such as a digital camera and the like.

Owner:浙江特源电池有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com