Additive-free method used for preparing high-mechanical-property electroformed copper layers at extremely low copper sulphate concentration

A technology of copper sulfate and additives, which is applied in the direction of electroforming and electrolysis, can solve the problems of additive consumption, affecting the quality of electroforming layer, and difficulty in maintenance of electroforming liquid, so as to improve dispersion ability, reduce solution resistance and optimize structure structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

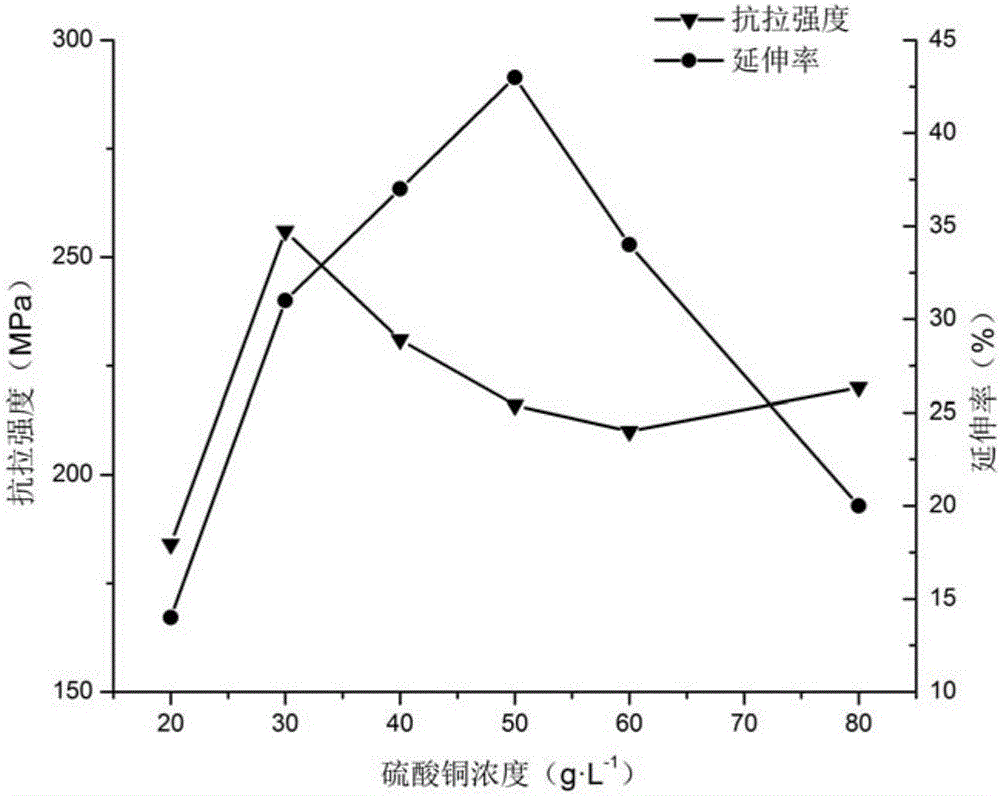

[0019] Prepare the electroforming solution with deionized water, the concentrations of copper sulfate and sulfuric acid are 20g / L and 170g / L respectively

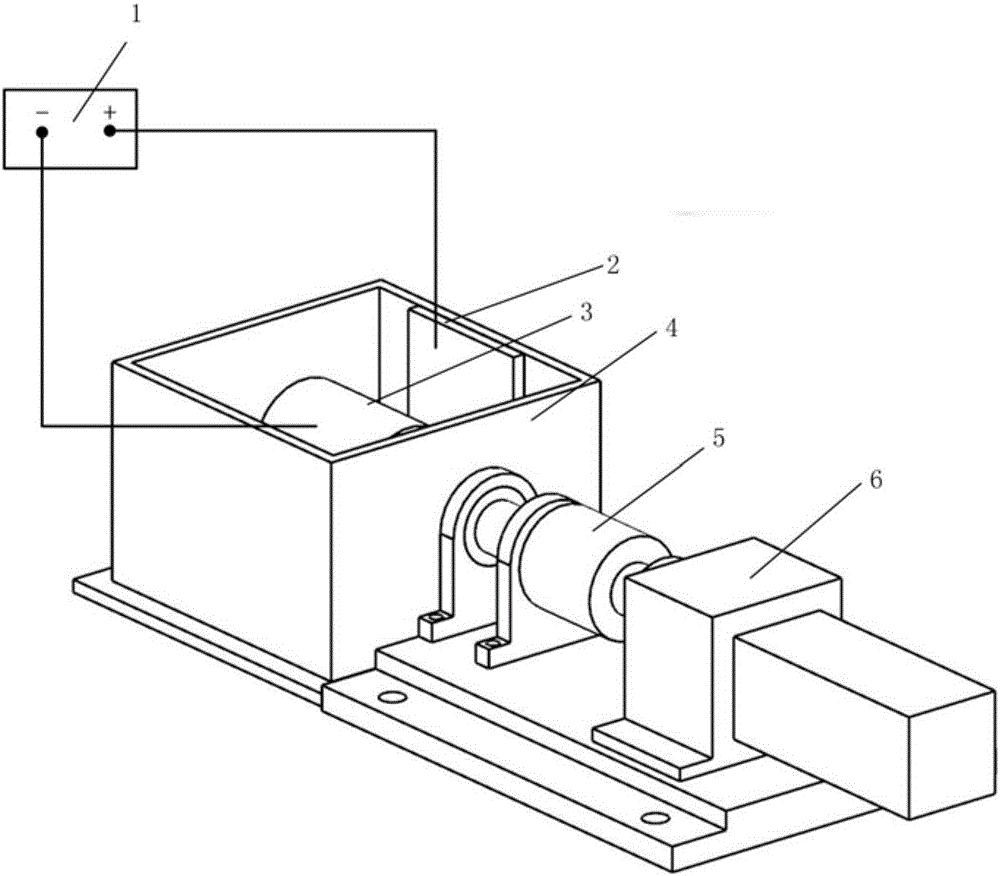

[0020] Anode 2 is made of phosphor copper plate, and workpiece 3 is a stainless steel mandrel. Before electroforming, anode 2 and workpiece 3 are ultrasonically cleaned with alcohol, and then rinsed with deionized water to obtain clean anode 2 and workpiece 3. The anode 2 is wrapped with two layers of polyester anode bags to prevent the anode mud from seeping out and affecting the quality of the electroforming layer;

[0021] The anode 2 and the workpiece 3 are placed in the electroforming tank 4, and the workpiece 3 keeps rotating in the electroforming tank 4 to accelerate ion migration and reduce concentration polarization. The electroforming process uses DC power supply 1, and the cathode current density is 0.5A / dm 2 , to prepare an electroformed copper layer with a thickness of 0.5mm, the tensile strength of the obtain...

Embodiment 2

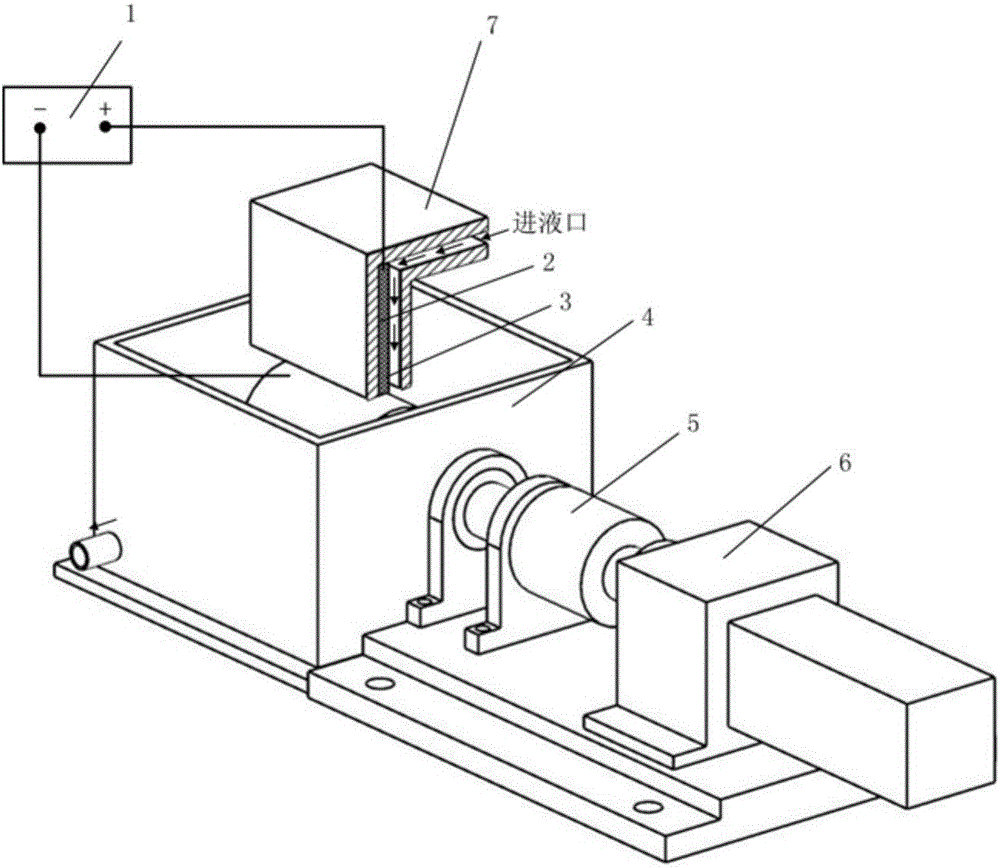

[0023] Prepare the electroforming solution with deionized water, the concentrations of copper sulfate and sulfuric acid are 50g / L and 170g / L respectively. Anode 2 uses a phosphor copper plate, and workpiece 3 is a stainless steel mandrel. Before electroforming, anode 2 and workpiece 3 are used Ultrasonic cleaning with alcohol, followed by rinsing with deionized water, to obtain clean anode 2 and workpiece 3 . The anode 2 is wrapped with two layers of polyester anode bags to prevent the anode mud from seeping out and affecting the quality of the electroforming layer;

[0024] The anode 2 and workpiece 3 are placed in the electroforming tank 4, and the workpiece 3 keeps rotating in the electroforming tank 8 to accelerate ion migration and reduce concentration polarization. The electroforming process uses DC power supply 1, and the cathode current density is 0.5A / dm 2 , an electroformed copper layer with a thickness of 0.5mm was prepared, the tensile strength of the obtained ele...

Embodiment 3

[0026] The electroforming solution was prepared with deionized water, and the concentrations of copper sulfate and sulfuric acid were 60g / L and 170g / L, respectively.

[0027] Anode 2 is made of phosphor copper plate, and workpiece 3 is a stainless steel mandrel. Before electroforming, anode 2 and workpiece 3 are ultrasonically cleaned with alcohol, and then rinsed with deionized water to obtain clean anode 2 and workpiece 3. The anode 2 is wrapped with two layers of polyester anode bags to prevent the anode mud from seeping out and affecting the quality of the electroforming layer;

[0028] The anode 2 and the workpiece 3 are placed in the electroforming tank 4, and the workpiece 3 keeps rotating in the electroforming tank 4 to accelerate ion migration and reduce concentration polarization. The solution temperature was 30°C. The electroforming process uses DC power supply 1, and the cathode current density is 0.5A / dm 2 , to prepare an electroformed copper layer with a thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com