Surface modification method of carbon material and application thereof in microbial fuel cell

A surface modification, fuel cell technology, applied in battery electrodes, circuits, electrical components, etc., to achieve the effects of high power output, low price, and reduced construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

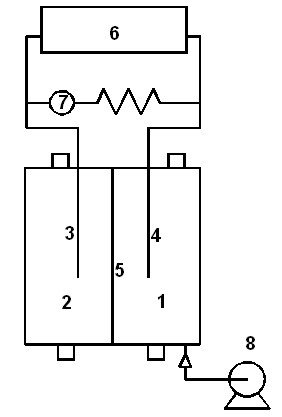

Method used

Image

Examples

Embodiment 1

[0036] The first step: preparation and characterization of potassium dichromate activated graphite material

[0037] (1) Clean a graphite rod with a diameter of 6 mm and 200 mL of graphite particles with a particle size of 5×4 mm with deionized water and ethanol, and air-dry. Then, at room temperature, soak graphite rods and 150 mL of pretreated graphite particles in 0.1 mol / L potassium dichromate and concentrated sulfuric acid solution with a volume ratio of 2:1 for 5 hours, then rinse with deionized water, and let them dry in the air. Dry.

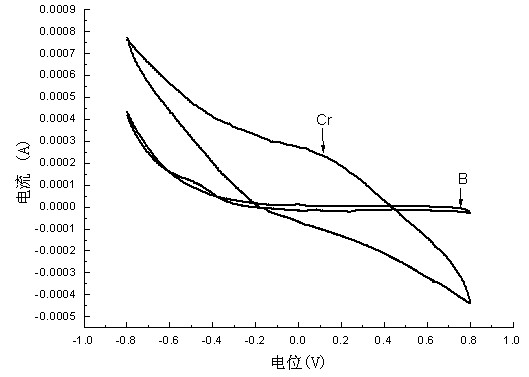

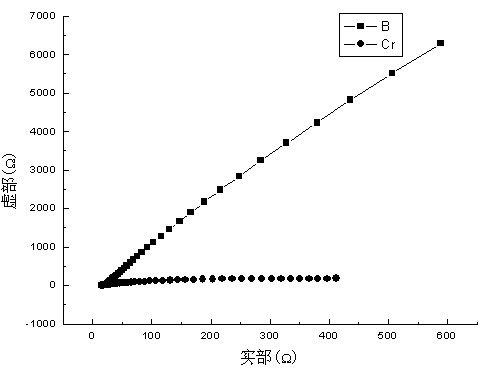

[0038] (2) Electrochemical tests were carried out on the graphite electrodes before and after activation: the electrochemical tests were carried out on the chemically activated electrodes using the traditional three-electrode system, that is, at room temperature using a Parstat 2273 electrochemical workstation, with 50mM phosphate buffer The solution (PBS) is the electrolyte, the calomel electrode (Hg / HgO electrode) is used as the refer...

Embodiment 2

[0046] The first step: preparation and characterization of potassium permanganate activated graphite material

[0047] (1) Clean a graphite rod with a diameter of 6 mm and 200 mL of graphite particles with a particle size of 5×4 mm with deionized water and ethanol, and air-dry. Put the graphite rod and 150mL pretreated graphite particles in the 0.1mol / L potassium permanganate and concentrated sulfuric acid solution with a volume ratio of 2:1 (single dichromate, permanganate, ferrate can be ) for 5 hours, rinsed with deionized water, and dried.

[0048] (2) Electrochemical tests were performed on the graphite electrodes before and after modification. The electrochemical test shows that the oxygen reduction current of the modified graphite electrode is significantly greater than that of the unactivated electrode in the cyclic voltammetry test, indicating that the oxygen reduction ability of the activated electrode is enhanced.

[0049] Step Two: Microbial Fuel Cells

[0050] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com