Intermediate-temperature solid oxide fuel cell (LSCF) cathode material with brownmillerite structure

A fuel cell cathode and solid oxide technology, which is applied to battery electrodes, structural parts, circuits, etc., and can solve problems such as inappropriate cathode materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

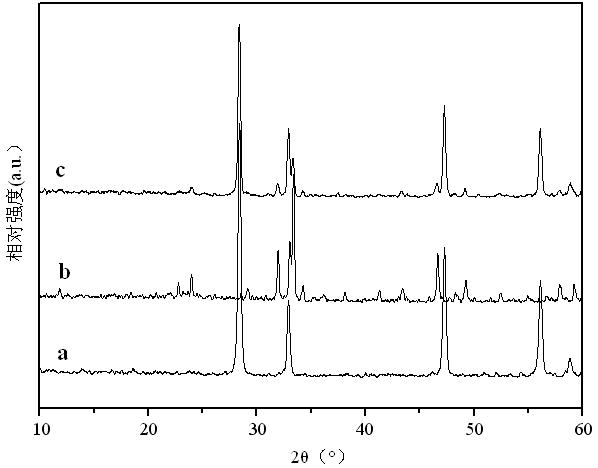

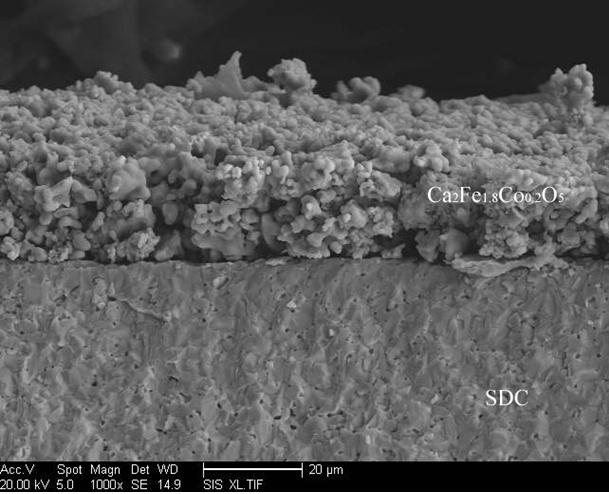

[0007] Specific embodiment 1: In this embodiment, the general formula of the composition of the cathode material of the medium temperature solid oxide fuel cell with the mayorite structure is A 2 Fe 2-x M x O 5±δ , where A is the main group of alkaline earth metals, M is a transition metal element, 0.1<x<1.0, δ=0~0.01.

[0008] The cathode material of the medium-temperature solid oxide fuel cell of the mayorite structure in this embodiment is prepared by the glycine-nitrate method.

specific Embodiment approach 2

[0009] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the A is Ca, Sr or Ba. Others are the same as the first embodiment.

specific Embodiment approach 3

[0010] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that M is Co, Mn or Ni. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Polarization resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com