Crevice-corrosion-avoiding sample packaging method and structure in stainless steel pitting study

A technology of crevice corrosion and encapsulation method, which is applied in the preparation of test samples, electrochemical variables of materials, etc., can solve the problems of measurement result influence, pitting corrosion measurement result loss of accuracy, etc., achieve low cost, simple process, The results are accurate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1 (adopt packaging structure of the present invention-with pre-passivation treatment)

[0053] 1. Cutting the working electrode: Grinding the 304 austenitic stainless steel sample (Φ10×2mm, 304 austenitic stainless steel composition shown in Table 1) obtained by wire cutting method with 180, 360, 600, 800, 1000, 1200 sandpaper in sequence After leveling, polish it, wipe it with alcohol and acetone, and dry it for later use;

[0054] 2. Pre-passivation treatment: heat the concentrated nitric acid solution with a mass fraction of 25% in a water bath and keep it at 50°C, put the working electrode in it and soak for 90min;

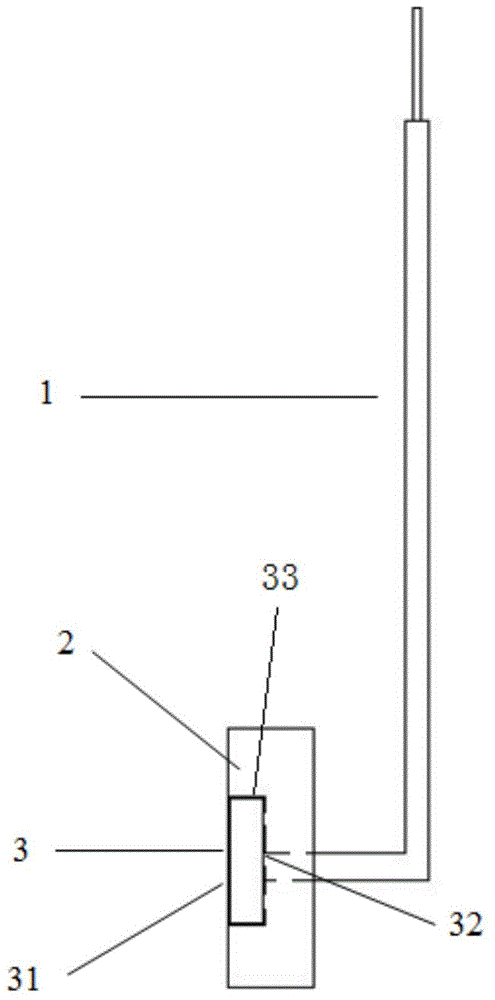

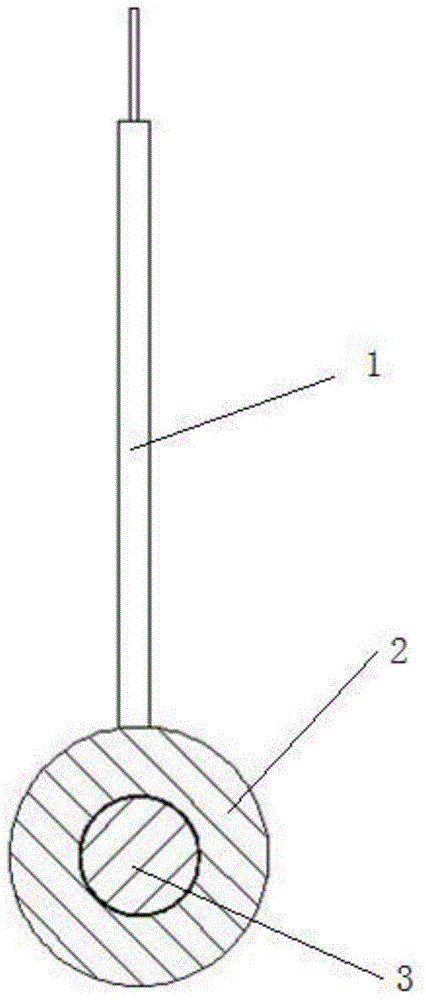

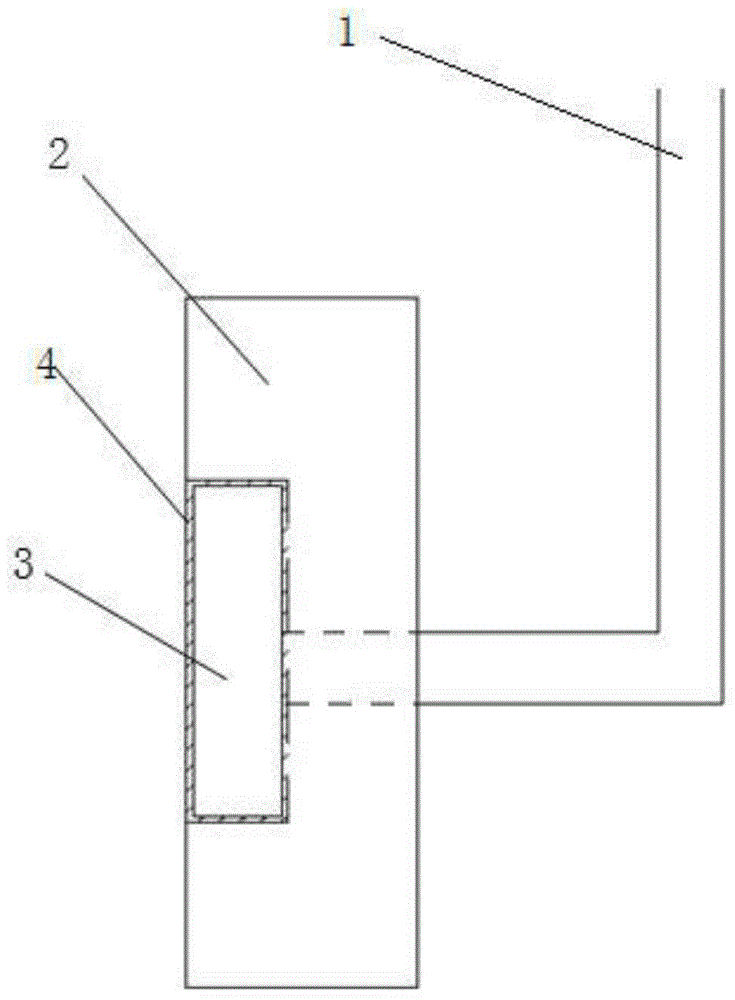

[0055] 3. Encapsulation: Paste a film on the center of the working surface of the working electrode. The thickness of the film is about 1mm and the diameter is 8mm; the working electrode is inlaid with phenolic resin, and the wire is welded on the non-working surface; after the working electrode is inlaid, the The scotch tape is removed, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com