Monitoring method for dynamic change of pH value in interface micro-region during metal stress corrosion process

A corrosion process and metal stress technology, which is applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of high price, complicated operation, and low accuracy, and achieve low cost, good reproducibility, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

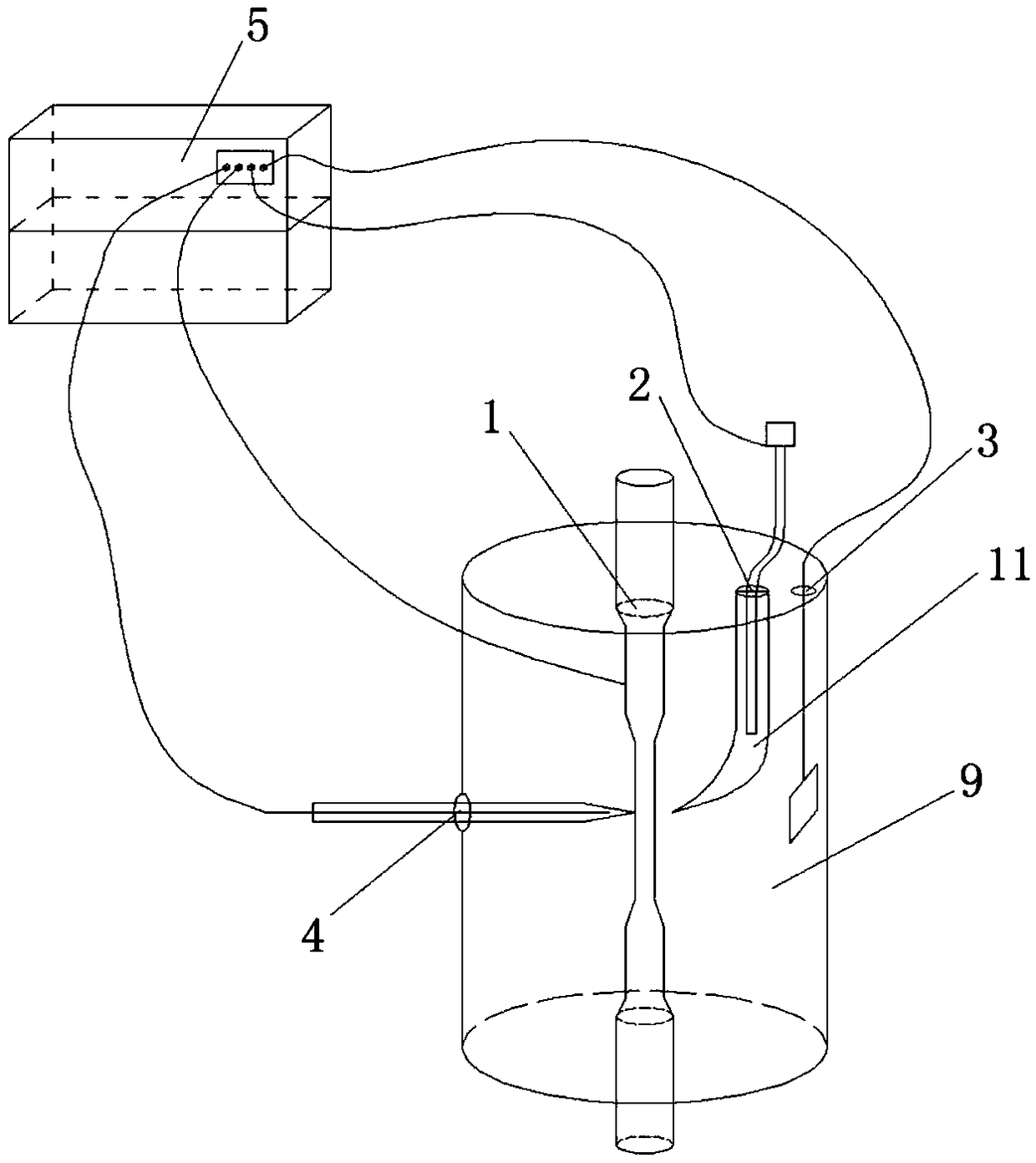

[0044]In the present invention, the experimental device for real-time in-situ monitoring of the dynamic change of the pH value of the micro-region of the electrode / electrolyte solution interface during the stress corrosion process of the metal is a double working electrode system, and two potentiostats are used together for measurement. The measurement can be performed by using two common potentiostats at the same time, or by means of other potentiostat devices. In the embodiment of the present invention, a scanning electrochemical microscope (Scanning Electrochemical Microscopy, SECM) is used as the potentiostat for measurement.

[0045] The method for monitoring the dynamic change of the interface micro-region pH value in the metal stress corrosion process includes the following specific steps:

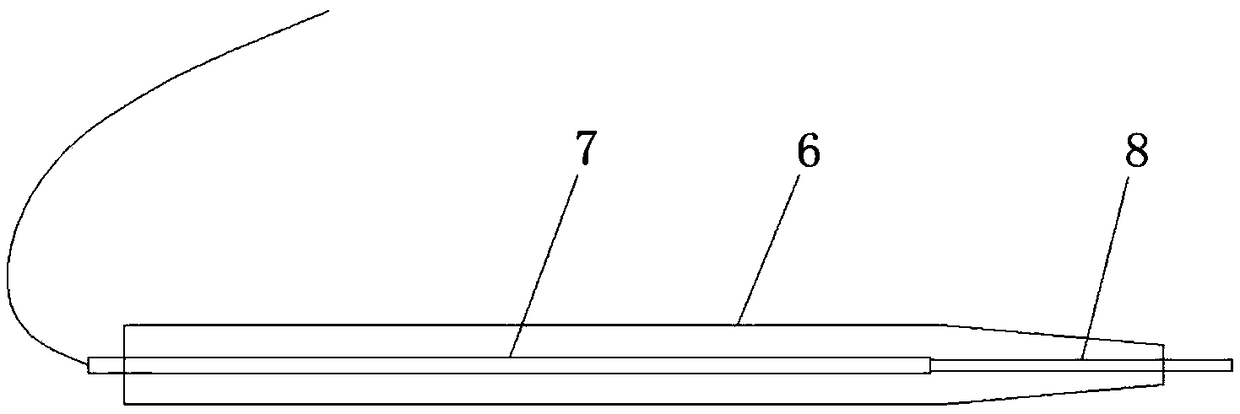

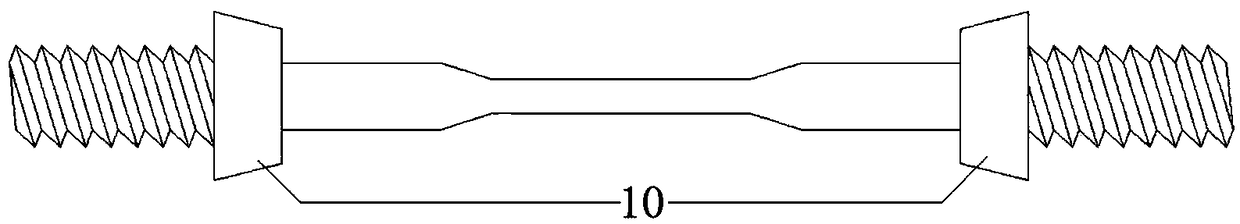

[0046] A, prepare the first working electrode 1, adopt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com