PN junction memory device based on ferroelectric doping

A technology of memory devices and PN junctions, applied in electrical components and other directions, can solve the problems that the type of carriers cannot be changed, the memory cannot realize the storage state, and the quality of the device is reduced, so as to improve the on-state current and durability, reduce the Power consumption, effect of uniform doping distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

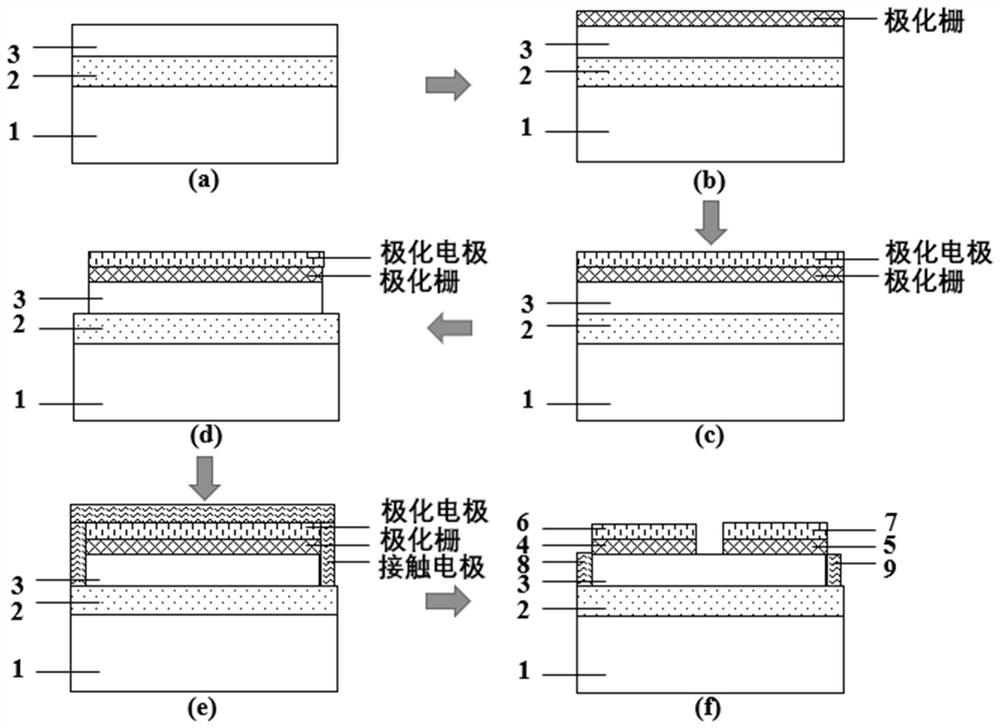

[0032] Embodiment 1: making based on ZrO 2 Material-doped Si channel PN junction memory device.

[0033] Step 1: Select the substrate.

[0034] Select an SOI substrate composed of Si as the substrate 1, SiO2 as the insulating oxide layer 2, and Si as the channel layer 3, such as figure 2 (a).

[0035] Step 2: Deposit a ferroelectric layer.

[0036] Put the SOI substrate into the reaction chamber, use the atomic layer deposition process, use tetrakis (dimethylamino) zirconium as the precursor zirconium source, H2O or O3 as the precursor oxygen source, use N2 as the purge gas, and use 250°C as the reaction temperature, a 5nm thick ZrO2 ferroelectric layer is deposited on the surface of SOI as a polarization gate, such as figure 2 (b).

[0037] Step 3: Deposition of positive polarizing electrode layer.

[0038]Using the reactive sputtering process, the reaction chamber is first evacuated with a molecular pump and a cold pump until the vacuum pressure is 8E-6Torr, and then...

Embodiment 2

[0047] Embodiment 2: making based on HfO 2 Material-doped Ge channel PN junction memory device.

[0048] Step 1: Select the substrate.

[0049] Select a GOI substrate consisting of Ge as the substrate 1, borosilicate glass as the insulating oxide layer 2 and Ge as the channel layer 3, as figure 2 (a).

[0050] Step 2: depositing a ferroelectric layer.

[0051] Put the GOI substrate into the reaction chamber, use the atomic layer deposition process, with HfCl 4 As the precursor hafnium source, H2O or O3 is the precursor oxygen source, N2 is used as the purge gas, and the reaction temperature is 300 °C, and a 10nm thick HfO2 ferroelectric layer is deposited on the surface of GOI as a polarization gate, such as figure 2 (b).

[0052] Step 3: Depositing an active polarizing electrode layer.

[0053] 3.1) Using the reactive sputtering process, first use a molecular pump and a cold pump to evacuate the reaction chamber until the vacuum pressure is 8E-6Torr;

[0054] 3.2) Wi...

Embodiment 3

[0061] Embodiment 3: Fabricate a SiGe channel PN junction storage device based on HZO material doping.

[0062] Step A: Select the substrate.

[0063] Select a SiGeOI substrate composed of Si as the substrate 1, BPSG as the insulating oxide layer 2, and SiGe as the channel layer 3, such as figure 2 (a).

[0064] Step B: depositing a ferroelectric layer.

[0065] Put the SiGeOI substrate into the reaction chamber, use the atomic layer deposition process, use HfCl4 as the precursor hafnium source, use tetrakis(dimethylamino) zirconium as the precursor zirconium source, H2O or O3 as the precursor oxygen source, and N2 As a purge gas, a 15nm-thick HZO ferroelectric layer was deposited on the surface of SiGeOI as a polarization gate at 260°C as a reaction temperature, such as figure 2 (b).

[0066] Step C: depositing a positive polarizing electrode layer.

[0067] Using the reactive sputtering process, the reaction chamber is first evacuated with a molecular pump and a cold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com