Electronickelling solution formula used for improving uniform distribution performance of neodymium-iron-boron manget coating and electronickelling method

A neodymium iron boron and nickel electroplating technology, applied in the field of electroplating nickel solution formulation, can solve the problems of reduced cathode polarization, poor dispersion ability, and high cost of liquid exchange, and achieves increasing cathode polarization, improving electrical conductivity, reducing The effect of changing the liquid medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

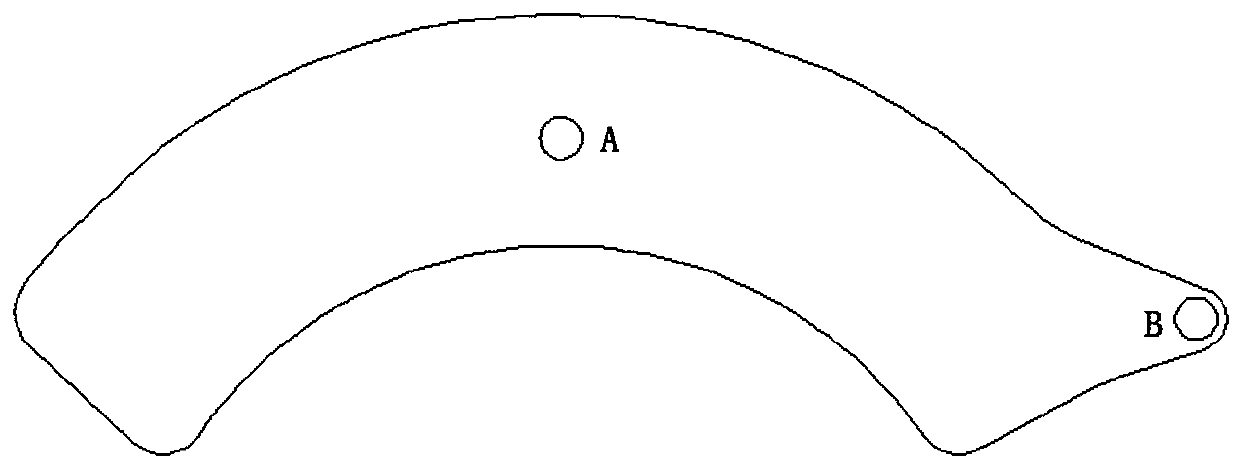

Image

Examples

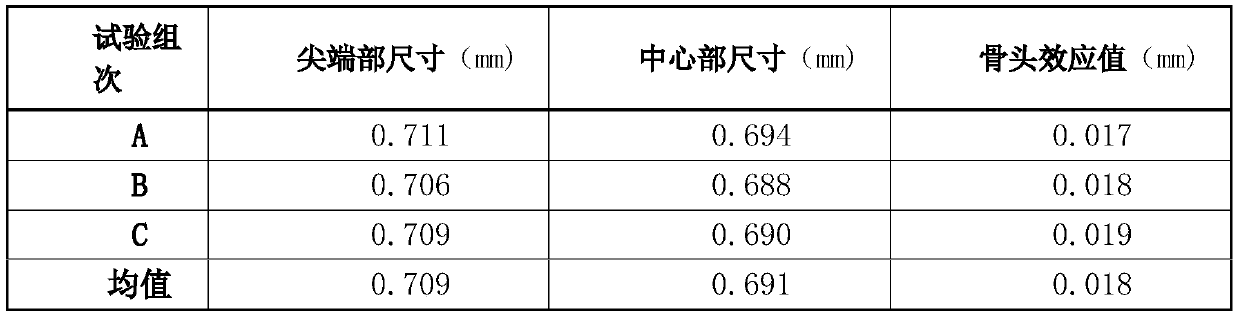

Embodiment 1

[0024] Embodiment 1: a kind of electroplating solution formula and method thereof for improving the uniform distribution of neodymium-iron-boron magnet coating comprise the following steps:

[0025] ① Pretreatment of NdFeB magnets;

[0026] ② Pre-nickel plating: Put the pre-treated NdFeB magnet into the first nickel electroplating solution for pre-nickel plating treatment, the time is 4648 seconds, in which the first nickel electroplating solution is composed of nickel chloride, boric acid, sodium sulfate or chlorine Potassium chloride conductive salt, o-sulfonyl benzimide and water, the mass volume concentration of nickel chloride is 70 grams per liter, the mass volume concentration of boric acid is 35 grams per liter, the mass volume concentration of sodium sulfate or potassium chloride 80 g / L, the mass volume concentration of o-sulfonyl benzimide is 0.1 mg / L, a high-frequency DC power supply is used in the pre-nickeling process, and its current density is 0.14 ampere / square...

Embodiment 2

[0046] Embodiment 2: a kind of electroplating solution formula and method thereof for improving the uniform distribution of neodymium-iron-boron magnet coating comprise the following steps:

[0047] ① Pretreatment of NdFeB magnets;

[0048] ② Pre-nickel plating: put the pre-treated NdFeB magnet into the first nickel electroplating solution for pre-nickel plating treatment, the time is 3615 seconds, in which the first nickel electroplating solution is composed of nickel chloride, boric acid, sodium sulfate or chlorine Potassium chloride conductive salt, o-sulfonyl benzimide and water, the mass volume concentration of nickel chloride is 150 grams per liter, the mass volume concentration of boric acid is 55 grams per liter, the mass volume concentration of sodium sulfate or potassium chloride 300 g / L, the mass volume concentration of o-sulfonyl benzimide is 0.9 mg / L, a high-frequency DC power supply is used in the pre-nickeling process, and its current density is 0.18 ampere / squa...

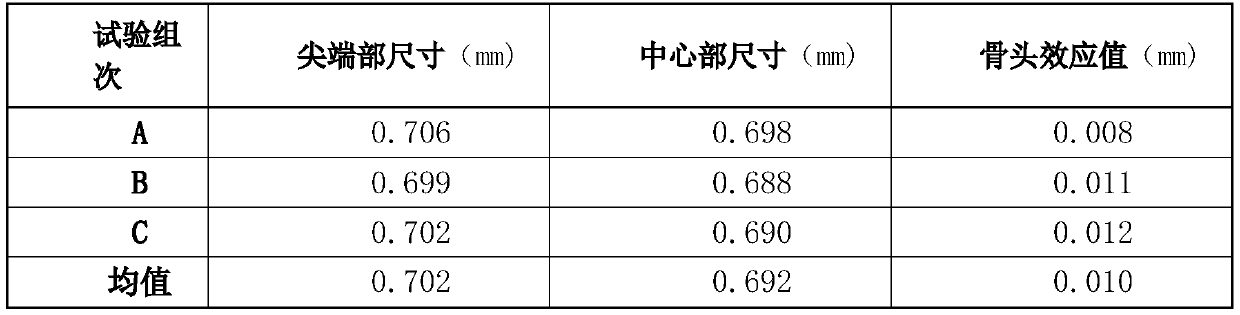

Embodiment 3

[0068] Embodiment 3: a kind of electroplating solution formula and method thereof for improving the uniform distribution of neodymium-iron-boron magnet coating comprise the following steps:

[0069] ① Pretreatment of NdFeB magnets;

[0070] ② Pre-nickel plating: put the pre-treated NdFeB magnet into the first nickel electroplating solution for pre-nickel plating treatment, the time is 8795 seconds, in which the first nickel electroplating solution is composed of nickel chloride, boric acid, sodium sulfate or chlorine Potassium chloride conductive salt, o-sulfonyl benzimide and water, the mass volume concentration of nickel chloride is 90 grams per liter, the mass volume concentration of boric acid is 45 grams per liter, the mass volume concentration of sodium sulfate or potassium chloride 160 g / L, the mass volume concentration of o-sulfonyl benzimide is 0.5 mg / L, a high-frequency DC power supply is used in the pre-nickeling process, and its current density is 0.14 ampere / squar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Perimeter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com