Oil casing pipe cathode protecting system based on pulse current power supply and building method thereof

An oil well casing and cathodic protection technology is applied in the field of corrosion and protection of gas well casings and oil wells, and can solve the problems of insufficient protection of oil well casings, limited DC current propagation distance, uneven distribution of protection currents, etc. It is convenient for technological transformation, great social and economic benefits, and the effect of extending the depth of protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and the examples given by the inventor.

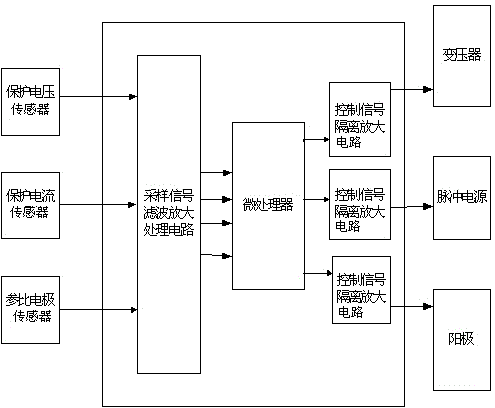

[0029] see figure 1 , 2 , the technical route of this embodiment is: on the basis of the original DC cathodic protection system, the pulse power supply is used as the power supply instead. The oil well casing cathodic protection system powered by the pulse current is composed of pulse power supply, auxiliary anode, reference electrode, protection potential It is composed of automatic detector and oil well casing.

[0030] A sort of Oil well casing cathodic protection system based on pulse current power supply , including oil well casing, the oil well casing is connected to the anode well system through the pulse power supply; the oil well casing is connected to the potential detector; the potential detector is connected to the reference electrode;

[0031] The pulse power supply includes a microprocessor, and the mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com