A luminescent part for laser GaN base peeling based on compound separation method and its making method

A light-emitting device, laser lift-off technology, applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high production rate, prone to cracks, damage to light-emitting devices, etc., to reduce the production rate of cracks, avoid crack extension, improve The effect of yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0037] A method for manufacturing laser lift-off GaN-based light-emitting devices using a synthetic separation method, the steps of which are as follows:

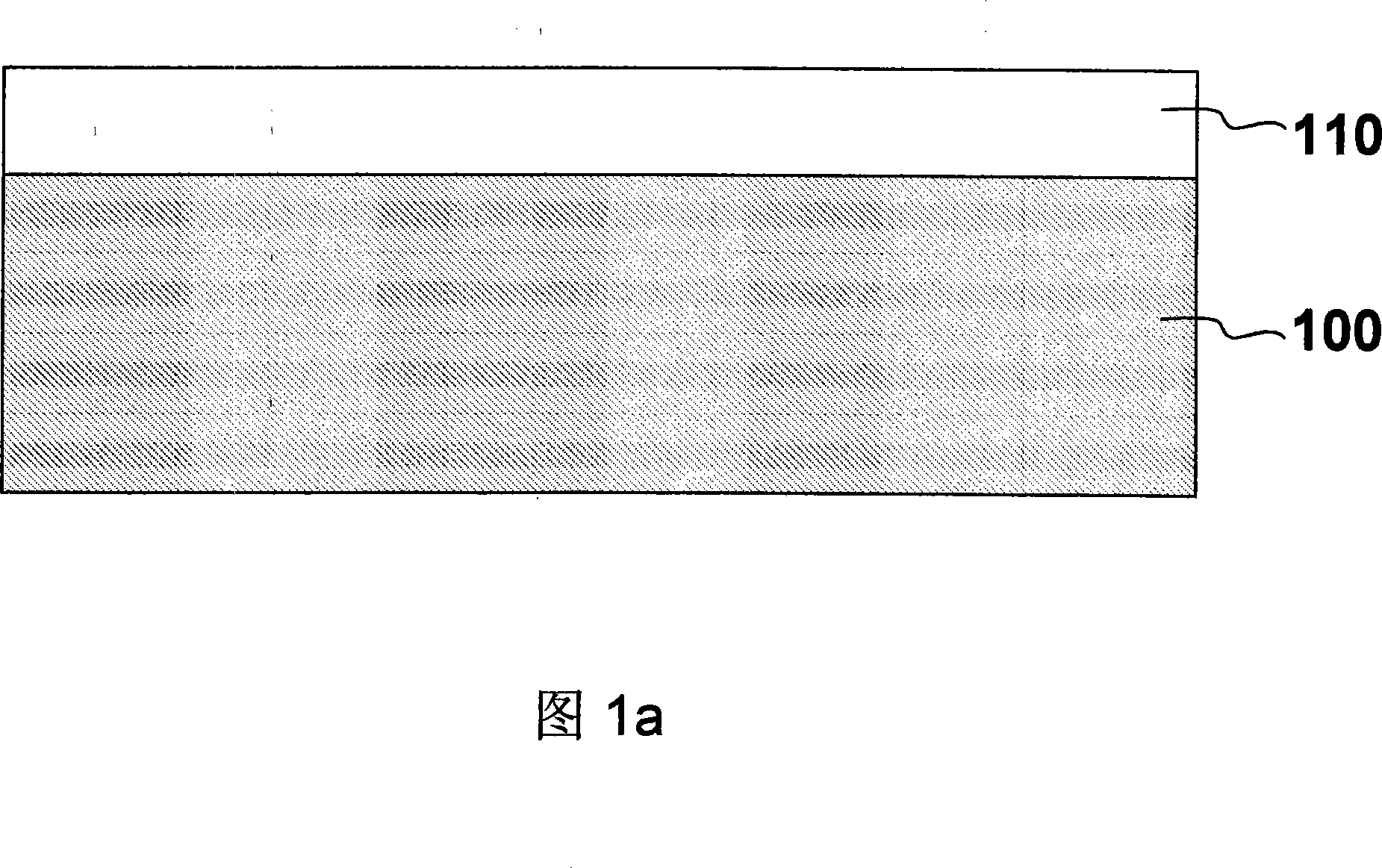

[0038] Step 1: First, as shown in FIG. 1a, a nitride semiconductor epitaxial film 110 is heteroepitaxially grown on a sapphire substrate 100, and the epitaxial film 110 has an N-GaN layer, an active layer and a P-GaN layer.

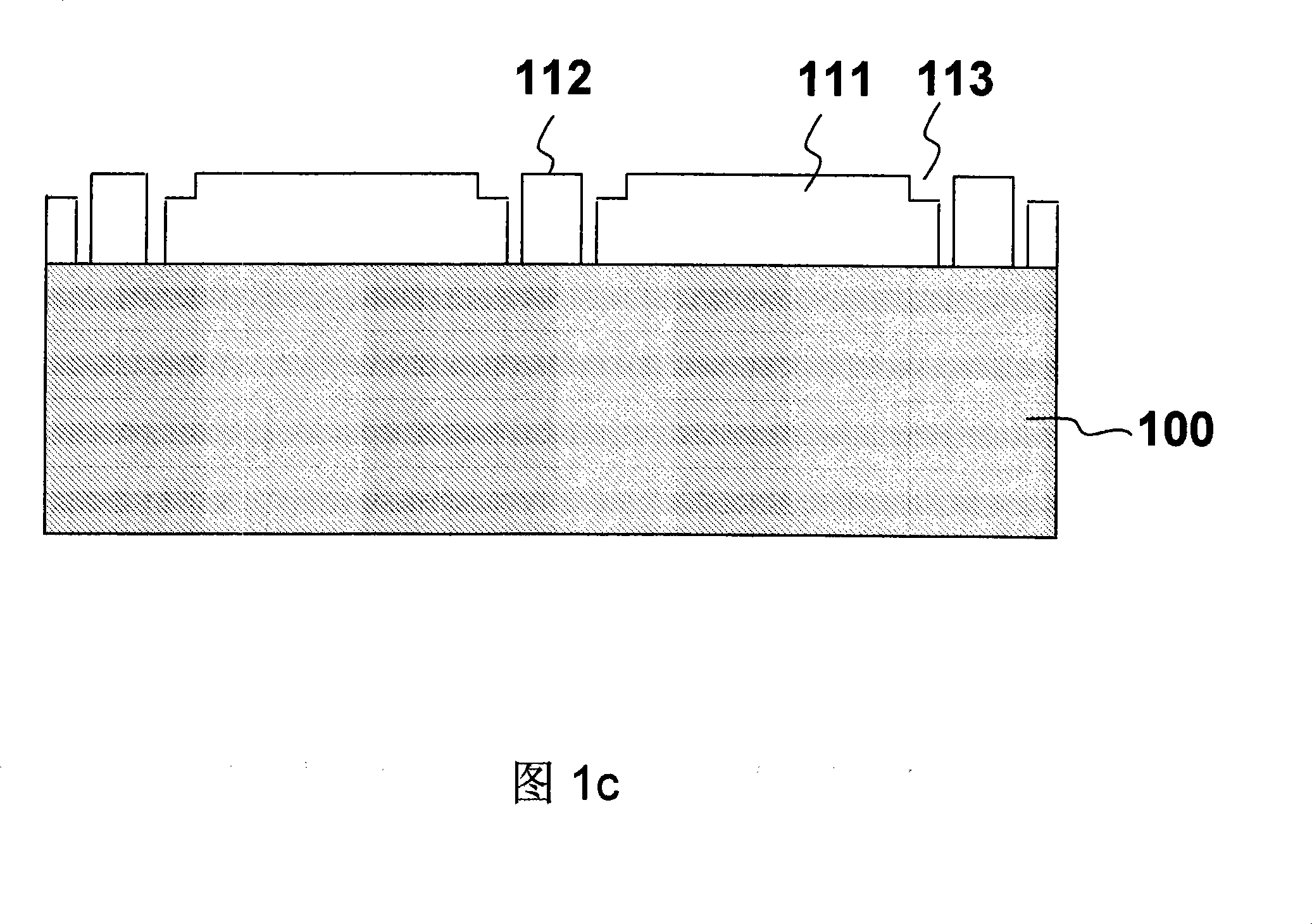

[0039] Step 2: firstly use dry etching to remove part of the GaN-based epitaxial layer at predetermined intervals, and form a plurality of GaN-based light emitting regions 111 and 112 of two different sizes on the epitaxial film 110 of the sapphire substrate 100, as shown in the figure As shown in 1b, the unit GaN-based light-emitting region 111 has a width of more than 300 μm, the unit GaN-based light-emitting region 112 has a width of 40-200 μm, the depth of the groove 113 for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com